1

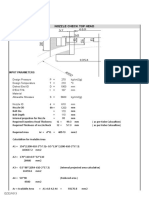

Input Echo, Component

1,

Description: Tube

Design Internal Pressure

60.00

Temperature for Internal Pressure

User Entered Minimum Design Metal Temperature

Design External Pressure

PEXT

400.00

0.00

65.00

Temperature for External Pressure

294.00

External Pressure Chart Name

kgf/cm^2

kgf/cm^2

C

HA-1

Include Hydrostatic Head Components

NO

Material Specification

SA-249 TP304

Material UNS Number

S30400

Material Form used

Wld. tube

Allowable Stress At Temperature

927.23

kgf/cm^2

Allowable Stress At Ambient

SA

1195.22

kgf/cm^2

Yield Stress At Temperature

Sy

1208.46

kgf/cm^2

Joint efficiency for Shell Joint

1.00

Design Length of Section

4000.000

mm.

CYLLEN

4000.000

mm.

Outside Diameter of Cylindrical Shell

19.050

mm.

Minimum Thickness of Pipe or Plate

1.6500

mm.

Nominal Thickness of Pipe or Plate

Tnom

1.6500

mm.

CA

0.0000

mm.

Length of Cylinder for Volume Calcs.

Shell/Head Int. Corrosion Allowance

Skip UG-16(b) Min. thickness calculation

Type of Element:

Internal pressure results, Shell Number

YES

Cylindrical Shell

1, Desc.: Tube

�2

ASME Code, Section VIII, Division 1, 2013

Thickness Due to Internal Pressure (Tr):

= (P*(D/2-CAE)) / (S*E+0.4*P) per Appendix 1-1 (a)(1)

= (60.00*(19.0500/2-0.000)/(927.23*1.00+0.4*60.00)

= 0.6008 + 0.0000 = 0.6008 mm.

Max. All. Working Pressure at Given Thickness (MAWP):

= (S*E*(T-CA-CAE)) / ((D/2-CAE)-0.4*(T-CA-CAE)) per Appendix 1-1 (a)(1)

= (927.23*1.00*(1.6500))/(19.0500/2-0.000-0.4*1.6500)

= 172.58 kgf/cm^2

Maximum Allowable Pressure, New and Cold (MAPNC):

= (SA*E*T) / (D/2-0.4*T) per Appendix 1-1 (a)(1)

= (1195.22*1.00*1.6500)/(19.0500/2-0.4*1.6500)

= 222.46 kgf/cm^2

Actual stress at given pressure and thickness (Sact):

= (P*((D/2-CAE)-0.4*(T-CA-CAE))) / (E*(T-CA-CAE))

= (60.00*(((19.0500/2-0.000)-0.4*(1.6500)))/(1.00*(1.6500))

= 322.36 kgf/cm^2

SUMMARY OF INTERNAL PRESSURE RESULTS:

Required Thickness plus Corrosion Allowance, Trca

0.6008

mm.

Actual Thickness as Given in Input

1.6500

mm.

Maximum Allowable Working Pressure

Maximum Allowable Pressure, NC

Design Pressure as Given in Input

MAWP

172.582

kgf/cm^2

MAPNC

222.460

kgf/cm^2

60.000

kgf/cm^2

Hydrostatic Test Pressures ( Measured at High Point ):

Hydrotest per UG-99(b); 1.3

* MAWP * Sa/S

289.20

kgf/cm^2

Hydrotest per UG-99(c); 1.3

* MAPNC

289.20

kgf/cm^2

Pneumatic per UG-100

* MAWP * Sa/S

244.71

kgf/cm^2

; 1.1

�3

Percent Elongation per UHA-44 ( 50 * tnom/Rf * (1-Rf/Ro) )

9.483 %

Note: Please Check Requirements of Table UHA-44 for Elongation limits.

External Pressure Results, Shell Number

1, Desc.: Tube

ASME Code, Section VIII, Division 1, 2013

External Pressure Chart

HA-1

at

Elastic Modulus for Material

294.00

1741639.00

C

kgf/cm^2

Results for Max. Allowable External Pressure (Emawp):

Corroded Thickness of Shell

TCA

1.6500

mm.

Outside Diameter of Shell

ODCA

19.050

mm.

Design Length of Cylinder or Cone

SLEN

4000.000

mm.

Diameter / Thickness Ratio

(D/T)

11.5455

Length / Diameter Ratio

LD

50.0000

Geometry Factor, A f(DT,LD)

0.0082522

Materials Factor, B, f(A, Chart)

647.8862

kgf/cm^2

74.82

kgf/cm^2

Maximum Allowable Working Pressure

EMAWP = (4*B)/(3*(D/T)) = ( 4 *647.8862 )/( 3 *11.5455 ) = 74.8215

Results for Reqd Thickness for Ext. Pressure (Tca):

Corroded Thickness of Shell

TCA

1.4697

mm.

Outside Diameter of Shell

ODCA

19.050

mm.

Design Length of Cylinder or Cone

SLEN

4000.000

mm.

Diameter / Thickness Ratio

(D/T)

12.9619

Length / Diameter Ratio

LD

50.0000

Geometry Factor, A f(DT,LD)

0.0065472

Materials Factor, B, f(A, Chart)

631.9785

kgf/cm^2

65.01

kgf/cm^2

Maximum Allowable Working Pressure

EMAWP = (4*B)/(3*(D/T)) = ( 4 *631.9785 )/( 3 *12.9619 ) = 65.0087

Results for Maximum Length Calculation: No Conversion

Corroded Thickness of Shell

TCA

1.6500

mm.

�4

Outside Diameter of Shell

ODCA

19.050

mm.

Design Length of Cylinder or Cone

SLEN

0.380E+07

mm.

Diameter / Thickness Ratio

(D/T)

Length / Diameter Ratio

11.5455

LD

50.0000

Geometry Factor, A f(DT,LD)

0.0082522

Materials Factor, B, f(A, Chart)

647.8862

kgf/cm^2

74.82

kgf/cm^2

Maximum Allowable Working Pressure

EMAWP = (4*B)/(3*(D/T)) = ( 4 *647.8862 )/( 3 *11.5455 ) = 74.8215

Summary of External Pressure Results:

Allowable Pressure at Corroded thickness

74.82

kgf/cm^2

Required Pressure as entered by User

65.00

kgf/cm^2

Required Thickness including Corrosion all.

1.4697

mm.

Actual Thickness as entered by User

1.6500

mm.

**********

mm.

4000.00

mm.

Maximum Length for Thickness and Pressure

Actual Length as entered by User

Weight and Volume Results, No C.A. :

Volume of Shell Component

VOLMET

360780.6

Weight of Shell Component

WMET

2.9

VOLID

779311.3

WWAT

0.8

Inside Volume of Component

Weight of Water in Component

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2014

mm.^3

kgf

mm.^3

kgf

Summary for shell/head, Div 1:

MAPNC

Description

kgf/cm^2

MAWP

kgf/cm^2

Min. T

Tr-int

Tr-ext

mm.

mm.

mm.

EMAWP

kgf/cm^2

---------------------------------------------------------------------Tube

222.460

172.582

1.650

0.601

1.470

74.822

---------------------------------------------------------------------Minimum MAWP

222.460

172.582

74.822

Note: Reqd. thk. reported above includes Corrosion Allowance.

Total Shell/Head weight is (New-Cold)

2.9 kgf

Total Shell/Head weight is (Corroded)

2.9 kgf

Total Shell/Head weight, filled with Water (New)

3.7 kgf

Total Shell/Head volume is (New-Cold)

779311.2 mm.**3

Total Shell/Head volume is (Corroded)

779311.2 mm.**3

Least MAWP and Overall Weight Results :

The Least MAWP (N C) for Tube was 222.46 kgf/cm^2.

The Least MAWP (Cor) for Tube was 172.58 kgf/cm^2.

The total sum of the Weights ( N C ) was 2.90 kgf .

The total sum of the Weights ( Cor ) was 2.90 kgf .

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2014