Professional Documents

Culture Documents

STRENGTH OF BASE BLOCK DURING ERECTION

Uploaded by

Shubham Bhamare0 ratings0% found this document useful (0 votes)

38 views3 pagesOriginal Title

BASE BLOCK CALCULATION (3308).ods

Copyright

© © All Rights Reserved

Available Formats

ODS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as ODS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

38 views3 pagesSTRENGTH OF BASE BLOCK DURING ERECTION

Uploaded by

Shubham BhamareCopyright:

© All Rights Reserved

Available Formats

Download as ODS, PDF, TXT or read online from Scribd

You are on page 1of 3

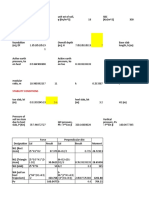

STRENGTH OF BASE BLOCK DURING ERECTION

Base block material SA-516 Gr. 70

Yield strength of base block material (Ysb) = 2671.7 kg/cm² 37999.5891 lb/in²

Load on base block = TV 117679.2 N (W) = 12,000 kg 26460 lb

Base block dimension

Width of base plate (L1) = 127.5 mm 5.0196850394 in

L1/2 (l1) = 63.75 mm 2.5098425197 in

Thickness of base plate (Tb) = 26 mm 1.0236220472 in

Cross section area of base plate = L1*Tb (A1) = 3315 mm² 5.13825 in²

Base ring OD. (do) = 1980 mm 77.952755906 in

Base ring ID. (di) = 1725 mm 67.913385827 in

L2/2 (l2) = 148.237478845 mm 5.8361212144 in

Skirt OD (Do) = 1826 mm 71.88976378 in

Skirt ID (Di) 1810 mm 71.25984252 in

0.55*[Do*Tsk]½ (Le) = 66.4749576908 mm 2.6171243185 in

Height of base block (BH) = 256 mm 10.078740157 in

BH + Le - Tb = Effective skirt height (L2) = 296.474957691 mm 11.672242429 in

Skirt thickness (Tsk) = 8 mm 0.3149606299 in

Cross section area of skirt = L2*Tsk (A2) = 2371.79966153 mm² 3.6762894754 in²

L3/2 (l3) = mm in

Width of compression plate (L3) = mm in

Thickness of compression plate (Tcp) = mm in

Cross section area of compression plate = Tcp*L3 (A3) = mm² in²

composite area (A1+A2+A3) 5686.79966153 mm² 8.8145394754 in²

Calculation of neutral axis

[(A1*l1) + (A2*l2) + (A3*l3)] / [A1 + A2 + A3] (Y1) = 98.9872838249 mm 3.8971371585 in

Combine moment of inertia around neutral axis

(Tb*L1^3 + L2*Tsk^3 + Tcp*L3^3) +

A1*(Y-l1)²+A2*(Y-l2)²+A3*(Y-l3)² (I) = 5325865.09701 mm⁴ 12.795390896 in⁴

12

L1-Y1 (Y2) = 28.5127161751 mm 1.1225478809 in

Max(Y1,Y2) (Y) = 98.9872838249 mm 3.8971371585 in

Minimum combine section modulus = I / Y Z = 53803.5280009 mm³ 3.2830912786 in³

Bending stress of base block due to load TV (As per Roark-7th Ed. case 15 of table 9.2)

Mean radius of base block = (Do - Tsk - 2*l2 + 2*Y )/2 (Rm) = 859.74980498 mm 33.848417519 in

Bending moment = 1.5*w*Rm² = 0.239*W*Rm (M) = 2465762.44068 kg-mm 214041.87853 lb-in

since, [w=W / (2*3.14*Rm)] = 2.2225396

Bending stress = M / Z (Sb) = 4582.90103325 kg/cm² 65182.601396 lb/in²

Tangential shear stress

Tangential force = w*Rm / 2 = W / 4*3.14 (T) = 955.414012739 kg 2106.6878981 lb

Tangential shear stress = T / (A1 + A2 + A3) (Ss) = 16.8005568967 kg/cm² 238.95432074 lb/in²

Total stress = Sb + Ss (St) = 4599.70159015 kg/cm² 65421.555717 lb/in²

Allowable stress = 0.9*Syb (Sa) = 2404.53 kg/cm² 34199.63019 lb/in²

OK

( bracing of skirt is required)

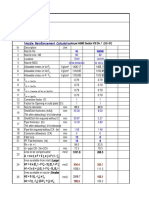

Base Ring Loads- with 1stiffeners beam/pipe

Reference Pressure Vessel Design Manual (3RD ED.) For Dennis R. Moss (Sec 7-5)

Ftail= Tail End Load = T 26454.284 lb = 117679.2 N 26454.28416 lb

Beam Section HEA200

Beam Material SA-36

Modulus of Elasticity of Strut material 199670 Mpa 28959737.46 Psi

End Connection Factor (K) 0.65

Beam /Pipe length (Ls) 1567.5 mm 61.712598425 In

Beam /Pipe radius of gyration (r) 35.89 mm 1.412992126 In

Beam /Pipe cross sec. area (As) 5308 mm² 8.2274164548 In²

radius of base ring to Neutral axis (Rb) 961.487283825 mm 37.853830072 In

Sectional Area of base ring section (Ab) 5686.79966153 mm² 8.8145571045 In²

Section modulus of base ring (Z) 53803.5280009 mm³ 3.2832927241 In³

Beam / Pipe yield strength (Fy) 248 MPa 35967.44 Psi

Allowable stress in combined (Fa) 145.2 MPa 21058.356 Psi

Allowable stress in Bending (0.66Fy) (Fb) 163.68 MPa 23738.5104 Psi

Allowable stress in shear (0.4Fy) (Fs) 99.2 MPa 14386.976 Psi

M=Kr*T*Rb Tt=Kt*T fa=Tt/Ab fb=M/Z Load Factor=

α Kr Kt Tt=Kt*T(lb) (Psi) (Psi) fa/Fa+fb/Fb

-0.0229 -22931.9679 0.1651 4367.60231 495.49878 -6984.4420849 -0.2706943154

5 -0.0148 -14820.6605 0.1708 4518.39173 512.60565 -4513.9625701 -0.1658114237

10 -0.0067 -6709.35305 0.1764 4666.53573 529.41239 -2043.4830554 -0.0609427839

15 -0.0055 -5507.67787 0.1747 4621.56344 524.31034 -1677.4860903 -0.045767208

20 -0.0042 -4205.8631 0.1729 4573.94573 518.90817 -1280.989378 -0.0293210624

25 0.0028 2803.90874 0.164 4338.5026 492.19746 853.99291868 0.0593480242

30 0.0098 9813.68058 0.1551 4103.05947 465.48674 2988.9752154 0.1480171108

35 0.0103 10314.3786 0.1397 3695.6635 419.2682 3141.4739508 0.1522464341

40 0.0107 10714.937 0.1242 3285.62209 372.74954 3263.4729392 0.155176684

45 0.0093 9312.98259 0.1032 2730.08213 309.72425 2836.4764799 0.1341962967

50 0.0078 7810.88862 0.0821 2171.89673 246.39885 2378.9802735 0.1119168361

55 0.0052 5207.25908 0.0567 1499.95791 170.16827 1585.986849 0.0748915103

60 0.0025 2503.48994 0.0313 828.019094 93.937686 762.49367739 0.0365813631

65 0.0031 3104.32753 0.0031 82.0082809 9.3037324 945.49215996 0.0402712718

70 0.0037 3705.16512 -0.0252 -666.647961 -75.63034 1128.4906425 0.0439469286

75 -0.0028 -2803.90874 -0.0548 -1449.69477 -164.466 -853.99291868 -0.0437850107

80 -0.0092 -9212.84299 -0.0843 -2230.09615 -253.0015 -2805.9767328 -0.1302178768

85 -0.0107 -10714.937 -0.01134 -299.991582 -34.03365 -3263.4729392 -0.1390920531

90 -0.0121 -12116.8913 -0.1425 -3769.73549 -427.6716 -3690.4693986 -0.1757722716

95 -0.0114 -11415.9141 -0.1694 -4481.35574 -508.404 -3476.9711689 -0.1706122675

100 -0.0107 -10714.937 -0.1963 -5192.97598 -589.1363 -3263.4729392 -0.1654522635

105 -0.0074 -7410.33023 -0.2194 -5804.06994 -658.4642 -2256.9812851 -0.1263453319

110 -0.0033 -3304.60672 -0.2425 -6415.16391 -727.792 -1006.4916542 -0.0769598288

115 0.0041 4105.72351 -0.2603 -6886.05017 -781.2134 1250.4896309 0.0155801295

120 0.0114 11415.9141 -0.2781 -0.91308371 -0.103588 3476.9711689 0.146464725

125 0.0107 10714.937 -0.106 -2804.15412 -318.1276 3263.4729392 0.1223689395

130 0.01 10013.9598 0.0661 1748.62818 198.37959 3049.9747096 0.1379026127

135 0.0083 8311.58661 0.0448 1185.15193 134.45394 2531.4790089 0.1130250055

140 0.0066 6609.21345 0.0234 619.030249 70.228174 2012.9833083 0.0881331464

145 0.0045 4506.2819 0.0104 275.124555 31.212522 1372.4886193 0.0592991565

150 0.0024 2403.35035 -0.0026 -68.7811388 -7.80313 731.99393029 0.0304651666

155 -0.0005 -500.697989 -0.0213 -563.476253 -63.92565 -152.49873548 -0.0094597499

160 -0.0015 -1502.09397 -0.0399 -1055.52594 -119.748 -457.49620643 -0.0249588073

165 -0.0028 -2803.90874 -0.0484 -1280.38735 -145.2583 -853.99291868 -0.0428728927

170 -0.0041 -4105.72351 -0.0569 -1505.24877 -170.7685 -1250.4896309 -0.0607869782

175 -0.0046 -4606.4215 -0.0597 -1579.32076 -179.1719 -1402.9883664 -0.067610137

180 -0.0051 -5107.11948 -0.0626 -1656.03819 -187.8754 -1555.4871019 -0.0744475476

Max. Load Factor 0.2706943154

Since fa/Fa+fb/Fb <1, three point support Beam is adequate

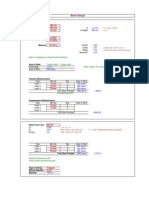

Stress check at Beam for three point support

F1=+0.453*(T) 53308.6776 N 11983.790724 lb

F2=-0.329*(T) -38716.4568 N -8703.459489 lb

Critical Buckling Stress , Cc

= Cc = 0.282

Allow.beam compressive strength-(Critical buckling per AISC)

σcr =[(1-(K*Ls²/r)/2*Cc²))]*Fy / (5/3)+((3*K*Ls/r)/8*Cc)-((K*Ls/r)3/8*Cc³)

σcr = 544.221653905 MPa 78932.820239 Psi

Tension Stress in Strut (beam / pipe) :

σT = F1/As σT = 10.043081688 MPa 1456.6284819 Psi

Compression stress in Strut (Beam / Pipe) :

σC = F2/As σC = -7.2939820648 MPa -1057.904571 Psi

strut section size is adequate for induced tensile stress

You might also like

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationFrom EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationNo ratings yet

- U-Tube Heat Exchanger Design: Tubes SpecDocument8 pagesU-Tube Heat Exchanger Design: Tubes SpecVipul SharmaNo ratings yet

- القواعد المشتركةDocument3 pagesالقواعد المشتركةمحمود عبد الحيNo ratings yet

- SBC foundation design parameters and calculationsDocument21 pagesSBC foundation design parameters and calculationskiran raghukiranNo ratings yet

- 3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesFrom Everand3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesNo ratings yet

- Stage Design For PC Girder BridgeDocument8 pagesStage Design For PC Girder BridgeIstiaque Yeassir100% (1)

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- Circular Beam Design and Reinforcement DetailsDocument11 pagesCircular Beam Design and Reinforcement DetailsVirat DesaiNo ratings yet

- Two Way Slab Design (DRAFT)Document72 pagesTwo Way Slab Design (DRAFT)ابو عمر الأسمريNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- SL No Item Cost/piece Quantity TotalDocument8 pagesSL No Item Cost/piece Quantity TotalSUNIL KUMAR K S Civil, KLEIThubballiNo ratings yet

- Design of Replaceent Scheme of Inadequate GussetDocument9 pagesDesign of Replaceent Scheme of Inadequate GussetPartha GangopadhyayNo ratings yet

- Slab Design Parameters from Excel SheetDocument29 pagesSlab Design Parameters from Excel SheetKhim KhadkaNo ratings yet

- Rigid Pavement Design Normal WeightDocument6 pagesRigid Pavement Design Normal WeightAmmad AlizaiNo ratings yet

- Flat Slab Fs1Document3 pagesFlat Slab Fs1johan.hafiz6926No ratings yet

- ASME Horizontal Vessel Analysis - Friction 0.025 PDFDocument10 pagesASME Horizontal Vessel Analysis - Friction 0.025 PDFSyed Zain AliNo ratings yet

- Fixed Base Anchor Bolt DesignDocument3 pagesFixed Base Anchor Bolt Designkhan84mind50% (2)

- ACI 318M-02 Building Code Requirements for Structural ConcreteDocument13 pagesACI 318M-02 Building Code Requirements for Structural ConcreteAamirShabbirNo ratings yet

- F-Table Slab and Staircase (ALWAYS)Document15 pagesF-Table Slab and Staircase (ALWAYS)Santosh BasnetNo ratings yet

- GROUP6 - GC42 - Design of Column Beam and SlabDocument8 pagesGROUP6 - GC42 - Design of Column Beam and SlabAlexander P. BelkaNo ratings yet

- Sheet PilesDocument34 pagesSheet PilesAashish BhandariNo ratings yet

- Roof Beam Design Data: Therefore Use W2 27.377 KN/MDocument17 pagesRoof Beam Design Data: Therefore Use W2 27.377 KN/MJay HernandezNo ratings yet

- Aci 95Document14 pagesAci 95Joseph AsfourNo ratings yet

- Wind Design - ASCE 7-16Document22 pagesWind Design - ASCE 7-16Nguyen Tan PhatNo ratings yet

- Lampiran Respon GempaDocument9 pagesLampiran Respon Gempaputra kompasNo ratings yet

- Beam-Column Hunch-End Plate Moment Conn PDFDocument11 pagesBeam-Column Hunch-End Plate Moment Conn PDFnagiA ahmedNo ratings yet

- PT. TECHNICs SPREADER BEAM CALCULATIONDocument4 pagesPT. TECHNICs SPREADER BEAM CALCULATIONHari Kiran100% (1)

- HAMTeK annexure 5.3a - Design of Base Plate and Anchor BoltsDocument7 pagesHAMTeK annexure 5.3a - Design of Base Plate and Anchor BoltsVenkatesha HebbarNo ratings yet

- Horizontal Vessel Stress AnalysisDocument12 pagesHorizontal Vessel Stress AnalysissridharNo ratings yet

- TyuopDocument36 pagesTyuopArjunRathodNo ratings yet

- Pd5500 Flange CalculationDocument6 pagesPd5500 Flange CalculationAliNo ratings yet

- MB15Document2 pagesMB15abhijitkolheNo ratings yet

- Columns GenerDocument29 pagesColumns GenerGino Paolo ObsiomaNo ratings yet

- Intake Well Bridge DesignDocument58 pagesIntake Well Bridge DesignAjayKumarMishra100% (1)

- Design of RCC BuildingDocument5 pagesDesign of RCC Buildingshreejay maneNo ratings yet

- Structural Computation: Prepared byDocument7 pagesStructural Computation: Prepared byJing JingNo ratings yet

- Deign of PartsDocument11 pagesDeign of PartsMohamad Ahmed Hussein Abd elaalNo ratings yet

- Roldan PS 3-4Document26 pagesRoldan PS 3-4Charles Warren GoNo ratings yet

- One-way slab design summaryDocument18 pagesOne-way slab design summaryjdpdeleonNo ratings yet

- Spreader Bar Calc REF.Document34 pagesSpreader Bar Calc REF.Gokul AmarnathNo ratings yet

- Nozzle Reinforcement Calculation Excel SheetDocument3 pagesNozzle Reinforcement Calculation Excel Sheetramesh punjabiNo ratings yet

- Heat Exchanger (Single)Document864 pagesHeat Exchanger (Single)Pruthviraj JuniNo ratings yet

- Rigid Pavement Design Bowzer WeightDocument6 pagesRigid Pavement Design Bowzer WeightAmmad AlizaiNo ratings yet

- Structural Analysis Quick CheckDocument6 pagesStructural Analysis Quick Checkmelchor anacionNo ratings yet

- Base Plate Design Excel-10 July 2023Document12 pagesBase Plate Design Excel-10 July 2023Reshu DavaneNo ratings yet

- Seafastening Design CalculationsDocument82 pagesSeafastening Design CalculationsInhake AutechreNo ratings yet

- Verifica Giunto Secondo AsmeDocument5 pagesVerifica Giunto Secondo AsmeFabio TemporiniNo ratings yet

- Column DesignDocument14 pagesColumn DesignAkash paudelNo ratings yet

- Load Capacity of PileDocument16 pagesLoad Capacity of PileJoseph HeartNo ratings yet

- RCC Design SheetsDocument40 pagesRCC Design SheetsAnonymous 9iK0i8h0dPNo ratings yet

- Scantling Calculation Design CheckDocument6 pagesScantling Calculation Design CheckShyamshesha GiriNo ratings yet

- Anchor bolt sizing checkDocument2 pagesAnchor bolt sizing checkmih150% (2)

- RCC Design SheetsDocument40 pagesRCC Design SheetsAnonymous nwByj9L100% (2)

- RCC Design SheetsDocument40 pagesRCC Design SheetsIbrahim El SharNo ratings yet

- Advanced Steel Composite BeamsDocument68 pagesAdvanced Steel Composite BeamsMert SarıNo ratings yet

- Design Calculation of Spillway GateDocument11 pagesDesign Calculation of Spillway GateAnonymous sfkedkymNo ratings yet

- Turboplast Metric PDFDocument2 pagesTurboplast Metric PDFdeli34No ratings yet

- Steinhart-Hart Equation GuideDocument4 pagesSteinhart-Hart Equation GuideOihane GomezNo ratings yet

- 19FL Nbnu8 PzApEUvA9tZuD3ml24BI31Document6 pages19FL Nbnu8 PzApEUvA9tZuD3ml24BI31ANH LÊNo ratings yet

- Beamtool Scan Plan: Inspection LayoutDocument3 pagesBeamtool Scan Plan: Inspection LayoutSantanu SahaNo ratings yet

- Consultancy ListDocument1 pageConsultancy Listrajpre1213No ratings yet

- Code For Cost Estimation by COCOMO ModelDocument7 pagesCode For Cost Estimation by COCOMO ModelMukta DebnathNo ratings yet

- Infiniti G37-09-Coupe5Document612 pagesInfiniti G37-09-Coupe5seregap84100% (1)

- AOPEN Hardware Brochure 2017Document60 pagesAOPEN Hardware Brochure 2017Marisagarcia2014No ratings yet

- KLUBER Cost Benefits Comparison-ELGIDocument15 pagesKLUBER Cost Benefits Comparison-ELGIrajkumar_kesirajuNo ratings yet

- mrr1 eDocument18 pagesmrr1 eAyan MajiNo ratings yet

- Rediant-Supplier Audit Check Sheet RevisedDocument8 pagesRediant-Supplier Audit Check Sheet RevisedRohit TripathiNo ratings yet

- 2 - 3. Asymmetric-Key CryptographyDocument43 pages2 - 3. Asymmetric-Key CryptographyPrachi VermaNo ratings yet

- RMFDocument245 pagesRMFsuryadiwaNo ratings yet

- Indian Standard: Code For Designation of SteelsDocument13 pagesIndian Standard: Code For Designation of SteelsAkash ParadkarNo ratings yet

- MarshallDocument1 pageMarshallBanta SINGHNo ratings yet

- Confined Space Flow ChartDocument1 pageConfined Space Flow CharthasdNo ratings yet

- Hitachi Ex5600 6Document1 pageHitachi Ex5600 6Edinson Rojas AlarcónNo ratings yet

- Ambernath Municipal Council construction project costsDocument1 pageAmbernath Municipal Council construction project costsnajuka ghodvindeNo ratings yet

- Wedge Anchor BZplus A4Document4 pagesWedge Anchor BZplus A4francisbautistaNo ratings yet

- John Petrucci Touring Rack System: Mesa Mesa MesaDocument1 pageJohn Petrucci Touring Rack System: Mesa Mesa MesaJose AGNo ratings yet

- Engineering For Steel ConstructionDocument2 pagesEngineering For Steel ConstructionBiju Muttathukatil0% (1)

- Flexural Design of PC Elements Ch4iDocument22 pagesFlexural Design of PC Elements Ch4inagham tariqNo ratings yet

- CB Mooring SystemsDocument5 pagesCB Mooring SystemsCojocaru LaviniaNo ratings yet

- Sound Pressure Meter (08-4c4)Document10 pagesSound Pressure Meter (08-4c4)Sri Krishna RakeshNo ratings yet

- Macedo-Et-Al Bray-2023-Seismic-Slope-Displacement-Procedure-For-Interface-And-Intraslab-Subduction-Zone-EarthquakesDocument19 pagesMacedo-Et-Al Bray-2023-Seismic-Slope-Displacement-Procedure-For-Interface-And-Intraslab-Subduction-Zone-EarthquakesxfvgNo ratings yet

- Basic Principles of PropulsionDocument45 pagesBasic Principles of PropulsionEverson VieiraNo ratings yet

- Job Procedure For Procedure NoDocument7 pagesJob Procedure For Procedure NoUmesh SharmaNo ratings yet

- EstimationDocument71 pagesEstimationSONU71% (7)

- 2 CasingDesignDocument34 pages2 CasingDesigncatur9No ratings yet