Professional Documents

Culture Documents

Machinery Maintenance Work Rev Rham

Machinery Maintenance Work Rev Rham

Uploaded by

Bala Subra ManiamCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Machinery Maintenance Work Rev Rham

Machinery Maintenance Work Rev Rham

Uploaded by

Bala Subra ManiamCopyright:

Available Formats

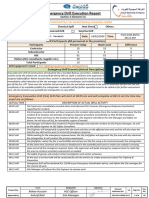

JOB HAZARD ANALYSIS FOR MACHINERIES MAINTENANCE WORKS

Section 1

MACHINERIES MAINTENANCE

WORKS

ACTIVITY

Assessment date

Revision

Location

Next review date

ASSESSMENT DETAILS

18/9/2015

1.0

RAPID project, pengerang, johor

CONTRACTO

R

SEG(M)

PERSONS CARRYING OUT ASSESSMENT

Name

ID #

Name

Mr. Zhu Kaoqin

ZK

Mr. Ayob

Mr. Zheng Xuemin

XM

Mr. Rham Vignesh

RV

Mr. Lockman B A

LBAR

Rahim

ID #

AY

Section 2

JOB SEQUENCE

RISKS /

HAZARD

1.Mobilization of

mechanical crew

to site

- collusion with

other road users

2 .Unloading of

accessories using

mobile crane.

(For piling rig and

other machine

require lifting)

-Sling snap

-Hook broken

-Hit worker

RISK

RATING

S

R

R

B

3

C

4

RISK

CATEGOR

Y

LOW

HIGH

CONTROL MEASURES

-Ensure attend induction class conducted by PMC and obtain valid

entry pass

-Follow speed limit 25 km/h and signage.

- Follow traffic rules and signage

-Stop work during rain or bad weather

-Wear proper PPE reflective clothes Helmet, safety boots, safety

glasses and dust mask)

- PTW to be obtained for any maintenance work

- Toolbox briefing to be held and discuss the task

- while driving no mobile phone engaged ( park a side safe place )

and proceed driving

- Medical assistants and facility by ISOS/ contact person

can be contacted at 019-2962787

-PMC duty phone (019-2373299) in case of emergency

- Apply permit to work prior to lifting.

-Lifting gear shall be inspected by competent person and color

coded.

-Crane operated by competent operator.

-Use tagline to control the load.

-Not to stand/work under suspended load.

-Ensure SWL stated on sling

-Barricade the lifting area.

-Ground condition to be checked to ensure it is safe to perform

work

-lifting supervisor the be present at site

-competent operator with valid PMA & competency cert

-crane to be inspected and color code

RISK

RATING

RESULTANT

RISK

CATEGORY

RR

B2

LOW

B2

LOW

JOB HAZARD ANALYSIS FOR MACHINERIES MAINTENANCE WORKS

Section 1

MACHINERIES MAINTENANCE

WORKS - CAMP

ACTIVITY

Assessment date

Revision

Location

Next review date

ASSESSMENT DETAILS

18/9/2015

1.0

RAPID project, pengerang, johor

CONTRACTO

R

PERSONS CARRYING OUT ASSESSMENT

Name

ID #

Name

Mr. Zhu Kaoqin

ZK

Mr. Ayob

Mr. Zheng Xuemin

XM

Mr. Rham Vignesh

RV

Mr. Lockman B A

LBAR

Rahim

RISK

RATING

JOB SEQUENCE

JOB SEQUENCE

3. working at

height

( for piling rig or

other machinery if

required )

RISK

CATEGOR

Y

RISKS /

HAZARD

RISKS /

HAZARD

-Pinching hazard

-Bad weather; rain

-fall from height

-Slip and fall ;

grease

-Sharp edges

- fracture bones

(bodily injuries)

RISK

RATING

S

R

R

4c

RISK

CATEGOR

Y

HIGH

SEG(M)

ID #

AY

RISK

RATING

RESULTANT

RISK

CATEGORY

RISK

RATING

RESULTANT

RISK

CATEGORY

CONTROL MEASURES

-competency signalman & rigger required

CONTROL MEASURES

-To stop work during bad weather; engrain

-Use body harness when working above 2.0m-double lanyard

-To stop work during bad weather; engrain

- ensure ladder/rung is not slippery

- practices 3 point contact when climbing

- Use inspected and color coded body harness

- wear approved safety helmet and appropriate hand gloves

RR

B3

LOW

JOB HAZARD ANALYSIS FOR MACHINERIES MAINTENANCE WORKS

Section 1

ACTIVITY

Assessment date

Revision

Location

Next review date

MACHINERIES MAINTENANCE

WORKS - CAMP

ASSESSMENT DETAILS

18/9/2015

1.0

RAPID project, pengerang, johor

CONTRACTO

R

SEG(M)

PERSONS CARRYING OUT ASSESSMENT

Name

ID #

Name

Mr. Zhu Kaoqin

ZK

Mr. Ayob

Mr. Zheng Xuemin

XM

Mr. Rham Vignesh

RV

Mr. Lockman B A

LBAR

Rahim

RISK

RATING

RISK

RATING

JOB SEQUENCE

3.Maintenance of

machine

-Manual handling

( ergonomic )

-Pinching hazard

-Struck by

machine parts

-Bad weather; rain

-Work at height

Slip and fall ;

grease

RISKS

-Sharp

edges/

- finger

injuries /

HAZARD

cut

- irritation

- oil splash and

object fly into

eyes

- object fall on

foot / leg

- oil spill

- improper hand

tools

- fall from height

( ladder )

C

3

RISK

CATEGOR

Y

MEDIUM

-Use PPE(helmet ,ear plug, gloves and etc.)

-Assemble according to machine manual.

-To stop work during bad weather; engrain

-Cover any protruding parts of machine during lifting

-Standby spill kit and containment tray

CONTROL MEASURES

-Barricade the area and place necessary signage (Do not operate)

-Ensure the machine is turn off and mot powered while repairing

- Ensure to wear appropriate hand gloves and clothing

- wear safety glass when necessary wear face shield

- wear safety boots

- standby spill kit and containment tray

B2

ID #

AY

RESULTANT

RISK

CATEGORY

LOW

JOB HAZARD ANALYSIS FOR MACHINERIES MAINTENANCE WORKS

Section 1

MACHINERIES MAINTENANCE

WORKS

ACTIVITY

Assessment date

Revision

Location

Next review date

ASSESSMENT DETAILS

18/9/2015

1.0

RAPID project, pengerang, johor

CONTRACTO

R

SEG(M)

PERSONS CARRYING OUT ASSESSMENT

Name

ID #

Name

Mr. Zhu Kaoqin

ZK

Mr. Ayob

Mr. Zheng Xuemin

XM

Mr. Rham Vignesh

RV

Mr. Lockman B A

LBAR

Rahim

ID #

AY

Section 2

JOB SEQUENCE

4. Trial run of

machine

RISKS /

HAZARD

-Collision with

other vehicle/

worker/equipment

-Poor access

-Oil spillage

-Machine topple

-Machine

breakdown

-Entanglement

- Flying object

5. Welding work of

machinery repair

-Potential fire

-Burns to skin

-Inhale toxic gas

-Electrocuted

- Bad weather

6. Housekeeping

- Slip and trip

- oil spill

- materials

obstruction

- lose material

- signage ( Do not

operate )

RISK

RATING

S

R

R

D

2

C

3

C

3

RISK

CATEGOR

Y

CONTROL MEASURES

RISK

RATING

RESULTANT

RISK

CATEGORY

RR

MEDIUM

-Competent operator

-Experienced signal man/ banksman

-High visibility vest for workers

-Provide containment tray

-Daily checklist to be provided to operator.

-Standby spill kit and containment tray

- when necessary wear face shield

- wear proper attire

- Ensure guarding is in place for open mechanical parts.

B2

LOW

MEDIUM

-Apply PTW before start work.

-Inspect the welding machine power cables and welding cable,

ensure in good condition

-Eliminate flammable material near welding area.

-Place fire extinguisher nearby.

-Use PPE (welding glove, welding shield ,face mask, welding suit)

-Stop work during bad weather.(raining, lighting)

-Install lighting arrestor pole.

C2

LOW

MEDIUM

- Maintain housekeeping.

- Timber materials shall be removed from site to designated

dumping area.

- No obstruction on the road / emergency access way

- Secure all the equipment after the work is completed.

- Removed the signage from equipment/machinery

C1

LOW

JOB HAZARD ANALYSIS FOR PILING INSTALLATION WORKS

Section 1

ACTIVITY

PILE RIG MAINTENANCE WORKS

ASSESSMENT DETAILS

Assessment date

17/9/2015

Revision

1.0

Location

RAPID project, pengerang, johor

Next review date

CONTRACTO

R

SEG(M)

PERSONS CARRYING OUT ASSESSMENT

Name

ID #

Name

Mr. Zhu Kaoqin

ZK

Mr. Ayob

Mr. Zheng Xuemin

XM

Mr. Rham Vignesh

RV

Mr. Lockman B A

LBAR

Rahim

ID #

AY

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 2020 Brigada Eskwela Monitoring ChecklistDocument1 page2020 Brigada Eskwela Monitoring ChecklistReno Tadashi88% (8)

- Audit Program Local Disaster Risk Reduction Management Fund CY 2021Document13 pagesAudit Program Local Disaster Risk Reduction Management Fund CY 2021Ei Mi San100% (1)

- DRRR Mid Term Exam 2018Document4 pagesDRRR Mid Term Exam 2018Ryan Negad100% (27)

- Supporting Community-Based Disaster ResponseDocument10 pagesSupporting Community-Based Disaster ResponseBill de BlasioNo ratings yet

- Hazus Mr4 Earthquake User ManualDocument270 pagesHazus Mr4 Earthquake User ManualIonut Ovidiu TomaNo ratings yet

- Earthquake Lecture Sy 2022 2023Document66 pagesEarthquake Lecture Sy 2022 2023XscdghdsyNo ratings yet

- Basic Fire Extinguishers TrainingDocument26 pagesBasic Fire Extinguishers TrainingshabanNo ratings yet

- Nfpa 4-7Document2 pagesNfpa 4-7mujahid1137No ratings yet

- JSA - HindalcoDocument9 pagesJSA - Hindalcopushpak26No ratings yet

- Business Continuity ManagementDocument19 pagesBusiness Continuity ManagementNOGENENo ratings yet

- NSTPDocument13 pagesNSTPYusoph Gracio SumaNo ratings yet

- Key Roles and Responsibilities During Disaster ResponseDocument10 pagesKey Roles and Responsibilities During Disaster Responserhoy villa bullecerNo ratings yet

- EN 14373-2005 Explosion Suppression Systems PDFDocument46 pagesEN 14373-2005 Explosion Suppression Systems PDFMurray PeartNo ratings yet

- American Survival Guide Magazine - Issue 1Document132 pagesAmerican Survival Guide Magazine - Issue 1agabatti100% (5)

- SRH Preparedness Toolkit ResourcesDocument15 pagesSRH Preparedness Toolkit ResourcesJoachim ChijideNo ratings yet

- DRRM Manual - Contingency PlanDocument43 pagesDRRM Manual - Contingency PlanChristopher MontebonNo ratings yet

- Emergency Drills ExercisesDocument28 pagesEmergency Drills ExercisesZawawi Ibnu RosyidNo ratings yet

- Notice: Meetings: Commercial Nuclear Power Plants Review of Emergency Preparedness Regulations and GuidanceDocument5 pagesNotice: Meetings: Commercial Nuclear Power Plants Review of Emergency Preparedness Regulations and GuidanceJustia.comNo ratings yet

- LAPDDocument55 pagesLAPDjetlee estacionNo ratings yet

- Emergency Response Plan: Safety FirstDocument4 pagesEmergency Response Plan: Safety FirstDilkhaz HSENo ratings yet

- Certificate of Experience: Purok 1, Poblacion, Manticao, Misamis OrientalDocument3 pagesCertificate of Experience: Purok 1, Poblacion, Manticao, Misamis OrientalRuth Joy SambulayNo ratings yet

- Hotel Management Database ProjectDocument45 pagesHotel Management Database ProjectFarrukh Tahir100% (1)

- Flood Risk and Resilience Assessment For Santa Rosa-Silang Subwatershed in The Laguna Lake Region, PhilippinesDocument23 pagesFlood Risk and Resilience Assessment For Santa Rosa-Silang Subwatershed in The Laguna Lake Region, PhilippinesWinjoe CapiliNo ratings yet

- Emergency Drill Execution Report - JAN 14, 2023Document4 pagesEmergency Drill Execution Report - JAN 14, 2023rehanhussain0333No ratings yet

- Introduction Disaster Rehabilitation Is An Integral Part of Disaster ManagementDocument2 pagesIntroduction Disaster Rehabilitation Is An Integral Part of Disaster ManagementYogi HertantoNo ratings yet

- DRR PLanDocument21 pagesDRR PLanCatherine Joy O. AbingNo ratings yet

- Design Procedures For Hydraulic Structures (55 Pages)Document55 pagesDesign Procedures For Hydraulic Structures (55 Pages)Younghee LEe100% (1)

- Educational Trip Consent Form 2022Document1 pageEducational Trip Consent Form 2022Monish SahuNo ratings yet

- Basic-Concept-of DisasterDocument19 pagesBasic-Concept-of DisasterElijah Del RosarioNo ratings yet

- Cuddalore District Disaster Risk Management Programme - A Joint Initiative by GOI & UNDP - Compiled DocumentDocument44 pagesCuddalore District Disaster Risk Management Programme - A Joint Initiative by GOI & UNDP - Compiled DocumentHansen Thambi PremNo ratings yet