Professional Documents

Culture Documents

Miter Bend Design Calculation

Uploaded by

Nischal Pokharel0 ratings0% found this document useful (0 votes)

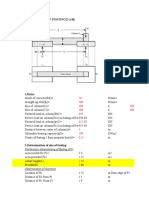

20 views1 pageThis document contains calculations for designing a miter bend, including determining the radius of curvature, number of side pieces, number of middle pieces, end miter angle, and middle miter angle based on inputs for the radius and thickness of the pipe, miter bend angle, number of segments, and radius of curvature factor. The output provides values for the cut back, end miter, and middle miter at various divisions of the miter bend angle.

Original Description:

Original Title

BendDesign_v2

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document contains calculations for designing a miter bend, including determining the radius of curvature, number of side pieces, number of middle pieces, end miter angle, and middle miter angle based on inputs for the radius and thickness of the pipe, miter bend angle, number of segments, and radius of curvature factor. The output provides values for the cut back, end miter, and middle miter at various divisions of the miter bend angle.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

20 views1 pageMiter Bend Design Calculation

Uploaded by

Nischal PokharelThis document contains calculations for designing a miter bend, including determining the radius of curvature, number of side pieces, number of middle pieces, end miter angle, and middle miter angle based on inputs for the radius and thickness of the pipe, miter bend angle, number of segments, and radius of curvature factor. The output provides values for the cut back, end miter, and middle miter at various divisions of the miter bend angle.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 1

Miter Bend Design Calculation

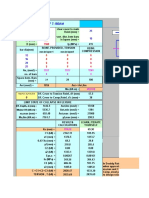

Deg. Cut Back (c) End Miter value(En) = Middle Miter Value(Mn)

Divisions =(r+rcos(d))*Tanb1 c+ (R-r-t/2)*tanb1 =2*En

0 170.86 E1= 595.08 M1= 1190.16

Input 30 159.41 E2= 583.64 M2= 1167.27

Enter Radius of Pipe (r )= 1050 mm 60 128.14 E3= 552.37 M3= 1104.73

Enter Miter Bend Angle(f) 37 Deg 90 85.43 E4= 509.65 M4= 1019.31

Enter Thickness of Pipe(t)= 12 mm 120 42.71 E5= 466.94 M5= 933.88

Enter factor for Radius of Curvature(R)= 3 D 150 11.45 E6= 435.67 M6= 871.34

Enter Number of Segments(N)= 5 parts 180 0.00 E7= 424.23 M7= 848.45

Output 210 11.45 E8= 435.67 M8= 871.34

Radius of Curvature 6300 mm 240 42.71 E9= 466.94 M9= 933.88

No. of side Piece 2 part 270 85.43 E10= 509.65 M10= 1019.31

No. of Middle Piece 3 part 300 128.14 E11= 552.37 M11= 1104.73

End Miter Angle(b 1) 4.625 Deg 330 159.41 E12= 583.64 M12= 1167.27

Middle Miter Angle(b2) 9.25 Deg 360 170.86 E1= 595.08 M1= 1190.16

You might also like

- 2 Storey Event CenterDocument5 pages2 Storey Event CenterjohnNo ratings yet

- Long Term Deflection of Continuous BeamDocument2 pagesLong Term Deflection of Continuous BeamgangeshNo ratings yet

- Design of Combined FootingDocument29 pagesDesign of Combined Footingsairin park83% (6)

- Oht - RDocument93 pagesOht - RAnkur DubeyNo ratings yet

- Wall Level: RW1 B3 To B2 455.00 KN.M 219.00 KN.M Vertical Dir. Negative M ReinforcementDocument24 pagesWall Level: RW1 B3 To B2 455.00 KN.M 219.00 KN.M Vertical Dir. Negative M Reinforcementalbert_pathNo ratings yet

- PG4 T-BeamDocument9 pagesPG4 T-BeamAmit Kumar PaulNo ratings yet

- Liquid Retaning Structure (28.122012) .Document9 pagesLiquid Retaning Structure (28.122012) .Vikram GaikwadNo ratings yet

- Beam-Column Hunch-End Plate Moment Conn PDFDocument11 pagesBeam-Column Hunch-End Plate Moment Conn PDFnagiA ahmedNo ratings yet

- Miter Bend Design CalculationDocument1 pageMiter Bend Design CalculationNischal PokharelNo ratings yet

- Miter Bend Design Calculation: Deg. Divisions Cut Back (R+rcos (D) ) Tanf End Miter Value (MM) Middle Miter Value (MM)Document3 pagesMiter Bend Design Calculation: Deg. Divisions Cut Back (R+rcos (D) ) Tanf End Miter Value (MM) Middle Miter Value (MM)Nischal PokharelNo ratings yet

- Miter Bend Design CalculationDocument1 pageMiter Bend Design CalculationNischal PokharelNo ratings yet

- Analisa Pier Head P.0 - Simpang Perawang - 20190930 PDFDocument12 pagesAnalisa Pier Head P.0 - Simpang Perawang - 20190930 PDFDio Akbar HakimNo ratings yet

- Chapter 10Document5 pagesChapter 10Richelle DandoNo ratings yet

- Appendix B-9 Design of Support Pier:: Force (N) X-Component Y-ComponentDocument5 pagesAppendix B-9 Design of Support Pier:: Force (N) X-Component Y-ComponentkkgbkjNo ratings yet

- 2beam 2Document5 pages2beam 2CelsoRapiNo ratings yet

- Beam 3 CeaDocument5 pagesBeam 3 CeaCelsoRapiNo ratings yet

- Design Integrity: 4 Pile CapDocument138 pagesDesign Integrity: 4 Pile CapAbdul LatifNo ratings yet

- MATHDocument18 pagesMATHUnknownNo ratings yet

- FootingDocument4 pagesFootingrudolfNo ratings yet

- Combined FootingDocument6 pagesCombined FootingnatnaelNo ratings yet

- Ce04 Exam3Document3 pagesCe04 Exam3woi mariaNo ratings yet

- Design of Typical BeamDocument10 pagesDesign of Typical BeamHaftom GebreegziabiherNo ratings yet

- Shear Wall Design (IS 13920-2016)Document8 pagesShear Wall Design (IS 13920-2016)Sahil OzaNo ratings yet

- Analysis of T-Beam: Nos in Layer 1 Nos in Layer2Document9 pagesAnalysis of T-Beam: Nos in Layer 1 Nos in Layer2p_ignatiusNo ratings yet

- SUBDIVISION OF LAND PARTITION On LineDocument3 pagesSUBDIVISION OF LAND PARTITION On LineJuly Roland CabrisosNo ratings yet

- Strap FootingDocument6 pagesStrap Footingrukesh104No ratings yet

- I) Selecting Trial Footing DepthsDocument5 pagesI) Selecting Trial Footing DepthsPraYush RajbhandariNo ratings yet

- Beam DesignDocument6 pagesBeam DesignRenz PagcaliwaganNo ratings yet

- Square FootingDocument21 pagesSquare FootingRakesh ShresthaNo ratings yet

- M6 +Welded+Connection-SupplementDocument3 pagesM6 +Welded+Connection-SupplementFrancis Ko Badongen-Cawi Tabaniag Jr.No ratings yet

- Example 1:: Nayana Manohari T K, Assistant Professor, CED, SVIT, Bengaluru - 560064Document7 pagesExample 1:: Nayana Manohari T K, Assistant Professor, CED, SVIT, Bengaluru - 560064Suryakant MangajNo ratings yet

- Strut Analysis and Design at - 10.00Document4 pagesStrut Analysis and Design at - 10.00SGOCTNo ratings yet

- University of Mines and Technology, TarkwaDocument2 pagesUniversity of Mines and Technology, TarkwaIsha IssahNo ratings yet

- Tuto 2 - Muhammad Najmi Bin KamarudinDocument18 pagesTuto 2 - Muhammad Najmi Bin KamarudinAzlan Abdul Rahim IINo ratings yet

- Module 4 B - AREAS OF IRREGULAR BOUNDARIESDocument3 pagesModule 4 B - AREAS OF IRREGULAR BOUNDARIESJuly Roland CabrisosNo ratings yet

- 074bel348 EMD AssignmentDocument11 pages074bel348 EMD Assignmentkeshav raj sharma100% (1)

- Mill Ball cHArging DetailsDocument4 pagesMill Ball cHArging DetailsSatish KumarNo ratings yet

- BASE BLOCK CALCULATION (3308) .OdsDocument3 pagesBASE BLOCK CALCULATION (3308) .OdsShubham BhamareNo ratings yet

- Designing of Slabs One Way FinalDocument2 pagesDesigning of Slabs One Way FinalZyril BestoNo ratings yet

- 500cubic Metre Concrete Tank DesignDocument18 pages500cubic Metre Concrete Tank DesignWjz WjzNo ratings yet

- Circular Hollow Concrete ColumnDocument3 pagesCircular Hollow Concrete ColumnUttam Kumar GhoshNo ratings yet

- Calculation Head LossvDocument14 pagesCalculation Head LossvcylinderNo ratings yet

- Anes Proracun VratilaDocument9 pagesAnes Proracun VratilaANES HAJDAREVIĆNo ratings yet

- TB JEMBATAN FULL-dikonversiDocument74 pagesTB JEMBATAN FULL-dikonversiDidit KuswadiNo ratings yet

- Design - of - Combined - Footing C2 G4Document8 pagesDesign - of - Combined - Footing C2 G4Aditya HadoleNo ratings yet

- Theory of MecanicalDocument31 pagesTheory of MecanicalHhH MmmNo ratings yet

- Strut Analysis and Design at - 0.5Document4 pagesStrut Analysis and Design at - 0.5SGOCTNo ratings yet

- Appendix 2 Design of StructureDocument32 pagesAppendix 2 Design of StructureCarlo CabanusNo ratings yet

- LotsDocument2 pagesLotsJoselito MedinaNo ratings yet

- Deep Sagar Final FootingDocument37 pagesDeep Sagar Final FootingBuddhiraj kadelNo ratings yet

- 14a. Check Shear - B400x800dDocument8 pages14a. Check Shear - B400x800dYoukhanna ZayiaNo ratings yet

- Input: KNM/M N/MM N/MM MM MM MM MM To These Bars C SDocument6 pagesInput: KNM/M N/MM N/MM MM MM MM MM To These Bars C ST Satheesh KumarNo ratings yet

- 1 Perenanaan Perhitungan Tulangan Kolom Rangka Bergoyang: C K B SDocument8 pages1 Perenanaan Perhitungan Tulangan Kolom Rangka Bergoyang: C K B SMiftakhul Ridho SujudiNo ratings yet

- Design of Dog Legged StaircaseDocument1 pageDesign of Dog Legged StaircaseKhim KhadkaNo ratings yet

- Unit 5 Mat Foundation Sample ProblemDocument6 pagesUnit 5 Mat Foundation Sample ProblemFaher Gaosel WatamamaNo ratings yet

- Gear Box Design:: Alloy Steel Is Used For Gears, Stainless Steel ForDocument14 pagesGear Box Design:: Alloy Steel Is Used For Gears, Stainless Steel ForMuhammad ArslanNo ratings yet

- Counterfort Retaining WallDocument7 pagesCounterfort Retaining WallAadarsha timilsinaNo ratings yet

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationFrom EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationNo ratings yet

- Lecture 4 Penstock Alignment Accessories 1Document14 pagesLecture 4 Penstock Alignment Accessories 1Nischal PokharelNo ratings yet

- Penstock Design Updated 1Document4 pagesPenstock Design Updated 1Nischal PokharelNo ratings yet

- Hydraulic Design of Penstock PipesDocument4 pagesHydraulic Design of Penstock PipesNischal PokharelNo ratings yet

- Hydraulic Design of Penstock PipesDocument4 pagesHydraulic Design of Penstock PipesNischal PokharelNo ratings yet

- Ultra Low Head - FinalDocument28 pagesUltra Low Head - FinalNischal PokharelNo ratings yet

- Bifurcation Methodology: Basic Welding ProcedureDocument7 pagesBifurcation Methodology: Basic Welding ProcedureNischal PokharelNo ratings yet

- Anchor Block List With SOP Revised 12th June 2019Document2 pagesAnchor Block List With SOP Revised 12th June 2019Nischal PokharelNo ratings yet

- Blade Optimization of Hydraulic Pressure MachineDocument5 pagesBlade Optimization of Hydraulic Pressure MachineNischal PokharelNo ratings yet

- 1 154 Days Fri 3/1/19Document1 page1 154 Days Fri 3/1/19Nischal PokharelNo ratings yet

- Final Project Page 1 EditedDocument19 pagesFinal Project Page 1 EditedNischal PokharelNo ratings yet

- Ultra Low Head - FinalDocument28 pagesUltra Low Head - FinalNischal PokharelNo ratings yet

- Kantipur College of Management and Information Technology: Lab Report of Microsoft Office WordDocument24 pagesKantipur College of Management and Information Technology: Lab Report of Microsoft Office WordNischal PokharelNo ratings yet