Professional Documents

Culture Documents

Critical Speed Formula

Critical Speed Formula

Uploaded by

LymeparkCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Critical Speed Formula

Critical Speed Formula

Uploaded by

LymeparkCopyright:

Available Formats

BASIC DESIGN

SELECTION TABLES

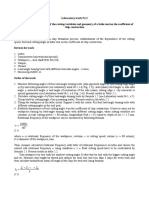

Critical Speed

All mechanical devices have several vibration frequencies. If a ballscrew or ball nut rotates at an

angular velocity equal to one of the ballscrews natural frequencies, a severe vibration will be set

up in the screw. The first order critical speed of the screw is the lowest natural traverse frequency.

(The second, and higher, order natural frequencies are normally an order of magnitude above all

ballscrew operating speeds.)

Critical Speed Formula

N=CS x 4.76 x 106 x D

L2

NS = N x FS

Where:

N =

NS =

D =

L =

FS =

CS =

Critical Speed (RPM)

Safe Drive Speed

Minor (root) Diameter (inches)

Length between Bearing

Supports (inches)

Factor of Safety (.80 maximum)

End Fixity Factor for

Critical Speed

CS

End Supports

.36

1.00

1.47

2.23

One end rigid, one end free

Both ends simple

One end rigid, one end simple

Both ends rigid

The maximum safe operating speed of a ballscrew assembly for normal operation is 80% of the critical speed provided the ball speed limit has

not been exceed. The critical speed is a function of the unsupported screw length, the screw diameter, and the end bearing supports.

The unsupported length is the dominate factor, because the critical speed is inversely proportional to the square of the unsupported length.

Using a fixed unsupported screw length, the critical speed can be varied by the selection of the screw diameter, lead and end bearing supports.

18

You might also like

- The Special Theory of Relativity A Critical Analysis Louis Essen DigitizedDocument26 pagesThe Special Theory of Relativity A Critical Analysis Louis Essen DigitizedStanley V Byers100% (1)

- Unit2ProgressCheckMCQPartA SOLUTIONSDocument16 pagesUnit2ProgressCheckMCQPartA SOLUTIONSzinakhalid2007No ratings yet

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Vibration Diagonistic ChartDocument1 pageVibration Diagonistic Chartjawadhussain1100% (10)

- NSMS MmsDocument19 pagesNSMS MmsAnkur ChelseafcNo ratings yet

- R&T 2008 - Principles and Practices of Vibrational Analysis - KeeferDocument64 pagesR&T 2008 - Principles and Practices of Vibrational Analysis - KeeferArnab De100% (1)

- Vibration AnalysisDocument75 pagesVibration Analysistylerdurdane100% (12)

- YCM XV SeriesDocument12 pagesYCM XV SeriesCNC SYSTEMSNo ratings yet

- Vibration BasicsDocument120 pagesVibration Basicspradeep.selvarajan100% (1)

- 20100716172219667Document6 pages20100716172219667김두리No ratings yet

- Chapter 3Document45 pagesChapter 3mashikhe100% (3)

- Bolts TheoryDocument30 pagesBolts TheoryIbrahim Mesfin100% (1)

- Tolerancing SystemDocument24 pagesTolerancing SystemLenis Enrique Julio QuintanaNo ratings yet

- Machine ToolDocument30 pagesMachine ToolRagavanSivaNo ratings yet

- Reduction of Shock Response Spectra Using Various Types of Shock Isolation MountsDocument11 pagesReduction of Shock Response Spectra Using Various Types of Shock Isolation MountssnayderNo ratings yet

- Bolted Joint AnalysisDocument19 pagesBolted Joint AnalysisSyed MajeedNo ratings yet

- Ballscrew Selection 1.1Document25 pagesBallscrew Selection 1.1Абдельнасир АбдельрахманNo ratings yet

- Introduction To Belt Drive: SelectionDocument40 pagesIntroduction To Belt Drive: Selectionsohkimfai6340100% (2)

- Basic Machinery VibrationsDocument85 pagesBasic Machinery Vibrationsد. ثائر جبار نتيشNo ratings yet

- TS27R User Guide (H-2000-5018-06-D)Document76 pagesTS27R User Guide (H-2000-5018-06-D)Felipe SchiehllNo ratings yet

- Basic Machinery VibrationsDocument181 pagesBasic Machinery Vibrationsxtremewhiz100% (1)

- Lanci I LancaniciDocument160 pagesLanci I Lancanicimiroslav11No ratings yet

- 1 Unit 1 NotesDocument33 pages1 Unit 1 NotesVikas RathodNo ratings yet

- Cutting Force Measurement: New Rotating Dynamometer For The Analysis of High Speed Cutting ProcessesDocument15 pagesCutting Force Measurement: New Rotating Dynamometer For The Analysis of High Speed Cutting ProcessesAmR El SHeNaWyNo ratings yet

- Ball Screws For High-Speed Machine Tools HMS Series: FeaturesDocument2 pagesBall Screws For High-Speed Machine Tools HMS Series: FeaturesSon PhamNo ratings yet

- English 2 Chip ContractionDocument3 pagesEnglish 2 Chip ContractionBozkurt EkinNo ratings yet

- Milling Tech Info FormulasDocument5 pagesMilling Tech Info Formulasசிலம்பரசன் செல்வராஜ்No ratings yet

- CM3068 en Alarm Criteria 010512Document6 pagesCM3068 en Alarm Criteria 010512FazliJaafarNo ratings yet

- HELIXLeadScrewSelection PDFDocument15 pagesHELIXLeadScrewSelection PDFJoel Diamante Gadayan Jr.No ratings yet

- Cutting Force Measurements in Conventional LatheDocument4 pagesCutting Force Measurements in Conventional LatheArpanNo ratings yet

- Transient Speed Vibration Analysis: Insights Into Machinery BehaviorDocument47 pagesTransient Speed Vibration Analysis: Insights Into Machinery Behaviorpeach5No ratings yet

- Fastener and Screw Torque DesignDocument6 pagesFastener and Screw Torque DesignjigneshNo ratings yet

- Muthu Cad 2Document8 pagesMuthu Cad 2Sagarias AlbusNo ratings yet

- Force CalcDocument12 pagesForce CalcSammy-papa Maropeng ShikaNo ratings yet

- Student Manual of Torsional Damped & Un Damped ApparatusDocument3 pagesStudent Manual of Torsional Damped & Un Damped ApparatusaqibNo ratings yet

- Aitek Magnetic Pickups MPU Cat08 - SensorsDocument40 pagesAitek Magnetic Pickups MPU Cat08 - SensorsJose Luis Castro Aguilar0% (1)

- Programming Spindle Speed Variation For Machine Tool Chatter SuppressionDocument12 pagesProgramming Spindle Speed Variation For Machine Tool Chatter SuppressionGatyo GatevNo ratings yet

- Bearing TestersDocument6 pagesBearing TestersAshwani KansaraNo ratings yet

- NFPA Web Phase 3 - ESFR Sprinklers and Obstructions 12.15.16Document75 pagesNFPA Web Phase 3 - ESFR Sprinklers and Obstructions 12.15.16Ashraf Adel Nashed ZakiNo ratings yet

- Operator PresentationDocument41 pagesOperator PresentationRoberto OrtegaNo ratings yet

- Research Inventy: International Journal of Engineering and ScienceDocument6 pagesResearch Inventy: International Journal of Engineering and ScienceresearchinventyNo ratings yet

- CIRP Annals - Manufacturing Technology: Y. Altintas (1), M. Eynian, H. OnozukaDocument4 pagesCIRP Annals - Manufacturing Technology: Y. Altintas (1), M. Eynian, H. OnozukafgdfsgdfNo ratings yet

- Bearing Mini ExpertDocument21 pagesBearing Mini ExpertgeorgepharoNo ratings yet

- Mechanical Shock and Vibration TestingDocument43 pagesMechanical Shock and Vibration TestingAmit Singh DehuryNo ratings yet

- Mech 5sem DMEDocument114 pagesMech 5sem DMEGanesh DongreNo ratings yet

- TR - Validation Test Case - NASADocument7 pagesTR - Validation Test Case - NASALav BajpaiNo ratings yet

- Design Calculation of Nozzle Junction Based On ASME Pressure Vessel Design CodeDocument7 pagesDesign Calculation of Nozzle Junction Based On ASME Pressure Vessel Design CodebiniamNo ratings yet

- Data Sheet Renishaw TS27R Toolsetting ProbeDocument2 pagesData Sheet Renishaw TS27R Toolsetting ProbePham LongNo ratings yet

- Data Sheet Renishaw TS27R Toolsetting Probe PDFDocument2 pagesData Sheet Renishaw TS27R Toolsetting Probe PDFPham LongNo ratings yet

- Vibration PresentationDocument22 pagesVibration PresentationZikireya79No ratings yet

- Rolling Element Bearing Analysis: by Brian P. Graney and Ken StarryDocument8 pagesRolling Element Bearing Analysis: by Brian P. Graney and Ken StarryAlejandro José Poveda GuevaraNo ratings yet

- Notes On Lesson: Faculty Name Code Subject Name CodeDocument108 pagesNotes On Lesson: Faculty Name Code Subject Name CodeJeba ChristoNo ratings yet

- Vibration & FFT Analyzer BasicDocument29 pagesVibration & FFT Analyzer BasicGTENG CPINo ratings yet

- Keys LectureDocument4 pagesKeys LectureellyNo ratings yet

- Metal Cutting Theory and MechanismDocument75 pagesMetal Cutting Theory and Mechanismnishantdubey1183No ratings yet

- Measurement While Drilling: Signal Analysis, Optimization and DesignFrom EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNo ratings yet

- BS en 1452 2 PVC U Pipe SpecDocument38 pagesBS en 1452 2 PVC U Pipe SpecmahdiNo ratings yet

- Thermo-Act: Automatic Fire Extinguishing SystemDocument8 pagesThermo-Act: Automatic Fire Extinguishing SystemelrajilNo ratings yet

- Certificate of Compliance: Centrifugal Fire Pumps (Horizontal, End Suction Type)Document1 pageCertificate of Compliance: Centrifugal Fire Pumps (Horizontal, End Suction Type)elrajilNo ratings yet

- 210 MW PP List of Temporary Piping Material For Acid CleaningDocument2 pages210 MW PP List of Temporary Piping Material For Acid CleaningelrajilNo ratings yet

- Pressure GuagesDocument6 pagesPressure GuageselrajilNo ratings yet

- KKS+ +Function+and+Type PDFDocument1 pageKKS+ +Function+and+Type PDFelrajilNo ratings yet

- Report 85 Pul Coal PDFDocument59 pagesReport 85 Pul Coal PDFelrajilNo ratings yet

- 2-Critical Speed of ShaftDocument5 pages2-Critical Speed of ShaftRidani Faulika Amma100% (3)

- Xinhua Digital Electro-Hydraulic Control System DEH-V For Steam TurbinesDocument36 pagesXinhua Digital Electro-Hydraulic Control System DEH-V For Steam TurbineselrajilNo ratings yet

- M Mahfoz C.V 20 Nov StartupDocument4 pagesM Mahfoz C.V 20 Nov StartupelrajilNo ratings yet

- Critical Speedy AwDocument72 pagesCritical Speedy AwelrajilNo ratings yet

- Improving Critical Speed Calculations Using Flexible Bearing Support FRF Compliance DataDocument27 pagesImproving Critical Speed Calculations Using Flexible Bearing Support FRF Compliance DataelrajilNo ratings yet

- Ultrasonic Testing MethodsDocument10 pagesUltrasonic Testing Methodselrajil67% (3)

- Electrical System COMMISSIONING PDFDocument18 pagesElectrical System COMMISSIONING PDFelrajilNo ratings yet

- Steam BlowingDocument25 pagesSteam Blowingelrajil0% (1)

- Identification of High Energy Gamma Particles From The Cherenkov Gamma Telescope Data Using A Deep Learning ApproachDocument13 pagesIdentification of High Energy Gamma Particles From The Cherenkov Gamma Telescope Data Using A Deep Learning ApproachkkarthiksNo ratings yet

- Bangladesh Hi-Tech Park Authority Act Gazette 18 March 2010Document12 pagesBangladesh Hi-Tech Park Authority Act Gazette 18 March 2010sayempathan5655No ratings yet

- FC Questions On Magnetic Materials and Its ClassificationsDocument13 pagesFC Questions On Magnetic Materials and Its ClassificationsDawa PenjorNo ratings yet

- OU - 1603 OU - 1603: Facuty of EngineeringDocument9 pagesOU - 1603 OU - 1603: Facuty of EngineeringMOHAMMED ASADULLAH HUSSAININo ratings yet

- Cambridge International AS & A Level: PHYSICS 9702/42Document28 pagesCambridge International AS & A Level: PHYSICS 9702/42Vinod ChackoNo ratings yet

- Unit 1 Physics Lesson 2 Forces in Nature PDFDocument4 pagesUnit 1 Physics Lesson 2 Forces in Nature PDFRishel AlamaNo ratings yet

- Barrier Tunneling by Matter Wave: Review & SummaryDocument7 pagesBarrier Tunneling by Matter Wave: Review & SummaryahmedNo ratings yet

- 3 - Modern Atomic TheoryDocument28 pages3 - Modern Atomic Theorysalvador.xyriesyuan.g7peaceNo ratings yet

- Origin of The Solar System - Early TheoriesDocument8 pagesOrigin of The Solar System - Early TheoriesCharles CaraigNo ratings yet

- Unit 5 - Antenna & Wave Propagation - WWW - Rgpvnotes.inDocument19 pagesUnit 5 - Antenna & Wave Propagation - WWW - Rgpvnotes.inRohit kumarNo ratings yet

- ( ) - BCS All Books PDF 2020Document4 pages( ) - BCS All Books PDF 2020Mohammad Asaduzzaman ShakibNo ratings yet

- MSC Physics-syllabus-CBCSS-2019Document3 pagesMSC Physics-syllabus-CBCSS-2019AshiqueNo ratings yet

- Physics Experiment 4Document2 pagesPhysics Experiment 4Debraj SarkarNo ratings yet

- 3.fluid Flow PhenomenaDocument19 pages3.fluid Flow PhenomenaMAHLATSE MULALANo ratings yet

- Albert Einstein The Theory of Relativity: February 2018Document3 pagesAlbert Einstein The Theory of Relativity: February 2018Ed VNo ratings yet

- Probability DistributionDocument15 pagesProbability Distributionpatty444No ratings yet

- A Review of The State-Of-The-Art Nanofluid SprayDocument38 pagesA Review of The State-Of-The-Art Nanofluid Spraywayneneo21No ratings yet

- 05 Tutorial ElectrodynamicsDocument4 pages05 Tutorial ElectrodynamicsmukeshNo ratings yet

- November 2002 QP - Paper 3 CIE Physics IGCSEDocument16 pagesNovember 2002 QP - Paper 3 CIE Physics IGCSESARVESH MORENo ratings yet

- Koskinen2015 PDFDocument200 pagesKoskinen2015 PDFNastase DamianNo ratings yet

- Electrostatics DPP - 230503 - 234530Document6 pagesElectrostatics DPP - 230503 - 234530duttsharmashiv0001No ratings yet

- NPTEL Web Course On Complex Analysis: A. SwaminathanDocument19 pagesNPTEL Web Course On Complex Analysis: A. SwaminathanMohit SharmaNo ratings yet

- PIP928 FinalDocument8 pagesPIP928 FinalfoynthoshzjtpadrygNo ratings yet

- Prog-1 Daily Practice Assignment-1 Subject: Physics Chapter: VectorsDocument13 pagesProg-1 Daily Practice Assignment-1 Subject: Physics Chapter: VectorsAkash AbbarapuNo ratings yet

- Reading Material Expanding UniverseDocument7 pagesReading Material Expanding Universealwena aquinoNo ratings yet

- Lectuer 3Document20 pagesLectuer 3ايمن العراقيNo ratings yet

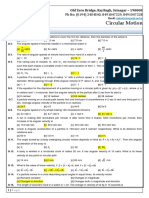

- Circular Motion (29-04-2021)Document3 pagesCircular Motion (29-04-2021)Maroofa BhatNo ratings yet