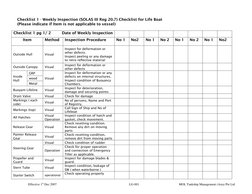

Checklist 1 - Weekly Inspection (SOLAS III Reg 20.

7) Checklist for Life Boat

(Please indicate if Item is not applicable to vessel)

Checklist 1 pg 1/ 2

Item

Date of Weekly Inspection

Method

Inspection Procedure

Outside Hull

Visual

Inspect for deformation or

other defects.

Inspect peeling or any damage

to retro reflective material

Outside Canopy

Visual

Inside

Hull

GRP

wood

Visual

Metal

Buoyant Lifeline

Visual

Drain Valve

Markings ( each

side)

Visual

Visual

Markings (top)

Visual

All Hatches

Visual

Operation

Release Gear

Visual

Painter Release

Gear

Visual

Visual

Steering Gear

Operation

Propeller and

Guard

Visual

Stern Tube

Visual

Starter Switch

operational

Effective 1st Dec 2007

No 1

No2

No 1

No 2

No 1

No 2

No 1

No2

Inspect for deformation or

other defects

Inspect for deformation or any

defects on internal structures.

Inspect condition of Buoyancy

Chambers.

Inspect for deterioration,

damage and securing points

Check for damage

No of persons, Name and Port

of Registry,

Call Sign of Ship and No of

Lifeboat

Inspect condition of hatch and

gasket, check movement.

Check resetting condition.

Remove any dirt on moving

parts

Check resetting condition,

remove dirt from moving parts

Check condition of rudder

Check for proper operation

and connection of Emergency

Tiller as applicable.

Inspect for damage blades &

guard.

Inspect condition, leakage of

SW ( when waterborne )

Check operating properly

LG-001

MOL Tankship Management (Asia) Pte Ltd

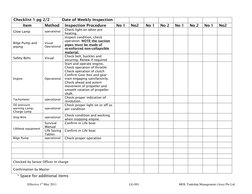

�Checklist 1 pg 2/2

Item

Method

Glow Lamp

operational

Bilge Pump and

piping

Visual

Operational

Safety Belts

Visual

Engine

Operational

Tachometer

operational

Oil pressure

warning Lamp,

Charge Lamp

operational

Stop Wire

operational

Lifeboat equipment

Survival

Manual

Life Saving

Tables

Bilge Pump

operational

Date of Weekly Inspection

Inspection Procedure

No 1

No2

No 1

No 2

No 1

No 2

No 1

No2

Check light on when pre

heating.

Inspect condition, check

operation. NOTE the suction

pipes must be made of

re-enforced non-collapsible

material.

Check belt, buckles and

securing. Renew if required

Start and operate engine,

Check operation of throttle

Check operation of clutch

Confirm Gear box and gear

train engaging satisfactorily.

Check ahead and astern

movement of propeller and

smooth rotation of propeller

shaft.

Check proper indication of

revolution.

Check proper light on or off as

per condition

Check condition and working

when stopping engine.

Confirm in Life boat

Confirm in Life boat

Check proper operation

Checked by Senior Officer In charge

Confirmation by Master

* Space for additional items

Effective 1st May 2011

LG-001

MOL Tankship Management (Asia) Pte Ltd

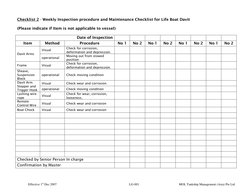

�Checklist 2 - Weekly Inspection procedure and Maintenance Checklist for Life Boat Davit

(Please indicate if Item is not applicable to vessel)

Item

Method

Visual

Davit Arms

operational

Frame

Visual

Sheave,

Suspension

Block

Davit Arm

Stopper and

Trigger Hook

Lashing wire

rope

Remote

Control Wire

Boat Chock

Date of Inspection

Procedure

No 1

No 2

No 1

No 2

No 1

No 2

No 1

No 2

Check for corrosion,

deformation and depression.

Moving out from stowed

position

Check for corrosion,

deformation and depression.

operational

Check moving condition

Visual

Check wear and corrosion.

operational

Check moving condition

Visual

Check for wear, corrosion,

looseness.

Visual

Check wear and corrosion

Visual

Check wear and corrosion

Checked by Senior Person In charge

Confirmation by Master

Effective 1st Dec 2007

LG-001

MOL Tankship Management (Asia) Pte Ltd

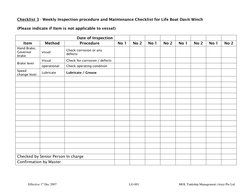

�Checklist 3 - Weekly Inspection procedure and Maintenance Checklist for Life Boat Davit Winch

(Please indicate if Item is not applicable to vessel)

Item

Hand Brake,

Governor

brake

Brake lever

Speed

change lever

Method

Date of Inspection

Procedure

visual

Check corrosion or any

defects

Visual

Check for corrosion / defects

operational

Check operating condition

Lubricate

Lubricate / Grease

No 1

No 2

No 1

No 2

No 1

No 2

No 1

No 2

Checked by Senior Person In charge

Confirmation by Master

Effective 1st Dec 2007

LG-001

MOL Tankship Management (Asia) Pte Ltd

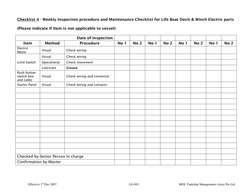

�Checklist 4 - Weekly Inspection procedure and Maintenance Checklist for Life Boat Davit & Winch Electric parts

(Please indicate if Item is not applicable to vessel)

Item

Electric

Motor

Limit Switch

Push button

switch box

and cable

Starter Panel

Method

Date of Inspection

Procedure

Visual

Check wiring

Visual

Check wiring

Operational

Check movement

Lubricate

Grease

Visual

Check wiring and connector

Visual

Check wiring and contacts

No 1

No 2

No 1

No 2

No 1

No 2

No 1

No 2

Checked by Senior Person In charge

Confirmation by Master

Effective 1st Dec 2007

LG-001

MOL Tankship Management (Asia) Pte Ltd

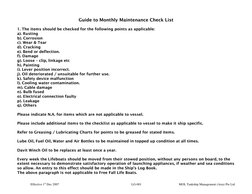

�Guide to Monthly Maintenance Check List

1. The items should be checked for the following points as applicable:

a). Rusting

b). Corrosion

c). Wear & Tear

d). Cracking

e). Bend or deflection.

f). Damage

g). Loose clip, linkage etc

h). Painting

i). Lever position incorrect.

j). Oil deteriorated / unsuitable for further use.

k). Safety device malfunction

l). Cooling water contamination.

m). Cable damage

n). Bulb fused

o). Electrical connection faulty

p). Leakage

q). Others

Please indicate N.A. for items which are not applicable to vessel.

Please include additional items to the checklist as applicable to vessel to make it ship specific.

Refer to Greasing / Lubricating Charts for points to be greased for stated items.

Lube Oil, Fuel Oil, Water and Air Bottles to be maintained in topped up condition at all times.

Davit Winch Oil to be replaces at least once a year.

Every week the Lifeboats should be moved from their stowed position, without any persons on board, to the

extent necessary to demonstrate satisfactory operation of launching appliances, if weather and sea conditions

so allow. An entry to this effect should be made in the Ships Log Book.

The above paragraph is not applicable to Free Fall Life Boats.

Effective 1st Dec 2007

LG-001

MOL Tankship Management (Asia) Pte Ltd

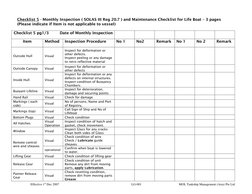

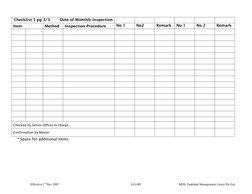

�Checklist 5 - Monthly Inspection ( SOLAS III Reg 20.7 ) and Maintenance Checklist for Life Boat 3 pages

(Please indicate if Item is not applicable to vessel)

Checklist 5 pg1/3

Item

Date of Monthly Inspection

Method

Inspection Procedure

Outside Hull

Visual

Inspect for deformation or

other defects.

Inspect peeling or any damage

to retro reflective material

Outside Canopy

Visual

Inside Hull

Visual

Buoyant Lifeline

Visual

Hand Rail

Markings ( each

side)

Visual

Visual

Markings (top)

Visual

Bottom Plugs

Visual

Visual

Operation

All Hatches

Window

Visual

Remote control

wire and sheaves

Visual

operational

Lifting Gear

Visual

Release Gear

Visual

Painter Release

Gear

Visual

Effective 1st Dec 2007

No 1

No2

Remark

No 1

No 2

Remark

Inspect for deformation or

other defects

Inspect for deformation or any

defects on internal structures.

Inspect condition of Buoyancy

Chambers.

Inspect for deterioration,

damage and securing points

Check for damage

No of persons, Name and Port

of Registry,

Call Sign of Ship and No of

Lifeboat

Check condition

Inspect condition of hatch and

gasket, check movement.

Inspect Glass for any cracks

Clean both sides of Glass

Check condition of wire

Check / Lubricate guide

sheaves

Confirm when boat is lowered

to water.

Check condition of lifting gear

Check condition of unit

Remove any dirt from moving

parts, apply Lubrication.

Check resetting condition,

remove dirt from moving parts

Grease

LG-001

MOL Tankship Management (Asia) Pte Ltd

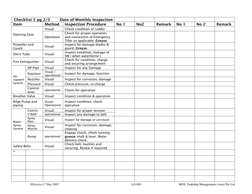

�Checklist 5 pg 2/3

Date of Monthly Inspection

Item

Method Inspection Procedure

No 1

Visual

Steering Gear

Operation

Propeller and

Guard

Visual

Stern Tube

Visual

Fire Extinguisher

Visual

HP Pipe

Visual

Regulator

Visual /

operational

Inspect for damage, function

Nozzles

Pressure

Control

lever

Breather Valve

Visual

Visual

Inspect for corrosion, damage

Check pressure, re-charge

operational

Check for operation

Visual

Inspect condition & operation

Bilge Pump and

piping

Visual

Operational

Inspect condition, check

operation

Visual

operational

Inspect for proper tension

Inspect any damage to belt

Visual

Inspect for damage or corrosion

Air

support

System

Clutch,

V-belt

Water

Spray

System

Spray

Pipe

Spray

Nozzle

Pump

Safety Belts

Visual

operational

Visual

No2

Remark

No 1

No 2

Remark

Check condition of rudder

Check for proper operation

and connection of Emergency

Tiller as applicable. Grease

Inspect for damage blades &

guard, Grease.

Inspect condition, leakage of

SW ( when waterborne )

Check for condition, charge

and securing arrangement

Inspect for any Damage

Inspect for corrosion, damage,

choking

Engage clutch, check turning,

grease shaft & lever. Water

delivery check.

Check belt, buckles and

securing. Renew if required

Effective 1st Dec 2007

LG-001

MOL Tankship Management (Asia) Pte Ltd

�Checklist 5 pg 3/3

Item

Method

Date of Monthly Inspection

Inspection Procedure

No 1

No2

Remark

No 1

No 2

Remark

Checked by Senior Officer In charge

Confirmation by Master

* Space for additional items

Effective 1st Dec 2007

LG-001

MOL Tankship Management (Asia) Pte Ltd

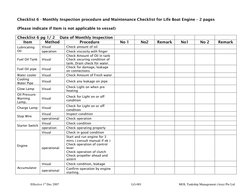

�Checklist 6 - Monthly Inspection procedure and Maintenance Checklist for Life Boat Engine 2 pages

(Please indicate if Item is not applicable to vessel)

Checklist 6 pg 1/ 2 Date of Monthly Inspection

Item

Method

Procedure

Lubricating

Oil

Visual

operation

Fuel Oil Tank

Visual

Fuel Oil pipe

Visual

Water cooler

Cooling

Water Pipe

Visual

Check amount of oil

Check viscosity with finger

Check Amount of Oil in tank

Check securing condition of

tank. Drain check for water.

Check for damage, leakage

on connections

Check Amount of Fresh water

Visual

Check any leakage on pipe

Glow Lamp

Visual

Check Light on when pre

heating

Oil Pressure

Warning

Lamp,

Visual

Check for Light on or off

condition

Charge Lamp

Visual

Stop Wire

Starter Switch

Engine

Visual

operational

Visual

operation

Visual

operational

Visual

Accumulator

operational

Effective 1st Dec 2007

No 1

No2

Remark

No1

No 2

Remark

Check for Light on or off

condition

Inspect condition

Check operation

Check condition

Check operating properly

Check in good condition

Start and run engine for 3

mins ( consult manual if ok )

Check operation of control

lever

Check operation of clutch

Check propeller ahead and

astern

Check condition, leakage

Confirm operation by engine

starting.

LG-001

MOL Tankship Management (Asia) Pte Ltd

�Additional Items as applicable:

Checklist 6 pg 2/2

Date of Monthly Inspection

Item

Method

Inspection Procedure

No 1

No2

Remark

No 1

No 2

Remark

Checked by Senior Person In charge

Confirmation by Master

Effective 1st Dec 2007

LG-001

MOL Tankship Management (Asia) Pte Ltd

�Checklist 7 - Monthly Inspection procedure and Maintenance Checklist for Life Boat Electrical parts 1 page

An Engineer or Electrician to assist for these checks.

(Please indicate if Item is not applicable to vessel)

Item

Method

Visual

Date of Inspection

Procedure

No 1

No 2

Remark

No 1

No 2

Remark

Check Lead Wires, electrolyte

Battery

Measure

operational

Inside Lamp

Canopy

Lamp

Search Light

Electric

wiring

Battery

Charger

Selector

switch

Battery

Charge

selector

operational

Measure Voltage of Battery

Operational check by starting

Charge if voltage is low

Check light on

operational

Check light on

operational

Check light on

Check condition of wire for

defects.

Check working of current

meter and regulating switches.

Check operation of battery

charge selector switch

Visual

operational

operational

operational

Cable & Plug

Visual

Start Key

switch

Contact

Battery

wiring

Engine Starter

Start Signal

wiring and

connection

Contact

Check operation of switch for

1, 2 or both battery charging.

Check condition of Plug and

Cable for charger.

Check if the contact is being

made when key is turned.

Check the battery wiring to

starter motor is good and

voltage present.

Check that wiring is intact and

contacts of connection to

starter motor are clean.

Checked by (Senior Person In charge)

Confirmation by Master

st

Effective 1 Dec 2011

LG-001

MOL Tankship Management (Asia) Pte Ltd

�Checklist 8 - Monthly Inspection procedure and Maintenance Checklist for Life Boat Davit 1 page

(Please indicate if Item is not applicable to vessel)

Item

Method

Visual

Davit Arms

operational

Frame

visual

Hinge and

Sheave Pins

Davit Arm

Stopper and

Trigger Hook

Sheaves &

Suspension

block

No 1

No 2

Remark

No 1

No 2

Remark

Check for corrosion,

deformation and depression.

Turning out from stowed

position

Check for corrosion,

deformation and depression.

Visual

Check for wear, Grease

Visual

Check condition

operational

Check movement, Grease

visual

Check for wear

operational

Check for movement, Grease

Lubricate

Check wear, wire breakage,

corrosion.

As required

Turn ends

Turn ends every 2.5 years

replace

visual

Boat Fall and

turnbuckle

Date of Inspection

Procedure

Gripes

visual

Deck

operation

device

Boat Chock

operation

Replace falls every 5 years

Check for wear, corrosion,

looseness.

Check movement

Lubricate

Grease

Visual

Davit

Lubricate

Hanging-off

pennant

Visual

Lubricate

Check for wear & corrosion

Grease Monthly as per

Manufacturers Lubrication

chart.

Check Condition, wear

Lubricate if required

Checked by Senior Person In charge

Confirmation by Master

Effective 1st Dec 2007

LG-001

MOL Tankship Management (Asia) Pte Ltd

�Checklist 9 - Monthly Inspection procedure and Maintenance Checklist for Life Boat Davit Winch 1 page

(Please indicate if Item is not applicable to vessel)

Item

Gear Box,

Gear Bearing,

Oil Seal

Hand Brake,

Governor

brake

Brake lever

Speed

change lever

Method

Visual

operational

Replace Oil

Date of Inspection

Procedure

operational

At least once a year

Check corrosion or any

defects

Check for proper operation

Visual

Check for corrosion / defects

operational

Check movement / operation

Lubricate

Grease

visual

No 1

No 2

Remark

No 1

No 2

Remark

Check level and deterioration

of Lubricating Oil.

Check unusual noises

Checked by Senior Person In charge

Confirmation by Master

Effective 1st Dec 2007

LG-001

MOL Tankship Management (Asia) Pte Ltd

�Checklist 10 - Monthly Inspection procedure and Maintenance Checklist for Life Boat Davit & Winch Electric

parts - 1 page

(Please indicate if Item is not applicable to vessel)

Item

Electric

Motor

Limit Switch

Push button

switch box

and cable

Starter Panel

Method

Date of Inspection

Procedure

Visual

Check wiring

operational

Check for normal operation

Visual

Check wiring

Operational

Check movement

Lubricate

Grease

Visual

Check wiring and connector

operational

Confirm normal operations

Visual

Check wiring and contacts

operational

Check for normal operation

No 1

No 2

Remark

No 1

Item

Method

Checked by Senior Person In charge

Confirmation by Master

Effective 1st Dec 2007

LG-001

MOL Tankship Management (Asia) Pte Ltd

�Checklist 11 - Monthly Inspection (SOLAS III Reg. 20.7) /// Liferaft

Date of Monthly Inspection

Item

Description

No 1

No 2

No 3

No 4

No 5

No 1

No 2

No 3

No 4

No 5

No 1

No 2

No 3

No 4

No 5

Check Condition of Container

Container

Check condition of watertight packing

Check markings & instructions on container

Identification Card

Check water tightness and vessel information provided

Check the condition of the Cradle for corrosion, paint if required

Cradle

Checked the condition of Automatic Painter system

Ladder ( Fwd Raft)

Checked the condition of Embarkation ladder

Manual Release

Unit

Check the condition of the release unit, lubricate

Manual Painter

Check condition of Manual release Painter

Check condition of connecting bolts, nuts & safety pin.

Check condition & expiry date of HRU

Hydrostatic

Release Unit

Check condition of connecting shackles & lubricate.

Check Weak link condition and proper connection, check for any

obstructions for launching

Check condition of wire, turnbuckle & shackles

Lashing apparatus

Check condition & tightness of lashing, lubricate

ILLUMINATION Tested Illumination for Embarkation/ Disembarkation

INSTRUCTION

Checked the condition of Operating Instruction

Checked by Senior Officer in charge (

Confirmed by the Master

Effective 1st Dec 2007

LG-001

MOL Tankship Management (Asia) Pte Ltd

�Checklist 12 - Monthly Inspection (SOLAS III Reg. 20.7) /// Other Life-Saving Appliances

Date of Monthly Inspection

EQUIPMENT

Description

LIFE BUOYS

Total Number of Life Buoys (III Reg.. 32.1)

Lifebuoys with Light and Smoke Signals capable of

quick release from the Bridge

Lifebuoys with Self Igniting Light (only)

LIFE JACKET

IMMERSION

SUITS

LINE

THROWING

APPLIANCES

COMMUNICA

TION

SOLAS

Requirement

pcs

Remark

Check

No.

Condition

Remark

Check

No.

Condition

Remark

(Smoke Signals)

Expiry ...............

(Smoke Signals)

Expiry ...............

(Smoke Signals)

Expiry ...............

Expiry ...............

Expiry ...............

Expiry ...............

Expiry ...............

Expiry ...............

Expiry ...............

Expiry ...............

Expiry ...............

Expiry ...............

( pcs)

2 pcs

Lifebuoys without any attachment

( pcs)

Total Numbers of Lifejackets (III Reg.. 7.2.1)

pcs

Number of Child Life Jackets

pcs

(Bridge)

( pcs)

(FWD Station)

( pcs)

(AFT Station)

( pcs)

(ECR)

( pcs)

Lifejackets Lights for Lifejackets (III Reg... 32.2)

pcs

Total Numbers of Immersion suits (III Reg.. 32.3)

psc

(Bridge)

( pcs)

(FWD Station)

( pcs)

(AFT Station)

( pcs)

(ECR)

( pcs)

(other)

( pcs)

Immersion suits for person on watch

Condition

(2 pcs)

Lifebuoys with Buoyant Lifeline

Life Jackets for person on watch

Check

No.

Line-throwing Appliances (III Reg.. 18)

1 pcs

Projectiles of Line-throwing Appliances with lines

4 pcs

Brief Instruction for Line-throwing Appliances

1 Vol.

Rocket Parachute Flares (III Reg.. 6.3)

12 pcs

Tow-way VHF Radiotelephone (III Reg.. 6.2.1)

3 pcs

Non-Rechargeable Batteries (Res. A.809)

3 pcs

Expiry ...............

Expiry ...............

Expiry ...............

Radar Transponders (III Reg.. 6.2.2)

2 pcs

Expiry ...............

Expiry ...............

Expiry ...............

On-Board Communication (III Reg.. 6.4)

1 set

Expiry ...............

Expiry ...............

Expiry ...............

Expiry ...............

Expiry ...............

Expiry ...............

Hand Flares

Satellite EPIRB (IV Reg.. 7.6.1)

Battery of EPIRB

EPIRB

1 set

Battery of Release Sensor of EPIRB

Date of last Annual Test (IV Reg.. 15.9.1)

Date of last shore based maintenance (IV Reg.. 15.9.2)

Effective 31st Dec 2007

LG-001

MOL Tankship Management (Asia) Pte Ltd

�Other Life Saving Appliances

Date of Monthly Inspection

EQUIPMENT

Description

SOLAS

Requirement

Check

No.

Condition

Remark

Check

No.

Condition

Remark

Check

No.

Condition

Remark

Visually check Cylinder is fully charged and seal intact.

(Smoke Signals)

Expiry ...............

Check condition of Hose for stiffness.

ELSA

( if Applicable)

Randomly perform te functional test and recharge

Cylinder.

Checked by Senior Officer in charge

Confirmed by the Master

Effective 31st Dec 2007

Expiry ...............

LG-001

MOL Tankship Management (Asia) Pte Ltd

�Checklist 13 - Monthly Inspection (SOLAS III Reg. 20.7) /// Lifeboat Equipment

Checklist 13 pg 1/ 2

Date of Monthly Inspection

Lifeboat Equipment

Reqn

Buoyant oar and thole pins, or crutches with lanyard or chain

1 set

Boat Hook

2 pcs

Buoyant bailer

1 pc

Bucket

2 pcs

Survival Manual (Refer to Instructions adopted by IMO A.657 (16))

1 vol.

Operational Compass (Fitted at Steering Position with illumination)

1 set

Sea anchor of adequate size fitted with a shock-resistant hawser

1 set

No.

1

No.

2

Remark

No.

1

No.

2

Remark

No. 1

No.

2

Remark

Efficient Painters

7

(One painter to be attached to release device in FWD for immediate

use)

(The other painter to be firmly secured at or near the bow ready

for use)

2 sets

Hatches (One at each end of the Lifeboat)

2 pcs

Water containing in the watertight receptacles (3l of fresh water for

each person)

3l x

person

10

Rustproof Dipper with lanyard

1 pc

11

Rustproof graduated Drinking vessel

1 pc

12

Food ration totaling not less than 10,000 kJ for each person

1 set

13

Rocket Parachute Flares

4 pcs

14

Hand Flares

6 pcs

15

Buoyant Smoke Signals

2 pcs

Effective 1st Dec 2007

LG-001

Expiry........

....

Expiry

..........

Expiry

..........

Expiry

..........

Expiry........

....

Expiry

..........

Expiry

..........

Expiry

..........

Expiry.........

...

Expiry

..........

Expiry

..........

Expiry

..........

MOL Tankship Management (Asia) Pte Ltd

�16

Waterproof Electric Torch with Spare Batteries and Spare Bulb

1 set

17

Copy of the Life-saving Signals table on a waterproof card or

container

1 copy

18

Daylight Signaling Mirror with Instruction

1 set

19

Whistle or equivalent sound signal

1 pc

20

First-aid outfit in a waterproof case capable of being closed after

use

1 set

21

Anti-seasickness medicine for 48 hours with Seasickness bag

22

Jack-knife, to be kept attached to the boat by lanyard

1 pc

23

Tin-Openers

3 pcs

24

Buoyant Rescue Quoits, attached to more than 30m of buoyant in

line

2 sets

25

Manual Pump suitable for effective bailing

1 set

26

Fishing Tackle

1 set

27

Tools for minor adjustment for Engine and its accessories

1 set

28

Portable Fire Extinguisher

1 pc

29

Searchlight

1 pc

30

31

Each

person

Radar Reflector, unless Radar Transponder is stowed in the

Lifeboat

Water Resistant Instructions for Starting and Operating Life Boat

Engine

Checked by Senior Officer in charge (

Expiry

..........

Expiry

..........

Expiry

..........

Expiry

..........

Expiry

..........

Expiry

..........

Expiry

..........

Expiry

..........

Expiry

..........

1 pc

1 set

Confirmed by the Master

Checklist 13 page 2 / 2

Effective 1st Dec 2007

LG-001

MOL Tankship Management (Asia) Pte Ltd

�Checklist 14 Monthly Inspection of Immersion Suits

Item

Procedure

Storage Bag

Immersion

Suit

Check condition of bag, ease of

removal and donning instructions are

legible. Confirm Suit is type and size

indicated on bag.

Check suit is clean and dry

Check for any damage, wear & tear

Suit Zipper

Check for operation and lubricate

If fitted, check attachment and

Inflatable

condition, check inflation hose for

Head support

deterioration.

and

The head support / buoyancy ring

buoyancy

should be tested for leaks at least

ring

quarterly.

Retro

reflective

Check condition and for peeling

tape

Whistle

Check condition and working

(if fitted)

Light

Check condition and expiry date

(if Fitted)

Storage

Store suit with zipper fully open

Checked by senior officer in charge

Confirmed by Master

Effective 1st Dec 2007

LG-001

MOL Tankship Management (Asia) Pte Ltd

�Checklist 15 Monthly Inspection of 2 Way Radio, SART & EPIRB

Item

2 Way Radio

Telephone

SART

EPIRB

Procedure

Visual Check for condition clean

any dirt or moisture.

Operational check talking test to

confirm operation and function.

Check expiry for Spare Battery

Clean contacts on battery and

charger.

Check condition of container Radome

and bracket for any damage, cracks

etc.

Check condition of securing rope

Operational test to confirm proper

function

Check condition of case and bracket

for any damage, looseness, cracks,

corrosion etc. confirm no obstruction

for release.

Check condition of unit, clean with

freshwater.

Check replacement date of

Hydrostatic release Sensor. If

replacement is required, same to be

done by Authorized Agent.

In case of Hydrostatic Release Units,

the replacement can be done by

Ships Staff

Checked by senior officer in charge

Confirmed by Master

Effective 1st Dec 2007

LG-001

MOL Tankship Management (Asia) Pte Ltd

�ELSA Record

No

1

Cabin

Master

Location

C - Deck

Maker

Interspiro

Model

Serial No Duration

HP

23

15 mins

Capacity

3 Ltrs

Pressure

200 bars

Manuf

Date

March 06

2

3

4

5

6

7

8

9

Effective 1st Dec 2007

LG-001

MOL Tankship management (Asia) Pte Ltd

�No

Cabin

Location

Maker

Model

Serial No

Size

Type

Manuf

Date

Senior Officer In-Charge

Master

Last Hydrostatic Test:___________________________________________

Last Shore Inspection: _________________________________________

Effective 1st Dec 2007

LG-001

MOL Tankship management (Asia) Pte Ltd

�Immersion Suit Details

No

Cabin

Location

Master

E - Deck

C/O

E - Deck

2/O-1

E - Deck

(OFF SPARE B)

2/O-2

E - Deck

3/O

E - Deck

R/O

E - Deck

OFF SPARE A

E - Deck

C/E

D - Deck

1/E

D - Deck

10

Master

E - Deck

Maker

Imperial Co

International Inc.

Imperial Co

International Inc.

Imperial Co

International Inc.

Imperial Co

International Inc.

Imperial Co

International Inc.

Imperial Co

International Inc.

Imperial Co

International Inc.

Imperial Co

International Inc.

Imperial Co

International Inc.

Imperial Co

International Inc.

Model

Serial No

Date of

Air Test

Size

Condition

Manufacture

Date

1409-ECA

167171

03 Aug 09

Adult

Good

2005.May

1409-ECA

167465

03 Aug 09

Adult

Good

2005.May

1409-ECA

167176

03 Aug 09

Adult

Good

2005.Apr

1409-ECA

168512

03 Aug 09

Adult

Good

2005.May

1409-ECA

167635

03 Aug 09

Adult

Good

2005.May

1409-ECA

167175

03 Aug 09

Adult

Good

2005.Apr

1409-ECA

168508

03 Aug 09

Adult

Good

2005.May

1409-ECA

167464

03 Aug 09

Adult

Good

2005.Apr

1409-ECA

167463

03 Aug 09

Adult

Good

2005.May

1409-ECA

168507

03 Aug 09

Adult

Good

2005.May

11

12

SAMPLE PAGE

Effective 1st Sept 2009 (Ver 1.2)

SAMPLE PAGE

SAMPLE PAGE

LG-001

SAMPLE PAGE

SAMPLE PAGE

MOL Tankship Management (Asia) Pte Ltd

�Immersion Suit Details

No

Cabin

Location

Effective 1st Sept 2009 (Ver 1.2)

Maker

Model

Serial No

LG-001

Date of

Air Test

Size

Condition

Manufacture

Date

MOL Tankship Management (Asia) Pte Ltd

�No

Cabin

Location

Effective 1st Sept 2009 (Ver 1.2)

Maker

Model

Serial No

LG-001

Date of

Air Test

Size

Condition

Manufacture

Date

MOL Tankship Management (Asia) Pte Ltd

�No

Cabin

Location

Maker

Model

Serial No

Date of

Air Test

Size

Condition

Manufacture

Date

Senior Officer In-Charge

Master

Notes:

Updated on:

Effective 1st Sept 2009 (Ver 1.2)

LG-001

MOL Tankship Management (Asia) Pte Ltd

�Life Jacket Record

No

1

Cabin

Master

Location

C - Deck

Maker

Cosalt Ltd

Model

No

Premier A

23

Size

Adult

Type

Manuf

Date

Inherent Buoyant

March 06

2

3

4

5

6

7

8

9

Effective 1st Dec 2007

LG-001

MOL Tankship Management (Asia) Pte Ltd

�No

Cabin

Location

Maker

Model

Serial No

Size

Type

Manuf

Date

Senior Officer In-Charge

Master

Effective 1st Dec 2007

LG-001

MOL Tankship Management (Asia) Pte Ltd

�Monitoring Record of Companys Representative

Date

Name of Company's

Representative

(Signature)

Effective 1st Dec 2007

Items Verified

Remarks

LG-001

MOL Tankship Management (Asia) Pte Ltd

�B) PARTICULARS FOR LIFERAFT

No.1 Life raft (Location :

Maker's name or trade mark

Model and serial number

Date of manufacture (Month and Year)

Name of approving authority

Capacity (Number of Persons)

Serviced

Last Done:

No.2 Life raft (Location:

Next Due:

)

Maker's name or trade mark

Model and serial number

Date of manufacture (Month and Year)

Name of approving authority

Capacity (Number of Persons)

Serviced

Last Done:

No.3 Life raft (Location:

Next Due:

)

Maker's name or trade mark

Model and serial number

Date of manufacture (Month and Year)

Name of approving authority

Capacity (Number of Persons)

Serviced

Last Done:

No.4 Life raft (Location:

Next Due:

)

Maker's name or trade mark

Model and serial number

Date of manufacture (Month and Year)

Name of approving authority

Capacity (Number of Persons)

Serviced

Last Done:

No.5 Liferaft (Location:

Next Due:

)

Maker's name or trade mark

Model and serial number

Date of manufacture (Month and Year)

Name of approving authority

Capacity (Number of Persons)

Serviced

Effective 1st Dec 2007

Last Done:

LG-001

Next Due:

MOL Tankship management (Asia) Pte Ltd

�Particulars for Life-Saving Appliances

Life-Saving Appliances

1

Line Throwing appliances with 4 rockets and Line

12 of Parachute Distress Flares

No.

Name of Manufacturer/ Type and Serial No.

Remarks

No. 1

3

Two-way Portable Radio Telephone Apparatus

No. 2

No. 3

EPIRB: Emergency Position Indicating Radio Beacons

No. 1

Radar Transponder

No. 2

Daylight Signaling Lamp and Source of Power

Lifeboat Davit

No. 1

Lifeboat Winch

Lifeboat Davit

No. 2

Lifeboat Winch

Effective 31st Dec 2007

LG-001

MOL Tankship Management (Asia) Pte Ltd

�Particulars of Lifeboat (

-side: No

Manufacturers Name

Lifeboat Model and Serial Number

Month and Year of Manufacture

Name of Approving Authority

Number of Persons the Lifeboat is approved to carry

Annual Thorough Examination ( Annual Periodic Servicing of Launching Appliances and On-Load Release Gear) (SOLAS Ch III Reg.20.11)

Sign / Name of Manufacturers Representative or Certified person

Examination

Date of Examination

Place of Examination

1

2

3

4

5

*Annual Periodic Servicing of Launching Appliances and On-Load Release Gear is including Dynamic Winch Brake Test (Annual Operating Test)

Five Yearly Thorough Examination (Annual Periodic Servicing of Launching Appliances and On-Load Release Gear) (SOLAS Ch III Reg.20.11)

Examination

Date of Examination

Place of Examination

Sign / Name of Manufacturers Representative or Certified person

Dynamic Test

Over-hauling

* Five Yearly Periodic Servicing of Launching Appliances and On-Load Release Gear is including Dynamic Winch Brake Test with 1.1 times total mass

Maintenance of Falls (SOLAS Chapter III Reg.20.4)

Date

Checked by senior Officer In-charge

Confirmed by the Master

Boat Falls Turned end to end

Boat Falls renewed

Hydrostatic Test for Air-Bottles for Lifeboat with self-contained air support system (if fitted )

Date

Effective 1st Dec 2007

Place

Name of Manufacturer

LG-001

Confirmed by Master

MOL Tankship Management (Asia) Pte Ltd

�Summary of Work done Monthly

Remarks:

Date

Sign PIC

Chief Officer

Master

Remarks:

Date

Sign PIC

Chief Officer

Master

Remarks:

Date

Sign PIC

Chief Officer

Master

Remarks:

Date

Sign PIC

Chief Officer

Master

Remarks:

Date

Sign PIC

Chief Officer

Master

Effective 1st Dec 2007

LG-001

MOL Tankship Management (Asia) Pte Ltd