Professional Documents

Culture Documents

Us3320883 PDF

Uploaded by

checolonoskiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Us3320883 PDF

Uploaded by

checolonoskiCopyright:

Available Formats

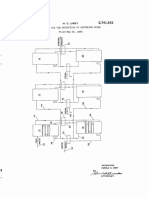

May 23, 1967

D. M. WELSH

3,320,883

EXPLOS IVL.1 TAP 1

Filed Oct. 18, 1965'

FIG.4

INVENTOR

David Martin WELSH

;

1 UN

AGENT

United States Patent 0

3,320,883

Patented May 23, 1967

3,320,883

oped textile covered detonating cord, referred to in the

trade as low energy cord, is described in United States

David Martin Welsh, lilrownsburg, Quebec, Canada, as

signor to Canadian Safety Fuse Company Limited,

Montreal, Quebec, Canada, a corporation of Canada

Filed Get. 18, 1965, Ser. No. 496,928

Patent No. 3,125,024 and comprises a core of high ex~

plosive such as PETN having a speci?c surface of at least

about 900 square centimeters per gram (e.g. 900-3400 sq.

cm./ gr.) in a concentration of at least 1.5 grains per foot

of length for speci?c surfaces of up to 3400 square cen

6 Claims. (Cl. 102-27)

timeters per gram (e.g. 1.5-10 grains per foot), con?ned

within a textile sheath preferably surrounded by a ther

EXPLGSIVE TAPE

Claims priority, application Canada, Sept. 3, 1965,

939,8 89

moplastic layer.

ABSTRACT OF THE DISCLOSURE

A ?exible weftless explosive tape comprises parallel

co-planar longitudinal detonating cords bonded together

By speci?c surface is meant the surface area per unit

weight of the high explosive in powder form. It is

measured by the standard nitrogen adsorption test using

the BET equation and apparatus. (See Encyclopedia of

by means of an adhesive. The tape can be provided with 15 Chemistry, Reinhold, 1957, or Small Particle Statistics

an adhesive backing.

by G. Herdan, Buttleworth, 1960.)

The high explosive content of the detonating cord strand

or strands of the explosive tape of the invention can be as

This invention relates to an improved explosive tape

low as the detonation-cross propagation reliability will

and, more particularly, to an explosive tape which is 20 permit for any given high explosive ingredient and can be

possessed of such ?exibility that it can be folded back on

as high as demanded by the application or use of the tape.

itself or tied in knots at any area without forming a crack

As previously mentioned, the tape may contain as little

at the bends.

as one textile covered detonating cord strand bonded in

Explosive compositions have heretofore been described

parallel longitudinal relationship to at least one ordinary

(cg. in United States Patents Nos. 2,992,087 and 2,999, 25 textile strand. If more than one textile covered detonat

743) which can be formed into ?exible, non-resilient

ing cord strands are present in the tape, they can be

sheets. Despite their many useful properties, however,

located in juxtaposition or in alternate relationship with

the said sheets have been found to lack the necessary

ordinary textile strands. The tape can of course wholly

?exibility to permit their being folded back on themselves

consist of strands of detonating cord. The textile cov

without tearing or cracking and hence no satisfactory ex

ered detonating cord strands may, if desired, have a ther

plosive tape can be made therefrom.

moplastic covering for waterproofing purposes.

A partial solution to the aforesaid ?exibility problem

The explosive tape may be provided with an adhesive

has been proposed in United States Patent No. 3,169,478

backing and thus take the form of a standard adhesive

which describes an explosive tape adapted to be folded

tape or the weftless adhesive glass ?bre tapes. It can be

at designated areas because of the presence in the tape 35 completely or partially enclosed in metal foil or covered

of a plurality of slits, essentially equal in length, arranged

with thermoplastic. Where RDX is the high explosive in

in echelon across the tape, torsion bars being de?ned

gredient of the detonating cord, for example, the tape can

by the section of the tape lying between the slits. As

be covered with a polyamide or a polyester such as poly

explicity pointed out by the patentee, the tape can only

ethylene terephthalate. The tape can also be so designed

40

be folded at designated areas and hence is not completely

that although it will cross propagate detonation within

?exible, being thus unsuitable for many applications such

as, for example, the strapping and/or lining of military

or other containers which must be quickly opened.

It is the primary object of this invention to provide an

explosive tape which is completely ?exible in the sense

that it can be folded at any area without any resultant

itself, it will not cross propagate detonation when over

lapping with another piece of the same tape.

Any ?exible adhesive can be used for bonding the

strands of the tape together in parallel longitudinal rela

tionship as long as such adhesive has no detrimental effect

on the detonating cord. Water-based latex adhesives are

tearing, discontinuities and hiatus of the explosive

particularly suitable.

composition in the region of the fold. Additional ob

The invention will be more fully illustrated by refer

jects of the invention Will appear hereinafter.

ence to the accompanying drawing wherein:

50

The improved explosive tape of this invention is weft

FIGURE 1 is a top view of an explosive tape consist

less and comprises essentially a plurality of strands bond

ing wholly of bonded strands of detonating cord;

ed together in parallel longitudinal relationship by means

of an adhesive, at least one of said strands being a tex

tile covered detonating cord.

FIGURE 2 is an end view of the same tape;

FIGURE 3 is a top view of an explosive tape com

Textile covered detonating cord or fuse is a well-known 55 prising alternate strands of detonating cord; and

FIGURE 4 is an end view of the tape of FIGURE 3.

article of commerce. It is an elongated cord-like material

All ?gures are slightly enlarged in dimension for clarity.

consisting of a core of high explosive such as pentae

In FIGURES 1 and 2 1 designates the tape consisting

rythritol tetranitrate (PETN), icyclotrimethylene trinitra

mine (RDX), nitromannite, lead azide, lead styph 60 of eight strands of detonating cord 2 bonded together in

parallel longitudinal relationship by adhesive 3. 4 repre

nate, tetryl, trinitrarnine, TNT or cyclotetramethylene

tetranitramine (HMX), con?ned within a textile sheath.

This sheath is normally surrounded by a thermo

sents the core of high explosive of each strand of detonat

ing cord 2 while 5 represents the textile sheath con?ning

plastic covering for waterproo?ng purposes when used

in the ?eld. A typical textile covered detonating fuse

core 4.

has a uniform velocity of detonation of the order of

6000 meters per second and comprises a core of

30-50 grains per foot of PETN having a speci?c sur

In FIGURES 3 and 4, the tape 6 is shown as being

made of four strands of detonating cord 7 bonded to

four ordinary textile strands 8 in alternate parallel lon

gitudinal relationship by means of adhesive 9. The high

face of 500 square centimeters per gram, a textile

explosive core 10 of each strand 7 is surrounded by a

sheath surrounding said core to contain the same, and, 70 textile sheath 11.

preferably, a waterproo?ng layer of thermoplastic sur

The following example serves to illustrate further one

rounding said textile sheath.

A more recently devel

speci?c embodiment of the explosive tape of the invention.

3,320,333

Example

2. An explosive tape as claimed in claim 1 comprising

at least two strands of said elongated cord-like material,

the high explosive of the core of said elongated cord~like

A tape approximately % wide, of the kind shown in

FIGS. 1 and 2 of the drawing, was fabricated by bonding

material being present in such a concentration as to en

together with a waterJbased latex adhesive eight strands 5 sure cross-propagation of the explosive detonation.

of textile covered detonating cord having a diameter of

'3. -An explosive tape as claimed in clailn 2 wherein

approximately 0.06", the explosive Core of which con

the high explosive of the core of the elongated cord-like

tained 4 grains per foot of PETN and was enclosed in a

material is pentaerythritol tetranitrate.

textile braid. The tape was completely ?exible and was

4. An explosive tape as claimed in claim 1 wherein

detonated by applying a conventional No. 6 blasting cap 10 each of the strands is an elongated vcord-like material as

to one end thereof.

de?ned in said claim.

Because of its flexibility, the improved explosive tape

5. An explosive tape as claimed in claim 1 wherein

of this invention can be formed into a linear shaped charge

ordinary textile strands alternate with strands of an elon

and applied to those uses which linear shaped charges

gated cord-like material as de?ned in said claim.

are normally applied to.

15

6. An explosive tape as claimed in claim 1 provided

The tape can, of course, be used where prior art sheet

with an adhesive backing.

"explosives have heretofore been used, e.g. for joining

metallic objects, Imetal hardening, etc. It is particularly

suitable for strapping and/ or lining military containers

References Cited by the Examiner

UNITED STATES PATENTS

or the like for quick opening thereof.

20

2,455,534

What I claim is:

3,021,785

1. A weftless explosive tape comprising essentially more

3,035,518

than two ?exible strands of substantially the same cross

section bonded together "by means of an adhesive in par

allel, co-planar longitudinal relationship when in the ?at

condition, at least one of said strands being an elongated

cord-like material having a core of high explosive con

25

3,062,142

3,160,949

12/1948

tBisch _____________ __ 102-22

2/ 196.2

Hradel et al. _____ __ 10227 X

5/1962

Coursen ___________ __ 102~22

11/1962

12/1964

Breza et al. ________ __ 102-23

Busseyet al. _____ __ 10223 X

FOREIGN PATENTS

797,472

7/1958

Great Britain.

?ned within a textile sheath, said tape being further char

acterized by complete ?exibility across its width and

7. BENJAMIN A. BORCI-IELT, Primary Examiner.

length.

O V. R. PENDEGRASS, Assistant Examiner.

You might also like

- JR Et Al. - 2004 - Liquid Armor Protective Fabrics Utilizing Shear Thickening FluidsDocument9 pagesJR Et Al. - 2004 - Liquid Armor Protective Fabrics Utilizing Shear Thickening FluidsThiago SantosNo ratings yet

- NATO Treaty SummaryDocument4 pagesNATO Treaty SummaryVioleta LIPANNo ratings yet

- 1.4 Diffraction of WavesDocument8 pages1.4 Diffraction of Wavespanitiafiziksmkb100% (1)

- Lock On Reference ManualDocument134 pagesLock On Reference ManualpongsagornNo ratings yet

- Business Data Communications and Networking: John Wiley & Sons, IncDocument40 pagesBusiness Data Communications and Networking: John Wiley & Sons, IncSolemnly SwearrNo ratings yet

- High Energy PhysicsDocument12 pagesHigh Energy PhysicsAVIJIT HAZRANo ratings yet

- Simla Accord outlines China-Britain-Tibet relationsDocument6 pagesSimla Accord outlines China-Britain-Tibet relationssimmikeNo ratings yet

- Cognitive Mapping ArticleDocument19 pagesCognitive Mapping Articleal60No ratings yet

- How Do Magnetic Gears WorkDocument5 pagesHow Do Magnetic Gears WorkbnbaNo ratings yet

- 1 s2.0 S2666721521000089 Main PDFDocument13 pages1 s2.0 S2666721521000089 Main PDFdadinNo ratings yet

- Cumulative LearningDocument6 pagesCumulative LearningDylan Aitken-SmithNo ratings yet

- 3.0 Fish BiologyDocument9 pages3.0 Fish BiologyJojenNo ratings yet

- Adrp1 - 02 ArmyDocument338 pagesAdrp1 - 02 ArmyinaseaofirrelevanceNo ratings yet

- 2.soil Suitability For Crop PDNDocument31 pages2.soil Suitability For Crop PDNSaurabh KumarNo ratings yet

- NSW Dept Health 2001-02Document200 pagesNSW Dept Health 2001-02Paul GallagherNo ratings yet

- UN Charter Articles on Peace & SecurityDocument2 pagesUN Charter Articles on Peace & SecurityRic SaysonNo ratings yet

- Damping Dissipation AbsorbtionDocument3 pagesDamping Dissipation AbsorbtionLia MatiasNo ratings yet

- The Geneva ConventionsDocument1,058 pagesThe Geneva Conventionsisenhand3749100% (1)

- 05-Tidal Bore RVF PDFDocument23 pages05-Tidal Bore RVF PDFBinaya Raj PandeyNo ratings yet

- Laffan - 1996 - The Politics of Identity and Political Order in EUDocument22 pagesLaffan - 1996 - The Politics of Identity and Political Order in EUMark Friis McHauNo ratings yet

- High Velocity Human Factors (HVHF) : A ManifestoDocument10 pagesHigh Velocity Human Factors (HVHF) : A Manifestomrahman4No ratings yet

- CMUN 2017 Conference HandbookDocument24 pagesCMUN 2017 Conference HandbookAryan PatelNo ratings yet

- 10-08-13 RE: Fine V Baca (09-A827), Fine V Baca (09-1250), and Fine V Baca (10-A24) at The Supreme Court of The United States - October 2009 Term Journal - Validity, or Lack ThereofDocument1,010 pages10-08-13 RE: Fine V Baca (09-A827), Fine V Baca (09-1250), and Fine V Baca (10-A24) at The Supreme Court of The United States - October 2009 Term Journal - Validity, or Lack ThereofHuman Rights Alert - NGO (RA)No ratings yet

- Modern Police Station Building Standards GuideDocument49 pagesModern Police Station Building Standards GuideVasudev AgrawalNo ratings yet

- Publication 2014 07 Electronic AttacksDocument39 pagesPublication 2014 07 Electronic Attacksdmk513No ratings yet

- Denver Sheriff Department Use of Force Policy PDFDocument39 pagesDenver Sheriff Department Use of Force Policy PDFMichael_Lee_RobertsNo ratings yet

- 6-02 - Use of ForceDocument13 pages6-02 - Use of ForceNews 5 WCYBNo ratings yet

- Brussels Treaty PDFDocument5 pagesBrussels Treaty PDFPetros ViolakisNo ratings yet

- Instructions SR-71 Blackbird 1-48 TestorsDocument13 pagesInstructions SR-71 Blackbird 1-48 TestorsMiguel MercadoNo ratings yet

- Coccp 2016-28Document77 pagesCoccp 2016-28En MahaksapatalikaNo ratings yet

- Role of the International Law Commission in Developing Public International LawDocument6 pagesRole of the International Law Commission in Developing Public International LawAyushi AgrawalNo ratings yet

- Logical AnalysisDocument28 pagesLogical AnalysisVirginia FernandezNo ratings yet

- Team 116 Project Technical Report For The 2019 IREC Design and Construction of Solid Experimental Sounding Rocket, HELENDocument30 pagesTeam 116 Project Technical Report For The 2019 IREC Design and Construction of Solid Experimental Sounding Rocket, HELENGenji Ömer GerezNo ratings yet

- Poisonous Snakes in BangladeshDocument27 pagesPoisonous Snakes in BangladeshKazi AlmuqtadirNo ratings yet

- Radio Frequency Identification ReportDocument28 pagesRadio Frequency Identification Reportkhuzainey ismail100% (1)

- 3L Dads0002 M134D Minigun 03 22 18Document2 pages3L Dads0002 M134D Minigun 03 22 18Theodor EikeNo ratings yet

- Human Rights AlertDocument120 pagesHuman Rights AlertHuman Rights Alert - NGO (RA)No ratings yet

- SOP 05M User Manual v1.11Document23 pagesSOP 05M User Manual v1.11codin1No ratings yet

- GSM Mobile JammerDocument4 pagesGSM Mobile JammerAjayNo ratings yet

- 2-Top 10 Fifth Generation Fighter AircraftDocument18 pages2-Top 10 Fifth Generation Fighter Aircrafttarun100% (1)

- Doctoral Iacp ArticleDocument7 pagesDoctoral Iacp Articleapi-555691262No ratings yet

- Vienna Convention on the Law of Treaties ExplainedDocument3 pagesVienna Convention on the Law of Treaties ExplainedBaymaxNo ratings yet

- Design of G-Force SuitsDocument549 pagesDesign of G-Force SuitsNikolai ChristiansenNo ratings yet

- Aerodynamics of the Airplane: The Drag Polar ChapterDocument88 pagesAerodynamics of the Airplane: The Drag Polar ChapterMuhammad Ishaq KhanNo ratings yet

- World Explosive Trace Detection (ETD) Technologies Market 2013-2023Document20 pagesWorld Explosive Trace Detection (ETD) Technologies Market 2013-2023VisiongainGlobalNo ratings yet

- How Is Crude Oil FormedDocument47 pagesHow Is Crude Oil FormedhutsonianpNo ratings yet

- A Mini Unmanned Aerial Vehicle (Uav) : System Overview and Image AcquisitionDocument7 pagesA Mini Unmanned Aerial Vehicle (Uav) : System Overview and Image AcquisitionhougieNo ratings yet

- LNG02Document11 pagesLNG02oo_wlNo ratings yet

- Module3 MODELLING AirQualityManagement PDFDocument50 pagesModule3 MODELLING AirQualityManagement PDFSarah AphirtaNo ratings yet

- Term Paper (TALD)Document8 pagesTerm Paper (TALD)Azhar MarzukiNo ratings yet

- Muos Wcdma Air InterfaceDocument6 pagesMuos Wcdma Air InterfaceRishi KatariyaNo ratings yet

- Related Application: Braided SleeveDocument6 pagesRelated Application: Braided Sleevenatarajan2006No ratings yet

- Scott & Williams, Inc. v. Lasticnit Co., Inc, 186 F.2d 416, 1st Cir. (1951)Document5 pagesScott & Williams, Inc. v. Lasticnit Co., Inc, 186 F.2d 416, 1st Cir. (1951)Scribd Government DocsNo ratings yet

- Textile Network v. Gerald SchwartzDocument9 pagesTextile Network v. Gerald SchwartzPriorSmartNo ratings yet

- Material For Radomes and Process For Making The SameDocument30 pagesMaterial For Radomes and Process For Making The SameHarryNo ratings yet

- Inflatable Packer Reinforcement MethodDocument5 pagesInflatable Packer Reinforcement Methodmohammadreza91No ratings yet

- 1955 - Patente - Velvet Type Fabric and Method of Producing SameDocument3 pages1955 - Patente - Velvet Type Fabric and Method of Producing SamePaulo De Melo MacedoNo ratings yet

- Us 5160773Document6 pagesUs 5160773Huan ZhangNo ratings yet

- Net Making Made Simple - A Guide to Making Nets for Sport and HomeFrom EverandNet Making Made Simple - A Guide to Making Nets for Sport and HomeNo ratings yet

- Anti-Corrosion Methods and Materials: Article InformationDocument6 pagesAnti-Corrosion Methods and Materials: Article InformationchecolonoskiNo ratings yet

- ماذا يثول الكتاب المقدس عن محمدDocument51 pagesماذا يثول الكتاب المقدس عن محمدAbu Ahmed GhariebNo ratings yet

- لماذا محمد صلى الله عليه و سلم هو الأعظم - أحمد ديداتDocument32 pagesلماذا محمد صلى الله عليه و سلم هو الأعظم - أحمد ديداتahmed.ne7970100% (1)

- SOAP AND DETERGENT MANUFACTURINGDocument13 pagesSOAP AND DETERGENT MANUFACTURINGXsey Doh TukarnamoNo ratings yet

- Us 541899Document1 pageUs 541899checolonoskiNo ratings yet

- 1734 DDocument11 pages1734 DPasha TanNo ratings yet

- Amphetamine Leucart ReactionDocument1 pageAmphetamine Leucart Reactionlukasz_wieczorek_praca100% (3)

- Patent - 一种用结晶控制技术制备球形化黑索今的方法 One Technique for Preparing ... - Google PatentsDocument9 pagesPatent - 一种用结晶控制技术制备球形化黑索今的方法 One Technique for Preparing ... - Google PatentschecolonoskiNo ratings yet

- 1734 DDocument11 pages1734 DPasha TanNo ratings yet

- Benzocaine (2 Steps)Document11 pagesBenzocaine (2 Steps)checolonoski0% (1)

- جورنال عراقى (جامعة تكريت) PDFDocument10 pagesجورنال عراقى (جامعة تكريت) PDFchecolonoskiNo ratings yet

- Us2589532 PDFDocument7 pagesUs2589532 PDFchecolonoskiNo ratings yet

- 1734 DDocument11 pages1734 DPasha TanNo ratings yet

- Us5032391 PDFDocument4 pagesUs5032391 PDFchecolonoskiNo ratings yet

- Us4278480 PDFDocument3 pagesUs4278480 PDFchecolonoskiNo ratings yet

- Us4216720 PDFDocument7 pagesUs4216720 PDFchecolonoskiNo ratings yet

- بي PDFDocument2 pagesبي PDFchecolonoskiNo ratings yet

- Us2741543 PDFDocument6 pagesUs2741543 PDFchecolonoskiNo ratings yet

- Us2787587 PDFDocument6 pagesUs2787587 PDFchecolonoskiNo ratings yet

- Us2942965 PDFDocument2 pagesUs2942965 PDFchecolonoskiNo ratings yet

- Ravi2011 PDFDocument11 pagesRavi2011 PDFchecolonoskiNo ratings yet

- Us857580 PDFDocument2 pagesUs857580 PDFchecolonoskiNo ratings yet

- Us2758006 PDFDocument16 pagesUs2758006 PDFchecolonoskiNo ratings yet

- Us3457127 PDFDocument5 pagesUs3457127 PDFchecolonoskiNo ratings yet

- Us2344840 PDFDocument3 pagesUs2344840 PDFchecolonoskiNo ratings yet

- Urey1931 PDFDocument9 pagesUrey1931 PDFchecolonoskiNo ratings yet

- Gb191022030a PDFDocument2 pagesGb191022030a PDFchecolonoskiNo ratings yet

- fل PDFDocument2 pagesfل PDFchecolonoskiNo ratings yet

- Urey1932 PDFDocument2 pagesUrey1932 PDFchecolonoskiNo ratings yet

- PEPUNNUManuscript11jan2013 PDFDocument25 pagesPEPUNNUManuscript11jan2013 PDFchecolonoskiNo ratings yet

- West Allegheny Marching Band Sponsorship 2023 Final 2Document2 pagesWest Allegheny Marching Band Sponsorship 2023 Final 2api-117237667No ratings yet

- The 4 Ms of OperationDocument14 pagesThe 4 Ms of OperationGodwill Jireh L. Patindol100% (7)

- Bom Cno175925Document15 pagesBom Cno175925Yuvraj BappiNo ratings yet

- Learning Plan 1Document7 pagesLearning Plan 1Jan michael MahilumNo ratings yet

- 1031 1192105956 13 202109 FGH F Torque Converter Erosion Jory For Cep - PDF 51376613 v1Document7 pages1031 1192105956 13 202109 FGH F Torque Converter Erosion Jory For Cep - PDF 51376613 v1Jesús SarriaNo ratings yet

- IEEE Standards and Network Protocols GuideDocument7 pagesIEEE Standards and Network Protocols GuideGray FullbusterNo ratings yet

- 13 10 01LE-Seriesv3Document6 pages13 10 01LE-Seriesv3achyuthramayyaNo ratings yet

- Nzs 4298 1998Document91 pagesNzs 4298 1998al_bundiNo ratings yet

- Engineer InstrumentationDocument4 pagesEngineer InstrumentationmangeshjoNo ratings yet

- L6 Software Tools For Plagiarism CheckingDocument13 pagesL6 Software Tools For Plagiarism Checkingrahulyadav.hbtiNo ratings yet

- Sandvine SolutionsDocument80 pagesSandvine SolutionsAsif Majeed MalikNo ratings yet

- Automan AC and AF Series ASL 62 305 448 Ed.05Document393 pagesAutoman AC and AF Series ASL 62 305 448 Ed.05yhorsNo ratings yet

- Caitlyn Hamilton Resume and References 2Document4 pagesCaitlyn Hamilton Resume and References 2api-326168876No ratings yet

- DX DiagDocument24 pagesDX DiagmmtrgriksdjNo ratings yet

- Brickwork and Stonework SupportDocument20 pagesBrickwork and Stonework SupportSanel GrabovicaNo ratings yet

- Muchmoon 3000-830 Op-Ll 22W Etdd L2,0 05 9002155634 enDocument1 pageMuchmoon 3000-830 Op-Ll 22W Etdd L2,0 05 9002155634 enDani Good VibeNo ratings yet

- Itc Final ProjectDocument90 pagesItc Final ProjectPriyanka Rupani0% (1)

- RRB ALP Allahabad Tier 1 Result Final ListDocument843 pagesRRB ALP Allahabad Tier 1 Result Final Listsumit_saraf_5100% (1)

- In Search of Air France Flight 447: Bipattaran MandalDocument40 pagesIn Search of Air France Flight 447: Bipattaran MandalRonyNo ratings yet

- North Reading Set 2 Group BDocument2 pagesNorth Reading Set 2 Group Bapi-281321560No ratings yet

- Midsteel Pipe Chart - Inches and MetricDocument1 pageMidsteel Pipe Chart - Inches and MetricThành CôngNo ratings yet

- Modul STEM Sifat Koligatif Larutan Pages 1-50 - Flip PDF Download - FlipHTML5Document76 pagesModul STEM Sifat Koligatif Larutan Pages 1-50 - Flip PDF Download - FlipHTML5Manawa MulkNo ratings yet

- Floor plan of a cottage with two bedrooms and living areaDocument1 pageFloor plan of a cottage with two bedrooms and living areaNithinNo ratings yet

- AMIGA - ABC Wide World of Sports Boxing InstructionsDocument2 pagesAMIGA - ABC Wide World of Sports Boxing InstructionsjajagaborNo ratings yet

- Dynamic System Analysis Installation and User's Guide: IBM SystemsDocument62 pagesDynamic System Analysis Installation and User's Guide: IBM SystemsKamalkant YadavNo ratings yet

- Hospital Project Schedule Update 24.01.23Document1 pageHospital Project Schedule Update 24.01.23Ahmed AbuelezzNo ratings yet

- Az2030 2035 PDFDocument34 pagesAz2030 2035 PDFEdenia JolvinoNo ratings yet

- Cititor Stand Alone Interior Sebury Cartele Proximitate Cod ControllerDocument7 pagesCititor Stand Alone Interior Sebury Cartele Proximitate Cod ControllerAndrei PantaNo ratings yet

- Handbook em Final EngDocument56 pagesHandbook em Final Engigor_239934024No ratings yet

- EOI Biometric ApplicationDocument3 pagesEOI Biometric ApplicationFrancis EkemuNo ratings yet