Professional Documents

Culture Documents

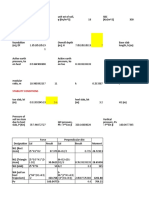

Miter Bend Design Calculation: Deg. Divisions Cut Back (R+rcos (D) ) Tanf End Miter Value (MM) Middle Miter Value (MM)

Uploaded by

Nischal Pokharel0 ratings0% found this document useful (0 votes)

15 views3 pagesOriginal Title

BendDesign

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views3 pagesMiter Bend Design Calculation: Deg. Divisions Cut Back (R+rcos (D) ) Tanf End Miter Value (MM) Middle Miter Value (MM)

Uploaded by

Nischal PokharelCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 3

Miter Bend Design Calculation

Deg. Cut Back End Miter value Middle Miter

Enter Miter Bend Angle(f) 60 Deg Divisions (r+rcos(d))*Tanf (mm) Value(mm)

Enter Radius of Pipe (r )= 250 mm 0 88.16 396.74 793.47

Enter factor for Radius of Curvature 4D 30 82.26 390.83 781.66

Enter Number of Segments(N)= 4 parts 60 66.12 374.69 749.39

90 44.08 352.65 705.31

120 22.04 330.61 661.23

150 5.91 314.48 628.96

180 0.00 308.57 617.14

Radius of Curvature 2000 mm 210 5.91 314.48 628.96

No. of side Piece 2 part 240 22.04 330.61 661.23

No. of Middle Piece 2 part 270 44.08 352.65 705.31

End Miter Angle 10 Deg 300 66.12 374.69 749.39

Middle Miter Angle 20 Deg 330 82.26 390.83 781.66

360 88.16 396.74 793.47

Miter Bend Design Calculation

Deg. Cut Back (c) End Miter value(En) = Middle Miter Value(Mn)

Divisions =(r+rcos(d))*Tanf c+ (R-r-t/2)*tanb1 =2*En

0 170.86 E1= 595.08 M1= 1190.16

Input 30 159.41 E2= 583.64 M2= 1167.27

Enter Radius of Pipe (r )= 1050 mm 60 128.14 E3= 552.37 M3= 1104.73

Enter Miter Bend Angle(f) 37 Deg 90 85.43 E4= 509.65 M4= 1019.31

Enter Thickness of Pipe(t)= 12 mm 120 42.71 E5= 466.94 M5= 933.88

Enter factor for Radius of Curvature(R)= 3 D 150 11.45 E6= 435.67 M6= 871.34

Enter Number of Segments(N)= 5 parts 180 0.00 E7= 424.23 M7= 848.45

Output 210 11.45 E8= 435.67 M8= 871.34

Radius of Curvature 6300 mm 240 42.71 E9= 466.94 M9= 933.88

No. of side Piece 2 part 270 85.43 E10= 509.65 M10= 1019.31

No. of Middle Piece 3 part 300 128.14 E11= 552.37 M11= 1104.73

End Miter Angle(b 1) 4.625 Deg 330 159.41 E12= 583.64 M12= 1167.27

Middle Miter Angle(b2) 9.25 Deg 360 170.86 E1= 595.08 M1= 1190.16

You might also like

- Miter Bend Design CalculationDocument1 pageMiter Bend Design CalculationNischal PokharelNo ratings yet

- Miter Bend Design CalculationDocument1 pageMiter Bend Design CalculationNischal PokharelNo ratings yet

- Miter Bend Design CalculationDocument1 pageMiter Bend Design CalculationNischal PokharelNo ratings yet

- Strip Footingkitta1331 With Print FormatDocument9 pagesStrip Footingkitta1331 With Print FormatShuvam PyakurelNo ratings yet

- Natural Hazards, Slope Stability.Document7 pagesNatural Hazards, Slope Stability.NelsonSilvaNo ratings yet

- Connection Design TableDocument9 pagesConnection Design TableMongkol JirawacharadetNo ratings yet

- Column Design of 300x400Document24 pagesColumn Design of 300x400karthik100% (1)

- University of Mines and Technology, TarkwaDocument2 pagesUniversity of Mines and Technology, TarkwaIsha IssahNo ratings yet

- KISSsoft Release 03/2017 Gear AnalysisDocument10 pagesKISSsoft Release 03/2017 Gear Analysiskarthikeyan NNo ratings yet

- Capacity BaruDocument49 pagesCapacity BaruAditya SandoyoNo ratings yet

- Dokumen - Tips Rumus FabrikasiDocument4 pagesDokumen - Tips Rumus FabrikasiAdam AbdullahNo ratings yet

- Lifting Lug Load Capacity Vs Crack Length CalculationDocument26 pagesLifting Lug Load Capacity Vs Crack Length CalculationklausNo ratings yet

- Lifting Lug Load Capacity Vs Crack Length CalculationDocument26 pagesLifting Lug Load Capacity Vs Crack Length CalculationklausNo ratings yet

- optics lab reportDocument2 pagesoptics lab reportMehwish IlyasNo ratings yet

- Dokumen - Tips Rumus FabrikasiDocument4 pagesDokumen - Tips Rumus FabrikasiIkhwanSaifudinNo ratings yet

- Orig Output1Document2 pagesOrig Output1Jamie FederizoNo ratings yet

- Calculation Head LossvDocument14 pagesCalculation Head LossvcylinderNo ratings yet

- LiftinglugDocument26 pagesLiftinglugErwin d'AdventuraNo ratings yet

- Lifting Lug Load Capacity Vs Crack Length CalculationDocument26 pagesLifting Lug Load Capacity Vs Crack Length CalculationRaja GopalNo ratings yet

- Single Bolt Capacity To EN 1993-1-8: Bolts Diameters, Hole Sizes and AreasDocument7 pagesSingle Bolt Capacity To EN 1993-1-8: Bolts Diameters, Hole Sizes and AreasSeçkin Doğu TurhalNo ratings yet

- Hasil Uji Material-1Document10 pagesHasil Uji Material-1eka kurniawanNo ratings yet

- Calculate Area of Land Parcel Using Coordinate GeometryDocument5 pagesCalculate Area of Land Parcel Using Coordinate Geometryemily andersonNo ratings yet

- Beam 3 Design and AnalysisDocument5 pagesBeam 3 Design and AnalysisCelsoRapiNo ratings yet

- Super Elevation With FRL (Meter) 2011Document16 pagesSuper Elevation With FRL (Meter) 2011sameerullah khanNo ratings yet

- 2beam 2Document5 pages2beam 2CelsoRapiNo ratings yet

- Screw DimensionDocument2 pagesScrew DimensionAbhijeet SinghNo ratings yet

- Slope Stabilty Analysis - Single Layer - 23.12.2013Document16 pagesSlope Stabilty Analysis - Single Layer - 23.12.2013somenathNo ratings yet

- RCC T-Girder Design Using STAAD ResultsDocument22 pagesRCC T-Girder Design Using STAAD Resultsvasu7900No ratings yet

- Analisa Pier Head P.0 - Simpang Perawang - 20190930 PDFDocument12 pagesAnalisa Pier Head P.0 - Simpang Perawang - 20190930 PDFDio Akbar HakimNo ratings yet

- Single bolt capacity and fillet weld strengthDocument17 pagesSingle bolt capacity and fillet weld strengthabhijitNo ratings yet

- Single Bolt Capacity To EN 1993-1-8: Bolts Diameters, Hole Sizes and AreasDocument17 pagesSingle Bolt Capacity To EN 1993-1-8: Bolts Diameters, Hole Sizes and AreasabhijitNo ratings yet

- Perancangan PorosDocument9 pagesPerancangan PorosBayu WibisonoNo ratings yet

- DIL-Column CalculationsDocument2 pagesDIL-Column Calculationsabu taherNo ratings yet

- DUCT CalculationDocument13 pagesDUCT CalculationMark SorianoNo ratings yet

- Experiment 1 Linear and Radial Heat Conduction (Spreadsheet)Document10 pagesExperiment 1 Linear and Radial Heat Conduction (Spreadsheet)Jing ZeNo ratings yet

- METODE YAMAGATA SHIP RESISTANCE CALCULATIONDocument104 pagesMETODE YAMAGATA SHIP RESISTANCE CALCULATIONZul SyahrilNo ratings yet

- Lifting Lug Load Capacity Vs Crack Length CalculationDocument26 pagesLifting Lug Load Capacity Vs Crack Length CalculationWansyah Putra SiregarNo ratings yet

- Lifting Lug Load Capacity Vs Crack Length CalculationDocument26 pagesLifting Lug Load Capacity Vs Crack Length CalculationMohamed NkNo ratings yet

- Lifting Lug Load Capacity Vs Crack Length CalculationDocument26 pagesLifting Lug Load Capacity Vs Crack Length CalculationRajneesh Pratap SinghNo ratings yet

- Lifting Lug Load Capacity Vs Crack Length CalculationDocument26 pagesLifting Lug Load Capacity Vs Crack Length CalculationFauzankalibataNo ratings yet

- Lifting Lug Load Capacity Vs Crack Length CalculationDocument26 pagesLifting Lug Load Capacity Vs Crack Length Calculationmashudi_fikriNo ratings yet

- Load Capacity vs Crack LengthDocument26 pagesLoad Capacity vs Crack LengthAnonymous 8J2KKHoNo ratings yet

- Lifting Lug Load Capacity Vs Crack Length CalculationDocument26 pagesLifting Lug Load Capacity Vs Crack Length CalculationSibiSamNo ratings yet

- Lifting Lug Load Capacity Vs Crack Length CalculationDocument26 pagesLifting Lug Load Capacity Vs Crack Length CalculationDinesh NallasivamNo ratings yet

- Lifting Lug Load Capacity Vs Crack Length CalculationDocument26 pagesLifting Lug Load Capacity Vs Crack Length Calculationlonewolf 3le7No ratings yet

- Load Capacity vs Crack LengthDocument26 pagesLoad Capacity vs Crack LengthSuneesh PNo ratings yet

- Lifting Lug Load Capacity Vs Crack Length CalculationDocument26 pagesLifting Lug Load Capacity Vs Crack Length CalculationPawan PawarNo ratings yet

- Load Capacity vs Crack LengthDocument26 pagesLoad Capacity vs Crack LengthilijarskNo ratings yet

- Lifting Lug Load Capacity Vs Crack Length CalculationDocument26 pagesLifting Lug Load Capacity Vs Crack Length CalculationvishalgoreNo ratings yet

- Cross Section Properties (All Dimensions Are in CMS)Document2 pagesCross Section Properties (All Dimensions Are in CMS)Hanamantrao KhasnisNo ratings yet

- Footing Design and AnalysisDocument5 pagesFooting Design and AnalysisRichelle DandoNo ratings yet

- SBC foundation design parameters and calculationsDocument21 pagesSBC foundation design parameters and calculationskiran raghukiranNo ratings yet

- STRENGTH OF BASE BLOCK DURING ERECTIONDocument3 pagesSTRENGTH OF BASE BLOCK DURING ERECTIONShubham BhamareNo ratings yet

- Geodetic SurveyingDocument4 pagesGeodetic SurveyingDanko ZaxoyNo ratings yet

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationFrom EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationNo ratings yet

- Modular Forms and Special Cycles on Shimura Curves. (AM-161)From EverandModular Forms and Special Cycles on Shimura Curves. (AM-161)No ratings yet

- Lecture 4 Penstock Alignment Accessories 1Document14 pagesLecture 4 Penstock Alignment Accessories 1Nischal PokharelNo ratings yet

- Hydraulic Design of Penstock PipesDocument4 pagesHydraulic Design of Penstock PipesNischal PokharelNo ratings yet

- Penstock Design Updated 1Document4 pagesPenstock Design Updated 1Nischal PokharelNo ratings yet

- Anchor Block List With SOP Revised 12th June 2019Document2 pagesAnchor Block List With SOP Revised 12th June 2019Nischal PokharelNo ratings yet

- Hydraulic Design of Penstock PipesDocument4 pagesHydraulic Design of Penstock PipesNischal PokharelNo ratings yet

- Penstock Draft v10 v4Document20 pagesPenstock Draft v10 v4Nischal PokharelNo ratings yet

- Hydraulic Design of Penstock PipesDocument4 pagesHydraulic Design of Penstock PipesNischal PokharelNo ratings yet

- BIFURCATION WELDING PROCEDUREDocument7 pagesBIFURCATION WELDING PROCEDURENischal PokharelNo ratings yet

- Penstock PipesDocument67 pagesPenstock PipesNischal PokharelNo ratings yet

- GC 2Document1 pageGC 2Nischal PokharelNo ratings yet

- Micro Hydropower Design AidsDocument27 pagesMicro Hydropower Design Aidsmagembe2100% (1)

- Water HammerDocument2 pagesWater HammerAlvin SmithNo ratings yet

- Seven TrialDocument1 pageSeven TrialNischal PokharelNo ratings yet

- Pressure Pipes Rev 1Document2 pagesPressure Pipes Rev 1Nischal PokharelNo ratings yet

- Second TrialDocument1 pageSecond TrialNischal PokharelNo ratings yet

- Third TrialDocument1 pageThird TrialNischal PokharelNo ratings yet

- Fourth TestingDocument1 pageFourth TestingNischal PokharelNo ratings yet

- BifurcationsDocument1 pageBifurcationsNischal PokharelNo ratings yet

- Ultra Low Head - FinalDocument28 pagesUltra Low Head - FinalNischal PokharelNo ratings yet

- Second TrialDocument1 pageSecond TrialNischal PokharelNo ratings yet

- Seven TrialDocument1 pageSeven TrialNischal PokharelNo ratings yet

- Penstock PipesDocument1 pagePenstock PipesNischal PokharelNo ratings yet

- 2Document1 page2Nischal PokharelNo ratings yet

- Surge TankDocument1 pageSurge TankNischal PokharelNo ratings yet

- Hydropower Expansion Joint Design TestingDocument1 pageHydropower Expansion Joint Design TestingNischal PokharelNo ratings yet

- 1 154 Days Fri 3/1/19Document1 page1 154 Days Fri 3/1/19Nischal PokharelNo ratings yet

- Sig Figs, Math OpsDocument28 pagesSig Figs, Math OpsDon King EvangelistaNo ratings yet

- Mathematical Studies Paper 2 SisnsuDocument11 pagesMathematical Studies Paper 2 SisnsuLucianaNo ratings yet

- Class 9 NTSE-Maths: Answer The QuestionsDocument14 pagesClass 9 NTSE-Maths: Answer The QuestionsHarshit GargNo ratings yet

- Applications of Image ProcessingDocument9 pagesApplications of Image ProcessingNilesh PatilNo ratings yet

- Smoothing Frequency Domain FiltersDocument22 pagesSmoothing Frequency Domain FiltersRaymond PraveenNo ratings yet

- A Simple Proof of The Erdos Gallai Theorem On Graph SequencesDocument4 pagesA Simple Proof of The Erdos Gallai Theorem On Graph SequencesAshwin PrakashNo ratings yet

- Automatically allocate planned and actual indirect activities using keysDocument4 pagesAutomatically allocate planned and actual indirect activities using keysSudharsan PonnambalamNo ratings yet

- Icsis 2022 Face MorphingDocument10 pagesIcsis 2022 Face MorphingprashantrinkuNo ratings yet

- Short-Term Scheduling MethodsDocument45 pagesShort-Term Scheduling MethodsAnton WilliamsNo ratings yet

- Water 08 00587 v2 PDFDocument9 pagesWater 08 00587 v2 PDFvinitNo ratings yet

- A Improved Hydro-Pneumatic Suspension: Mathematical Modeling and SimulationDocument6 pagesA Improved Hydro-Pneumatic Suspension: Mathematical Modeling and SimulationAhmadMoaazNo ratings yet

- 4403 - Tugas 2 - Matematika Rekayasa IDocument2 pages4403 - Tugas 2 - Matematika Rekayasa IKharisma NugrahaNo ratings yet

- Principles of Compiler Design - Tutorial 9Document7 pagesPrinciples of Compiler Design - Tutorial 9dani cabiloNo ratings yet

- Kelvin Temperature Scale & Types of ThermometersDocument3 pagesKelvin Temperature Scale & Types of ThermometersAshok PradhanNo ratings yet

- Grade 6 Math LessonsDocument49 pagesGrade 6 Math LessonsCindy GellangarinNo ratings yet

- A New Higher Order Shear DeforDocument8 pagesA New Higher Order Shear Deforamira khaldiNo ratings yet

- Java Placement QuestionsDocument18 pagesJava Placement QuestionsmeenakshiNo ratings yet

- The Design of Vibro Replacement (Priebe Teory)Document17 pagesThe Design of Vibro Replacement (Priebe Teory)paduco100% (3)

- Consolidation by FEM PDFDocument25 pagesConsolidation by FEM PDFAstrid AubryNo ratings yet

- Challenges PDFDocument40 pagesChallenges PDFYahooNo ratings yet

- Proprties of MatterDocument24 pagesProprties of Matterrishithhr rajeevNo ratings yet

- Applied Mathematics Demo PDFDocument157 pagesApplied Mathematics Demo PDFAbhishek Kumar AmarNo ratings yet

- DLL Mathematics-6 Q3 W6Document10 pagesDLL Mathematics-6 Q3 W6Sheryl Ilagan Del RosarioNo ratings yet

- Visual guide to basic 3D shapesDocument10 pagesVisual guide to basic 3D shapesBel JaNo ratings yet

- Multi Component DistillationDocument71 pagesMulti Component DistillationManu Jain83% (6)

- Econ 3030: Math Review of Monotonic TransformationsDocument4 pagesEcon 3030: Math Review of Monotonic TransformationsSafal AryalNo ratings yet

- A Demonstration Lesson in Math 6 by JUNITO C. COMEROSDocument4 pagesA Demonstration Lesson in Math 6 by JUNITO C. COMEROSJun Cueva Comeros0% (1)

- SFM Challenger Series PortfolioDocument28 pagesSFM Challenger Series PortfolioAmeerHamsaNo ratings yet

- Reflection with MirrorsDocument4 pagesReflection with MirrorsSenenNo ratings yet