Professional Documents

Culture Documents

2 10 PDF

2 10 PDF

Uploaded by

Hardik JainOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2 10 PDF

2 10 PDF

Uploaded by

Hardik JainCopyright:

Available Formats

Machine Design II

Prof. K.Gopinath & Prof. M.M.Mayuram

Module 2 - GEARS

Lecture 10 - SPUR GEAR DESIGN

Contents

10.1 Problem 3 Spur gear design

10.1.1 Buckingham Approach

10.1.2 AGMA Approach

10.1 Problem 3 - Design of Spur gear

A pair of gears is to be designed to transmit 30kW power from a pinion running at

960rpm to a gear running at 320rpm. Design the gears so that they can last for 108

cycles. Assume 20o full depth involute spur gear for the system. Motor shaft diameter is

30mm.

Data given:

W = 30 kW; n 1 = 960 rpm; n 2 = 320 rpm; Life = 108 cycles; 20o full depth involute spur

gear.

Solution:

i = n 1 / n 2 = 960 / 320 = 3

In order to keep the size small and meet the centre distance, Z 1 = 17 chosen

Z 2 = i Z 1 = 3 x 17 = 51

2n1 2 x x 960

100.48 rad/s

60

60

Torque is given by,

T1

w 30x1000

298.57 Nm

100.48

Indian Institute of Technology Madras

Machine Design II

Prof. K.Gopinath & Prof. M.M.Mayuram

From Lewis equation for pinion we have,

p

Ft

2T1

[]p

b Y m bYZ1m 2

(10.1)

SAE 1050 hardened by OQT with permissible bending strength of 532 and hardness of

223Bhn is selected for pinion and SAE 1045 hardened by WQT with permissible

bending strength of 487 and hardness of 215 Bhn is selected for the gear from Table

10.1. Face width b = 10m is chosen for both wheels.

Table 10.1 Safe static stresses for use in the Lewis equation

Material

[ ] MPa

BHN

Gray cast iron

ASTM 25

ASTM 35

ASTM 50

122

183

228

174

212

223

Cast steel(low carbon)

0.2% C not heat treated

0.2% C WQT

304

380

180

250

Forged carbon steel

SAE 1020 case hardened and WQT

SAE 1030 not heat treated

SAE 1035 not heat treated

SAE 1040 not heat treated

SAE 1045 hardened by WQT

SAE 1045 hardened by WQT

SAE 1050 hardened by OQT

274

304

350

380

456

487

532

156

180

190

202

205

215

223

Alloy steel

SAE 2320 case hardened and WQT

SAE 2345 hardened by OQT

SAE 3115 case hardened and OQT

SAE 3145 hardened by OQT

SAE 3245 hardened by OQT

SAE 4340 hardened by OQT

SAE 4640 hardened by OQT

SAE 6145 hardened by OQT

761

761

563

806

989

989

837

1019

225

475

212

475

475

475

475

475

Indian Institute of Technology Madras

Machine Design II

Prof. K.Gopinath & Prof. M.M.Mayuram

10.1.1 Buckingham approach:

The preliminary dimensions are found from Lewis equation and then they are checked

for dynamic loads by Buckingham equation.

From equation (10.1) substituting the value of b = 10m, we have,

T1

[]p

5YZ1m3

(10.2)

From Table 10.2, for the pinion Y = 0.25808 for Z 1 = 17

For the gear, Y = 0.39872, for Z 2 = 51

For gear, Y[] g = 0.39872x 487 = 194.17

For pinion, Y[] p = 0.25808 x 542 = 139.87

Table 10.2 Values of the Lewis form factor Y

Number of

teeth

12

13

14

15

16

17

18

19

20

21

22

24

26

28

30

34

38

45

50

60

75

100

Indian Institute of Technology Madras

=20

a=0.8m*

b=m

0.335 12

0.348 27

0.359 85

0.370 13

0.379 31

0.387 57

0.395 02

0.401 79

0.407 97

0.413 63

0.418 83

0.428 06

0.436 01

0.442 94

0.449 20

0.459 20

0.467 40

0.478 46

0.484 58

0.493 91

0.503 45

0.513 21

=20

a=m

b=1.25m

0.229 60

0.243 17

0.255 30

0.266 22

0.276 10

0.285 08

0.293 27

0.300 78

0.307 69

0.314 06

.0319 97

0.330 56

0.339 79

0.347 90

0.355 10

0.367 31

0.377 27

0.390 93

0.398 60

0.410 47

0.422 83

0.435 74

=25

a=m

b=1.25m

0.276 77

0.292 81

0.307 17

0.320 09

0.331 78

0.342 40

0.352 10

0.360 99

0.369 16

0.376 71

0.383 70

0.396 24

0.407 17

0.416 78

0.425 30

0.439 76

0.451 56

0.467 74

0.476 81

0.490 86

0.505 46

0.520 71

Machine Design II

Prof. K.Gopinath & Prof. M.M.Mayuram

Hence, for the same face width pinion will be weaker and consideration for the design

is,

T

298.57 x1000

13610

3

3

5YZ1m 5x0.25808 x17m

m3

532 MPa

(10.3)

m = 2.93 mm. Since motor shaft diameter is 30 mm, to get sufficiently large pinion m = 4

mm is taken.

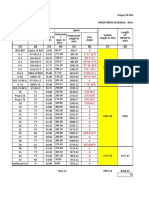

Table 10.3 Data for pinion and gear

Wheel

b=10m

Pinion 17 4mm 40 mm

Gear

d

68mm

V =wrv

Material

Hardness

3.42 m/s SAE1050

223

51 4mm 40 mm 204mm 3.42 m/s SAE1045

215

We will now use Buckingham dynamic load approach for the design.

F t = T 1 /r 1 = 298.57/0.034 = 8781 N

Buckingham dynamic load is given by,

9.84V (Cb + Ft )

Fi

9.84V +0.4696 Cb+ Ft

(10.4)

For V=3.42 m/s permissible error is e= 0.088 mm from Fig.10.1. From Table 10.4, if we

choose I class commercial cut gears, expected error is 0.050 for m=4mm. In order to

keep the dynamic load low precision cut gears are chosen. So, e = 0.0125

Indian Institute of Technology Madras

Machine Design II

Prof. K.Gopinath & Prof. M.M.Mayuram

Fig. 10.1 Permissible error

Table 10.4 Expected error in tooth profile

Gear quality and expected error e

Module

First class commercial

Carefully cut gears

Precision gears

gears

Up to 4

5

6

7

8

9

10

0.050

0.056

0.064

0.072

0.080

0.085

0.090

0.025

0.025

0.030

0.035

0.038

0.041

0.044

Table 10.5 Value of C

Material of pinion and

Tooth form

gear

14.5o

0.0125

0.0125

0.0150

0.0170

0.0190

0.0205

0.0220

Cast iron and cast iron

steel and cast iron

steel and steel

5720 e

7850 e

11440 e

20o Full depth Cast iron and cast iron

steel and cast iron

steel and steel

5930 e

8150 e

11860 e

20o Stub

tooth

6150 e

8450 e

12300 e

Cast iron and cast iron

steel and cast iron

steel and steel

From Table 10.5, if material for both gear and pinion are steel, then,

Indian Institute of Technology Madras

Machine Design II

Prof. K.Gopinath & Prof. M.M.Mayuram

C = 11860e = 11860 x 0.0125 = 148.25

Substituting the values F t = 8781 N, C = 148 .25, V=3.42 m/s, b= 40mm in eqn. (10.4),

Buckingham dynamic load is given by,

9.84x3.42(148.25x40 +8781)

Fi

5464N

9.84x3.42+0.4696 148.25x40+8781

(10.5)

F d = F t + F i = 8781 + 5464 = 14245 N

Beam strength of the pinion is given by,

F tp = bYm [] p = 40x0.25808 x4x542 = 22381 N

Since F tp (22381)> F d (14245) the design is safe from tooth bending failure

consideration.

Wear strength of the pinion is given by,

[ ]

Fts bd1 I H

Cp

(10.6)

From Table 10.6 for steel vs steel, pinion and gear C p = 191 MPa0.5 and substituting i

=3, =200 we

I

sin cos i

sin 20o cos 20o 3

0.1205

2

i 1

2

3 1

Table 10.6 Elastic coefficient C p for spur gears in MPa0.5

Pinion Material

(=0.3 in all cases)

Gear Material

Steel

Cast iron

Al Bronze

Tin Bronze

Steel, E=207 GPa

191

166

162

158

Cast iron, E=131 GPa

166

149

149

145

Al Bronze, E=121 GPa

162

149

145

141

Tin Bronze, E=110

GPa

158

145

141

137

Indian Institute of Technology Madras

Machine Design II

Prof. K.Gopinath & Prof. M.M.Mayuram

Surface fatigue strength of the pinion material is sf = sf K L K R K T

sf = 2.8(Bhn) 69MPa

= 2.8 x 223-69 = 555.4MPa

K L = 0.9 for 108 cycles life from graph1

K R = 1.0 taken for 99 reliability

K T = 1.0 for operating temperature <120oC (assumed)

Table 10.7 Surface fatigue strength sf (MPa) for metallic spur gears (107 cycle

life 99% reliability and temperature <120oC)

Material

sf (MPa)

Steel

2.8 (Bhn)-69MPa

Nodular iron

0.95(2.8(Bhn)-69MPa)

Cast iron, grade 20

379

Cast iron, grade 30

482

Cast iron, grade 40

551

Tin Bronze, AGMA 2C (11% Sn)

207

Aluminium Bronze (ASTM 148 52) (Alloy 9C H.T.)

448

Fig.10.2 Life factor K L

Indian Institute of Technology Madras

Machine Design II

Prof. K.Gopinath & Prof. M.M.Mayuram

Table 10.8 Reliability factor K R

Reliability (%)

KR

50

1.25

99

1.00

99.9

0.80

Surface fatigue strength of the pinion material is sf = sf K L K R K T

= 555.4x0.9x1x1 = 500MPa

Assuming, factor of safety, s = 1.1

[ H ] = sf /s = 500/1.1 = 455MPa

Wear strength of the pinion is:

2

2

[ ]

455

Fts = bd1 I H = 40x68x0.1205

=1860 N

Cp

191

Since F ts (1860) << F d (14245), the design is not safe. Revision is necessary.

As the SAE1050 can attain a hardness of 800 VPN(~750 Bhn) after oil quenching,

increase the hardness to 475 Bhn and increase the b to 13m

= 13 x 4 = 52 mm.

From Table 10.7, we know that,

sf = 2.8(Bhn) 69MPa

= 2.8 x 475-69 = 1261MPa

K L = 0.9 for 108 cycles life from Fig.10.1

K R = 1.0 taken for 99 reliability

K T = 1.0 for operating temperature <120oC Assumed.

Surface fatigue strength of the pinion material is sf = sf K L K R K T

= 1261x0.9x1x1 = 1135MPa

Indian Institute of Technology Madras

Machine Design II

Prof. K.Gopinath & Prof. M.M.Mayuram

Fig.10.3 Effect of carbon content on the hardness of fully hardened steel

Assuming factor of safety, s = 1.1

[ H ] = sf /s = 1135 /1.1 = 1032MPa

2

2

[ ]

1032

Fts = bd1 I H = 52x68x0.1205

=12439 N

C

191

Since F ts (12439)< F d (14245), still it is not safe. Hence increase the module to 5mm.

Table 10.9 Properties of pinion and gear

Wheel

b=13m

V =wrv

85mm

4.27 m/s

C 50

475

51 5mm 65 mm 255mm 4.27 m/s

C 45

450

Pinion 17 5mm 65 mm

Gear

Indian Institute of Technology Madras

Material Hardness

Machine Design II

Prof. K.Gopinath & Prof. M.M.Mayuram

With new dimensions F d = 16098 N

F ts = 19436 N. Since F ts > F d , the revised design is safe from surface fatigue (pitting)

considerations.

If b = 50 mm, F d = 13186 N

F ts = 14951 N , Face width of 50 mm is adequate

10.1.2 AGMA Approach

Data given:

W = 30 kW; n 1 = 960 rpm; n 2 = 320 rpm; Life = 108 cycles; 20o full depth involute spur

gear.

Solution:

i = n 1 / n 2 = 960 / 320 = 3

In order to keep the size of gears small and avoid interference, Z 1 = 17 is chosen.

Z 2 = i Z 1 = 3 x 17 = 51

1 =

T1

2n1 2x960

100.48rad / s

=

60

60

1000W 1000x30

298.57 Nm

1

100.48

AGMA equation for tooth bending stress is,

Ft

K K K

bmJ v o m

d1 = m Z1

2T1

K K K [ ]

b Z1 m 2 J v o m

Face width, b= 10 to 13 m.

Indian Institute of Technology Madras

Machine Design II

Prof. K.Gopinath & Prof. M.M.Mayuram

b = 10 m is assumed for the first trial.

J = 0.34404 for pinion Z 1 = 17 mating with gear Z 2 =51

For gear J = 0.40808

These values are obtained from the table

Table 10.10 AGMA geometry factor J for teeth having = 20o, a=1m, b=1.25m and

r f =0.300m

Number

of teeth

Number of teeth in mating gear

1

17

25

35

50

85

300

1000

18

0.244 86 0.324 04 0.332 12 0.338 40 0.344 04 0.350 50 0.355 94 0.361 12

19

0.247 94 0.330 29 0.338 78 0.345 37 0.351 34 0.358 22 0.364 05 0.369 63

20

0.250 72 0.336 00 0.344 85 0.351 76 0.358 04 0.365 32 0.371 51 0.377 49

21

0.253 23 0.341 24 0.350 44 0.357 64 0.364 22 0.371 86 0.378 41 0.384 75

22

0.255 52 0.346 07 0.355 59 0.363 06 0.369 92 0.377 92 0.384 79 0.391 48

24

0.259 51 0.354 68 0.364 77 0.372 75 0.380 12 0.388 77 0.396 26 0.403 60

26

0.262 89 0.362 11 0.372 72 0.381 15 0.388 97 0.398 21 0.406 25 0.414 18

28

0.265 80 0.368 60 0.379 67 0.388 51 0.396 73 0.406 50 0.415 04 0.423 51

30

0.268 31 0.374 62 0.385 80 0.395 00 0.403 59 0.413 83 0.422 83 0.431 79

34

0.272 47 0.383 94 0.396 71 0.405 94 0.415 17 0.426 24 0.436 04 0.445 86

38

0.275 75 0.391 70 0.404 46 0.414 80 0.424 56 0.436 33 0.446 80 0.457 35

45

0.280 13 0.402 23 0.415 79 0.426 85 0.437 35 0.450 10 0.461 52 0.473 10

50

0.282 52 0.408 08 0.422 08 0.435 55 0.444 48 0.457 78 0.469 75 0.481 93

60

0.286 13 0.417 02 0.431 73 0.443 83 0.455 40 0.469 60 0.482 43 0.495 57

75

0.289 79 0.426 20 0.441 63 0.454 40 0.466 68 0.481 79 0.495 54 0.509 70

100

0.293 13 0.435 61 0.451 80 0.465 27 0.478 27 0.494 37 0.509 09 0.524 35

150

0.297 38 0.445 30 0.462 26 0.476 45 0.490 23 0.507 36 0.523 12 0.539 54

300

0.301 41 0.455 26 0.473 04 0.487 98 0.502 78 0.520 78 0.537 65 0.555 33

Rack

0.305 75 0.465 54 0.484 15 0.499 88 0.534 67 0.534 67 0.552 72 0.571 73

The tooth bending stress is given by,

78 (200V) 0.5

Kv

78

Indian Institute of Technology Madras

0.5

1.15

is assumed.

Machine Design II

Prof. K.Gopinath & Prof. M.M.Mayuram

K o = 1.25 is taken assuming uniform power source and moderate shock load from the

table 7

K m = 1.3 assuming accurate mounting and precision cut gears for face width of about

50mm.

Table 10.11 -Overload factor K o

Driven Machinery

Source of power Uniform Moderate Shock Heavy Shock

Uniform

1.00

1.25

1.75

Light shock

1.25

1.50

2.00

Medium shock

1.50

1.75

2.25

Table 10.12 Load distribution factor K m

Face width ( mm)

Characteristics of Support

Accurate mountings, small bearing

0 - 50

150

225

400 up

1.3

1.4

1.5

1.8

1.6

1.7

1.8

2.2

Over

Over

Over

Over

2.2

2.2

2.2

2.2

clearances, minimum deflection, precision

gears

Less rigid mountings, less accurate gears,

contact across the full face

Accuracy and mounting such that less than

full-face contact exists

Substituting these values in the equation,

1

2T1

298570 x1.15 x1.25 x1.3

Kv Ko Km

2

10m x17xm 2 x 0.34404

b Z1 m J

9539

m3

Indian Institute of Technology Madras

Machine Design II

Prof. K.Gopinath & Prof. M.M.Mayuram

e = e kL kv ks kr kT kf km

The pinion is of steel C50 OQT with 223Bhn hardness and tensile strength of 660MPa

and the gear is of C45 OQT with hardness 210Bhn and tensile strength of 465MPa.

For pinion e = 0.5 ut = 0.5 x 660 = 330MPa

k L = 1 for bending, k V = 1 assumed expecting m to be <5mm; k S = 0.73 from the

Fig.10.4 for ut = 660MPa, k r = 0.897 for 90% reliability

Fig. 10. 4 Surface factor k s

Table 10.13 Reliability factor K r

Reliability factor R

0.50

0.90

0.95

0.99

0.999

0.9999

Factor Kr

1.000

0.897

0.868

0.814

0.753

0.702

kT =1 assumed based on operating temperature <120oC

kf = 1.- and km = 1.33 for ut= 660MPa

( Ultimate tensile strength = 660 MPa for

SAE 1050 OQT condition)

e

= e kL kv ks kr kT kf km

= 330x1x1x0.73x0.897x1x1x1.33 = 287.4MPa

Factor of safety on bending of 1.5 assumed

Indian Institute of Technology Madras

Machine Design II

Prof. K.Gopinath & Prof. M.M.Mayuram

[] = e / s = 287.4 / 1.5 =191.6MPa

Fig.10.5 - Miscellaneous effects factor km

From tooth bending fatigue considerations,

9539

[ ] 191.6

m3

Solving the equation we get m = 3.68mm

Now take m=4 mm as the next standard value. From this module, the dimensions

calculated are given in Table 10.14.

Table 10.14 Dimensions of pinion and gear

Wheel

b=10m

V =wrv

68mm

3.42 m/s

C 50

223

51 4mm 40 mm 204mm 3.42 m/s

C 45

205

Pinion 17 4mm 40 mm

Gear

Material Hardness

Ft = T1 / r1 = 29857/34 = 8781N

The tooth has to be checked from surface durability considerations now.

The contact stress equation of AGMA is given below:

H Cp

Ft

KV Ko Km

bd1 I

Cp = 191 MPa0.5 from the table for steel vs steel

Indian Institute of Technology Madras

Machine Design II

Prof. K.Gopinath & Prof. M.M.Mayuram

Substituting i =3, =200 we get I= 0.1205

sin cos i

sin 20o cos 20o 3

I

0.1205

2

i 1

2

3 1

78 (200V) 0.5

Kv

78

0.5

78 (200x3.42) 0.5

78

0.5

1.15

From Table 10.11 and 10.12,

Ko = 1.25 and Km = 1.3 assumed as in the case of bending stress calculation

H Cp

Ft

8781x1.15x1.25x1.3

K V K o K m 191

bd1 I

40x68x0.1205

H = 1209MPa

The surface fatigue strength of the pinion material is given by,

sf = sf KL KR KT

Where sf = 2.8(Bhn) 69MPa

= 2.8 x 223-69 = 555.4MPa

KL= 0.9 for 108 cycles life from graph1

KR = 1.0 taken for 99% reliability

KT = 1.0 for operating temperature <120oC assumed.

Substituting the values in the equation,

sf = sf KL KR KT

= 555.4x0.9x1x1 = 500MPa

Assuming a factor of safety, s = 1.1

From Fig. 10.2 and Table 10.8, we get,

[H] = sf /s = 500/1.1 = 455MPa

H = 1209MPa

Indian Institute of Technology Madras

Machine Design II

Prof. K.Gopinath & Prof. M.M.Mayuram

Since H (1209) >> [H] (455), the design is not safe and surface fatigue failure will

occur.

Solution:

Increase the surface hardness of the material to 475Bhn and also increase the b to 13m

= 13 x 4 = 52 mm

From Fig. 3 we get,

Surface fatigue strength of the pinion material as

sf = sf KL KR KT

where sf = 2.8(Bhn) 69MPa = 2.8 x 475-69 = 1261MPa

KL= 0.9 for 108 cycles life from graph1

KR = 1.0 taken for 99% reliability

KT = 1.0 for operating temperature <120oC Assumed.

Substituting these values we get,

sf = sf KL KR KT

= 1261x0.9x1x1 = 1135MPa

Assuming a factor of safety s = 1.1

[H] = sf /s = 1135 /1.1 = 1032MPa

H Cp

Ft

8781x1.15x1.25x1.3

K V K o K m 191

b d1 I

52x68x0.1205

As H (1185) > [H] (1032) the design is not safe from surface durability considerations.

Hence increase the module to 5mm and take b=10m

H Cp

Ft

7025x1.17x1.25x1.3

K V K o K m 191

bd1 I

50x85x0.1205

Indian Institute of Technology Madras

Machine Design II

Prof. K.Gopinath & Prof. M.M.Mayuram

H =975MPa < [H ] (1032MPa). Hence the design is safe from surface durability

consideration. Final specification of the pinion and gear are given in the Table 10.20

and 10.21.

Table 10.20 Values for gear and pinion

Wheel

b=10m

Pinion

17

5mm

50 mm

85mm

Gear

51

5mm

50 mm

255mm

Table 10.21 Specification of gear and pinion

Wheel

Material Steel

Hardness Manufacturing quality

Pinion

SAE1050 OQT

475Bhn

Precision cut

Gear

SAE 1045 OQT

450Bhn

Precision cut

-------------------

Indian Institute of Technology Madras

You might also like

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- F. Reif - Fundamentals of Statistical and Thermal Physics PDFDocument333 pagesF. Reif - Fundamentals of Statistical and Thermal Physics PDFAllan SeeberNo ratings yet

- Kesten Chapter 9 10.24Document28 pagesKesten Chapter 9 10.24Jzaross JosephNo ratings yet

- Steel Construction With TrussesDocument6 pagesSteel Construction With TrussesNero PereraNo ratings yet

- Rocker Bogie CalculationsDocument13 pagesRocker Bogie Calculationsravi100% (2)

- SCR Heat Exchanger Design 2018 For NO PHASE CHANGEDocument37 pagesSCR Heat Exchanger Design 2018 For NO PHASE CHANGEAnonymous 1uUqRkc9p8100% (1)

- Internal GearsDocument4 pagesInternal GearsBranislav DjordjevicNo ratings yet

- PowerPack+brochure+ (V1 0)Document2 pagesPowerPack+brochure+ (V1 0)Khánh VũNo ratings yet

- Cbs CatalogueDocument195 pagesCbs Cataloguemadaboutalfa8168No ratings yet

- Design of Machine Members II R5320305 Set 3Document2 pagesDesign of Machine Members II R5320305 Set 3Ravi Kumar KamarthiNo ratings yet

- Note On Gear BoxDocument32 pagesNote On Gear BoxanupbagNo ratings yet

- Dozer: Engine WeightsDocument28 pagesDozer: Engine WeightssafvafNo ratings yet

- Spur GearDocument11 pagesSpur GearvenkatkavinNo ratings yet

- Hydraulic Cone Crusher PDFDocument16 pagesHydraulic Cone Crusher PDFJanethDeNunuraNo ratings yet

- Gears: Looking For GATE Preparation Material? Join & Get Here Now!Document8 pagesGears: Looking For GATE Preparation Material? Join & Get Here Now!Akash SoniNo ratings yet

- Rotating TrolleyDocument12 pagesRotating TrolleyInderdeep TatlaNo ratings yet

- 15ME3112 Design of Machine ElementsDocument29 pages15ME3112 Design of Machine Elementslikhith saiNo ratings yet

- NIS Bearing Units Cataloguexsx BgsssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssDocument162 pagesNIS Bearing Units Cataloguexsx BgsssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssEsca Dwi Nugroho33% (3)

- TS 5 Transfer SystemDocument246 pagesTS 5 Transfer SystemSantosh DengleNo ratings yet

- Roller Chains - ENGDocument122 pagesRoller Chains - ENGPok Jak SallehNo ratings yet

- ABB CatalogueDocument6 pagesABB CatalogueNavneet SinghNo ratings yet

- Mac ListDocument13 pagesMac ListHariman SallehNo ratings yet

- 3220-CRN-001 - 5t X 8.5m Arm X 30m HOL Pillar Jib Crane - GA Drawing PDFDocument1 page3220-CRN-001 - 5t X 8.5m Arm X 30m HOL Pillar Jib Crane - GA Drawing PDFpawan100% (1)

- Fenner Dual Duty Pulley With Taper Lock Bush: A / Spa C / SPC 8V Timing PulleyDocument3 pagesFenner Dual Duty Pulley With Taper Lock Bush: A / Spa C / SPC 8V Timing PulleyPankaj Pandey100% (1)

- Catalogo - Generale - 2016 - ENG Escavatori SXNC093A16.compressed PDFDocument29 pagesCatalogo - Generale - 2016 - ENG Escavatori SXNC093A16.compressed PDFFlorin SpiridonNo ratings yet

- Spec Plummer Block BearingDocument2 pagesSpec Plummer Block BearingSithipol PoprayoonNo ratings yet

- Z M B (MM) N H (Hours) : Gear Design (Is-4460) (Spur or Helical)Document16 pagesZ M B (MM) N H (Hours) : Gear Design (Is-4460) (Spur or Helical)Babu RajamanickamNo ratings yet

- Lecture 16 - Worm Gears Worked Out ProblemsDocument19 pagesLecture 16 - Worm Gears Worked Out ProblemsApurba haldar50% (2)

- Gear Terminology: Pitch Circle: Addendum Circle: Dedendum Circle: ClearanceDocument11 pagesGear Terminology: Pitch Circle: Addendum Circle: Dedendum Circle: ClearanceFawad HassanNo ratings yet

- Ramsey Conveyor Protection SwitchesDocument6 pagesRamsey Conveyor Protection SwitchesArif AmirNo ratings yet

- Design of Main GirderDocument58 pagesDesign of Main GirderovikbasuNo ratings yet

- AMW 1618 TipperDocument11 pagesAMW 1618 TipperMohanraj VenuNo ratings yet

- Hydraulic Power Pack Minipack HPM TG2 XXX X S N N 05S C18CDDocument1 pageHydraulic Power Pack Minipack HPM TG2 XXX X S N N 05S C18CDjuniorNo ratings yet

- DesignDocument4 pagesDesignJigneshkumar PatelNo ratings yet

- 123456Document34 pages123456ankitsarvaiyaNo ratings yet

- Roller Conveyor Chain AttachmentsDocument19 pagesRoller Conveyor Chain AttachmentsRichard VachonNo ratings yet

- General Design RequirementsDocument8 pagesGeneral Design RequirementsRohit ShresthaNo ratings yet

- Gundlach Roll Crushers BrochureDocument2 pagesGundlach Roll Crushers Brochurerajeevup2004No ratings yet

- Screw Feeder CalculationDocument5 pagesScrew Feeder CalculationHirenNo ratings yet

- Vertical and Horizontal Screw ConveyorsDocument4 pagesVertical and Horizontal Screw ConveyorsLLNo ratings yet

- 2013 Wright Specifications CatalogDocument189 pages2013 Wright Specifications CatalogcenicercNo ratings yet

- E1102m PDFDocument283 pagesE1102m PDFBhawani Singh RajawatNo ratings yet

- EMCO Electro - Hydraulic Drum BrakeDocument7 pagesEMCO Electro - Hydraulic Drum Brakehardik033No ratings yet

- Gearbox SuperDocument15 pagesGearbox Super10delpiNo ratings yet

- Full CatalogDocument92 pagesFull CatalogYip Ying MunNo ratings yet

- Power LockDocument88 pagesPower Lockash remoNo ratings yet

- Tehnicki Vodic PDFDocument273 pagesTehnicki Vodic PDFSlaven Dadan-NanoNo ratings yet

- Jaw Crusher For Primary Crushing - Fote Heavy MachineryDocument18 pagesJaw Crusher For Primary Crushing - Fote Heavy MachineryIvy100% (1)

- NORD Universal Worm Gear Units CatalogueDocument101 pagesNORD Universal Worm Gear Units CatalogueJ Jick PerSeiNo ratings yet

- Profile CalculationDocument13 pagesProfile CalculationAtsis PapadopoulosNo ratings yet

- Dmu 60 / 80 / 100 Monoblock Classic Series: CNC Universal Milling MachinesDocument24 pagesDmu 60 / 80 / 100 Monoblock Classic Series: CNC Universal Milling MachinesButch BorjaNo ratings yet

- Cat 390DLDocument32 pagesCat 390DLLenin ValerioNo ratings yet

- Wheel Model 6 CatalogDocument40 pagesWheel Model 6 CatalogHernan LopezNo ratings yet

- Renold Chain CatalogueDocument24 pagesRenold Chain CatalogueThang NguyenNo ratings yet

- Sepction - 3Document3 pagesSepction - 3k koradiaNo ratings yet

- WND Petrojet NDT RT and PWHT Unit RatesDocument4 pagesWND Petrojet NDT RT and PWHT Unit RatesAhmed al-sheaikhNo ratings yet

- WeldingDocument1 pageWeldingNNo ratings yet

- Vulcan Industrial Engineering Co. Pvt. LTDDocument3 pagesVulcan Industrial Engineering Co. Pvt. LTDk koradiaNo ratings yet

- PAK AMIN PARAMETRIkDocument525 pagesPAK AMIN PARAMETRIkandratheshithandNo ratings yet

- Compression & Biaxial Bending IS 800 2007Document22 pagesCompression & Biaxial Bending IS 800 2007Anirban BhattacharjeeNo ratings yet

- MS SheetDocument57 pagesMS SheetPradeep AnuradhaaNo ratings yet

- Type A Tower-2 4th Floor Beam BBSDocument24 pagesType A Tower-2 4th Floor Beam BBSsandeep1995kasettyNo ratings yet

- OPGW Drum ScheduleDocument5 pagesOPGW Drum SchedulePrabhakar SvNo ratings yet

- HW 8Document1 pageHW 8Muhammad WaqasNo ratings yet

- NUST Hostel Admission Form New PDFDocument2 pagesNUST Hostel Admission Form New PDFMuhammad Waqas0% (1)

- Fire Damper PDFDocument20 pagesFire Damper PDFMuhammad WaqasNo ratings yet

- Ishq Ka SheenDocument271 pagesIshq Ka Sheenroadsign100% (3)

- Module 2 - GEARS Lecture - 4: Worked Out Problems On Involute Spur GearsDocument8 pagesModule 2 - GEARS Lecture - 4: Worked Out Problems On Involute Spur GearsMuhammad WaqasNo ratings yet

- Spur GearDocument12 pagesSpur GearIsrael CeballosNo ratings yet

- Shiglay SM ch17Document33 pagesShiglay SM ch17Muhammad WaqasNo ratings yet

- Asme 46.1 2001Document25 pagesAsme 46.1 2001jr_satish6965No ratings yet

- Anvisa Ba Be Guideline IIDocument170 pagesAnvisa Ba Be Guideline IIdrsmitaNo ratings yet

- Solbin Brochure 2.2014RS PDFDocument12 pagesSolbin Brochure 2.2014RS PDFHandonoZchvaniaAgustyNo ratings yet

- Cdu Unit Chemistry Informal Diagnostics: Grade Level: 9 Stream: ADV The Year 2023/2024Document27 pagesCdu Unit Chemistry Informal Diagnostics: Grade Level: 9 Stream: ADV The Year 2023/2024alshamsi5001010No ratings yet

- ICMIEE 2020 Template PaperDocument3 pagesICMIEE 2020 Template PaperFarhan AnjumNo ratings yet

- Tuv Rheinland Morocco Voc Productlist en v2Document92 pagesTuv Rheinland Morocco Voc Productlist en v2scagiranNo ratings yet

- Synozol Red HF-6BN 150% (Eng)Document5 pagesSynozol Red HF-6BN 150% (Eng)Jomar OroscoNo ratings yet

- Wang 2012Document5 pagesWang 2012Carmen AguilarNo ratings yet

- Semiconductor Theory and DiodeDocument7 pagesSemiconductor Theory and DiodeStefon BishopNo ratings yet

- Greening Textile Industry in Vietnam PDFDocument332 pagesGreening Textile Industry in Vietnam PDFJuan CubasNo ratings yet

- Astm E1131 08 Tga PDFDocument5 pagesAstm E1131 08 Tga PDFThomas Sørensen Quaade100% (1)

- GS Circulating: ISO VG 100, 150Document1 pageGS Circulating: ISO VG 100, 150Axel Mahya AvichenaNo ratings yet

- Whatvespprpstphys N16 P1 PDFDocument15 pagesWhatvespprpstphys N16 P1 PDFjszNo ratings yet

- Gptms + Sio2 + Mtms + FasDocument6 pagesGptms + Sio2 + Mtms + FasTamilarasiNo ratings yet

- Osborne Reynold'S Demonstration: Experiment No. - 07Document6 pagesOsborne Reynold'S Demonstration: Experiment No. - 07John Michael Menoza ZapantaNo ratings yet

- The Myth of The "Biphasic" Hyaluronic Acid FillerDocument7 pagesThe Myth of The "Biphasic" Hyaluronic Acid FillerThaís SagratzhiNo ratings yet

- Nucleotides and Nucleic AcidsDocument65 pagesNucleotides and Nucleic AcidsnutriNo ratings yet

- Jee Main 2023 April 8 Morning Shift Question Paper With SolutionsDocument25 pagesJee Main 2023 April 8 Morning Shift Question Paper With SolutionsPavithraBhishmaNo ratings yet

- Lead Acetate Cotton WoolDocument2 pagesLead Acetate Cotton WoolGopal MallickNo ratings yet

- Teaching & Learning BiologyDocument178 pagesTeaching & Learning BiologyobsrvrNo ratings yet

- Kiman PDFDocument6 pagesKiman PDFLeha QurniatiNo ratings yet

- Spiral Heat ExchangersDocument8 pagesSpiral Heat ExchangersHolayilNo ratings yet

- PIA B2 - Module 2 (PHYSICS) SubModule 2.1 (Matter) FinalDocument20 pagesPIA B2 - Module 2 (PHYSICS) SubModule 2.1 (Matter) FinalInterogator5No ratings yet

- PyMOL ProtocolDocument5 pagesPyMOL ProtocolMonica Fan HsuNo ratings yet

- Modeling Concentration Polarization in Reverse Osmosis Processes PDFDocument18 pagesModeling Concentration Polarization in Reverse Osmosis Processes PDFIbrahim Al-MutazNo ratings yet

- Steel Castings, Alloy, Specially Heat-Treated, For Pressure-Containing Parts, Suitable For High-Temperature ServiceDocument3 pagesSteel Castings, Alloy, Specially Heat-Treated, For Pressure-Containing Parts, Suitable For High-Temperature ServiceRed RedNo ratings yet

- Development of Antimicrobial Needle Punched Nonwoven Fabric For Various Technical Applications Final 10.07.2020Document56 pagesDevelopment of Antimicrobial Needle Punched Nonwoven Fabric For Various Technical Applications Final 10.07.2020ANo ratings yet