Professional Documents

Culture Documents

Kootenay Highline System

Uploaded by

bubbaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kootenay Highline System

Uploaded by

bubbaCopyright:

Available Formats

A A

Rigging for RescueNotes

The Kootenay Highline System

L

The term 'highline'often inappropriately referred to as a 'Tyrolean'refers to a system that uses a

track rope (mainline) to suspend a load over a span. Highlines can be much more practical for

rescue work than is commonly assumed. However, many people do not appreciate the high levels

of force that can be easily placed on the track rope if some key principles are not taken into account.

This has led to highlines being set up with excessively low safety factors through the use of illconsidered rigging concepts. To increase the safety of using highlines, practitioners must first

obtain the proper in-depth training in basic physics and rigging principles, and also have access to

the appropriate equipment. With this approach, rescuers can rig effective, efficient and safe

highlines that can be more practical than other techniques available in certain applications.

The Kootenay Highline System (KHS):

In 1985, in the province of British Columbia, serious thought and consideration was given to the

rigging and operating principles of highlines. This work led to the development of the key concepts

and principles of the Kootenay Highline System. Since then, several practical variations have also

been developed, such as the English Reeve, the Norwegian Reeve and the drooping highline

variations. In addition, the KHS has been tested in several variations and its concept of belaying

with the taglines was demonstrated as early as 1986. This cannot be said for most of the other

highline techniques in use today.

Though there are many ways to categorize highlines, for the KHS a distinction is drawn between

horizontal highlines, sloping highlines and steep highlines. A horizontal highline is one that has no

more than a 10 change in angle between end stations. A sloping highline has more than 10 but no

more than 45 angle between end stations; and a steep highline has an angle greater than 45.

To really understand the KHS is to realize that there is no 'one-correct-way' to rig it. Each KHS is

built using the deliberate application of key rigging and operating principles and concepts to the

specific rescue situation at hand. While some specialized gearsuch as Prusik Minding Pulleys

and Kootenay Carriagesmay help the efficiency of operating a KHS, it is by no means essential,

and can often be substituted as long as the replacement equipment can meet the same performance

and safety criteria.

Key KHS Principles:

This handout provides a overview of the primary rigging and operating principles of the KHS up to

100 metres (m) in length. For extreme highlines (i.e. those greater than 100m in length), additional

considerations that must be taken into account such as formulas and calculations are not covered in

this handout.

Rescue teams wishing to perform safe and effective rescues with this highline technique must have

a thorough understanding of all of the KHS principles, the most important of which are:

KHS-1 1997 Rigging for Rescue P.O. Box 745 Ouray, CO 81427

U.S.A.

Page 1 of 7

A A

Rigging for RescueNotes

The Kootenay Highline System

L

1. Minimize any loss of breaking strength in the highline's track rope by

having no knots or sharp bends in it. Also, anchor the fixed end of the

track rope with a high strength tie-off (Figure 1) or a Kootenay

Carriage with the pins inserted.

2. Attach the tensioning pulley system to the track rope with a gently

acting slipping clutch to prevent over-tensioning (Figure 2). At the

present time, Tandem 8 mm 3 wrap Prusik Hitches are used.

Mechanical rope clamps such as Gibbs or handled ascenders are

unacceptable.

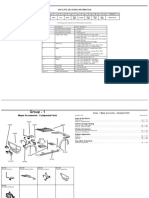

Figure 1:

High Strength Tie-Off

Figure 2: Tensioning System for a Single Track Rope

3. Attach the load by hanging it from a device capable of sustaining multiple direction forces, such

as a Kootenay Carriage, a solid pear shaped or round rigging ring, or equivalent. There are

many ways to accomplish this. Consideration must also be given as to whether or not the load

will be suspended from one or two attachment points and if the tagline will be one continuous

rope or whether two separate ropes will be used. Some examples of various combinations are

shown in Figure 3.

4. Rig the taglines to handle shock forces in case of track rope failure by the use of Prusik bypasses at end knots and managing the taglines with Tandem 8 mm 3 wrap Prusik Hitchesas

per Prusik Belaying attached to suitable end point anchorage. At the load, the taglines should

be attached directly to the device capable of sustaining multiple direction forces, as is shown in

the examples in Figure 3, and not to the load itself.

5. The KHS is intended to be operated with a Static System Safety Factor of 10:1 or greater on the

track rope. If lack of clearance requires minimal deflection (sag), then the track rope may be

doubled or quadrupled in order to maintain the principle of a minimum 10:1 safety factor.

Graphics created by Earl Frm

KHS-1 1997 Rigging for Rescue P.O. Box 745 Ouray, CO 81427

U.S.A.

Page 2 of 7

A A

Rigging for RescueNotes

The Kootenay Highline System

L

Additional KHS Principles:

While the first five points describe the most important rigging principles of the KHS, the following

principles are also important, but may or may not apply depending on the specific rigging

requirements of the highline being set up:

(a) Single Tagline with

Pulley & Rigging Ring

(b) Single Tagline with

Kootenay Carriage

d) Two Taglines with two Kootenay Carriages

(c) Two Taglines with

Kootenay Carriage

(e) Single Tagline with two Kootenay Carriages

Figure 3: Examples of Methods to attach the load and tagline(s) to central attachment point

6. Consistent with the principle of minimizing any loss of strength in the track rope, any pulleys

supporting the track rope must be of a large enough diameter. This is especially true for any

track rope support pulleys at the tensioning end of the highline. The track rope tension may be

adjusted from time to time, which will result in considerable movement of the track rope over

the support pulley. At the fixed end of the track rope, any support which has a smooth, large

diameter curved surface would do, since the track rope will not move significantly at this end

during any adjustment of track rope tension.

7. The pulley from which the load is supported, also needs to be of large enough diameter or

proper configuration to minimize the loss of any track rope breaking strength.

8. The track rope and taglines should have their own independent anchor systems with a breaking

strength greater than or equal to the breaking strength of the ropes. For example, an 11.1 mm

track rope with a breaking strength of 30 kiloNewtons (kN) must have an anchor system

strength of 30+ kN. If the track rope is doubled (i.e. two 11.1 mm ropes), then the minimum

anchor system breaking strength must be 60+ kN.

Graphics created by Earl Frm

KHS-1 1997 Rigging for Rescue P.O. Box 745 Ouray, CO 81427

U.S.A.

Page 3 of 7

A A

Rigging for RescueNotes

The Kootenay Highline System

L

Figure 4: Example of Highline Station Set-up with High Strength Tie-off

9. Both the track rope and taglines must be able to run freely through pulleys or rollers without

contacting the ground, cliff, or other obstacles.

10. On highline spans greater than 30m or so, tagline hangers should be employed to support the

taglines thereby minimizing excessive tagline slack. A tagline hanger can be easily be

constructed using a sling of accessory cord, Girth Hitch it around the tagline and clip it to the

track rope with a non-locking carabiner at regular intervals as required (see Figure 4).

11. The attendant (if used) and patient are connected to the carriage(s) with a back-up in addition to

their primary support. If the attendant's primary support is an attachment directly to their

harness, then the harness connection should be such that it would keep the attendant upright and

maintain their position relative to the patient in the event of a track rope failure.

12. The tension in the track rope should never exceed one tenth of the track rope's breaking strength

to maintain a minimum 10:1 Static System Safety Factor. Some general guidelines have been

developed for the proper tensioning of the KHS. These 'general' guidelines are based on the

knowledge gained from a series of trials to see how much force can be applied to a track rope

with various combinations of pullers and pulley system mechanical advantages. With the

following suggested guidelines, 'average' rescuers should not be able to over-tension the track

rope (i.e., to more than one tenth its breaking strength). Variation between people's pulling

ability must be taken into account and corrected for. The guidelines for 11 mm (30 kN breaking

strength) track ropes are as follows:

Graphics created by Earl Frm

KHS-1 1997 Rigging for Rescue P.O. Box 745 Ouray, CO 81427

U.S.A.

Page 4 of 7

A A

Rigging for RescueNotes

The Kootenay Highline System

L

It is important to distinguish between tensioning the track rope with and without a load on it.

With no load placed on the system, have only one person pre-tension the system by pulling

on a 2:1 pulley system. Pulling on the pulley system assumes 'normal' pulling; the rope is

not wrapped around any part of the puller's body, and once the puller reaches his/her

maximum pulling ability, no additional attempts are made to 'heave-ho' more tension into

the system.

With the load at center-span, the maximum force that can be applied to the track rope is a

multiple of 12 (i.e., the number of pullers times the mechanical advantage is less than or

equal to 12). This means, for example, that 6 people can pull on a 2:1, 3 people can pull on

a 4:1, or even 2 people can pull on a 6:1. The same guidelines apply to single, double, and

quadruple track rope tensioning.

If the track rope is 12.5 mm in diameter (40+ kN), the sample principles apply except that a

multiple of 18 can be used instead of the multiple of 12 described above. Therefore, 9 people

can pull on a 2:1 (though usually impractical), 6 people can pull on a 3:1, 3 people can pull on a

6:1 or 2 people can pull on a 9:1.

It is important to recognize, understand and take into account that there will be differences in

the capabilities between people's pulling ability, as well as differences in actual versus ideal

mechanical advantage between pulley systems.

13. When

double

or

quadruple track ropes are

used to either reduce sag

or enable larger loads to

be transported, it is

important to ensure that

there is equal tension in

each track rope. This can

be accomplished with the

use of pulley systems-inOptional

series pulling on all track

ropes. Figure 5 is an

example of a compound

Figure 5: Example of Pulley System Set-up to Apply Equal Tension to each

6:1 pulling on each track

Track Rope in a Double Track Rope System

rope of a double track

rope highline. If these

were 11 mm track ropes,

then a maximum of 2 people would pull on this pulley system as per the criteria outlined in #12

above. Note the connector strap between the pulleys connecting the Tandem Prusiks to each

track rope. This is used so that the integrity of the pulley system will be maintained, even if one

of the track ropes were to fail. Additional anchorage of the track ropes with Tandem Prusiks is

Graphics created by Earl Frm

KHS-1 1997 Rigging for Rescue P.O. Box 745 Ouray, CO 81427

U.S.A.

Page 5 of 7

A A

Rigging for RescueNotes

The Kootenay Highline System

L

optional, and mostly used for drooping highlines or those highlines that require the tensioning

system to be reset during the operation.

14. Once the load has passed mid-span and

begins to travel towards the destination

station, a pulley system on the tagline may

be required to help pull the tagline and load

into the station. This can be easily done by

making a simple 3:1 pulley system out of the

tagline (Figure 6). Note that the Tandem Figure 6: Example of Pulley System attached to Tagline

Prusiks are still in place to maintain the

belay capability of the tagline.

15. For sloping highlines, the speed of

descent out of the top station must be

controlled (Figure 7). A brakerack can be

used at this station for additional control.

Tandem Prusiks with an LR Hitch are still

placed on the tagline in front of the

brakerack so that the tagline can still act as

a belay in the event of a mainline failure.

Figure 7: Use of a Brakerack on the Tagline

Operational Logistics:

There are many ways to set up a highline. Therefore, any examples in this handout are not to be

construed as 'the way' of how to set up a KHS. Many factors must be taken into consideration, and

rescuers should practice various ways of setting up highlines so as not to resort to just one method.

The key variables that determine how a KHS will be set up are: the span, the angle between end

stations, length of ropes, available equipment, access limitations to either side, the terrain, number

of people, the size and location of the load, and communication considerations.

Often the greatest difficulty in setting up a highline is getting the first line across. Pre-planning

which equipment needs to be at each end station, and once the first line is across, prioritizing which

ropes and equipment will be ferried back and forth is the key to efficiency. If the span is very short,

then the track rope and taglines themselves may be tossed to the other station. However, if this can

not be done, then either a messenger cord or a pilot line may need to be put in place first. A

messenger cord is a small diameter cord capable of hauling the ropes across, whereas a pilot line is

an even smaller diameter cordlike that used for a line gunwhich is used to pull a messenger

cord in place. There are various ways in which the first line (or rope) can be placed across the span:

it may be carried or walked over; a cord may be lowered from each end station and then tied

together; it may be thrown across; shot across with a line gun, compound bow, slingshot, or solid or

air fueled rocket, or it may be transported across with a water craft in river rescue. These are just a

few examples and there are many more options other those than just these listed here.

Graphics created by Earl Frm

KHS-1 1997 Rigging for Rescue P.O. Box 745 Ouray, CO 81427

U.S.A.

Page 6 of 7

A A

Rigging for RescueNotes

The Kootenay Highline System

L

Example of a KHS Set-up:

Again, there are numerous ways to set up a highline. The following example is by no means

comprehensive and does not do justice to some of the logistical priorities, operational movements

for smoothness and communication requirements which lend to efficiency and expediency. This is

best learned through competent instruction and practice in setting up highlines a variety of ways.

The following example assumes that this is a single track rope, two tagline highline; the rescuers

have pre-planned which equipment will go to which end station. For clarity, the end stations are

called Station One and Station Two:

1. From Station One, establish a messenger cord between end stations that is twice the length of

the span. Tie a 'floating middle tie' (e.g. butterfly knot) in the middle of the messenger cord.

2. Clip the track rope to the floating middle tie and have Station Two pull it over by pulling in the

messenger cord. Once the Station Two receives the track rope, they can quickly attach a Prusik

Hitch a few metres from the end of the track rope and clip it to an anchor (e.g. a sling in a tree

where the high strength tie-off will go). Station Two then clips their tagline to the floating

middle tie to be pulled back across by Station One. If the span requires it, tagline hangers are

put on at regular intervals; feeding out enough tagline to allow it to hang below the track rope.

3. Station One now receives Station Two's tagline, and connects it to Station One's tagline and

carriage unit which was set up while they were waiting for Station Two's tagline to arrive.

(Note: the messenger cord should be left across the span for the duration of the operation

though it can be placed out of the way on either side).

4. Station Two now proceeds with tying a high strength tie-off with the track rope and should

advise Station One when this has been completed. They can also set up a tagline/belay anchor

system, as well as any backties required (for both the track rope and tagline anchor systems).

5. Station One completes any rigging required while Station Two is working on their end. This

may include setting up the tensioning system, tagline and track rope anchor systems, and

placing support pulleys. Once Station Two has completed the high-strength tie-off, Station One

can complete the pre-tensioning of the track rope and get the attendant/patient ready.

6. Once all system components are checked, the patient and/or attendant can be attached to the

carriage unit and communication set-up to start sending them across the highline.

###

KHS-1 1997 Rigging for Rescue P.O. Box 745 Ouray, CO 81427

U.S.A.

Page 7 of 7

You might also like

- MetalCut User ManualDocument71 pagesMetalCut User Manualnammaris0% (1)

- DWSD Wastewater Master Plan Collection System Design StandardsDocument11 pagesDWSD Wastewater Master Plan Collection System Design StandardsPiero Cacciuttolo OpazoNo ratings yet

- Mil M 8090FDocument83 pagesMil M 8090Feuroporsche914No ratings yet

- Ring BusDocument11 pagesRing BusDon Oliveros ÜNo ratings yet

- Simulation of three-phase transformerless UPSDocument7 pagesSimulation of three-phase transformerless UPSTài Nguyễn Minh NhậtNo ratings yet

- APS Dynamics, 114 Dual Amplifier, 380W 0-2kHz PDFDocument15 pagesAPS Dynamics, 114 Dual Amplifier, 380W 0-2kHz PDFLulu Sweet ThingNo ratings yet

- Beware of Line-Current Unbalance On VFDs - (EC&M) MagazineDocument4 pagesBeware of Line-Current Unbalance On VFDs - (EC&M) MagazineMenaNo ratings yet

- Aimt ProspectusDocument40 pagesAimt ProspectusdustydiamondNo ratings yet

- SAP MM ReportsDocument59 pagesSAP MM Reportssaprajpal95% (21)

- Hercules Segers - Painter EtchterDocument4 pagesHercules Segers - Painter EtchterArtdataNo ratings yet

- 6 - Best of “ Reversible Direct Current Sub-Station”Document11 pages6 - Best of “ Reversible Direct Current Sub-Station”Fernando GuedesNo ratings yet

- Power System OscillationsDocument9 pagesPower System Oscillationssaghiram8071No ratings yet

- Guidelines For The Installation of Cable in Cable Trays PDFDocument7 pagesGuidelines For The Installation of Cable in Cable Trays PDFStefanos DiamantisNo ratings yet

- Introduction To The Project and Overview of Power System SecurityDocument9 pagesIntroduction To The Project and Overview of Power System Securitysalagasim100% (1)

- Super-High Frequency Models and Behaviour PDFDocument23 pagesSuper-High Frequency Models and Behaviour PDFalokinxxNo ratings yet

- High Voltage Distribution System For Agricultural Pumps: A Case StudyDocument9 pagesHigh Voltage Distribution System For Agricultural Pumps: A Case StudyAkshat GangwalNo ratings yet

- AC DC Railway Electrification and Protection: November 2014Document43 pagesAC DC Railway Electrification and Protection: November 2014Akhilesh kumar Srivastava100% (1)

- Guide Spec 9395P 200-600kW UPS PDFDocument19 pagesGuide Spec 9395P 200-600kW UPS PDFabual3ezNo ratings yet

- 315 033260 9 - DpuDocument52 pages315 033260 9 - Dpuogautier60% (5)

- Basic Concept For Electrical DesigningDocument2 pagesBasic Concept For Electrical DesigningJoel RemegioNo ratings yet

- DC ReportDocument15 pagesDC Reportapi-251473627No ratings yet

- Value of Lost LoadDocument7 pagesValue of Lost LoadLuis AntonioNo ratings yet

- POWER SYSTEM OPERATION AND CONTROL Q&ADocument12 pagesPOWER SYSTEM OPERATION AND CONTROL Q&Amksamy2021No ratings yet

- Evaluation of Distribution System Reliability Indices of Nasik AreaDocument10 pagesEvaluation of Distribution System Reliability Indices of Nasik AreaGuru MishraNo ratings yet

- Unit Commitment Problem OptimizationDocument22 pagesUnit Commitment Problem Optimizationnadeem100% (1)

- The Load As An Energy Asset in A Distributed DC MGDocument8 pagesThe Load As An Energy Asset in A Distributed DC MGAakanksha DugarNo ratings yet

- Design of Hydraulic and Pneumatic Systems Lecture NotesDocument135 pagesDesign of Hydraulic and Pneumatic Systems Lecture NotesvanajaNo ratings yet

- Engineering of Headrace Tunnel for Neelum Jhelum Hydropower ProjectDocument22 pagesEngineering of Headrace Tunnel for Neelum Jhelum Hydropower ProjectKukuh Prasetyo Pangudi Utomo0% (1)

- AECMSGuideRevision 20091120Document104 pagesAECMSGuideRevision 20091120kmattaiNo ratings yet

- Diesel Generator IEEE Paper 01601575Document11 pagesDiesel Generator IEEE Paper 01601575martinpellsNo ratings yet

- Electric Power Transmission CompressDocument42 pagesElectric Power Transmission CompressGanesh KotnalaNo ratings yet

- Generator TheoryDocument4 pagesGenerator TheoryRachit KhannaNo ratings yet

- Slup 224Document191 pagesSlup 224marcosscaratoNo ratings yet

- DR Lalit Goel: Nanyang Technological University, SingaporeDocument126 pagesDR Lalit Goel: Nanyang Technological University, SingaporeKavita ChaurasiaNo ratings yet

- Audible Noise ReductionDocument4 pagesAudible Noise ReductionGaurav SharmaNo ratings yet

- Power System Blackout: Share/download Essay: Chapter1: IntroductionDocument23 pagesPower System Blackout: Share/download Essay: Chapter1: Introductions_banerjeeNo ratings yet

- Motor Calculations - HTMDocument4 pagesMotor Calculations - HTMDaniel Bejarano SánchezNo ratings yet

- Control Logix System Users ManualDocument435 pagesControl Logix System Users ManualDrumsdotcom100% (14)

- CATERHAM CAR SALES & COACHWORKS LTD V BIRKIN CARS (PTY) LTD AND ANOTHER 1998 (3) SA 938 (SCA)Document14 pagesCATERHAM CAR SALES & COACHWORKS LTD V BIRKIN CARS (PTY) LTD AND ANOTHER 1998 (3) SA 938 (SCA)Rodney UlyateNo ratings yet

- Simulation of A Doubly-Fed Induction Generator With Hydro TurbineDocument6 pagesSimulation of A Doubly-Fed Induction Generator With Hydro TurbineHazrul_Mohamed_BasriNo ratings yet

- Fly by WireDocument20 pagesFly by WireAnurag RanaNo ratings yet

- Low Power Boost Converter For Portable Applications by Eddy Wells and Mark JordanDocument9 pagesLow Power Boost Converter For Portable Applications by Eddy Wells and Mark JordanberbouNo ratings yet

- Power Electronics Devices and ApplicationsDocument52 pagesPower Electronics Devices and Applicationsmanoj kumarNo ratings yet

- RUS BULLETIN 1724E-151 RD-GD-2016-80 SUBJECT: Mechanical Loading On Wooden Distribution CrossarmsDocument19 pagesRUS BULLETIN 1724E-151 RD-GD-2016-80 SUBJECT: Mechanical Loading On Wooden Distribution CrossarmsMd. KibriaNo ratings yet

- Matrix Converter - Reading NotesDocument4 pagesMatrix Converter - Reading NotesAnsar NiaziNo ratings yet

- NUREG-0050 Recommendations Related To Browns Ferry FireDocument96 pagesNUREG-0050 Recommendations Related To Browns Ferry Firescott56794No ratings yet

- Power System Fault Analysis and Symmetrical ComponentsDocument27 pagesPower System Fault Analysis and Symmetrical Componentsግርማ ገ.No ratings yet

- PS7101 AdvancedPowerSystemAnalysisDocument20 pagesPS7101 AdvancedPowerSystemAnalysismadhes14No ratings yet

- Application UpsDocument8 pagesApplication UpsAerwin BautistaNo ratings yet

- Components of Distribution System Substation and Busbar LayoutsDocument10 pagesComponents of Distribution System Substation and Busbar LayoutsBahaaldeen Ahmedaltegani Basheir MohammedNo ratings yet

- Power Quality Improvement in Grid Connected PV SystemDocument6 pagesPower Quality Improvement in Grid Connected PV SystemEditor IJTSRDNo ratings yet

- IEEE STD 1547Document4 pagesIEEE STD 1547elchicogrisNo ratings yet

- Electric Power Load Analysis for Surface ShipsDocument46 pagesElectric Power Load Analysis for Surface ShipsLincoln RibeiroNo ratings yet

- Ancillary Services in Power SystemsDocument5 pagesAncillary Services in Power SystemsNitakashi87No ratings yet

- ML023030070 USNRC Power Plant Engineering 3Document170 pagesML023030070 USNRC Power Plant Engineering 3MutahirrasoolNo ratings yet

- Assignment WindDocument3 pagesAssignment WindShameer Majeed. ANo ratings yet

- Fire Pump Installation RequirementsDocument48 pagesFire Pump Installation Requirementsczds6594No ratings yet

- 11 Major Power Grid BlackoutsDocument32 pages11 Major Power Grid BlackoutsChetan KotwalNo ratings yet

- FLX Pro 15 - 17Document2 pagesFLX Pro 15 - 17Samer Al-MimarNo ratings yet

- E Grupos DMimeDocument3 pagesE Grupos DMimeue3b2No ratings yet

- Eaton - 9395 - 275kVA - Manual - 1027212 - en PDFDocument133 pagesEaton - 9395 - 275kVA - Manual - 1027212 - en PDFCesar VilledaNo ratings yet

- 3500 44 Aeroderivative Monitor 129774 01 Rev D PDFDocument87 pages3500 44 Aeroderivative Monitor 129774 01 Rev D PDFlancasaNo ratings yet

- 4 Fastenings For High Speed Track - Vipul Kumar (RDSO)Document10 pages4 Fastenings For High Speed Track - Vipul Kumar (RDSO)devidattairsmeNo ratings yet

- A Simple Method For Simultaneously Tensi PDFDocument8 pagesA Simple Method For Simultaneously Tensi PDFAmit R. GhuleNo ratings yet

- Rescue BelaysDocument12 pagesRescue BelaysbubbaNo ratings yet

- Accidents in MR Excerpt 2Document2 pagesAccidents in MR Excerpt 2bubbaNo ratings yet

- Class 20 - Edge Transition WorksheetDocument1 pageClass 20 - Edge Transition WorksheetbubbaNo ratings yet

- Parallel PlaquettesDocument24 pagesParallel PlaquettesbubbaNo ratings yet

- Accidents in MR Excerpt 1Document3 pagesAccidents in MR Excerpt 1bubbaNo ratings yet

- Class 21 - Overall System WorksheetDocument1 pageClass 21 - Overall System WorksheetbubbaNo ratings yet

- Class 18 - Haul and Lower System WorksheetDocument1 pageClass 18 - Haul and Lower System WorksheetbubbaNo ratings yet

- Class 13 - Belay WorksheetDocument1 pageClass 13 - Belay WorksheetbubbaNo ratings yet

- Technical Rescue Avalanche Advisory WorksheetDocument1 pageTechnical Rescue Avalanche Advisory WorksheetbubbaNo ratings yet

- Class 12 - Avy Field PracticeDocument1 pageClass 12 - Avy Field PracticebubbaNo ratings yet

- Introduction To Technical Rescue, Spring 2016 Worksheet For Class 8 Structure and StrengthDocument1 pageIntroduction To Technical Rescue, Spring 2016 Worksheet For Class 8 Structure and StrengthbubbaNo ratings yet

- Class 15 - Hauling WorksheetDocument1 pageClass 15 - Hauling WorksheetbubbaNo ratings yet

- Class 17 - Lowering WorksheetDocument1 pageClass 17 - Lowering WorksheetbubbaNo ratings yet

- Class 4 - Anchor Worksheet 1Document2 pagesClass 4 - Anchor Worksheet 1bubbaNo ratings yet

- Agreement:: Behavior Research MethodsDocument1 pageAgreement:: Behavior Research MethodsPaisan NgerndeeNo ratings yet

- Class 3 - Knot and Physics WorksheetDocument1 pageClass 3 - Knot and Physics WorksheetbubbaNo ratings yet

- Class 5 - Anchor Worksheet 2Document1 pageClass 5 - Anchor Worksheet 2bubbaNo ratings yet

- A12 Design For Buckling-Columns and PlatesDocument20 pagesA12 Design For Buckling-Columns and PlatesOSCARDELTANo ratings yet

- Voodoo SystemDocument1 pageVoodoo SystembubbaNo ratings yet

- Shear and Moment DiagramDocument8 pagesShear and Moment DiagrambubbaNo ratings yet

- Parleremo Pzfra1Document218 pagesParleremo Pzfra1Lucia FerentNo ratings yet

- A APJ Abdul Kalam Technological University First Semester M. Tech. Degree Examination December 2016 Ernakulum II ClusterDocument2 pagesA APJ Abdul Kalam Technological University First Semester M. Tech. Degree Examination December 2016 Ernakulum II ClusterAshwin JoseNo ratings yet

- Assessment of Concrete Strength Using Flyash and Rice Husk AshDocument10 pagesAssessment of Concrete Strength Using Flyash and Rice Husk AshNafisul AbrarNo ratings yet

- Business Continuity Generaly Accepted Practices GAP v2.1 (Disaster Recovery Journal 2015) PDFDocument140 pagesBusiness Continuity Generaly Accepted Practices GAP v2.1 (Disaster Recovery Journal 2015) PDFducuhNo ratings yet

- Floor CraneDocument6 pagesFloor CranejillianixNo ratings yet

- Dental Pulp TissueDocument77 pagesDental Pulp TissueJyoti RahejaNo ratings yet

- Bioprocess Engineering QuestionsDocument13 pagesBioprocess Engineering QuestionsPalanisamy Selvamani100% (1)

- Python operators and data types quizDocument34 pagesPython operators and data types quizATUL SHARMANo ratings yet

- Vsphere Storage PDFDocument367 pagesVsphere Storage PDFNgo Van TruongNo ratings yet

- Beef & Dairy 2016Document36 pagesBeef & Dairy 2016The Standard NewspaperNo ratings yet

- Main Application of Fans and BlowerDocument5 pagesMain Application of Fans and Blowermissy forlajeNo ratings yet

- 2010 - Caliber JEEP BOITE T355Document484 pages2010 - Caliber JEEP BOITE T355thierry.fifieldoutlook.comNo ratings yet

- Solutions for QAT1001912Document3 pagesSolutions for QAT1001912NaveenNo ratings yet

- Gorsey Bank Primary School: Mission Statement Mission StatementDocument17 pagesGorsey Bank Primary School: Mission Statement Mission StatementCreative BlogsNo ratings yet

- Topic 4a Presentation: Types of PatrolDocument4 pagesTopic 4a Presentation: Types of PatrolGesler Pilvan SainNo ratings yet

- Applsci 13 13339Document25 pagesApplsci 13 13339ambroseoryem1No ratings yet

- Fit Friend Business Game StrategiesDocument7 pagesFit Friend Business Game StrategiesSanchit AggarwalNo ratings yet

- Cellular Tower: Bayombong, Nueva VizcayaDocument17 pagesCellular Tower: Bayombong, Nueva VizcayaMonster PockyNo ratings yet

- Arnica The Miracle Remedy - Case RecordsDocument4 pagesArnica The Miracle Remedy - Case Recordskaravi schiniasNo ratings yet

- Online Student Enrollment SystemDocument29 pagesOnline Student Enrollment SystemajidonsonNo ratings yet

- Audiology DissertationDocument4 pagesAudiology DissertationPaperWritingHelpOnlineUK100% (1)

- Workbook. Unit 3. Exercises 5 To 9. RESPUESTASDocument3 pagesWorkbook. Unit 3. Exercises 5 To 9. RESPUESTASRosani GeraldoNo ratings yet

- UK Journal Compares Clove & Rosemary Oil Antibacterial ActivityDocument5 pagesUK Journal Compares Clove & Rosemary Oil Antibacterial ActivityNurul Izzah Wahidul AzamNo ratings yet

- 2020-Effect of Biopolymers On Permeability of Sand-Bentonite MixturesDocument10 pages2020-Effect of Biopolymers On Permeability of Sand-Bentonite MixturesSaswati DattaNo ratings yet

- Wind Hydro 2Document6 pagesWind Hydro 2Vani TiwariNo ratings yet

- Façade Lift PerformanceDocument2 pagesFaçade Lift PerformanceIgor DzuklevskiNo ratings yet