Professional Documents

Culture Documents

Angle Grinder

Angle Grinder

Uploaded by

Thomi Habibi0 ratings0% found this document useful (0 votes)

26 views1 pagetTUGAS BAHASA INGGRIS

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumenttTUGAS BAHASA INGGRIS

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

26 views1 pageAngle Grinder

Angle Grinder

Uploaded by

Thomi HabibitTUGAS BAHASA INGGRIS

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

An angle grinder, also known as a side grinder or disc grinder, is a handheld power tool used

for cutting, grinding and polishing.[1]

Angle grinders can be powered by an electric motor, petrol engine or compressed air. The motor

drives a geared head at a right-angle on which is mounted an abrasive disc or a thinner cut-off

disc, either of which can be replaced when worn. Angle grinders typically have an adjustable

guard and a side-handle for two-handed operation. Certain angle grinders, depending on their

speed range, can be used assanders, employing a sanding disc with a backing pad or disc. The

backing system is typically made of hard plastic, phenolic resin, or medium-hard rubber

depending on the amount of flexibility desired.

Angle grinders may be used for removing excess material from a piece. There are many different

kinds of discs that are used for various materials and tasks, such as cut-off discs (diamond

blade), abrasive grinding discs, grinding stones, sanding discs, wire brush wheels and polishing

pads. The angle grinder has large bearings to counter side forces generated during cutting,

unlike a power drill, where the force is axial.

Angle grinders are widely used in metalworking and construction, as well as in emergency

rescues. They are commonly found in workshops, service garages and auto body repair shops.

There is a large variety of angle grinders to choose from when trying to find the right one for the

job. The most important factors in choosing the right grinder are the disc size and how powerful

the motor is. Other factors include power source (pneumatic or electric), rpm, and arbor size.

Generally disc size and power increase together. Disc size is usually measured in inches or

millimetres. Common disc sizes for angle grinders in the U.S.A. include 4, 4.5, 5, 6, 7, 9 and

12 inches. Discs for pneumatic grinders also come much smaller. Pneumatic grinders are

generally used for lighter duty jobs where more precision is required. This is likely because

pneumatic grinders can be small and light yet remain powerful, because they do not contain

heavy copper motor windings, while it is harder for an electric grinder to maintain adequate

power with smaller size. Electric grinders are more commonly used for larger, heavy duty jobs.

However, there are also small electric grinders and large pneumatic grinders.

Through a sound pressure level and vibrations study conducted by the National Institute for

Occupational Safety and Health, grinders under an unloaded condition ranged from 91 to

103 dBA.[2] In addition, angle grinders produce sparks when cutting ferrous metals. They also

produce shards cutting other materials. The blades themselves may also break. This is a great

hazard to the face and eyes especially, as well as other parts of the body, and as such, a full face

shield and other protective clothing must be worn. Angle grinders should never be used without

their guard or handle attached; they are there as a necessary precaution for safety. All work

should be securely clamped or held firmly in a vice.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Recreational Drugs Professor BuzzDocument64 pagesRecreational Drugs Professor BuzzGiovanni Mictil100% (1)

- Citizen B12VIDocument4 pagesCitizen B12VIIonut-Catalin DimacheNo ratings yet

- BSL3 Design GuidelinesDocument17 pagesBSL3 Design GuidelinesharishupretiNo ratings yet

- F806faa Flexible PavementDocument24 pagesF806faa Flexible PavementWaqas Muneer Khan0% (1)

- Mould Wax en PDFDocument2 pagesMould Wax en PDFAnupam GhoshNo ratings yet

- Project: Client: Consultant: Contractor: TitleDocument7 pagesProject: Client: Consultant: Contractor: TitleLokeswara Sri hariNo ratings yet

- Chapt1 Computer ArchitectureDocument50 pagesChapt1 Computer ArchitecturePetro BahaNo ratings yet

- Concrete Manure TanksDocument4 pagesConcrete Manure Tanksshivas34regalNo ratings yet

- Nonreinforced Concrete Sewer, Storm Drain, and Culvert Pipe: Standard Specification ForDocument5 pagesNonreinforced Concrete Sewer, Storm Drain, and Culvert Pipe: Standard Specification ForRobbi Shobri RakhmanNo ratings yet

- SAE Flat Washer Dimensions & Specifications - AFT FastenersDocument1 pageSAE Flat Washer Dimensions & Specifications - AFT FastenersKai LinNo ratings yet

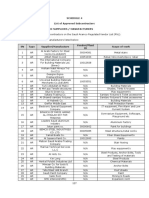

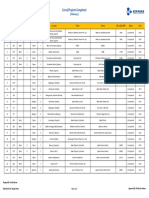

- List of Approved SubcontractorsDocument6 pagesList of Approved Subcontractorsmohammad abu alrubNo ratings yet

- Surface TensionDocument28 pagesSurface TensionNur Sofia0% (2)

- Equipment IndexDocument48 pagesEquipment IndexBagus Deddy AndriNo ratings yet

- StaticsDocument30 pagesStaticsJm Beja100% (1)

- List of Projects CompletedDocument15 pagesList of Projects CompletedRohit SharmaNo ratings yet

- Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingDocument5 pagesSafety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingWitara SajaNo ratings yet

- Amc CR 650 PDSDocument1 pageAmc CR 650 PDSShooWin Allen JohnNo ratings yet

- B S RDocument7 pagesB S RAbdul Rashid QureshiNo ratings yet

- Epikote Resin 828Document2 pagesEpikote Resin 828Dorleans NjinkeuNo ratings yet

- Zest BarDocument2 pagesZest Barrita.baharian2663No ratings yet

- Inorganic "Metallic" Finishes, Processes, and EquipmentDocument29 pagesInorganic "Metallic" Finishes, Processes, and EquipmenthaisamdoNo ratings yet

- EUBP PP Plastics StrategyDocument2 pagesEUBP PP Plastics StrategyDonato GalloNo ratings yet

- Ms 01 147 PDFDocument17 pagesMs 01 147 PDFrinthusNo ratings yet

- Tool Room Project ReportDocument49 pagesTool Room Project Reportlokeshkrkushwaha67% (3)

- Ni Energy ConsumptionDocument10 pagesNi Energy ConsumptionjokanovNo ratings yet

- MAPEH (Health) : Quarter 1 - Module 2: Community Health ProblemsDocument21 pagesMAPEH (Health) : Quarter 1 - Module 2: Community Health ProblemsKhian Francois Rivera Salalila100% (1)

- Ccad-Aed-Sp - G-213100 - 0 - Fire Pumps PDFDocument5 pagesCcad-Aed-Sp - G-213100 - 0 - Fire Pumps PDFArun UdayabhanuNo ratings yet

- KaoliniteDocument2 pagesKaoliniteMarino ObsivacNo ratings yet

- Ankit Dwivedi: Career Summary - Total of 1 Year 6 Months ExperienceDocument3 pagesAnkit Dwivedi: Career Summary - Total of 1 Year 6 Months ExperienceAnkit DwivediNo ratings yet

- Pipe-Jacking: State-Of-The Art in UK and EuropeDocument16 pagesPipe-Jacking: State-Of-The Art in UK and EuropeMilagros Alvarez SanzNo ratings yet