Professional Documents

Culture Documents

Pan Conveyors PDF

Uploaded by

Christian MakandeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pan Conveyors PDF

Uploaded by

Christian MakandeCopyright:

Available Formats

W E

C O N V E Y

Q U A L I T Y

PAN CONVEYORS

W E

C O N V E Y

CONTENTS

2 Clinker Transport and

Discharge

4 Deep-Drawn Pan

Conveyor type KZB

6 Deep-Drawn Pan

Conveyor type KZB-Q 250

8 Bucket Apron Conveyor

type BZB 250

10 Pivoting Pan Conveyor

type SPB

14 Silo Discharge

15 Reversible Conveyor

16 Components

Clinker dust reclaim

(TKF HN)

17 Accessories

18 Conversions and

Refurbishments

19 After-Sales Service

CLINKER

TRANSPORT

AND

DISCHARGE

Proven technology

Patented plate design

Spillage free

Quality

Reliability

Long service life

Low maintenance

Reliable conveying equipment for hot,

abrasive cement clinker is essential for

economic operation in cement plants.

Conveying systems forming the link

in materials management are vital for

the availability and productivity of the

entire plant.

To receive an optimum overall

conveying and storage layout, early

implementation of experienced layout

engineers is recommended.

Q U A L I T Y

Clinker transport from

cooler to storage

(KZB)

Automatic clinker

discharge (Mole)

W E

C O N V E Y

Deep-Drawn Pan Conveyor

Spillage free design

Silo discharge conveyors

Collecting

chute

28

Feed chute

Cleaning scraper, C-shaped

Deep-Drawn Pan Conveyor under clinker cooler

Fines

chute

Dust hood

Overload

chute

Weather cover

Feeding and discharge - type KZB 250

DEEP DRAWN PAN CONVEYOR

TYPE KZB 250

Reliable conveying equipment for

hot, abrasive cement clinker is

essential for economic operation in

cement plants. Conveying systems

forming the link in materials

management are vital for the

availability and thus the productivity

of the entire plant.

Experience has shown that even

coolers of the latest design do not

always ensure effective reduction

of the clinker temperature. Red

spots may occur occasionally. Plant

operators who wish to be on the

save side choose AUMUND pan

conveyors for their reliability in

conveying hot materials.

AUMUND Deep-Drawn Pan

Conveyors type KZB 250 are

well-known for low maintenance,

tightness and a long service life.

They are particularly suitable for

applications with coolers. The

material is directly discharged

onto the Deep-Drawn Pan Conveyor

arranged over the whole length

of the cooler - a very economic

solution as drag chains are not

required.

Slopes up to 28

Patented pan sealing

Contact-free pan overlapping

Suitable for hot material

(up to 700 C)

AUMUND Deep-Drawn Pan

Conveyors are equipped either with

single-strand or double-strand

chains. The single-strand types

(central chains) are designed for a

max. pan width of 800 mm and for

low conveying capacities. Higher

conveying capacities are handled

with double chain strands

provided for pan widths from

800 to 3,000 mm.

Modular system

Electrical soft start

Variable-speed drives

with frequency control

Standard chain sizes with

breaking loads from 220 to

1,800 kN for each chain strand

Q U A L I T Y

The characteristic profile of the

bottom plates provides high

rigidity even with a pan width

exceeding 2,000 mm. DeepDrawn Pan Conveyors may be

designed with slopes matching

the angle of repose of the

conveyed material. Stiffeners

pressed into the side walls of

the pans as well as a special

sealing edge increase the pans

solidity and the dust-tight

fitting between the pans.

AUMUND attach particular

importance to the design of

feed chutes and dust hoods.

Proper dimensioning of

dedusting connections in the

transfer areas considerably

reduce the need for cleaning.

Weather covers, chutes for

collection of fines, distribution

chutes and flat gates complete

the product range.

The pan conveyors are driven

by bevel spur gears either foot

mounted with flexible coupling

between gearbox and drive

shaft or shaft-mounted. For

inclined conveying, the gear

box is fitted with a back stop.

A hydraulic coupling is installed

between gear box and motor

or, for soft start up of the

motor, with a flexible coupling.

Alternatively, the flexible

coupling between motor and

gearbox can be provided with

a disc brake to stop the fully

loaded conveyor in any given

position if the back stop fails

to work properly. Frequency

converters adapt the conveying

speed to the actual conveying

capacity, thus minimizing wear

and ensuring a longer service

life of chains, rollers and rails.

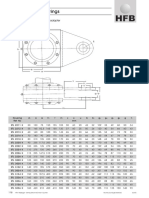

Conveying capacity - Deep Drawn Pan Conveyor Type KZB 250

The capacities indicated correspond to a brimfull filling (water filling) =100 %

Preferred sizes

Conveyor section type KZB 250

Width

Theoretical conveying capacity m3 /h

Side wall Plate thickness Conveyor speed m /s

mm

height mm

mm

400

400

400

400

400

600

600

600

600

600

800

800

800

800

800

1.000

1.000

1.000

1.000

1.000

1.200

1.200

1.200

1.200

1.200

1.400

1.400

1.400

1.400

1.400

1.600

1.600

1.600

1.600

1.600

1.800

1.800

1.800

1.800

1.800

2.000

2.000

2.000

2.000

2.000

2.200

2.200

2.200

2.200

2.200

2.400

2.400

2.400

2.400

2.400

100

150

200

250

300

150

200

250

300

350

200

250

300

350

400

200

250

300

350

400

200

250

300

350

400

250

300

350

400

450

250

300

350

400

450

250

300

350

400

450

250

300

350

400

450

250

300

350

400

450

250

300

350

400

450

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

0.10

12

19

26

33

40

28

39

50

60

71

52

66

81

95

109

65

83

101

119

137

78

99

121

143

164

116

141

166

192

217

132

161

190

219

248

149

181

214

246

279

166

202

238

274

310

182

222

261

301

341

199

242

285

328

372

0.15

17

28

39

50

60

42

58

75

91

107

78

99

121

143

164

97

124

151

178

205

117

149

181

214

246

174

212

249

287

325

199

242

285

328

372

224

272

321

369

418

248

302

356

410

464

273

333

392

451

511

298

363

428

492

557

Permissible

0.20

23

37

52

66

81

56

78

99

121

143

104

132

161

190

219

130

166

202

238

274

156

199

242

285

328

232

282

333

383

433

265

323

380

438

495

298

363

428

492

557

331

403

475

547

619

364

444

523

602

681

397

484

570

657

743

0.25

29

47

65

83

101

70

97

124

151

178

130

166

202

238

274

162

207

252

297

342

194

248

302

356

410

290

353

416

479

542

331

403

475

547

619

373

454

535

616

697

414

504

594

684

774

455

554

653

752

851

497

605

713

821

929

0.30

35

56

78

99

121

84

117

149

181

214

156

199

242

285

328

194

248

302

356

410

233

298

363

428

492

348

423

499

575

650

397

484

570

657

743

447

544

642

739

836

497

605

713

821

929

546

665

784

903

1.022

596

726

855

985

1.115

0.35

40

66

91

116

141

98

136

174

212

249

181

232

282

333

383

227

290

353

416

479

272

348

423

499

575

406

494

582

670

759

464

564

665

766

867

522

635

748

862

975

580

706

832

958

1.084

638

776

915

1.053

1.192

696

847

998

1.149

1.300

0.40

46

75

104

132

161

112

156

199

242

285

207

265

232

380

438

259

331

403

475

547

311

397

484

570

657

464

564

665

766

867

530

645

760

876

991

596

726

855

985

1.115

662

806

950

1.094

1.238

729

887

1.045

1.204

1.362

795

968

1.140

1.313

1.486

filling degree

80 %

80 %

80 %

80 %

80 %

80 %

80 %

80 %

80 %

80 %

90 %

90 %

90 %

90 %

90 %

100 %

100 %

100 %

100 %

100 %

100 %

100 %

100 %

100 %

100 %

100 %

100 %

100 %

100 %

100 %

110 %

110 %

110 %

110 %

110 %

110 %

110 %

110 %

110 %

110 %

120 %

120 %

120 %

120 %

120 %

120 %

120 %

120 %

120 %

120 %

120 %

120 %

120 %

120 %

120 %

W E

C O N V E Y

Clinker silo feeding type KZB-Q 250

Collecting

chute

Intermediate

chute

Fines

chute

Feed chute

Dust hood

Cleaning scraper, C-shaped

Dust hood

Feed

chute

Weather cover

Feeding and discharge - type KZB-Q 250

Deep-Drawn Pan Conveyor with baffles

type KZB-Q 250

DEEP DRAWN PAN CONVEYOR

TYPE KZB-Q 250

Standard Deep-Drawn Pan

Conveyors with baffles are

applied for inclination angles

up to 40. The basic concept of

this economic inclined conveyor

includes the use of standard

elements like deep drawn pans,

chains and rollers.

The Deep-Drawn Pan Conveyor

type KZB-Q 250 is designed for

inclination angles between 28

and 40. These slopes are still

practicable for walkways in

conveyor bridges.

The AUMUND range of conveyor

chains shown on page 9 is

designed for lifts of more than

60 m. With an efficient plant

layout, feeding of clinker silos

can thus be performed with just

one conveyor.

Standardized components reduce

the variety of parts and constitute

the AUMUND modular system:

components such as sprockets,

chains, rollers and rails of

AUMUND pan conveyors are

interchangeable to a large extent,

an important asset for spare

parts management.

The deep-drawn pans are

equipped with baffles for inclined

conveying. These baffles are

bolted to the bottom plate and

hold in a loose fitting by cams

which arepressed into the upper

part of the side boards.The loose

fitting allows the baffles to bend

in case foreign bodies get onto

the conveyor. Bent baffles will

not affect proper functioning

of the conveyor, they may be

replaced at any time, for example

during a regular stop of the

system.

Tightness of side walls

Q U A L I T Y

As a standard, the rollers of

AUMUND pan conveyors are

separated from the traction

element, the chain. This

important design feature of

AUMUND pan conveyors

ensures that the chain selection

is always made to suit the

actual traction force, whereas

the rollers are chosen in

accordance with the weight of

the pan conveyor itself and

the conveyed material. The

separation of traction elements

and carrying elements

simplifies maintenance and

assembly.

All rollers are fastened to their

brackets by means of stub

shafts, a simple but efficient

and safe fixing means.

Depending on the respective

plate width, rollers are arranged

at intervals of 500, 1,000 or

1,500 mm.

Slopes up to 40

Conveying capacities

exceeding 750 t/h

Exchangeable baffles

Deep-drawn pans of

solid design

Material temperatures

up to 700 C

Conveying capacity - Deep Drawn Pan Conveyor with Baffles Type KZB-Q 250

The capacities indicated correspond to a brimfull filling (water filling) =100 %

Preferred sizes

Conveyor section type KZB-Q 250

Width

Theoretical conveying capacity m3 /h

Side wall Plate thickness Conveyor speed m /s

mm

height mm

mm

400

400

400

400

600

600

600

600

800

800

800

800

800

1.000

1.000

1.000

1.000

1.000

1.200

1.200

1.200

1.200

1.200

1.400

1.400

1.400

1.400

1.400

1.600

1.600

1.600

1.600

1.800

1.800

1.800

1.800

2.000

2.000

2.000

2.000

2.200

2.200

2.200

2.200

2.400

2.400

2.400

2.400

250

300

350

400

250

300

350

400

250

300

350

400

450

250

300

350

400

450

250

300

350

400

450

250

300

350

400

450

300

350

400

450

300

350

400

450

300

350

400

450

300

350

400

450

300

350

400

450

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

0.10

33

40

48

55

50

60

71

82

66

81

95

109

124

83

101

119

137

155

99

121

143

164

186

116

141

166

192

217

161

190

219

248

181

214

246

279

202

238

274

310

222

261

301

341

242

285

328

372

0.15

50

60

71

82

75

91

107

123

99

121

143

164

186

124

151

178

205

232

149

181

214

246

279

174

212

249

287

325

242

285

328

372

272

321

369

418

302

356

410

464

333

392

451

511

363

428

492

557

Permissible

0.20

66

81

95

109

99

121

143

164

132

161

190

219

248

166

202

238

274

310

199

242

285

328

372

232

282

333

383

433

323

380

438

495

363

428

492

557

403

475

547

619

444

523

602

681

484

570

657

743

Reduced output factor

Side wall

height

mm

250

300

350

400

450

35

0.822

0.863

0.888

0.905

0.918

40

0.701

0.769

0.812

0.841

0.863

0.30

99

121

143

164

149

181

214

246

199

242

285

328

372

248

302

356

410

464

298

363

428

492

557

348

423

499

575

650

484

570

657

743

544

642

739

836

605

713

821

929

665

784

903

1.022

726

855

985

1.115

30

Reduced output factor up to

angle of inclination of

30

0.949

0.960

0.968

0.973

0.976

0.25

83

101

119

137

124

151

178

205

166

202

238

274

310

207

252

297

342

387

248

302

356

410

464

290

353

416

479

542

403

475

547

619

454

535

616

697

504

594

684

774

554

653

752

851

605

713

821

929

45

0.589

0.682

0.741

0.782

0.811

0.35

116

141

166

192

174

212

249

287

232

282

333

383

433

290

353

416

479

542

348

423

499

575

650

406

494

582

670

759

564

665

766

867

635

748

862

975

706

832

958

1.084

776

915

1.053

1.192

847

998

1.145

1.300

Co

nv

ey

ing

0.40

132

161

190

219

199

242

285

328

265

323

380

438

495

331

403

475

547

619

397

484

570

657

743

464

564

665

766

867

645

760

876

991

726

855

985

1.115

806

950

1.094

1.238

887

1.045

1.204

1.362

968

1.140

1.313

1.486

filling degree

80 %

80 %

80 %

80 %

80 %

80 %

80 %

80 %

90 %

90 %

90 %

90 %

90 %

95 %

95 %

95 %

95 %

95 %

95 %

95 %

95 %

95 %

95 %

95 %

95 %

95 %

95 %

95 %

95 %

95 %

95 %

95 %

95 %

95 %

95 %

95 %

95 %

95 %

95 %

95 %

95 %

95 %

95 %

95 %

95 %

95 %

95 %

95 %

dir

ec

tio

n

W E

Clinker silos 2 x 60,000 t

Bucket Apron Conveyor

type BZB 250

C O N V E Y

Clinker transport with

conveyor type BZB 250

Collecting

chute

Intermediate

chute

Fines

chute

Feed chute

Feed chute

Dust hood

Cleaning scraper, C-shaped

Clinker silo feeding with conveyor type BZB 250

Dust hood

Weather cover

Feeding and discharge - type BZB 250

BUCKET APRON CONVEYOR

TYPE BZB 250

AUMUND Bucket Apron

Conveyors type BZB 250 are

the proper solution for clinker

transport systems with up to

60 inclination. These conveyors

with their narrow curve radius

offer considerable advantages

particularly for the modernization

or conversion of existing plants

where only restricted space is

available.

The modular system also applies

for the AUMUND Bucket

Apron Conveyor, ensuring

interchangeability and combination

of components like those used for

the construction of Deep-Drawn

Pan Conveyors. Standardized

chains are used as well; merely

the angular fishplates are modified

for the solid bucket fixing. The

standard chain sizes are documented on page 9. The roller selection

suits the bucket size and the load

requirements. Standard roller

diameters are diameters 108/140

and 160 mm.The standard roller

spacing is 1,000 mm which means

that one out of two buckets is

fitted with a set of rollers. Same as

the deep drawn pan conveyor, the

Bucket Apron Conveyor features

the proven roller brackets and stub

shafts to fasten the rollers.

An essential asset of AUMUND

Bucket Apron Conveyors - the tight

bucket arrangement - above all

takes effect where very finegrained clinker with a high ratio

of dust has to be conveyed. To

increase the buckets solidity and

ensure safe operation, the bucket

bottom is provided with a built-in

stiffener. Depending on the

individual plant requirements,

the overlapping of the buckets

is either forward or backward.

Slopes up to 60

Lifts exceeding 60 m

Minimum curve radius 8 m

Tight bucket arrangement for

fine-grained materials

Standard bucket sizes are

available up to a width of 1,600

mm. When choosing the bucket

size, it has to be considered that

the actual conveying capacity

is subject to a reduction factor

defined by the angle of inclination.

Q U A L I T Y

The reduction factor is based

upon the assumption that the

material in the bucket will form

an angle of repose of at least

25. If feeding of the material is

arranged in the inclined section

only, a higher reduction must

be accounted for as the factor

will decrease gradually to a

water filling level.

In particular large buckets with

a width of 1.200 mm and more

require adequate design of the

feed chutes. For a uniform

bucket filling, feed chutes with

saddles have proved to be a

good solution, as they ensure

even material distribution over

the whole bucket width. Expert

planning of the chute system is

therefore considered to be a

pre-requisite for trouble-free

operation with only little dust

generation.

The take-up station standard

provides for spring tensioning.

In special cases counterweights

are added where considerable

chain elongations resulting

from considerable temperature

differences of the conveyed

material have to be compensated. C-shaped cleaning

scrapers arranged around the

take-up station and recycling

the collected fines, are used to

minimize cleaning around the

take-up station. Depending

on the contents of fines in

the conveyed material, the

operating time of these

cleaning scrapers can be

adjusted by means of sequence

control. For the drive station

area, fines collecting chutes

are the most suitable solution.

Frequency controlled motors

are provided to adapt the

conveyor speed to varying

conveying capacities.

Monitoring of the bucket

filling level or control of the

drive unit form part of the

equipment.

Conveying capacity - Bucket Apron Pan Conveyor Type BZB 250

The capacities indicated correspond to a filling of 100 % and a angle of repose of 25.

Preferred sizes

Bucket

Bucket

Theoretical conveying capacity m3 /h

Conveyor speed m / s

0,10

0.15

0.20

Sides wall height

mm

0.25

0.30

400

mm

200

24

35

47

59

71

0.35

83

400

250

30

45

59

74

89

104

600

200

35

53

71

89

106

124

600

250

44

67

89

111

133

156

600

300

53

80

107

134

160

187

800

200

47

71

95

118

142

165

800

250

59

89

119

148

178

207

800

300

71

107

143

178

214

249

800

350

83

125

167

208

250

291

800

400

95

143

191

238

286

334

1.000

300

89

134

178

223

267

312

1.000

350

104

156

208

260

312

364

1.000

400

119

179

238

298

357

417

1.200

350

125

187

250

312

375

437

1.200

400

143

214

286

357

429

500

1.400

350

146

219

291

364

437

510

1.400

400

167

250

334

417

500

584

1.600

350

167

250

333

416

500

583

1.600

400

191

286

381

476

572

667

Permissible filling degree

70-80 % of the theoretical conveying capacity

Reduced output factor

Side wall height

mm

250

300

350

400

450

Reduced output factor up to angle of inclination of

30

0.949

0.960

0.968

0.973

0.976

35

0.822

0.863

0.888

0.905

0.918

40

0.701

0.769

0.812

0.841

0.863

45

0.589

0.682

0.741

0.782

0.811

50

0.589

0.682

0.741

0.782

0.811

55

0.589

0.682

0.741

0.782

0.811

60

0.589

0.682

0.741

0.782

0.811

Recommended

inclination max. 45

Link chains

acc.to

AUMUND

standard

for type

KZB 250

KZB-Q 250

BZB 250

Type

Chain pitch:

250 mm

B

B

B

B

B

250 x 30/50 x 8

250 x 30/50 x 8

250 x 45/70 x 10

250 x 45/70 x 10

250 x 60/80 x 10

250 x 60/80 x 10

250 x 60/90 x 12

250 x 60/90 x 12

250 x 60/90 x 12 v

250 x 60/90 x 12 v

AU 625

AU 625 W

AU 725

AU 725 W

for conveyor type

breaking load KN

KZB

BZB

KZB

BZB

KZB

BZB

KZB

BZB

KZB

BZB

KZB

BZB

KZB

BZB

220

220

450

450

520

520

700

700

900

900

1.200

1.500

1.800

1.800

Link surface pressure 50 N/mm2 max.

W E

C O N V E Y

Feed chute

Upper run

Feed chute

Lower run

Discharge station

Upper run

Discharge station

Lower run

Drive station

Overflow

Pivoting Pan Conveyor type SPB - operation principle

PIVOTING PAN CONVEYOR

TYPE SPB

Wherever feeding of more than two

clinker silos or several mill hoppers

in line is required, AUMUND

Pivoting Pan Conveyors type SPB

have proved a reliable solution.

With its intermediate discharge

stations placed at any given

position, the Pivoting Pan Conveyor

ensures multiple distribution of

various materials with just one

conveyor.

A pan reversing system integrated

into the drive and take-up station

allows for simultaneous material

conveying in the upper and lower

run. The graphic shows the

principle of the pan reversing

system as well as specific feeding

and discharge features. Depending

10

on given requirements, upper run

feeding can be performed by a

simple feed chute whilst a two-way

chute feeds the lower run. All feed

chutes are equipped with overflow

systems for direct feeding of the

silos or hoppers during periods

when the Pivoting Pan Conveyor

is not in operation. The overflow

chutes` operation principle is

illustrated by the examples for

clinker silo and mill hopper

feeding.

Simultaneous conveying in the

upper and lower run provides

multiple solutions for material

handling. For example, material

discharged onto the upper run

can subsequently be transferred

to the lower run through a discharge

station located on the upper run.

The material may then be

distributed into clinker silos or

mill hoppers through discharge

stations on the lower run.

Separate conveying on the upper

as well as the lower run is another

possibility. A hopper can thus be

loaded with cement clinker by way

of the lower run, whilst for example

gypsum is conveyed on the upper

run. These are just two out of many

solutions available either for new

plants or, in particular, for

conversion or modernization in

existing plants.

Q U A L I T Y

Several intermediate

discharge stations

Simultaneous conveying on the

upper and lower run; even with

different materials

PLC-controlled operation

Automatic feeding of clinker

silos and mill hoppers

Center distances of 400 m

and more

Take-up station

Standardized components and the variety

of applications make the Pivoting Pan

Conveyor a versatile and reliable system.

The variety of applications and the

related operations require perfect

functioning of the individual components

such as the discharge stations and the

pan and chain arrangement. The

conveying elements of the Pivoting Pan

Conveyor consist of 1 m long pans

equipped with rollers at one end and

with a carrier axle at the other end. The

carrier axle allowing the pan to perform

the reversing movement is linked to both

chain strands. The graphic demonstrates

how the pans in the lower run are pulled

by the carrier axle while being pushed in

the upper run. This arrangement enables

the material discharge by lowering the

rails in the discharge station and by

turning the pans in the drive and take-up

stations.

With their slightly conical shape the pans

overlap by approx. 70 mm. This pan

arrangement with side boards of 150 or

200 mm forms a tight material carrying

surface.

Automated material distribution

into silos or hoppers controlled

by level sensors

Customized layout and planning

Low energy consumption

Clinker silos 3 x 25,000 t

Turning of pans at drive station and take-up station

Clinker silo feeding with Pivoting Pan Conveyor type SPB

Mill hopper feeding

11

W E

For intermediate discharge into either

silos or hoppers, the discharge stations

are of stationary design. Switching from

one discharge station to the other is

performed by a lever system lowering

the corresponding rail and actuated

by a gear motor.The rail points setting

is controlled by limit switches. The

position of the rollers is monitored at

any given moment to prevent their

collision with the rails during the

switching operations. The whole system

is PLC-controlled for smooth and safe

operation.

Feeding of long clinker storage halls

requires continuous shifting of the

discharge point. Mobile discharge

carriages which can be moved to any

given position above the hall are used

with this particular application. A

capstan drive actuates the movement of

the discharge carriage. If moved while

clinker is being conveyed, the clinker is

continuously distributed over the whole

travel length of the carriage. A slotted

discharge opening in the storage hall

roof is required over the carriages

travel length. A roof-shaped rubber

strip sealing minimizes dust emission

through the slotted opening. Sensors

fitted to the conveyor supports monitor

the position of the discharge carriage.

Level indicators control automatic

shifting of the carriage as soon as a

maximum filling level is reached inside

the storage hall.

The Pivoting Pan Conveyor is designed

for a multitude of applications.The

examples shown provide information

on technical modifications which have

been repeatedly been carried out:

Conveying capacity - Pivoting Pan Conveyor Type SPB

The conveying capacities indicated were determined according to the sketch

(with an angle of 10) and will apply for horizontal conveying.

Preferred sizes

Carrier plate

Width

Theoretical conveying capacity m3/h

Side wall height Plate thickness

mm

mm

400

400

600

600

800

800

1.000

1.000

1.200

1.200

1.400

1.400

1.600

1.600

150

250

150

250

150

250

150

250

150

250

150

250

150

250

5

5

5

5

5+6

5+6

5

5

6

6

6

6

6

6

Conveyor speed m /s

0.10

26

32

40

50

56

68

72

88

90

110

110

132

130

156

0.15

39

48

60

75

84

102

108

132

135

165

165

198

195

234

0.20

52

64

80

100

112

136

144

176

180

220

220

264

260

312

0.25

65

80

100

125

140

170

180

220

225

275

275

330

325

390

please refer to type KZB 250 (page 4).

Feeding of individual bins

Drive station

Feeding - lower run

Feeding of individual bins

Drive station

Take - up station

Feeding

Upper run

Feeding of storage hall and storage bins

Take - up station

Feeding

Upper run

Discharge

carriage

Take - up station

Feeding of bin or storage silo

Drive

Feed chute with

station emergency overflow

Discharge station

Take - up station

with forced discharged

Possible applications - Pivoting Pan Conveyor type SPB

12

0.30

78

96

120

150

168

204

216

264

270

330

330

396

390

468

Permissible filling degree

Drive station

Material feeding onto the lower

run and distribution into different

bins

Material feeding onto the upper

run, discharge onto the lower

run and subsequent distribution

into bins

C O N V E Y

Q U A L I T Y

Material feeding onto the upper

run and discharge onto the lower

run followed by either bin feeding

or material distribution over a

defined area with the discharge

carriage

Material feeding onto the lower

run and material distribution over

a defined area of a clinker storage

hall with the discharge carriage

Material feeding onto the upper

run, discharge onto the lower

run and, when required, material

distribution with the discharge

carriage

Material feeding onto the upper

run and distribution into bins via

discharge stations. At the same

time conveying of a separate

material loaded onto the lower

run and distributed into a clinker

storage hall with a discharge

carriage

Feeding with Pivoting Pan Conveyor

Feeding of storage hall and storage bins

Drive station

Feeding - lower run

Storage bin feeding

Drive station

Discharge carriage

Feeding

Upper run

Discharge carriage

Feeding of storage hall and storage bins

Drive station

Feeding

Lower run 1

Feeding

Lower run 2

Feeding Upper run

Discharge carriage

Take - up station

Take - up station

Take - up station

Feeding of storage hall

Drive

station

Feed chute with emergency

overflow

Direction of travel for mobile

discharge carriage

Take - up station

with forced discharged

Further combinations are possible

including upper and lower run conveying

as well as stationary and mobile design

of the discharge stations. Our project

department will be pleased to assist you

in finding the appropriate layout for your

particular needs.

Most outdated clinker storage halls

are equipped with overhead travelling

cranes to either distribute clinker in the

hall in continuous operation or to feed

the mill hoppers. Also additives like

gypsum and sand have to be conveyed

to the respective mill hoppers. This

application is best served with a Pivoting

Pan Conveyor ensuring automated

feeding of the mill hoppers and

representing an economic and sensible

project. The Pivoting Pan Conveyor and

the discharge stations are controlled by

material level sensors in the mill hoppers

and ensure feeding on demand.

This operation mode is efficient and

minimizes dust generation in the clinker

hall, thus providing improved working

conditions for the crane driver and

allowing to comply with environmental

regulations.

Possible applications - Pivoting Pan Conveyor type SPB

13

W E

C O N V E Y

SILO DISCHARGE

For clinker silo discharge with low dust

emission, for proportional addition of lowburnt or foreign clinker AUMUNDs range

of products includes gravity discharge

systems operating in combination with the

Deep-Drawn Pan Conveyor type KZB 250.

The gravity discharge unit is designed

to prevent the clinker from falling in an

uncontrolled manner onto the pan

conveyor. The material column on the pan

conveyor is reclaimed with low speed thus

minimizing the generation of dust and

avoiding dust filters. The gravity discharge

systems are provided with a shell valve

which can either be operated manually or

by means of a gear motor. As the height

of the material layer on the pan conveyor

is preset during commissioning, the

discharge capacity and feeding onto

the subsequent conveying equipment is

maintained at a fixed rate.

For maximum use of the stored volume,

large clinker silos are equipped with a

multitude of gravity discharge units. The

motorized discharge units are actuated

by remote control to allow for automatic

change of the discharge points at regular

intervals and uniform discharge of the

stored material.

For automatic operation the pan conveyor

is fitted with an ultrasonic sensor ensuring

switching from one silo discharge point to

another if the material flow is insufficient.

Combined with the Deep-Drawn Pan

Conveyor, the silo discharge systems

are used in direct feeding of the mill

hoppers. The 20 m curve radius and the

28 inclination of the pan conveyor allow

for a layout with a direct conveying line,

thus avoiding additional transfer points.

Conveying from clinker silo to

mill hopper with minimised dust

generation

No dust filters

Discharge capacities exceeding

750 t/h

More than 2,000 silo discharge

systems in operation

Variable discharge capacity with

frequency-controlled conveyor drive

Silo discharge with remote control

Silo discharge system with low-burnt clinker dosage

and truck tipping station

Rod grate

Rod grate

Silo discharge

Deep drawn pan conveyor type KZB 250

Conveying direction

Conveying direction

Silo gravity discharge

14

Q U A L I T Y

REVERSIBLE CONVEYOR

For special plant constellations, alternate

conveying into two directions is required. The

appropriate solution for this application is the

Deep-Drawn Pan Conveyor of special design:

the reversible pan conveyor. By simply changing

the travel direction, alternate feeding of two

clinker silos is possible with just one conveyor.

Clinker silos 2 x 60,000 t

This design developed by AUMUND is based

on a divided deep-drawn pan and half a chain

pitch, i.e. 125 mm. By alternating a troughshaped bottom plate with a cover plate to

form the well-known deep-drawn pan with

the 250 mm spacing, conveying is possible in

both directions. The illustration demonstrates

that the combination of one bottom plate

and one cover plate each bolted onto the two

corresponding chain links is guided around the

sprocket as a rigid unit. Always one cover plate

points in the requested conveying direction.

This is achieved by defining the adequate

center distance, which, for this reversible DeepDrawn Pan Conveyor, comes up to a multiple

of 250 mm plus 125 mm. This asymmetrical

center distance ensures that the adequate

turning point of the chain articulation matches

the given conveying direction. With this

arrangement the overlapping cover plates

always point in the chosen conveying direction.

For the reversible Deep-Drawn Pan Conveyor, a

horizontal arrangement is preferred. For larger

center distances a drive unit can be installed

for both sprockets.

Clinker silo feeding with reversible pan conveyor

Reversible pan conveyor - functional principle

15

W E

C O N V E Y

Drive shaft and tail axle

Runway with upper guideline

Forged and hardened roller bodies

Deep pan

Roller

Roller bracket

Ball bearing

Securing ring

Grease nippel

Hexagon

head screw

with nut

Roller axle

Cover

Intermediate washer

Washer

Grease chamber

Spacer ring

Labyrinth seal

Roller with sealing elements

Chain

COMPONENTS

AUMUND pan conveyors feature standardized

components wich have proved reliable in practical

operation for a thousand times. With the concept

of a modular system, components of different

pan conveyor types are interchangeable, a major

advantage for spare parts management.

AUMUND pan conveyor tracks feature bogietype rails complying with DIN/EN 5901/5902.

The rail size ranging from S14 to S30 is chosen

in accordance with the pan conveyor size. In the

curved area, the rollers are guided by upper

guide-rails to prevent the conveying elements

from being lifted off the rails. The standard curve

radius for Deep-Drawn Pan Conveyors is 20 m

whereas the curve radius for Bucket Apron

Conveyors may be reduced to 8 m.

The standard roller design for AUMUND pan

conveyors features a tempered running surface

and a sealing system preventing dust penetration.

16

Multiple metal sealing, a labyrinth seal and a

grease chamber form part of the system

and provide efficient protection against dust

penetration without the necessity of relubrication.

AUMUND rollers are fitted with stub shafts

connected to the roller bracket by a simple

hexagon head screw for quick and easy

dismantling.

The drive and tail shaft sprockets are equipped

with exchangeable toothed segments allowing

to replace the sprocket segments even with the

conveyor strand closed. The sprockets feature a

double tooth pitch and ensure meshing with the

sprocket teeth only after each second turn. As a

result, the service life of the segments is twice

as long as with a single tooth pitch.

The standard chains of AUMUND pan conveyors

are listed in the table on page 9.

Q U A L I T Y

ACCESSORIES

C-shaped cleaning scraper, tension station

Two-way distribution chute

Three-way distribution chute

In order to minimize cleaning

especially at take-up and feeding

stations, AUMUND cleaning

scrapers ensure automatic

recycling of spillage onto the

conveyor. These scrapers are

available as C-shaped scrapers

for installation around the take-up

station or as straight scrapers for

installation underneath any given

point of the conveyor. Operation

of the scraper is controlled by a

timer for intermittent operation

actuating the gear motor on

account of the actual amount of

spillage. Cleaning may further

be reduced by installing fines

recycling chutes.

Remote control of downstream

conveying directions is performed

with the AUMUND two or threeway distribution chute. The chutes

are fitted with shell gates actuated

either by a gear motor or a

hydraulic / pneumatic cylinder.

Casing and shell gates are of

wear-resistant design for a long

service life. Motorized flat gates of

sturdy design complete the range

of accessory equipment for

material distribution.

If required, an automatic lubrication

system may be provided for

intermittent chain lubrication.

Chain lubrication system

Motor-operated flat gate

In addition, AUMUND offers

maintenance trolleys with rack

and pinion drive to be installed

inside conveyor bridges for

transportation of heavy tools, oil

bins or equipment components to

the top of high clinker silos. The

maintenance trolleys are designed

to suit any angle of inclination.

The range of accessory equipment

is completed by truck and ship

loading systems with low dust

generation and electronic control

for easy loading operations.

Maintenance trolley

Truck loading station

17

W E

C O N V E Y

Retrofitting a heavy Apron Feeder

CONVERSIONS AND REFURBISHMENTS

Upgrading of existing plant components

Targeting increased efficiency

Higher output

Improved higher availability

With our expert team of engineers planning

selective modernisation measures we pay

special attention to the upgrading of existing

plant components, targeting increased

efficiency, higher output rates and improved

availability.

the feasibility and analysis of the bulk materials

properties and the technical specifications of

the existing plant.

Engineered conversions and refurbishments for

increased efficiency and output are performed on

AUMUND equipment same as on equipment

of other manufacturers.

Upgrading of your materials handling

and storage equipment to state-of-the-art

technology is achieved through a tailor-made

refurbishment process under optimum

utilization of time and budget.

Most of the existing components are re-used

in the refurbishment process to save costs.

For each project, a system drawing showing

how the new components fit into the existing

geometry is generated after verification of

Conversion of a Bucket Elevator

18

Q U A L I T Y

AFTER-SALES

SERVICE

THE AUMUND GROUP

Supervises assembly and

commissioning jobs

Proactive maintenance

AUMUND continues to place high

emphasis on the service to the customer

also after the successful completion

of design, engineering, manufacture,

delivery, assembly and commissioning.

Thus, after-sales service means

for all companies of the

AUMUND Group:

Expert consulting in all aspects of the

transport and storage technology

Modification and conversion concepts

for a capacity increase or a

modernization

Stockkeeping of spare parts

Maintenance and inspection services

A team of well-experienced field

engineers supervises assembly and

commissioning jobs.

An outstanding feature of the

AUMUND after-sales service is

the proactive maintenance.

Within the frame of a maintenance

program, our partner company

PREMAS offers field inspections

and maintenance seminars for all

products of the AUMUND Group.

GERMANY

SWITZERLAND

AUMUND-Frdererbau

GmbH & Co. KG

Saalhoffer Str. 17

47495 Rheinberg

Tel.:

+49 - 2843 - 72 0

Fax:

+49 - 2843 - 6 02 70

e-mail: aumund@aumund.de

www.aumund.com

AUMUND AG

Ober Altstadt 32a, P.O. Box

6301 Zug

Tel.:

+41 - 41 - 710 10 82

Fax:

+41 - 41 - 710 42 02

e-mail: zug@aumund.ch

AUMUND Frdertechnik

GmbH

Saalhoffer Str. 17

47495 Rheinberg

Tel.:

+49 - 2843 - 72 0

Fax:

+49 - 2843 - 6 02 70

e-mail: aumund@aumund.de

www.aumund.com

SCHADE Lagertechnik

GmbH & Co.KG

Dorstener Strae 360

44653 Herne

Tel.:

+49 - 2325 - 58 74 0

Fax:

+49 - 2325 - 58 74 74

e-mail:

info@schade-lagertechnik.de

www.schade-lagertechnik.com

THE NETHERLANDS

AUMUND Holding B.V.

Spoorstraat 42-52

5911 KJ Venlo

Tel.:

+31 - 77 - 351 98 75

Fax:

+31 - 77 - 320 07 28

e-mail: aumund@aumund-holding.nl

GREAT BRITAIN

B&W Mechanical Handling Ltd.

Lancaster Way

Ely, Cambridgeshire CB6 3NP

Tel.:

+44 - 1353 - 665 001

Fax:

+44 - 1353 - 666 734

e-mail: sales@bwmech.co.uk

www.bwmech.co.uk

FRANCE

AUMUND France S.A.R.L.

53, Rue dHauteville . 75010 Paris

Tel.:

+33 - 1 - 42 46 72 72

Fax:

+33 - 1 - 42 46 72 74

e-mail: aumund@aumund.fr

PREMAS AG

Loewenstr. 55, P.O. Box

8023 Zrich

Tel.

+41 - 44 - 2 10 30 05

Fax

+41 - 44 - 2 10 31 15

e-mail: info@premas.ch

www.premas.ch

BRAZIL

AUMUND Ltda.

Rua Haddock Lobo, 337 - 11. andar

01414-001 So Paulo, SP

Tel.:

+55 - 11 - 3059 0160

Fax:

+55 - 11 - 3059 0161

e-mail: aumund@aumund.com.br

USA

AUMUND Corporation

2300 Windy Ridge Parkway

Suite 150S

Atlanta, GA 30339

Tel.:

+1 - 770 - 226 - 95 78 / 80

Fax:

+1 - 770 - 953 - 48 44

e-mail: sales@aumundusa.com

INDIA

AUMUND Engineering

Private Ltd.

2nd Floor, Lakshmi Neela Rite Choice

Chambers . 9, Bazulla Road,

T. Nagar Chennai - 600 017

Tel.:

+91 - 44 - 2815 60 48 / 49

Fax:

+91 - 44 - 2815 60 46

e-mail: aumund@vsnl.com

HONG KONG SAR

AUMUND Asia (H.K.) Ltd.

1301 Oxford House, Taikoo Place,

979 King's Road, Quarry Bay

Hong Kong

Tel.:

+852 - 3695 - 43 33

Fax:

+852 - 3695 - 43 11

e-mail: info@aumund-asia.com

P.R. CHINA

POLAND

AUMUND Polska

Representative Office

ul. Lektorska 34 G . 44-210 Rybnik

Tel.:

+48 - 32 - 426 32 11

Fax:

+48 - 32 - 426 32 01

e-mail: aumund@post.pl

AUMUND (China)

Room 909, East Ocean Center,

No.24A, Jian Guo Men Wai Street,

Chao Yang District . Beijing 100004

Tel.:

+86 - 10 - 65 15 58 13 / 14

Fax:

+86 - 10 - 65 15 58 15

e-mail: aumund@aumund.cn

2006 by AUMUND Frdertechnik GmbH All rights reserved. Neither this document nor any part of it may be reproduced or stored,

processed, duplicated of circulated e.g. by using electronic systems in any form or by any means without the prior authorisation of

AUMUND Frdertechnik GmbH. In case of infringements the infringing party will be obliged to compensate for all damages incurred.

19

W E

C O N V E Y

Q U A L I T Y

Your partner for all requirements regarding material

handling and storage.

We design, engineer, manufacture, erect and service

reliable equipment.

Reputation and competence proven by more than

10.000 installations in over 100 countries.

www.aumund.com

AU MUND Foerdertechnik GmbH . Saalhoffer Str. 17 . 47495 Rheinberg (Germany)

Tel.: + 49 (0) 28 43-720 . Fax: + 49 (0) 28 43-6 02 70 . e-mail: aumund@aumund.de

GB Technical data subject to change without notice A-GB-018-III/06-MA

AUMUND Headquarters in Rheinberg, Germany

You might also like

- Assessor Contract TemplateDocument4 pagesAssessor Contract TemplateChristian Makande100% (2)

- BROCHURE PEGSON 4242SR - TerexPegson+SpecsDocument9 pagesBROCHURE PEGSON 4242SR - TerexPegson+SpecsGoran Erakovic100% (1)

- Pan Conveyors PDFDocument24 pagesPan Conveyors PDFcachorrexNo ratings yet

- A Review On Numerical and Experimental Study of Screw ConveyorDocument4 pagesA Review On Numerical and Experimental Study of Screw ConveyorMangatur SimamoraNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Letter of Intent For SDP Accreditation - Hist QualsDocument3 pagesLetter of Intent For SDP Accreditation - Hist QualsChristian MakandeNo ratings yet

- C-10 Ce ManualDocument193 pagesC-10 Ce Manualbercketowzhenya80% (5)

- Bucket ElevatorsDocument16 pagesBucket Elevatorssdmel100% (3)

- Pan ConveyorsDocument24 pagesPan ConveyorswereerNo ratings yet

- Conveying and StoringDocument28 pagesConveying and StoringTin Nguyen100% (1)

- Flexowell - 2013 - EnglischDocument5 pagesFlexowell - 2013 - Englischeduardo_chaban100% (1)

- Bucket Elevators 150520Document16 pagesBucket Elevators 150520RICARDOALEXBORGESNo ratings yet

- Pipe Conveyors: Optimal Solutions For Specialised HandlingDocument6 pagesPipe Conveyors: Optimal Solutions For Specialised Handlingneeshakothari31No ratings yet

- Bucket Elevators Catalogue: Gambarotta GschwendtDocument64 pagesBucket Elevators Catalogue: Gambarotta GschwendtRICARDOALEXBORGESNo ratings yet

- PaletDocument70 pagesPaletargaNo ratings yet

- Pipe Conveyor SystemDocument6 pagesPipe Conveyor Systemsurajit81100% (2)

- BEUMER Bucket ElevatorsDocument12 pagesBEUMER Bucket ElevatorsIsmailNo ratings yet

- Marg Conveyor Bag Handling PresentationDocument8 pagesMarg Conveyor Bag Handling PresentationMarg ConveyorsNo ratings yet

- Bucket Elevator PresentationDocument8 pagesBucket Elevator PresentationSalmanNo ratings yet

- VibratingEquipmentBrochure PDFDocument10 pagesVibratingEquipmentBrochure PDFWilliam VillamizarNo ratings yet

- New High Capacity Bucket Elevator DevelopmentsDocument53 pagesNew High Capacity Bucket Elevator Developmentsnathaniel villanueva100% (1)

- Tenova Takraf Bulk Materials Handling enDocument16 pagesTenova Takraf Bulk Materials Handling engabriell_189100% (1)

- Bucket Elevator ChainDocument4 pagesBucket Elevator Chainluisreng100% (1)

- Eriez-Vibratory Feeders PDFDocument16 pagesEriez-Vibratory Feeders PDFruben quedo salazarNo ratings yet

- Jenikes' TheoryDocument209 pagesJenikes' TheoryMohammad Bataineh100% (1)

- CDM Bucket Elevators: Centrifugal ContinuousDocument2 pagesCDM Bucket Elevators: Centrifugal ContinuousOcta IrawanNo ratings yet

- Apron Feeder CatDocument4 pagesApron Feeder CatNarsi ReddyNo ratings yet

- Presentación Equipo 2Document62 pagesPresentación Equipo 2Ruben Lopez RicoNo ratings yet

- P139-05-M-30-900-R00 CSU - DATASHEET (2020 - 09 - 03rd)Document6 pagesP139-05-M-30-900-R00 CSU - DATASHEET (2020 - 09 - 03rd)CongOanh PHAN100% (1)

- Dura FlexDocument16 pagesDura FlexJohn ChivNo ratings yet

- CEMA Elevador de CangilonesDocument20 pagesCEMA Elevador de CangilonesCORDOVA DAVILA HECTOR ALONSONo ratings yet

- Belt Scale Application GuidelinesDocument25 pagesBelt Scale Application Guidelinesบิ๊ก บิ๊กNo ratings yet

- Bulk Material Handling Belt-Conveyor-CatalogDocument21 pagesBulk Material Handling Belt-Conveyor-CatalogjayNo ratings yet

- Design Efficient FeedersDocument0 pagesDesign Efficient FeedersRajaram JayaramanNo ratings yet

- GSI Bucket Elevator AssemblyDocument38 pagesGSI Bucket Elevator AssemblyElias ArizaNo ratings yet

- Belt Feeder Properly DesignedDocument2 pagesBelt Feeder Properly DesignedCarlos Ediver Arias Restrepo100% (1)

- 06 Kuenzel Elevators GB 10 07Document2 pages06 Kuenzel Elevators GB 10 07Mauricio MpintoNo ratings yet

- Beltwall: Corrugated Sidewall BeltingDocument8 pagesBeltwall: Corrugated Sidewall Beltingcanito73No ratings yet

- C 107 - Pulley Catalog - 04 2014Document46 pagesC 107 - Pulley Catalog - 04 2014kawula alit100% (1)

- Telescopic ChuteDocument2 pagesTelescopic Chutebiswajit sabuiNo ratings yet

- Pipe Conv Presentation ColourDocument25 pagesPipe Conv Presentation Colourgunduanil17No ratings yet

- Belt Bucket Elevator DesignDocument14 pagesBelt Bucket Elevator Designking100% (1)

- Conveyor Chain Selection: P (2.1W + M) F CDocument2 pagesConveyor Chain Selection: P (2.1W + M) F Cmanoj983@gmail.comNo ratings yet

- Ship Unloader LargepneumaticDocument10 pagesShip Unloader LargepneumaticTaufik SinggihNo ratings yet

- Bearing Centre and Face Width in Conveyor PulleyDocument8 pagesBearing Centre and Face Width in Conveyor PulleyPrashant MishraNo ratings yet

- Synergy Shuttle ConveyorDocument5 pagesSynergy Shuttle ConveyorTamal Tanu RoyNo ratings yet

- Enclosed Roller Belt ConveyorsDocument4 pagesEnclosed Roller Belt ConveyorsBuguinNo ratings yet

- Frank Loeffler - Pipe Tube Conveyor PDFDocument12 pagesFrank Loeffler - Pipe Tube Conveyor PDFIgor San Martín Peñaloza0% (1)

- Chain Conveyor PT MagmaDocument22 pagesChain Conveyor PT MagmaendriaberNo ratings yet

- Beumer Chain Bucket Elevator enDocument8 pagesBeumer Chain Bucket Elevator enArghya BasakNo ratings yet

- Material Handling Expertise: Screw Conveyors, Drag Conveyors & Bucket ElevatorsDocument18 pagesMaterial Handling Expertise: Screw Conveyors, Drag Conveyors & Bucket ElevatorsSanjeevNo ratings yet

- Hosch Opearting Manual1 PDFDocument13 pagesHosch Opearting Manual1 PDFZahoor AhmedNo ratings yet

- Brochure - Slide Gate Valve - Pubc-0502-SvDocument2 pagesBrochure - Slide Gate Valve - Pubc-0502-SvedgarspalaciosNo ratings yet

- 9.long Overland ConveyorsDocument14 pages9.long Overland ConveyorsMauricio MpintoNo ratings yet

- KWS Cat PDFDocument126 pagesKWS Cat PDFThaveep RatanakuhaNo ratings yet

- 2010 - Telescopic ChuteDocument29 pages2010 - Telescopic ChutesteelageNo ratings yet

- Soportes Take UP STL Series - Rodamientos SmilovicDocument4 pagesSoportes Take UP STL Series - Rodamientos SmilovicAlejandro SmilovicNo ratings yet

- Automatic Samplers: Proven & DependableDocument6 pagesAutomatic Samplers: Proven & DependableHarish KumarNo ratings yet

- 10 Drag Conveyor Section VIIDocument11 pages10 Drag Conveyor Section VIIBUDAPESNo ratings yet

- Mato Belt Cleaner CatalogueDocument12 pagesMato Belt Cleaner Catalogueleeyod100% (1)

- AUMUND Pan Conveyors Fd0a10Document24 pagesAUMUND Pan Conveyors Fd0a10Bruno100% (1)

- Pan Conveyors PDFDocument24 pagesPan Conveyors PDFRaji SuriNo ratings yet

- Roller Conveyor CatalogueDocument50 pagesRoller Conveyor CatalogueAbudo Paixao100% (2)

- Drag Chain ConveyorsDocument20 pagesDrag Chain Conveyorsmseif1980No ratings yet

- Saqa 115056 MatrixDocument14 pagesSaqa 115056 MatrixChristian MakandeNo ratings yet

- Articulation, Construct and Portability With Other Courses/qualificati OnsDocument6 pagesArticulation, Construct and Portability With Other Courses/qualificati OnsChristian MakandeNo ratings yet

- Engineering DrawingDocument26 pagesEngineering DrawingChristian Makande100% (1)

- 234201000-KM-04-POE GuideDocument31 pages234201000-KM-04-POE GuideChristian MakandeNo ratings yet

- Finlay Training Services Ad24a98430Document1 pageFinlay Training Services Ad24a98430Christian MakandeNo ratings yet

- Accreditation Guidelines For ProvidersDocument12 pagesAccreditation Guidelines For ProvidersChristian MakandeNo ratings yet

- Example Individual Risk DashboardDocument1 pageExample Individual Risk DashboardChristian MakandeNo ratings yet

- A MatrixDocument6 pagesA MatrixChristian MakandeNo ratings yet

- Oxy Acetylene Cutting TorchDocument2 pagesOxy Acetylene Cutting TorchChristian Makande100% (1)

- SAQA - 8964 - Assessment GuideDocument40 pagesSAQA - 8964 - Assessment GuideChristian Makande100% (4)

- Course OutlineDocument1 pageCourse OutlineChristian MakandeNo ratings yet

- Sansa 10295Document15 pagesSansa 10295Christian MakandeNo ratings yet

- Title: Safe Work Procedure TemplateDocument1 pageTitle: Safe Work Procedure TemplateChristian MakandeNo ratings yet

- Quick Sell Repossessed Properties FNB: WWW - Quicksell.co - ZaDocument9 pagesQuick Sell Repossessed Properties FNB: WWW - Quicksell.co - ZaChristian MakandeNo ratings yet

- Alignment Matrix - 256520 - Control TrafficDocument1 pageAlignment Matrix - 256520 - Control TrafficChristian MakandeNo ratings yet

- Vehicle Hoist: Do NotDocument1 pageVehicle Hoist: Do NotChristian MakandeNo ratings yet

- National Certificate - Construction Plant OperationsDocument1 pageNational Certificate - Construction Plant OperationsChristian MakandeNo ratings yet

- International/Regional Show Performance Contract: Agreement To Engage ArtistDocument3 pagesInternational/Regional Show Performance Contract: Agreement To Engage ArtistChristian MakandeNo ratings yet

- Christian SADocument219 pagesChristian SAChristian MakandeNo ratings yet

- SUmmative Assessment - CAPADocument11 pagesSUmmative Assessment - CAPAChristian MakandeNo ratings yet

- Eea 13Document16 pagesEea 13Christian Makande0% (1)

- Management Unit Standard ListDocument1 pageManagement Unit Standard ListChristian MakandeNo ratings yet

- HR Tasks For The Social CollectiveDocument2 pagesHR Tasks For The Social CollectiveChristian MakandeNo ratings yet

- Torcky Vibes: International/Regional Show Performance ContractDocument3 pagesTorcky Vibes: International/Regional Show Performance ContractChristian MakandeNo ratings yet

- Data Extraction - TheknotDocument8 pagesData Extraction - TheknotChristian MakandeNo ratings yet

- 66789Document2 pages66789Christian MakandeNo ratings yet

- Floor PlanDocument1 pageFloor PlanChristian MakandeNo ratings yet

- Review On Three Way Unloading Tipper MechanismDocument3 pagesReview On Three Way Unloading Tipper Mechanismشہزاد نقویNo ratings yet

- CPW ManualDocument10 pagesCPW ManualvinodsnNo ratings yet

- Manual Gl1000 - EngDocument34 pagesManual Gl1000 - EngAlbertsenNo ratings yet

- EMF Nienburg 23225Document91 pagesEMF Nienburg 23225Ильнур Тагиров0% (1)

- ELIDA Products CatalogueDocument37 pagesELIDA Products CatalogueAbhishek AgarwalNo ratings yet

- Cema B 07Document6 pagesCema B 07jasgxNo ratings yet

- Motion Control Drives D31 1 Complete English 06 2018 PDFDocument400 pagesMotion Control Drives D31 1 Complete English 06 2018 PDFDavidMarianNo ratings yet

- Lubrication DetailsDocument16 pagesLubrication DetailsSaravanan ParamasivamNo ratings yet

- PS & HS Series Stackers PDFDocument3 pagesPS & HS Series Stackers PDFMilan SjausNo ratings yet

- Flyingbelt Factsheet July2016Document28 pagesFlyingbelt Factsheet July2016nicolasNo ratings yet

- Bruks Siwertell-Port-mobile UnloadersDocument6 pagesBruks Siwertell-Port-mobile UnloadersUdien HamzahNo ratings yet

- Ramsey Weiight ScaleDocument4 pagesRamsey Weiight ScaleIkram Hisan AkbarNo ratings yet

- Hoja de Datos 14092018v2Document1 pageHoja de Datos 14092018v2José TimanáNo ratings yet

- Ht2003 Tub Drag Types TB Jul2015Document3 pagesHt2003 Tub Drag Types TB Jul2015agung wijayaNo ratings yet

- Plant Engineering September 2016 MagazineDocument68 pagesPlant Engineering September 2016 MagazineMariver LlorenteNo ratings yet

- Conveyor SystemDocument32 pagesConveyor SystemAJ BantayNo ratings yet

- ConeDocument8 pagesCone채경호No ratings yet

- Hopper Discharge SystemsDocument8 pagesHopper Discharge Systemsafzalian_ali5352No ratings yet

- Webinar Application Solutions: Conveyor Load Sharing Conveyor Load SharingDocument9 pagesWebinar Application Solutions: Conveyor Load Sharing Conveyor Load Sharingesau hernandezNo ratings yet

- Rapiscan 632DV DatasheetDocument2 pagesRapiscan 632DV DatasheetClipping ValleyNo ratings yet

- Vibrating ConveyorDocument4 pagesVibrating ConveyorMinh Nguyễn vănNo ratings yet

- Bottle Washers, Factors Affecting Washing Operations, Power Requirements of Can and Bottle WashersDocument3 pagesBottle Washers, Factors Affecting Washing Operations, Power Requirements of Can and Bottle WashersMonty KushwahaNo ratings yet

- Mining 01 00011Document13 pagesMining 01 00011bernardNo ratings yet

- BRANDT HS 2172 Centrifuge Technical FlyerDocument2 pagesBRANDT HS 2172 Centrifuge Technical FlyerCrudeMan FangNo ratings yet

- Continuous Band Sealer Instruction Manual: Distributed byDocument45 pagesContinuous Band Sealer Instruction Manual: Distributed byCarlos Enrique Rugeles BarrosoNo ratings yet

- Tira X Coal MillDocument3 pagesTira X Coal MillMohamed ShehataNo ratings yet

- Automation Catalogue En-Uk Part2Document40 pagesAutomation Catalogue En-Uk Part2Abid Hossain Rupam100% (1)

- Xis 7858Document2 pagesXis 7858Tedy ManNo ratings yet