0% found this document useful (0 votes)

850 views12 pagesStructural Anchor Bar Analysis

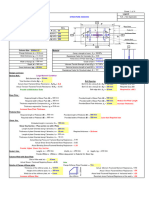

This document provides calculations to check the design of an anchor bar connection embedded in concrete. Key values given include material strengths, design loads, and connection parameters. Calculations are shown to check the required insert plate thickness, capacity of the anchor bar, stresses on welds, and pull-out resistance of the anchor bar. The results indicate the insert plate thickness is not adequate and needs to be increased to 16mm. Otherwise, all other checks show acceptable stresses and capacities.

Uploaded by

Jvv GudboyCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

850 views12 pagesStructural Anchor Bar Analysis

This document provides calculations to check the design of an anchor bar connection embedded in concrete. Key values given include material strengths, design loads, and connection parameters. Calculations are shown to check the required insert plate thickness, capacity of the anchor bar, stresses on welds, and pull-out resistance of the anchor bar. The results indicate the insert plate thickness is not adequate and needs to be increased to 16mm. Otherwise, all other checks show acceptable stresses and capacities.

Uploaded by

Jvv GudboyCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

- Material Strength and Stresses: Covers material properties such as plate thickness and calculated stresses applied on anchor bars.

- Concrete Tension Strength: Describes the concrete tension capacity focusing on depth of embedment and edge effects.

- Connection Parameters: Lists connection parameters including types, dimensions and spacing relevant to anchor bars.

- Anchor Bar Checks and Calculations: Provides detailed formulae and assessments for allowable bending stresses and welding checks for anchor bars.

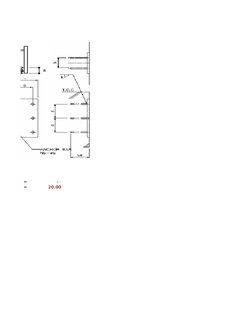

- Graphical Diagram Details: Illustrates diagrammatic representations of stress-related calculations and layout of inserted bars.

- Shear and Design Specifications: Concludes with specific shear values and supporting design handbook references for comprehensive understanding.