Professional Documents

Culture Documents

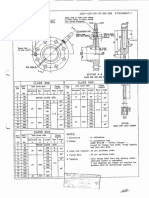

900 Series Specification - CD0309

Uploaded by

Daren Marc TaylorCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

900 Series Specification - CD0309

Uploaded by

Daren Marc TaylorCopyright:

Available Formats

BALL VALVES

900 SERIES

SPECIFICATION SHEET

TWO PIECE FLANGED BALL VALVE

Construction

The valve body is constructed of ASTM A351-CF8M (Stainless Steel 316) or ASTM A216WCB (Carbon Steel) in a two piece casting bolted together with integral flanges each end.

Materials of construction for ball & stem are CF8M (Type 316). All materials conform to

American Society for Testing (ASTM) A351-CF8M or ASTM A216-WCB.

Design

The valve body has two cast sections with integral flanges.

The two cast sections are bolted together and conform to ASME B16.34.

The end to end dimensions conform to ASME B16.10 class 150.

The end flanges conform to ASME B16.5 class 150.

The ball is full port per schedule 40 pipe.

The valve body is designed for minimal pressure drop across the valve.

The valve body has an integral mounting pad conforming to ISO 5211.

The stem has blow-out prevention.

The body gasket material is Teflon (PTFE).

The seat material is 15% Glass reinforced Teflon (RTFE).

The packing gland assembly enables online adjustment of the packing.

The packing material is Teflon (PTFE).

The valve packing can be adjusted without removing the operator.

The valves are tested to API 598.

Valve sizes available are thru 12.

Operation

The following operators can be utilized on the valve:

Chain wheel operator.

Worm Gear operator.

Pneumatic actuator.

Hydraulic actuator.

Electric motor actuator.

Copyright 2009 Alloy Valves and Control Inc. All rights reserved. No part of this brochure may be used or reproduced in any manner whatsoever without written permission from AVCO

This brochure is general in nature and we reserve the right to alter dimensions, materials or make design improvements.

3210 S. Susan St, Santa Ana, CA 92704 Tel (714) 427-0877 Fax (714) 427-6392 Website: www.avcovalve.com

CD0309

You might also like

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- A Practical Guide to Piping and Valves for the Oil and Gas IndustryFrom EverandA Practical Guide to Piping and Valves for the Oil and Gas IndustryRating: 5 out of 5 stars5/5 (3)

- FlowTek Ball Valve DesignDocument0 pagesFlowTek Ball Valve DesignGohilakrishnan ThiagarajanNo ratings yet

- L&T Aquaseal Butterfly Check ValvesDocument24 pagesL&T Aquaseal Butterfly Check ValvesSohail PathanNo ratings yet

- Model"Dc": Dual Chamber Orifice FittingDocument13 pagesModel"Dc": Dual Chamber Orifice FittingFrankNo ratings yet

- Valves & ControlsDocument16 pagesValves & ControlseborresonNo ratings yet

- GE Reciprocating Compressor BrochureDocument13 pagesGE Reciprocating Compressor Brochurepratik banerjeeNo ratings yet

- Valves Reference PDFDocument35 pagesValves Reference PDFJulio RodriguezNo ratings yet

- Forged Steel Valves PDFDocument12 pagesForged Steel Valves PDFDiwakar NigamNo ratings yet

- L&T Pipeline Ball ValvesDocument24 pagesL&T Pipeline Ball Valvesjamil vora100% (1)

- DBB CatalogueDocument20 pagesDBB Cataloguerawrr90No ratings yet

- Uf FloatingDocument20 pagesUf Floatingmhidayat108100% (1)

- Ball Valve Seat Seal Injection SystemDocument28 pagesBall Valve Seat Seal Injection SystemmudrijasmNo ratings yet

- Valves & Controls: Crosby Safety Valves Style HSLDocument12 pagesValves & Controls: Crosby Safety Valves Style HSLeborresonNo ratings yet

- Tyco Fig.110-190 Ball Valves DatasheetDocument24 pagesTyco Fig.110-190 Ball Valves DatasheetMahdi Daly100% (1)

- Prochem Ball ValvesDocument5 pagesProchem Ball Valvesmd_taheriNo ratings yet

- Biffi Hydraulic ActuatorsDocument28 pagesBiffi Hydraulic ActuatorsMuthu Kumar R100% (1)

- American ValveDocument12 pagesAmerican Valveviller_lpNo ratings yet

- Aloyco Stainess Steel ValvesDocument26 pagesAloyco Stainess Steel Valvescristi_molins100% (1)

- Rovalve PDFDocument4 pagesRovalve PDFWilliam ValenciaNo ratings yet

- AloycoDocument32 pagesAloycoSidney RiveraNo ratings yet

- Butterfly Valve ConcentricDocument6 pagesButterfly Valve ConcentricpramodtryNo ratings yet

- OpGL Globe ValveDocument20 pagesOpGL Globe Valvemanmohansingh1999No ratings yet

- Tyco Catalogue NetDocument34 pagesTyco Catalogue NetAhmad Nasser0% (1)

- Adco Ball ValveDocument20 pagesAdco Ball ValverajeshygawdeNo ratings yet

- Worcester Controls C44 Series Cryogenic 3-Piece Ball Valve BrochureDocument8 pagesWorcester Controls C44 Series Cryogenic 3-Piece Ball Valve BrochureKakoDaNo ratings yet

- Constructional Details of Air Suspension System Presentation - 0Document23 pagesConstructional Details of Air Suspension System Presentation - 0harshmsingh169No ratings yet

- Anti Blow Out StemDocument48 pagesAnti Blow Out StemimthiyazmuhammedNo ratings yet

- IOM Ball Valve Top EntryDocument8 pagesIOM Ball Valve Top Entrytoader56No ratings yet

- Block and Bleed Valve-SystemsDocument4 pagesBlock and Bleed Valve-Systemsvmr456No ratings yet

- PressureDocument84 pagesPressureHangloque GabanoNo ratings yet

- Actuator SpecificationDocument12 pagesActuator SpecificationFactory FactoryNo ratings yet

- Válvula DurcoDocument12 pagesVálvula DurcoJames Henrry López EspejoNo ratings yet

- Flowcon ABM InstructionDocument4 pagesFlowcon ABM InstructionJeff Anderson CollinsNo ratings yet

- Performance Prodcuts A SPPE MC001 E3Document67 pagesPerformance Prodcuts A SPPE MC001 E3SonthiMNo ratings yet

- Pilot Operated Pressure Regulator 6" 25P: Typical ApplicationsDocument2 pagesPilot Operated Pressure Regulator 6" 25P: Typical ApplicationsMatias MancillaNo ratings yet

- Swing Check ValvesDocument5 pagesSwing Check Valveslilama45-1No ratings yet

- Constant Speed Vertical Turbine Irrigation Pumping StationDocument11 pagesConstant Speed Vertical Turbine Irrigation Pumping StationGie Mak0% (1)

- Western Valve Online Product CatalogDocument85 pagesWestern Valve Online Product CatalogJhoseph BernalNo ratings yet

- Fire HydrantDocument6 pagesFire HydrantdileepsiddiNo ratings yet

- Iso 9001 CertifiedDocument4 pagesIso 9001 CertifiedLuis R. Salas SotoNo ratings yet

- Eops & Hopd SpecDocument6 pagesEops & Hopd SpecNaveen NagisettiNo ratings yet

- Flowserve Vlatb001Document20 pagesFlowserve Vlatb001Selva KumarNo ratings yet

- Apollo ValvesDocument44 pagesApollo ValvesDevdatt WaghuleNo ratings yet

- AV13 Air Vent For Steam Systems: DescriptionDocument2 pagesAV13 Air Vent For Steam Systems: DescriptionUtku KepcenNo ratings yet

- Items 4-7 and 9-17)Document5 pagesItems 4-7 and 9-17)Haroldo VieiraNo ratings yet

- BH BT ValvesDocument51 pagesBH BT ValvesAntra ChowdhuryNo ratings yet

- B-313 Series E-1510 Technical BrochureDocument8 pagesB-313 Series E-1510 Technical BrochureAnonymous 7xHNgoKE6eNo ratings yet

- Alco ComponentDocument76 pagesAlco Componenttamolisandip1No ratings yet

- Installation Notes For Check Valve: Products ListDocument2 pagesInstallation Notes For Check Valve: Products ListMashudi FikriNo ratings yet

- Enflow Floating BallvalvesDocument8 pagesEnflow Floating Ballvalvesa100acomNo ratings yet

- Suction Guide & Flo-Trex Valve Series: Pump TrimDocument8 pagesSuction Guide & Flo-Trex Valve Series: Pump Trimsiva_nagesh_2No ratings yet

- 3 Piece Tube Bore Ball Valves, / "-4": High Purity ApplicationsDocument4 pages3 Piece Tube Bore Ball Valves, / "-4": High Purity ApplicationsrodrurenNo ratings yet

- Actuated ValvesDocument4 pagesActuated ValvestjendraNo ratings yet

- Angle ValveDocument12 pagesAngle ValveAjeesh SivadasanNo ratings yet

- PP66S12 Pump SpecDocument4 pagesPP66S12 Pump SpeccaomandanteNo ratings yet

- Orifice Flange Weld NippleDocument1 pageOrifice Flange Weld NippleDaren Marc TaylorNo ratings yet

- Valve CV Comparison - CD180227Document1 pageValve CV Comparison - CD180227Daren Marc TaylorNo ratings yet

- When To Use Trunnion Ball Valves - CD180227Document1 pageWhen To Use Trunnion Ball Valves - CD180227Daren Marc TaylorNo ratings yet

- BC5500GXHBDocument13 pagesBC5500GXHBDaren Marc TaylorNo ratings yet

- Service Applications:: Alloy Valves and Control Flow Measurement & Control Solutions Engineered For EngineersDocument1 pageService Applications:: Alloy Valves and Control Flow Measurement & Control Solutions Engineered For EngineersDaren Marc TaylorNo ratings yet

- Control Valve HysteresisDocument1 pageControl Valve HysteresisDaren Marc TaylorNo ratings yet

- Is A 1000 WOG Valve Stronger Than An ASME B16Document1 pageIs A 1000 WOG Valve Stronger Than An ASME B16Daren Marc TaylorNo ratings yet