Professional Documents

Culture Documents

Design of one way slab reinforcement and moment capacity calculation

Uploaded by

Zyril BestoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of one way slab reinforcement and moment capacity calculation

Uploaded by

Zyril BestoCopyright:

Available Formats

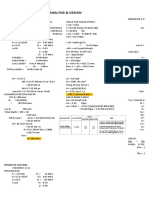

DESIGN OF ONE WAY SLAB (S3)

w L2

1. THICKNESS: M=

16

(3.33+10)(2) (13.6)(3.332 )

t= = 0.148m =

180 16

=9.43 KN.m

Say t = 150mm

f’c = 21 MPa

4. MOMENT CAPACITY OF CONCRETE:

fy = 275 MPa

ρ f ' c 600

Floor finish = 0.77 KPa b =0.85 β1 ∙

fy 600+fy

ρ 21 600

¿ SLAB = 5 KPa b =0.85 ( 0.85 ) ∙

275 600+275

ρb =0.0378

2. LOADS :

DEADLOAD: ρ = 0.5( ρb )

ρ = 0.5(0.0378)

Wt. of slab = 23.54(1.0) (0.15) = 3.531 KN/m ρ = 0.0189

Floor finish = 0.77(1.0) = 0.77 KN/m

DL = 3.531+ 0.77 = 4.301 KN/m Mu=∅ b d 2 ( R)

LIVELOAD: Mu ρfy

2

=R=ρfy (1−0.59 ' )

∅b d f c

LL = 5 KN/m (1.0) = 5 KN/m

Mu ( 0.0189 )( 275 )

Wu = 1.2DL + 1.6LL =( 0.0189 ) (275)(1−0.59 )

∅b d 2

21

Wu = 1.2(4.301) + 1.6(5) = 13.16 KN/m

Mu

=4.438

∅ b d2

3. DETERMINE MAXIMUM MOMENT:

(13.71 x 106 )

NEGATIVE MOMENT: =4.438

(0.9)(1000) d 2

w L2

M= d= 58.59 < 150 – 30 = 120 mm

11

Use: d = 120mm

(13.6)(3.332 )

= t = 150mm

11

=13.16 KN.m

POSITIVE MOMENT DUE TO DEADLOAD:

1. DESIGN OF REINFORCEMENT:

Mu (13.71 x 1 06 )

=

Use: M = 13.71KN.m ∅ b d 2 (0.9)(1000)¿ ¿

Mu

=¿ 1.057

∅ b d2

0.85 f ' c

ρ= ¿

fy

0.85(21)

= ¿

275

ρ = 0.003965

ρ 1.4

min ¿ =0.00509

275

ρ< ρ min

Therefore, use ρ=0.00509

A s=0.00509 ( 1000 ) (120 ) = 610.8 mm2

Use: 12mm ∅ BAR

1000 A s 1000(113.09)

S= = = 185.15 mm

A sreq . 610.8

USE: 12 mm ∅ BARS SPACED @ 0.15 m O.C.

6. Design of temperature and shrinkage

bars

ρ = 0.0018

A s=0.0018 ( 1000 ) (120 ) = 216 mm2

1000 A s 1000(113.09)

S= = = 523.56 mm

A sreq . 216

USE: 12 mm ∅ BARS SPACED @ 0.30 m O.C.

You might also like

- Resilience WorkbookDocument54 pagesResilience WorkbookLeo Siu100% (1)

- m5 Mage The AscensionDocument20 pagesm5 Mage The AscensionQuentin Agnes0% (1)

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Baxa Resumen PDFDocument12 pagesBaxa Resumen PDFChepe Camacho100% (3)

- Column Footing 1Document5 pagesColumn Footing 1Ayreesh Mey SpntNo ratings yet

- Design of Concrete Slope ProtectionDocument7 pagesDesign of Concrete Slope ProtectionChris Angelo G CaadlawonNo ratings yet

- DESIGN OF TWO-WAY SLAB REINFORCEMENT FOR FLOOR LEVELS 2-5Document180 pagesDESIGN OF TWO-WAY SLAB REINFORCEMENT FOR FLOOR LEVELS 2-5Gino Paolo ObsiomaNo ratings yet

- STRUCTURAL ANALYSIS (1 Storey)Document12 pagesSTRUCTURAL ANALYSIS (1 Storey)Yllor Koichi RamosNo ratings yet

- Strategic Planning Assignment - TescoDocument16 pagesStrategic Planning Assignment - TescoKayode Trinity Omosebi100% (1)

- History of DentistryDocument24 pagesHistory of DentistryEzhilarasi INo ratings yet

- 2010 7.0 DESIGN OF SLAB and BEAMsDocument71 pages2010 7.0 DESIGN OF SLAB and BEAMsJoseph Tan LantoNo ratings yet

- CIC-presentation of RP-577 PresentationDocument181 pagesCIC-presentation of RP-577 PresentationIbrahim Eldesoky75% (4)

- Design of Masonry WallDocument4 pagesDesign of Masonry WallIrene Valentino PacunayenNo ratings yet

- Over Head Tank - Circular Flat SlabDocument14 pagesOver Head Tank - Circular Flat SlabVi Jay100% (1)

- Column Footing 2Document7 pagesColumn Footing 2Ayreesh Mey Spnt100% (1)

- Structural analysis & design of roof beam, column and footingDocument7 pagesStructural analysis & design of roof beam, column and footingAntonio EstradaNo ratings yet

- Design of Rectangular FootingDocument9 pagesDesign of Rectangular Footingsairin park100% (2)

- VW Crafter 2f Component Locations EngDocument118 pagesVW Crafter 2f Component Locations EngHugo Emilio Garcia Gonzalez100% (2)

- Design of Critical Two-Way SlabDocument8 pagesDesign of Critical Two-Way SlabBevelyn Manalo100% (1)

- Combined Footing Design1Document39 pagesCombined Footing Design1John Carlo Amodia0% (2)

- Concrete Slab Reinforcement SpacingDocument8 pagesConcrete Slab Reinforcement SpacingMark Carlo Bautista100% (2)

- Structural Computation: Prepared byDocument7 pagesStructural Computation: Prepared byJing JingNo ratings yet

- PR & PublicityDocument16 pagesPR & PublicityVipul Partap100% (2)

- Midcheek Lift Using Facial Soft-Tissue Spaces of The MidcheekDocument11 pagesMidcheek Lift Using Facial Soft-Tissue Spaces of The MidcheekЩербакова ЛенаNo ratings yet

- Introduction to Pidilite IndustriesDocument8 pagesIntroduction to Pidilite IndustriesAbhijit DharNo ratings yet

- Brfo193 Radiotherapy Dose Fractionation Third-Edition PDFDocument137 pagesBrfo193 Radiotherapy Dose Fractionation Third-Edition PDFMed MedNo ratings yet

- 2narrative Essay - My Favorite TeacherDocument9 pages2narrative Essay - My Favorite TeacherHerbertKoh100% (1)

- Design of Box CulvertDocument34 pagesDesign of Box CulvertAl Patrick Dela CalzadaNo ratings yet

- Power Grid FailureDocument18 pagesPower Grid Failurechandra 798No ratings yet

- Designing of Slabs Two WayDocument3 pagesDesigning of Slabs Two WayZyril BestoNo ratings yet

- Design One Way SlabDocument22 pagesDesign One Way Slabjohn rey toledoNo ratings yet

- Design and Analysis For Third Floor BeamDocument83 pagesDesign and Analysis For Third Floor BeamVergel Pabunan NogadasNo ratings yet

- Plates # 3Document9 pagesPlates # 3Joshua Perez AlbayNo ratings yet

- Class Room 1 8M Minimum Thickness of SlabDocument7 pagesClass Room 1 8M Minimum Thickness of Slabdiego lopezNo ratings yet

- Fy 276 Mpa: Formula For Transferring The Weight of Slab To BeamDocument19 pagesFy 276 Mpa: Formula For Transferring The Weight of Slab To Beamraymark mendozaNo ratings yet

- NSCP Code: Specificatio N ScoreDocument17 pagesNSCP Code: Specificatio N ScoreMarco SatomeraNo ratings yet

- S-2 Computation Midas Critical SectionDocument8 pagesS-2 Computation Midas Critical SectionDannica YanoNo ratings yet

- Slab Design CalculationsDocument8 pagesSlab Design Calculationsdiego lopezNo ratings yet

- Office 4M Minimum Thickness of SlabDocument8 pagesOffice 4M Minimum Thickness of SlabRafaella ManaloNo ratings yet

- Design of Stairs and Landing: Page NoDocument6 pagesDesign of Stairs and Landing: Page NoJun Dela PeñaNo ratings yet

- Design of Box CulvertDocument24 pagesDesign of Box CulvertAl Patrick Dela CalzadaNo ratings yet

- 2-Slab (RoofDeck)Document17 pages2-Slab (RoofDeck)JuNe RaMos JavierNo ratings yet

- Gelai Roofdeck GirderDocument9 pagesGelai Roofdeck GirderJelly CaseNo ratings yet

- Stairway 1Document10 pagesStairway 1Anissah ManialaNo ratings yet

- Null 4Document5 pagesNull 4emranahmed056studentNo ratings yet

- Sample ComputationDocument8 pagesSample ComputationTonette AmorNo ratings yet

- Design For S-7 4M Minimum Thickness of SlabDocument24 pagesDesign For S-7 4M Minimum Thickness of Slabdiego lopezNo ratings yet

- Footing Slab PurlinsDocument5 pagesFooting Slab PurlinsMichael RojasNo ratings yet

- Design of Slabs1Document8 pagesDesign of Slabs1Tonette AmorNo ratings yet

- Load Combination On Frame CDocument6 pagesLoad Combination On Frame Cjolmarie llantoNo ratings yet

- Footing Ina MoDocument6 pagesFooting Ina MoHades HadesNo ratings yet

- Slab DesignDocument12 pagesSlab DesignPAOLO AGORILLANo ratings yet

- Manual ComputationsDocument26 pagesManual ComputationsIan EncarnacionNo ratings yet

- BEAMSDocument80 pagesBEAMSLorence LatorzaNo ratings yet

- Appendix 2 Design of StructureDocument32 pagesAppendix 2 Design of StructureCarlo CabanusNo ratings yet

- Analisa DataDocument39 pagesAnalisa DataUtomo YohanesNo ratings yet

- Plates in Timber - Final With Solution - Solution22Document47 pagesPlates in Timber - Final With Solution - Solution22John Lloyd JuanoNo ratings yet

- Design and Analysis For First Floor BeamDocument2 pagesDesign and Analysis For First Floor BeamVergel Pabunan NogadasNo ratings yet

- Beam DesignDocument6 pagesBeam DesignRenz PagcaliwaganNo ratings yet

- Group 3Document32 pagesGroup 3Clarens CortezNo ratings yet

- Design of Footing: Longitudinal Transverse Beam ColumnDocument3 pagesDesign of Footing: Longitudinal Transverse Beam ColumnShōya IshidaNo ratings yet

- Pool AnalysisDocument5 pagesPool Analysisnemat1233No ratings yet

- Design of Beam DoneDocument2 pagesDesign of Beam DoneEmelyn Del Rosario EstebeNo ratings yet

- 2S-3 beam design calculationsDocument4 pages2S-3 beam design calculationsDenver PiliNo ratings yet

- Wall FootingDocument3 pagesWall FootingFrancis Ko Badongen-Cawi Tabaniag Jr.No ratings yet

- Perencanaan Kolom Bulat: Data: 2Document7 pagesPerencanaan Kolom Bulat: Data: 2Silviano Da Coneicicao AparicoNo ratings yet

- Design of Distillation ColumnDocument21 pagesDesign of Distillation Columnusmanafzal246100% (1)

- Slab DesignDocument13 pagesSlab DesignLimwell AquinoNo ratings yet

- Slab DesignDocument384 pagesSlab Designalbert domingoNo ratings yet

- TOP CHORD AND WEB MEMBER DESIGNDocument11 pagesTOP CHORD AND WEB MEMBER DESIGNjoe kyleNo ratings yet

- Slab Design: 6,000MM X 4900MMDocument21 pagesSlab Design: 6,000MM X 4900MMJohnPhilip2000 GeraldizoNo ratings yet

- P=γh P=9.81 (1.849) P=18.139 kn /m F= Ph: Structural Analysis Of Bench FlumeDocument16 pagesP=γh P=9.81 (1.849) P=18.139 kn /m F= Ph: Structural Analysis Of Bench FlumeAllyssa OpantoNo ratings yet

- (One-Storey Residential Building) : CE 123 Construction Methods and Project ManagementDocument7 pages(One-Storey Residential Building) : CE 123 Construction Methods and Project Managementjolmarie llantoNo ratings yet

- Chapter 4Document6 pagesChapter 4Zyril BestoNo ratings yet

- Influence of Television On Social InteractionDocument5 pagesInfluence of Television On Social InteractionZyril BestoNo ratings yet

- Schematic 1Document1 pageSchematic 1Zyril BestoNo ratings yet

- Schematic 1Document1 pageSchematic 1Zyril BestoNo ratings yet

- Effects of Philippine Teleseryes on StudentsDocument1 pageEffects of Philippine Teleseryes on StudentsZyril BestoNo ratings yet

- Chapter 4Document6 pagesChapter 4Zyril BestoNo ratings yet

- Break FreeDocument1 pageBreak FreeZyril BestoNo ratings yet

- Guide in Quantity Take-Off and EstimatingDocument31 pagesGuide in Quantity Take-Off and EstimatingZyril BestoNo ratings yet

- INTRODUCTIONDocument2 pagesINTRODUCTIONZyril BestoNo ratings yet

- PHIVOLCS Earthquake Intensity ScaleDocument18 pagesPHIVOLCS Earthquake Intensity ScaleZyril BestoNo ratings yet

- Victory in DefeatDocument12 pagesVictory in DefeatZyril BestoNo ratings yet

- 1.1 Background of The StudyDocument6 pages1.1 Background of The StudyZyril BestoNo ratings yet

- Beams: FHWA/TX-04/0-4086-2Document142 pagesBeams: FHWA/TX-04/0-4086-2Hyoga RianNo ratings yet

- Lesson 1Document7 pagesLesson 1Zyril BestoNo ratings yet

- The Everyday English Dictionary (London: Paekakariki Press, 2016), Hollywood Starlet (Chicago: Dancing Girl Press, 2015), Landfall and JuncturesDocument5 pagesThe Everyday English Dictionary (London: Paekakariki Press, 2016), Hollywood Starlet (Chicago: Dancing Girl Press, 2015), Landfall and JuncturesZyril BestoNo ratings yet

- 1Document8 pages1Zyril BestoNo ratings yet

- Beam - Girder LoadsDocument11 pagesBeam - Girder LoadsZyril BestoNo ratings yet

- Design of one way slab reinforcement and moment capacity calculationDocument2 pagesDesign of one way slab reinforcement and moment capacity calculationZyril BestoNo ratings yet

- Ce Project Slab1Document1 pageCe Project Slab1Zyril BestoNo ratings yet

- EnglishDocument2 pagesEnglishZyril BestoNo ratings yet

- Design of Stairs M-5Document3 pagesDesign of Stairs M-5Zyril BestoNo ratings yet

- Second Floor: Store Store Activity AreaDocument1 pageSecond Floor: Store Store Activity AreaZyril BestoNo ratings yet

- Ce Project S1Document1 pageCe Project S1Zyril BestoNo ratings yet

- INTRODUCTIONDocument2 pagesINTRODUCTIONZyril BestoNo ratings yet

- Design of Primary BeamsDocument24 pagesDesign of Primary BeamsZyril BestoNo ratings yet

- Third Floor: Store Store OfficeDocument1 pageThird Floor: Store Store OfficeZyril BestoNo ratings yet

- Solving for Loads and Column DesignDocument6 pagesSolving for Loads and Column DesignZyril BestoNo ratings yet

- Effects of Philippine Teleseryes on StudentsDocument1 pageEffects of Philippine Teleseryes on StudentsZyril BestoNo ratings yet

- National Capital Region Schools Division Office Novaliches High School MAPEH Department Definitive Budget of Work for Blended Learning Modality Quarter 1 Grade 10Document9 pagesNational Capital Region Schools Division Office Novaliches High School MAPEH Department Definitive Budget of Work for Blended Learning Modality Quarter 1 Grade 10Ma. Cristina Angenel RamosNo ratings yet

- Studi Kasus Pada PT Damar Bandha Jaya Corp. BogorDocument10 pagesStudi Kasus Pada PT Damar Bandha Jaya Corp. BogorMayHan13No ratings yet

- Stress Management Towards Employees in Reliance Life Insurance SureshDocument90 pagesStress Management Towards Employees in Reliance Life Insurance SureshSuresh Babu Reddy100% (3)

- Pharmaceutical Stability The Science and RegulationsDocument32 pagesPharmaceutical Stability The Science and RegulationsMostofa Rubal100% (1)

- Mason E0010Document24 pagesMason E0010SandeepNo ratings yet

- LPC Licensure Process HandbookDocument14 pagesLPC Licensure Process HandbookMac PatelNo ratings yet

- Logging Levels in Log4j - Tutorialspoint ExamplesDocument3 pagesLogging Levels in Log4j - Tutorialspoint ExamplesJai PannuNo ratings yet

- Manual Mta TemperaturaDocument2 pagesManual Mta TemperaturaChristian JacoboNo ratings yet

- Set 1Document24 pagesSet 1TutorTutorNo ratings yet

- Set 177Document599 pagesSet 177adilfarooq25No ratings yet

- Structural Stainless Steel Designing With Stainless Steel: Ing. Maarten FortanDocument153 pagesStructural Stainless Steel Designing With Stainless Steel: Ing. Maarten FortanJohn Philip Neri BesedillasNo ratings yet

- Nature of MarketingDocument15 pagesNature of MarketingMohamaad SihatthNo ratings yet

- Introduction To Engineering Economy: Title of The LessonDocument16 pagesIntroduction To Engineering Economy: Title of The LessonsdanharoldNo ratings yet

- TECHNICALPAPER2Document8 pagesTECHNICALPAPER2spiderwebNo ratings yet

- ESBG Financial Systems Difference EU-US PDFDocument12 pagesESBG Financial Systems Difference EU-US PDFDominiqueCarriouNo ratings yet

- Solar Pump Inverter PV100 PV200 User Manuel Rev1Document49 pagesSolar Pump Inverter PV100 PV200 User Manuel Rev1faitgpsNo ratings yet

- Impact of Sugarcane Molasses in Concrete As Time Retarding and Water Reducing AdmixtureDocument131 pagesImpact of Sugarcane Molasses in Concrete As Time Retarding and Water Reducing AdmixtureMohamed MoralesNo ratings yet