Professional Documents

Culture Documents

Zebra Conversion 300 Dpi A 203 Dpi

Uploaded by

Jorge Alberto BetancourtOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Zebra Conversion 300 Dpi A 203 Dpi

Uploaded by

Jorge Alberto BetancourtCopyright:

Available Formats

Printhead Conversion Kit

Installation Instructions

This kit includes the parts and documentation necessary to install the Printhead Conversion kit in

the following printers:

ZM400

ZM600

Read these instructions thoroughly before installing this kit.

Caution A qualified service technician must perform this installation.

Note For optimal printing quality and proper printer performance across our product line,

Zebra strongly recommends the use of genuine Zebra supplies as part of the total solution.

Specifically, the ZM400 and ZM600 are designed to work only with genuine Zebra

printheads, thus maximizing safety and print quality.

Prepare for Installation

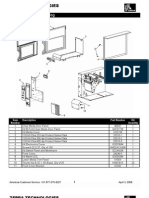

Parts List

Before proceeding, verify that your kit contains the items for your printer listed below.

Table 1 Kit List

3

Item Qty Part Number

Description

Ref

1 79805

ZM400 600/300 to 203 dpi

1 79806

ZM400 203/600 to 300 dpi

Ref

1 79807

ZM400 203/300 to 600 dpi

Ref

1 79808

ZM600 203 to 300 dpi

Ref

1 79809

ZM600 300 to 203 dpi

Ref

Bold = Part available for purchase.

Italic = Part not available for purchase; listed and shown for reference only.

Printed on

chlorine-free

recycled paper.

2007 ZIH Corp. All product names and numbers are Zebra

trademarks, and Zebra and the Zebra logo are registered

trademarks of ZIH Corp. All rights reserved.

79805L-001

Printhead Conversion Kit

Prepare for Installation

Table 2 Parts List

Kit Number

79805

79806

79807

79808

79809

79800M

79866M

79524

79801M

79867M

79525

79802M

79867M

79525

79804M

79867M

79525

79803M

79866M

79524

2

3

Printhead

Drive Belt

Pulley

Figure 1 Kit Contents

1

Reference Materials

The following manuals and CDs may be helpful references while performing this procedure.

ZM400/ZM600 User CD

ZM400/ZM600 Maintenance Manual

Z Series Maintenance Manual (CD)

Tools Required

Tools You need these tools to complete this procedure:

Phillips Screwdriver Set

Metric Nutdriver Set

Metric Hex Key (Allen wrench) Set

47362* Zebra Preventive Maintenance

Kit

Antistatic Wriststrap

* In place of the Preventive Maintenance Kit, you may use clean swabs and a solution containing

isopropyl alcohol ( 90%) with deionized water (10%).

79805L-001 B

ZM400/ZM600 Installation Instruction

7/27/07

Printhead Conversion Kit

Prepare for Installation

Remove the Electronics Cover

Note Retain all parts removed during disassembly, unless otherwise directed.

1.

Caution Turn off (O) the printer and disconnect it from the power source before

performing the following procedure.

Open the media cover and remove the media and ribbon.

2. See Figure 2. Remove the screw and washer securing the electronics cover.

Figure 2 Locate the Electronics Cover Mounting Screw

1

2

1

2

3

4

Media door

Electronics cover

Washer

Mounting screw

3. Close the media door.

7/27/07

ZM400/ZM600 Installation Instruction

79805L-001 B

Printhead Conversion Kit

Prepare for Installation

4. See Figure 3. Remove the four mounting screws on the rear of the printer.

Figure 3 Remove the Electronics Cover Mounting Screws

1

1

2

Electronics cover

Mounting screws (4)

5. See Figure 4. Remove the electronics cover by pressing in on the electronics cover with

the palm of your hand, and then lifting up on the cover.

Figure 4 Remove the Electronics Cover

2

79805L-001 B

ZM400/ZM600 Installation Instruction

7/27/07

Printhead Conversion Kit

Remove the Old Drive Belt and Platen Pulley

Remove the Old Drive Belt and Platen Pulley

1. See Figure 5. Loosen the stepper motor locking and pivot screws.

Figure 5 Remove the Drive Belt

1

3

4

5

6

1

2

3

4

5

6

Pivot screw

Stepper motor

Drive belt

Set screws (2)

Platen pulley

Locking screw

2. Swing the stepper motor to the right to loosen the drive belt and then tighten the locking

screw to snug the motor in place.

3. Remove the drive belt from the stepper motor and then from the platen pulley and discard

it.

4. Loosen the two set screws securing the platen pulley.

7/27/07

ZM400/ZM600 Installation Instruction

79805L-001 B

Printhead Conversion Kit

Install the New Drive Belt and Platen Pulley

5. See Figure 6. Slide the platen pulley from the coupling assembly and discard it.

Figure 6 Remove the Platen Pulley

Install the New Drive Belt and Platen Pulley

1. See Figure 7. Slide the platen pulley all the way onto the coupling drive shaft in the proper

orientation and align the set screws with the flat spots on the drive shaft.

Figure 7 Align the Screws

1

1

2

Setscrews (2)

Flats on shaft

2. See Figure 5 on page 5. Install the drive belt onto the platen pulley and the stepper motor

pulley.

79805L-001 B

ZM400/ZM600 Installation Instruction

7/27/07

Printhead Conversion Kit

Remove the Gear Cover

3.

Caution Do not over tighten the drive belt, or damage to the bearings and platen

roller will occur. The belt should deflect under finger pressure but no more than 6 mm

(1/4 inch).

Loosen the locking screw and then rotate the motor down until the drive belt is just taut.

Tighten the locking screw and then the pivot screw.

Remove the Gear Cover

1. See Figure 8. Lay the printer on its side, media door down on a mat.

Figure 8 Lay the Printer on its Side

1

1

2

7/27/07

Gear cover

Mounting screw

ZM400/ZM600 Installation Instruction

79805L-001 B

Printhead Conversion Kit

Remove the Gear Cover

2. Remove the gear cover mounting screw.

Figure 9 Remove the Gear Cover

1

2

1

2

3

Mounting screw

Gear cover

Compound gear

3. Slide the cover off the drive assembly.

79805L-001 B

ZM400/ZM600 Installation Instruction

7/27/07

Printhead Conversion Kit

Remove the Gear Cover

4. See Figure 10. Remove the compound gear.

Figure 10 Remove the Compound Gear

1

1

2

7/27/07

Compound gear turned to 300/600 dpi

Compound gear turned to 200 dpi

ZM400/ZM600 Installation Instruction

79805L-001 B

10

Printhead Conversion Kit

Reinstall the Compound Gear and Gear Cover

5. See Figure 11. Turn the compound gear around to the proper dpi.

Note There is a statement on both sides of the compound pulley.

THIS SIDE OUT/200 dpi. and THIS SIDE OUT/300 DPI. THIS SIDE OUT/300 DPI is

also used for 600 dpi.

Figure 11 Compound Gear DPI Location

DPI Statement

Reinstall the Compound Gear and Gear Cover

1. See Figure 9 on page 8. With the proper side facing out slide the compound gear into the

printer. Ensure that the gears mesh.

2. Ensure all gears mesh together.

3. Align the gear cover and slide it back into place.

4. Install the mounting screw in the proper hole in the gear cover, through the compound

gear, and then into the proper mounting hole in the main frame.

5. Tighten the mounting screw.

79805L-001 B

ZM400/ZM600 Installation Instruction

7/27/07

Printhead Conversion Kit

Reinstall the Electronics Cover

Reinstall the Electronics Cover

1. See Figure 12. Install the electronics cover by aligning it and sliding down, ensuring the

lower flanges are inside the base and the upper flanges are between the main frame and the

media door.

Figure 12 Locate the Upper and Lower Flanges

1

1

2

3

Electronics cover

Upper flanges (3)

Lower flanges (2)

2. See Figure 3 on page 4. Install the four mounting screws.

3. See Figure 2 on page 3. Open the media door.

4. Install the electronics cover mounting screw and lock washer.

7/27/07

ZM400/ZM600 Installation Instruction

79805L-001 B

11

12

Printhead Conversion Kit

Remove the Old Printhead

Remove the Old Printhead

Caution The printhead may be hot and could cause severe burns. Allow the printhead to

cool.

1.

Caution Observe proper electrostatic safety precautions when handling

static-sensitive components such as circuit boards and printheads.

Connect yourself to an antistatic device.

2. See Figure 13. Rotate the printhead pressure dials to the #1 position.

Figure 13 Locate the Printhead Pressure Dials

1 2

1 2

ZM400

1

2

ZM600

Postion #1

Pressure dial

3. Do you have a cutter option installed?

79805L-001 B

If

Then

No

Continue with step 4.

Yes

You may find it easier to replace the printhead with the cutter assembly

removed. Go to Remove the Cutter Assembly on page 18.

ZM400/ZM600 Installation Instruction

7/27/07

Printhead Conversion Kit

Remove the Old Printhead

4. See Figure 14. Locate and remove the thumbscrew from the print mechanism.

Figure 14 Remove the Thumbscrew

2

1

1

2

7/27/07

Print mechanism

Thumbscrew

ZM400/ZM600 Installation Instruction

79805L-001 B

13

14

Printhead Conversion Kit

Remove the Old Printhead

5. See Figure 15. Open the print mechanism and latch it in the vertical position.

6.

Caution The printhead may be hot and could cause severe burns. Allow the

printhead to cool.

Disconnect the printhead data and power cables.

7. Remove and discard the printhead assembly from the printer.

Figure 15 Remove the Printhead

3

5

1

2

3

4

5

79805L-001 B

Printhead assembly

Print mechanism

Printhead data cable connector

Printhead power cable connector

Latch assembly

ZM400/ZM600 Installation Instruction

7/27/07

Printhead Conversion Kit

Install the New Printhead

Install the New Printhead

1. See Figure 16. Align the two forks with the bearings and set the printhead assembly onto

the platen housing. This is done for ease of connecting the printhead cables.

2.

Caution An improperly connected printhead data or power cable may cause the

printhead to generate excessive heat and/or display HEAD COLD or other false error

messages.

Connect the power and data cables to the printhead.

Figure 16 Align the Forks and Bearings

1

2

3

4

1

2

3

4

5

6

7

7/27/07

Thumbscrew

Alignment holes (2)

Cable guide

Alignment pins (2)

Platen housing

Forks (2)

Bearings (2)

ZM400/ZM600 Installation Instruction

79805L-001 B

15

16

Printhead Conversion Kit

Install the New Printhead

3. Connect both printhead power and data cables to the printhead connectors and carefully

slide them into position. Ensure the cables are in their proper channels and are not binding

the printhead.

Note When mounting the printhead fork assembly onto the print mechanism, visually

inspect and ensure the cables are in their channels at the back of their carrier assembly,

power cable under data cable, and are not binding on the print mechanism.

4. See Figure 17. Tip the printhead fork assembly slightly and insert the printhead ribbon

guide into the print mechanism as shown.

5. Tip the printhead fork assembly up and into the print mechamism ensuing that the two

locating protrusions on either side of the print printhead snap into the locating holes of the

ribbon guide plate. Move the assembly back and forth to be sure that it is engaged. There

should be little movement.

6. While holding the printhead in place, install the thumb screw to secure the fork assembly.

Figure 17 Install the Printhead Fork Assembly

1

4

5

1

2

3

4

5

79805L-001 B

4

5

Thumbscrew

Print mechanism

Printhead fork assembly

Ribbon guide plate

Printhead ribbon guide

ZM400/ZM600 Installation Instruction

7/27/07

Printhead Conversion Kit

Install the New Printhead

7. Clean the printhead with the Zebra Preventative Maintenance kit.

8. See Figure 13 on page 12. Rotate the two printhead pressure dials to the desired position

for your daily printing.

9. Did you remove a cutter assembly?

10.

If

Then

No

Continue with step 10.

Yes

Got to Reinstall the Cutter Assembly on page 19.

Caution When you are loading media or ribbon, remove all jewelry that could come

into contact with the printhead or other printer parts.

Reinstall the media and ribbon.

11. Reconnect the AC power cord and data cables

12. Turn on (l) the printer.

7/27/07

ZM400/ZM600 Installation Instruction

79805L-001 B

17

18

Printhead Conversion Kit

Remove the Cutter Assembly

Remove the Cutter Assembly

1. See Figure 18. Unlatch the printhead and turn the latch assembly clockwise to access the

cutter mounting screw.

2.

Caution The cutter blade is sharp. Do not touch or rub the blade with your fingers.

Remove the cutter mounting screw.

Figure 18 Remove the Cutter Assembly

5

1

2

3

4

5

Cutter assembly

Mounting screw

Printhead latch

Platen assembly hooks (2)

Cutter harness

Note The cutter guard does not need to be removed from the cutter assembly during this

procedure.

3. Slide the cutter assembly to the left then lift up and remove the assembly from the platen

assembly hooks.

4. Go to step 4 on page 13.

79805L-001 B

ZM400/ZM600 Installation Instruction

7/27/07

Printhead Conversion Kit

Reinstall the Cutter Assembly

Reinstall the Cutter Assembly

1. See Figure 18 on page 18. Reinstall the cutter assembly on the hooks of the platen

housing.

a.

Hold the cutter assembly as far to the left as possible, and align the larger part of the

step slot with the hooks on the platen housing.

b.

Slide the cutter assembly onto the hooks and then push down and slide the assembly

to the right.

2. Using the cutter mounting screw removed earlier, secure the cutter assembly onto the

platen assembly.

The mounting tab on the cutter fits behind and attaches to the platen assembly.

3. Turn the latch assembly counterclockwise until it snaps in place.

4.

Caution When you are loading media or ribbon, remove all jewelry that could come

into contact with the printhead or other printer parts.

Reinstall the media and ribbon.

5. Reconnect the AC power cord and data cables

6. Turn on (l) the printer.

7/27/07

ZM400/ZM600 Installation Instruction

79805L-001 B

19

You might also like

- Small Block Chevrolet: Stock and High-Performance RebuildsFrom EverandSmall Block Chevrolet: Stock and High-Performance RebuildsRating: 4 out of 5 stars4/5 (6)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsFrom EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsRating: 5 out of 5 stars5/5 (5)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Suzuki GSX-R1000 2005-2006Document6 pagesSuzuki GSX-R1000 2005-2006Mr. TNo ratings yet

- Fuel System Pressure - TestDocument7 pagesFuel System Pressure - TestHamilton MirandaNo ratings yet

- BMW E60 Engine Seals NotebookDocument24 pagesBMW E60 Engine Seals NotebookPeter McCracken100% (6)

- Ecomat Opertors ManualDocument36 pagesEcomat Opertors Manualryanswj50% (2)

- SKF Locknut Shaft Details InchDocument6 pagesSKF Locknut Shaft Details InchKOMATSU SHOVELNo ratings yet

- Zebra 110xi3 Parts CatalogDocument11 pagesZebra 110xi3 Parts CatalogDaniel MerlosNo ratings yet

- Summacut Maintenance ManualDocument50 pagesSummacut Maintenance ManualMo_DaviesUK67% (3)

- Error 400Document11 pagesError 400joecentrone100% (1)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Omc 64-86Document572 pagesOmc 64-86jeff83% (6)

- 70 070 Autocreaser 50 Service ManualDocument31 pages70 070 Autocreaser 50 Service ManualWilliam John DavisonNo ratings yet

- Magic BowDocument13 pagesMagic BowSteve Dowell80% (5)

- Machinerycourse Outline and Hand OutDocument81 pagesMachinerycourse Outline and Hand OutKKDhNo ratings yet

- Motor 12V140-3 PDFDocument596 pagesMotor 12V140-3 PDFRAMON CALDERON100% (2)

- Unit 21688 - v3 PDFDocument36 pagesUnit 21688 - v3 PDFTyrone Berry100% (1)

- WP-5050F Carton Sealer English ManualDocument24 pagesWP-5050F Carton Sealer English Manualensi116No ratings yet

- Challenger Electric Pin PNDocument4 pagesChallenger Electric Pin PNStefanescu MarinNo ratings yet

- Tractor Design and TestingDocument235 pagesTractor Design and TestingCristian-Nicolae Spulber100% (1)

- Printhead Maintenance Kit: Installation InstructionsDocument9 pagesPrinthead Maintenance Kit: Installation InstructionsTeresa Cruz SuarezNo ratings yet

- Refilare C Artus Samsung CLP 500 - 510Document5 pagesRefilare C Artus Samsung CLP 500 - 510Gabriel DaneaNo ratings yet

- FD-FE 1500 Maint Manual Rev 2 11-08Document28 pagesFD-FE 1500 Maint Manual Rev 2 11-08ddeppenjrNo ratings yet

- Installation Instructions Winch Mounting Kit: Part Number: 74180 Application: Honda Foreman 500 & Honda RubiconDocument14 pagesInstallation Instructions Winch Mounting Kit: Part Number: 74180 Application: Honda Foreman 500 & Honda RubiconManuel Castro EdiolaNo ratings yet

- 42" Side Discharge Mower: Operator's ManualDocument24 pages42" Side Discharge Mower: Operator's ManualChad Zimmerman100% (1)

- Yosh R55 InstallDocument6 pagesYosh R55 Installsnoop43No ratings yet

- Fireball Ignition PDFDocument14 pagesFireball Ignition PDFLucian LeonteNo ratings yet

- OPOS UpgradeManualDocument22 pagesOPOS UpgradeManualAndrew LobodaNo ratings yet

- C107C1 - CAT TH580B Chain Shackles - Dist PDFDocument15 pagesC107C1 - CAT TH580B Chain Shackles - Dist PDFBart JohnNo ratings yet

- Platen Roller Assembly Maintenance KitDocument7 pagesPlaten Roller Assembly Maintenance Kitavinash0No ratings yet

- Z UTEC User Manual 23-1Document66 pagesZ UTEC User Manual 23-1TeeJay RexNo ratings yet

- Free Flow Headers Reel Position, Hydraulic Ram Seals - Rp7982 MandatoryDocument7 pagesFree Flow Headers Reel Position, Hydraulic Ram Seals - Rp7982 MandatoryMessi EmetievNo ratings yet

- 9typ8312 KTDocument25 pages9typ8312 KTaboubakry dialloNo ratings yet

- Multiplex Minimag Model RC Airplane Manual M13209Document18 pagesMultiplex Minimag Model RC Airplane Manual M13209Anett ÁrvaiNo ratings yet

- Service and Parts Manual Rexel Shredder RSS1830, RSS2230, RSX1530 MERCRYDocument24 pagesService and Parts Manual Rexel Shredder RSS1830, RSS2230, RSX1530 MERCRYRaltec Ltd100% (1)

- SR85-TR85 SMDocument226 pagesSR85-TR85 SMshef981100% (1)

- Installation Guide Bare 2WD V1.0.0Document26 pagesInstallation Guide Bare 2WD V1.0.0anuruddhadsNo ratings yet

- Suzuki GSX-R1000 2009-2010Document6 pagesSuzuki GSX-R1000 2009-2010Mr. TNo ratings yet

- Service and Parts Manual Rexel Shredder RDS2050, RDX1750, RDS2270, RDX1970Document24 pagesService and Parts Manual Rexel Shredder RDS2050, RDX1750, RDS2270, RDX1970Raltec Ltd100% (1)

- March 2002 3035 - All Active SolutionsDocument38 pagesMarch 2002 3035 - All Active SolutionsMario de OzNo ratings yet

- C203 C253 C353 Installation ManualDocument18 pagesC203 C253 C353 Installation ManuallaitangNo ratings yet

- Expert 52 ManualDocument58 pagesExpert 52 ManualDiana ArghirNo ratings yet

- Disassembly and Reassembly: 5.1 General Precautions On DisassemblyDocument36 pagesDisassembly and Reassembly: 5.1 General Precautions On DisassemblySilvia NevarezNo ratings yet

- 04-11 GM Colorado / Canyon 2WD / 4WD 4" Suspension Lift Installation InstructionsDocument10 pages04-11 GM Colorado / Canyon 2WD / 4WD 4" Suspension Lift Installation Instructionstrimoca_234178616No ratings yet

- 2012 Dorado Pro Service ManualDocument29 pages2012 Dorado Pro Service ManualSea RidersNo ratings yet

- X3SA Manual V.01Document9 pagesX3SA Manual V.01adrianNo ratings yet

- Blackhawk Pump Manual 2018Document75 pagesBlackhawk Pump Manual 2018Ivan MaltsevNo ratings yet

- Service Manual: VCR Mechanism UnitDocument34 pagesService Manual: VCR Mechanism UnitcobrabrNo ratings yet

- Desktop Printer Service ManualDocument58 pagesDesktop Printer Service ManualMiguel Angel Lasso CastañoNo ratings yet

- Cables k7 PDFDocument6 pagesCables k7 PDFlombardiacmNo ratings yet

- Lexmark T 520 Summit WebDocument10 pagesLexmark T 520 Summit WebservicerNo ratings yet

- Piston: Zoom Sized For PrintDocument8 pagesPiston: Zoom Sized For PrintHillary WoodwardNo ratings yet

- R22 Slip-On Exhaust Boosts GSX-R1000 PerformanceDocument6 pagesR22 Slip-On Exhaust Boosts GSX-R1000 PerformanceDaniel MartínNo ratings yet

- Installation Instructions For:: Crank Angle Sensor Replacement For EMS P/N 30-6600Document24 pagesInstallation Instructions For:: Crank Angle Sensor Replacement For EMS P/N 30-6600Ryan FrederickNo ratings yet

- Hydraulic 4 Roll Bending Machine Instruction ManualDocument79 pagesHydraulic 4 Roll Bending Machine Instruction ManualGeLoRa66No ratings yet

- Prototrak & Trak CNC: Service and Troubleshooting ManualDocument85 pagesPrototrak & Trak CNC: Service and Troubleshooting ManualDavid LucioNo ratings yet

- Dimple & Wave Key Duplicating Machine BW 339C InstructionsDocument15 pagesDimple & Wave Key Duplicating Machine BW 339C InstructionsPaul Jurczak0% (1)

- Power System Location Index: Ac5uuw00007216Document51 pagesPower System Location Index: Ac5uuw00007216chí công lêNo ratings yet

- Rear SealDocument9 pagesRear SealHammad Uddin JamilyNo ratings yet

- Roland CM - 500 - 400 - 300Document63 pagesRoland CM - 500 - 400 - 300BryanHumphries100% (1)

- Manitou Tower ServiceDocument35 pagesManitou Tower ServiceKélio Wolfrane Santos MachadoNo ratings yet

- 92242N200CDocument12 pages92242N200CRicardo Julio EtcheverryNo ratings yet

- YOSHIMURA EXHAUST INSTALLATION GUIDE FOR 2007 SUZUKI GSX-R1000Document6 pagesYOSHIMURA EXHAUST INSTALLATION GUIDE FOR 2007 SUZUKI GSX-R1000Daniel MartínNo ratings yet

- 3 D Printer ManualDocument14 pages3 D Printer ManualyuliantoNo ratings yet

- Installation ManualDocument11 pagesInstallation ManualSándor SzabóNo ratings yet

- B-SX4 SX5 Parts ListDocument72 pagesB-SX4 SX5 Parts ListJorge Alberto BetancourtNo ratings yet

- ZxMplus PartsDocument1 pageZxMplus PartsJorge Alberto BetancourtNo ratings yet

- ZMx00 Series Parts CatalogDocument10 pagesZMx00 Series Parts CatalogJorge Alberto BetancourtNo ratings yet

- E ClassDocument17 pagesE ClassJorge Alberto BetancourtNo ratings yet

- Aerzen Usa TB Series Turbo Brochure PDFDocument4 pagesAerzen Usa TB Series Turbo Brochure PDFherrerafaridNo ratings yet

- Jomokenyattauniversity of Agriculture and Technology (Jkuat)Document39 pagesJomokenyattauniversity of Agriculture and Technology (Jkuat)Joe NjoreNo ratings yet

- Short Term Courses at ILP Pasir Gudang 2013/2014Document8 pagesShort Term Courses at ILP Pasir Gudang 2013/2014msanusiNo ratings yet

- Hitachi Router M12VC - BD - 9292 PDFDocument4 pagesHitachi Router M12VC - BD - 9292 PDFjimmyboy111No ratings yet

- Parker Jet-Pipe Servovalves: Care and Handling GuideDocument9 pagesParker Jet-Pipe Servovalves: Care and Handling Guidebbkkss2No ratings yet

- DC Motor DrivesDocument20 pagesDC Motor DrivesashiqnafasNo ratings yet

- STC800Document9 pagesSTC800Amit SinghNo ratings yet

- Pakistan Council of ScientificDocument61 pagesPakistan Council of Scientificsufianabrar522No ratings yet

- Clutch Cable PDFDocument4 pagesClutch Cable PDFVEERAMANINo ratings yet

- GP080-120VX Folleto Comercial - CompressedDocument16 pagesGP080-120VX Folleto Comercial - CompressedhiabyyNo ratings yet

- Grove TMS800E PDFDocument36 pagesGrove TMS800E PDFGILMAR NIETONo ratings yet

- Critical engineering watch informationDocument100 pagesCritical engineering watch informationRj DeciertoNo ratings yet

- VTO (Vertical Take Off) : 3D FoamyDocument1 pageVTO (Vertical Take Off) : 3D Foamyantonio eusebioNo ratings yet

- 7.1 - en-US - 2022-04 - BRK - Flygt Basic Repair KitDocument52 pages7.1 - en-US - 2022-04 - BRK - Flygt Basic Repair KitFernando ChavesNo ratings yet

- 3maintain - 32+45+53CDN - 20100205ADocument13 pages3maintain - 32+45+53CDN - 20100205APracetak GwkNo ratings yet

- IDB - DOAS Submittal Rev2Document78 pagesIDB - DOAS Submittal Rev2Jamie CheNo ratings yet

- Air Conditioning TechnicianDocument3 pagesAir Conditioning Technicianaungmyothant7792No ratings yet

- Quo GCMDocument11 pagesQuo GCMcost_engineerNo ratings yet

- 650hp Doosan PU180TI diesel engineDocument2 pages650hp Doosan PU180TI diesel engineAlfonso Alberto ArguelloNo ratings yet

- Operator Parts IdentificationDocument3 pagesOperator Parts IdentificationRodolfo Franco RFNo ratings yet

- Info Diag 365Document8 pagesInfo Diag 365Bilal Abderrahmen ELHABOUCHINo ratings yet

- Catalogo Rodamiento Axial Crapodina NSKDocument18 pagesCatalogo Rodamiento Axial Crapodina NSKMiguel Angel AguirreNo ratings yet