Professional Documents

Culture Documents

A Creep-Properties Evaluation of P91 Steel PDF

Uploaded by

mahmoud_allam3Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Creep-Properties Evaluation of P91 Steel PDF

Uploaded by

mahmoud_allam3Copyright:

Available Formats

UDK 539.37:539.53:669.

14

Izvirni znanstveni ~lanek

ISSN 1580-2949

MTAEC 9, 36(6)319(2002)

R. [TURM ET AL.: A CREEP-PROPERTIES EVALUATION OF P91 STEEL WELDMENTS ...

A CREEP-PROPERTIES EVALUATION OF P91 STEEL

WELDMENTS USING SHORT-TERM TESTING

OCENITEV LASTNOSTI LEZENJA VARA IZ JEKLA P91

S KRATKOTRAJNIMI PRESKUSI

Roman [turm, Monika Jenko, Boris Ule

Institute of Metals and Technology, Lepi pot 11, 1000 Ljubljana, Slovenia

roman.sturm@imt.si

Prejem rokopisa - received: 2002-10-18; sprejem za objavo - accepted for publication: 2002-12-09

A key factor in any power station is the choice of materials designed to operate at the highest possible steam temperature

consistent with reasonable component weights and thicknesses. Over the last two decades a new generation materials,

particularly in the form of modified 9Cr-1Mo steels, have been widely used for replacement equipment and for new

constructions.

This paper is concerned with the creep properties of modified P91 steel weldments, where the application of the small-punch

test method for the assessment of material creep properties is used. Experiments have shown that the small-punch test can be

used to describe the time-to-failure by means of an equation of the Dorn type, in which stress is replaced by load. The tests were

carried out at temperatures from 560 C to 640 C and at loads from 460 to 610 N. The disc-shaped test specimens (8 mm x 0.5

mm) were machined from pure welds. There were three different states of welds: as-welded and with two different post-weld

heat treatments (PWHTs). For small-punch tests less material is needed to establish creep activation energies and load

exponents than with conventional creep tests. The conventional constant-load creep tests were performed at 600 C and 620 C

under applied stresses ranging from 130 to 150 MPa. The microstructures of all the samples were also examined before and

after the creep testing.

Key words: P91 steel, weld, small-punch, short term creep testing

V vsaki termoelektrarni je klju~nega pomena izbor materiala, s katerim naj sistem pri razumnih te`ah in debelinah komponent

deluje pri najvi{jih mo`nih temperaturah. V zadnjih dveh desetletjih se za nove konstrukcije in zamenjave opreme veliko

uporablja nova generacija materialov, najve~ v obliki modificiranih jekel 9Cr-1Mo.

V tem prispevku je narejena raziskava o lastnostih lezenja varov iz dodajnega materiala iz modificiranega jekla P91, pri ~emer

je bila za oceno lastnosti lezenja materiala uporabljena metoda merjenja z uporabo majhnega bata (small-punch). Eksperimenti

so pokazali, da lahko s preskusi "small-punch" opi{emo ~as do loma z ena~bo Dornovega tipa, v kateri napetost zamenjamo z

obremenitvijo. Preskusi lezenja so bili narejeni pri temperaturah od 560 C do 640 C in pri obremenitvah od 460 N do 610 N.

Preizku{anci v obliki diska (8 mm x 0,5 mm) so bili izrezani iz ~istega vara. Zvari so bili v treh stanjih, in sicer v varjenem

stanju in z dvema razli~nima toplotnima obdelavama. Pri presku{anju z majhnim batom potrebujemo mnogo manj materiala za

ugotovitev aktivacijske energije lezenja in obremenitvenega koeficienta kot pa pri konvencionalnih preskusih lezenja. Poleg

preskusov z majhnim batom smo izvedli tudi konvencionalne preskuse lezenja pri konstantni obremenitvi pri temperaturah 600

C in 620 C ter pri uporabljenih napetostih od 130 MPa do 150 MPa. Mikrostrukturo preizku{ancev smo pregledali pred

meritvami lezenja in po njih.

Klju~ne besede: jeklo P91, var, majhni bat, kratkotrajni preskusi lezenja

1 INTRODUCTION

A number of test techniques for extracting

mechanical property data from small volume specimens

are under development 1,2. The small-punch creep

method is a test technique originally developed for

estimating the fracture-appearance transition temperature

3. In the small-punch test a thin circular disc is supported

over a receiver hole and forced to deform into the hole

by a spherical penetrator 4-6. When the evaluation of the

observed dependence of the minimum displacement rate

upon stress and temperature was performed, we found,

that the load exponent and the measured activation

energy were typical of the values for the investigated

experimental steel. Over the last two decades a new

generation of materials, particularly in the form of

modified 9Cr-1Mo 7-10, have been widely used for

replacement equipment and for new constructions. In the

last few years a lot of effort was put into development of

MATERIALI IN TEHNOLOGIJE 36 (2002) 6

new welding consumables for high-temperature applications. We have tested an existing material for possible

use in high-temperature applications.

2 EXPERIMENTAL PROCEDURE

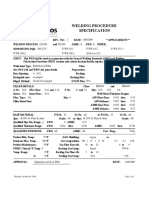

For these experiments we used electrodes of

modified P91 steel for the weldments. We also prepared

buttered carbon steel plates 20 mm thick with 21 passes.

The specimens for the small-punch creep measurements,

with dimensions of 8 mm 0,5 mm, were machined

from pure welds (Figure 1a). The relatively coarse

martensitic microstructure of the experimental P91 steel

weldment in the as-welded condition is shown in Figure

1b. The welds were in three different conditions, i.e.

as-welded and with two different post-weld heat

treatments: PWHT-1 (2h/760 C, air); PWHT-2 (2h/760

C, 150 C/h till 300 C, air) (Figure 1c). The chemical

319

R. [TURM ET AL.: A CREEP-PROPERTIES EVALUATION OF P91 STEEL WELDMENTS ...

Figure 2: Schematic illustration of the dies in the small-punch test

equipment

Slika 2: Shemati~ni prikaz orodja majhnega bata

Figure 1: P91 steel weldment: a) Schematic presentation of pure weld

and location of the specimens, b) The microstructure in the as-welded

condition (AW), c) Welding parameters

Slika 1: Var iz jekla P91: a) shematski prikaz ~istega vara in lokacija

preizku{ancev, b) mikrostruktura v varjenem stanju (AW), c) parametri varjenja

composition of the P91 steel in wt. % is as follows:

C=0,06; Mo=1,0; Si=0,36; Mn=0,6; P=0,015; Cr=9,5;

Ni=0,95 and V=0,21.

The experimental work consisted of tests on

small-punch test equipment (Figure 2). The tests were

carried out at temperatures from 560 C to 640 C, and at

loads from 430 to 610 N. Under each test condition at

least three tests were performed. The test specimens

(disc specimens of diameter D = 8 mm and thickness t =

0,5 mm) were placed on the central axis of the lower die

of the specimen holder and fixed by the upper die so that

there was a loose fitting, i.e. neglecting friction between

the upper die and the specimen. The ball and the puncher

were inserted into the hole in the upper die of the holder.

During the test a constant load acted on the specimen by

means of a ceramic ball of diameter d = 2,5 mm. During

the initial step of loading, the specimen rapidly deformed

plastically into the hole in the lower die, the stresses in

the disc were reduced, and further deformation of the

disc occurred only as a result of creep. The diameter of

the hole was a = 4 mm, and its shoulder radius was R =

320

0,2 mm. The temperature of the specimen was measured

with a thermocouple in the direct vicinity of the

specimen, the permissible variation in temperature being

1 C. The displacement of the punch, i.e. the central

deflection of the disk specimens, was measured using an

inductive transducer with a high measuring accuracy

(repeatability approximately 1 m), and was recorded

continuously by a computer.

Before and after the creep testing of the specimens of

the P91 steel weldments, high-resolution imaging and

Auger-electron spectroscopy (HRAES) were performed

using a static electron beam with 10 keV/1nA of a

diameter of about 10 nm. For each specimen several

characteristic regions of the microstructure were selected

for multi-point analysis.

3 RESULTS

The mechanical properties of the experimental P91

all-welded steel in the as-welded condition and with two

different PWHTs at different testing temperatures are

listed in Table 1. From the mid section of the deposited

all-weld metal Charpy V-notch test specimens were

made for testing all three different welding conditions.

The Charpy impact tests were performed over a

temperature range in which the transition from tough to

brittle behaviour is expected (Figure 3).

Short-term creep tests were performed on a smallpunch test device. The dependence of the applied load P

on the time-to-rupture tr in the small-punch creep tests

can be described by means of a modified form of the

Dorn equation, i.e. an Arrhenius-type equation (4):

Q

(1)

t r = B P n exp

RT

where P is the load (N) acting on the disc, Q is the

activation energy (kJ/mol), n is the load exponent, R is

the universal gas constant (R=8,314 J/molK), T is the

MATERIALI IN TEHNOLOGIJE 36 (2002) 6

R. [TURM ET AL.: A CREEP-PROPERTIES EVALUATION OF P91 STEEL WELDMENTS ...

Table 1: Mechanical properties of the P91 steel weldment at different temperatures

Tabela 1: Mehanske lastnosti vara iz jekla P91 pri razli~nih temperaturah

Welding

conditions

As welded

PWHT-1

PWHT-2

Temp.

(C)

20

500

620

20

500

620

20

500

620

Yield stress

Measured

844 >

750 >

343 >

601 >

416 >

214 <

487 <

366 <

215 <

(MPa)

11

550

380

280

550

380

280

550

380

280

Tensile strength (MPa)

11

Measured

1057 >

700

944 >

440

358 >

330

708 >

700

478 >

440

229 <

330

630 <

700

439 <

440

225 <

330

Charpy-V impact energy

(J)

140

PWHT-2

PWHT-1

As welded

120

100

80

Required

toughness at

20C > 40 J

60

40

20

0

-60

-40

-20

20

40

60

Material conditions of P91

steel weldment

As welded

PWHT-1

PWHT-2

Apparent activation energy

Q (kJ/mol)

352 4

476 151

554 24

MATERIALI IN TEHNOLOGIJE 36 (2002) 6

229

228

2,5

Displacement (mm)

Figure 3: Charpy-V impact energy of P91 steel weldments

Slika 3: Udarna energija Charpy-V varov iz jekla P91

2,0

1,5

580 C

600 C

620 C

P = 580 N

Initial hot

deformation

1,0

250

500

750 1000 1250 1500 1750 2000

Time to rupture tr (min)

2,5

Displacement (mm)

Table 2: The activation energy determined with the small-punch

testing method

Tabela 2: Aktivacijska energija, dolo~ena z metodo presku{anja z

majhnim batom

Hardness

HV3

353

The curves of the time dependence of the

small-punch displacement, i.e. the central disc deflection

at a load of 520 N and a temperature of 600 C of the

P91 steel weldment for the as-welded condition and for

two different PWHTs, respectively, are given in Figure

6. It can be seen that the same general features of the

curves can be observed as in conventional creep tests.

However, the registered curves have a very pronounced

stage of primary creep in which the deflection rate

decreases by several orders of magnitude (initial hot

Test temperature (C)

absolute temperature (K) and B is the constant of the

modified Dorn equation.

Examples of the time dependence of the punch

displacement, i.e. of the central deflection in the

small-punch test at a load of 580 N and temperatures of

580, 600 and 620 C, respectively (a); and at a

temperature of 600 C and loads of 550, 580 and 610 N,

respectively (b); are given for the P91 steel weldment in

the as-welded condition in Figure 4. From the tests

under constant load with three different temperatures we

can calculate the line slope in the diagram ln(t) vs. 1/RT,

which represents the activation energy Q (Table 2). In a

similar way we can calculate the load exponent n (the

line slope in the diagram ln(t) vs. ln(P)) from tests at

constant temperature with three different loads (Figure

5).

Elongation Reduction of area

(%)

(%)

14

43

8

32

17

77

20

66

17

65

26

88

27

69

19

69

24

88

2,0

1,0

550 N

580 N

610 N

T = 600 C

1,5

Initial hot

deformation

0

200

400

600

800

1000

Time to rupture tr (min)

Figure 4: Central disc displacement vs. time in the small-punch test at

different temperatures and loads. The P91 steel weldment is in the

as-welded condition. a) P = const. = 580 N, b) T = const = 600 C

Slika 4: Upogib diska v odvisnosti od ~asa pri preskusu z majhnim

batom pri razli~nih temperaturah in obremenitvah, var iz jekla P91 v

varjenem stanju: a) P = konst. = 580 N, b) T = konst = 600 C

321

R. [TURM ET AL.: A CREEP-PROPERTIES EVALUATION OF P91 STEEL WELDMENTS ...

PWHT-2

n = 7,3 2,3

n = 8,3 8,2

Displacement (mm)

Time to rupture tr (min)

2,5

103

n = 8,9 3,7

102

..... As welded

---- PWHT-1

PWHT-2

430

460

490

520

550

580

2,0

P = 520 N

T = 600 C

0

250 500 750 1000 1250 1500 1750 2000 2250

Time to rupture tr (min)

Load P (N)

Figure 5: Load exponent n for P91 steel weldments in three different

heat-treatment conditions

Slika 5: Obremenitveni koeficient n za var iz jekla P91 v treh razli~nih toplotnih obdelavah

PWHT-1

1,5

1,0

610

As welded

Figure 6: Time dependence of the central disc displacement in the

small-punch test for the P91 steel weldment for three different

heat-treatment conditions

Slika 6: ^asovna odvisnost upogibanja diska pri preskusu z majhnim

batom za var iz jekla P91 pri treh razli~nih toplotnih obdelavah

b

c

Figure 7: HRAES spectra of as-welded and crept specimens of P91 steel weldment shows chromium peaks that indicate a carbide precipitation

process: a) SEM, as-welded, b) SEM, as-welded after 2040 min creep test, c) HRAES, as-welded, d) HRAES, as-welded after 2040 min creep

test

Slika 7: HRAES-spekter varjenega in lezenega preizku{anca iz vara iz jekla P91 ka`e kromove vrhove, ki indicirajo proces precipitacije

karbidov: a) SEM, varjeno stanje, b) SEM, varjeno stanje po 2040-minutnem preskusu lezenja, c) HRAES, varjeno stanje, d) HRAES, varjeno

stanje po 2040-minutnem preskusu lezenja

322

MATERIALI IN TEHNOLOGIJE 36 (2002) 6

R. [TURM ET AL.: A CREEP-PROPERTIES EVALUATION OF P91 STEEL WELDMENTS ...

deformation). The steady-state creep is missing but the

minimum deflection rate can be evaluated.

In parallel with the small-punch tests we also

performed conventional constant-load creep tests with

some lower stresses. The results (time-to-rupture) we

obtained were very different to the results of the

small-punch creep tests. The results are presented in

Table 3.

Table 3: Time to rupture for conventional constant-load creep tests

Tabela 3: ^as do loma pri konvencionalnih preskusih lezenja s

konstantno obremenitvijo

Material conditions of P91

steel weldment

As welded

PWHT-1

PWHT-2

Time to rupture at = 130

MPa, T = 620 C

381,6 h

26,6 h

30,6 h

4 DISCUSSION

The results of the Charpy-V impact energy (Figure

3) show that the P91 steel weldment has toughness in the

as-welded condition that is too low for crack-free

welding. Both PWHTs of the P91 steel weldments

ensure toughness higher than 40 J, which is recommended for welding in high-temperature applications

11 . The mechanical properties of P91 (Table 1) in

comparison with the producers data 11 shows that at

room temperature the yield and the tensile strength are

high enough for as-welded and PWHT conditions. But at

620 C only the as-welded microstructure has the

required yield and tensile strength, while PWHT-1 and

PWHT-2 do not reach the minimum required level.

The short-term creep tests show interesting results.

The comparison of the calculated activation energies Q

of the P91 all-welded steels for different heat-treatment

conditions shows great variation in the values obtained.

Because of this it is better to talk about apparent

activation energies. We can also find differences in the

calculated load exponents, but these are not so large. The

comparison of average time-to-rupture for the same

small-punch testing parameters (P=520 N, T=600 C)

shows that in the case of PWHT-1 the time to rupture is

498 minutes, and in the case of PWHT-2 it is 171

minutes. In other words, for PWHT-1 the time to rupture

is almost three-times longer than in the case of PWHT-2.

However, the results are somewhat different for

conventional constant-load creep testing using the same

testing parameters (Table 3), where for both PWHTs

very similar times to rupture are measured. In the case of

the conventional creep testing the role of yield stress is

shown in the time-to-rupture. The yield stress of the

as-welded material is much higher than it is in the case

of a different PWHT, and because of this the

time-to-rupture is approximately 14 times longer than for

both cases of PWHT.

MATERIALI IN TEHNOLOGIJE 36 (2002) 6

The established discrepancy in the activation energy

Q as well as in the power n between the as-welded and

the PWHT microstructure obtained with the small-punch

creep testing could also be partially explained by the

unstable character of the as welded microstructure.

Namely, the possible precipitation-hardening reactions

(precipitation of vanadium carbides for instance 12) in

thermodynamically unstable microstructure of as-welded

specimens for very short testing periods can coincide

with the main creep reaction of the actual creep

mechanism and can provoke some disturbances in the

creep behavior. High-resolution imaging and analysis

(HRAES) of the as-welded microstructure of the P91

steel before testing and after 2040 minutes of

small-punch creep testing shows a large difference in

precipitation-hardening kinetics (Figure 7). The HRAES

spectra of the as-welded microstructure after 2040

minutes of creep testing (Figure 7d) shows chromium

peaks that indicate a carbide precipitation process.

According to these results the hypothesis of a disturbing

effect of the precipitation-hardening reactions on the

rupture time of small-punch creep testing of an

as-welded microstructure is well established. Therefore,

a high applied load, i.e. a short rupture time during creep

measurement of an all-welded microstructure should be

avoided.

5 CONCLUSIONS

We have investigated the possibilities of using the

small-punch creep-testing method for the assessment of

as-welded material properties. The main advantage of

small-punch creep tests in comparison with conventional

constant-load creep tests is the small amount of material

required for testing to establish the creep activation

energies and the load exponents. A large discrepancy

between the results obtained for small-punch and

conventional creep testing was observed. This

discrepancy is caused by the precipitation-hardening

reactions (the precipitation of chromium carbides) in the

thermodynamically unstable microstructure of as-welded

specimens during very short testing periods, which

coincide with the main creep reaction of the actual creep

mechanism and therefore induce disturbances in the

creep behavior. Of course it was established that the

material characteristics obtained during small-punch

creep measurements are relevant if the times-to-rupture

are not too short. Only when the stress in the specimen is

low enough, the values of the activation energy approach

the values of self-diffusion. A comparison of

small-punch creep-testing results and conventional

creep-testing results is only possible when very similar

and sufficiently long times-to-rupture under both testing

methods are used.

323

R. [TURM ET AL.: A CREEP-PROPERTIES EVALUATION OF P91 STEEL WELDMENTS ...

ACKNOWLEDGEMENTS

The partial support of the European Union as part of

the project SMARTWELD GRD1-2000-25352 is gratefully acknowledged.

6 REFERENCES

1

Lucas G. E.: The development of small specimen mechanical test

techniques, Journal of Nuclear Materials, 117 (1983) 327-399

2

Lucas G. E.: Rewiew of small specimen test technique for irradiation

testing, Metallurgical Transactions A, 21 (1990) 1105-1119

3

Baik J. M., Kameda J., Buck O.: Small-punch test evaluation of

intergranular embrittlement of an alloy steel, Scripta Metall., 17

(1983) 1443-1457

4

Parker J. D., James J. D.: Disc-bend creep deformation behaviour of

1/2Cr1/2Mo1/4V low alloy steel, Proceedings of the 5th International

Conference on the Creep and Fracture of Engineering Materials and

Structures, The Institute of Metals, London, 1993, 651

324

Dobe{ F., Mili~ka K., Ule B., Meile K., Schwarzkopf C.: Miniturized

disk-bend creep test of heat-resistant steels at elevated temperatures,

Engineering Mechanics, 5 (1998) 3, 157-160

6

Ule B., [u{tar T.: The effect of initial hot plastic deformation on

creep behaviour of 12Cr steel specimens in small-punch tests,

Materials at high temperatures, 18 (2001) 3, 163-170

7

Viswanathan R., Bakker W. T., Materials for boilers in ultra supercritical power plants, Proceedings of 2000 International Joint Power

Generation Conference, Miami Beach, Florida, 2000, 1-22

8

Okamura H., Ohtani R., Saito K, Iseki T., Uchida H.: Basic investigation for life assessment technology of modified 9Cr-1Mo steel,

Nuclear Engineering and Design, 193 (1999) 243-254

9

Otoguro Y., Matsubara M., Itoh I., Nakazawa T.: Creep rupture

strength of heat affected zone for 9Cr ferritic heat resistant steels,

Nuclear Engineering and Design, 196 (2000) 51-61

10

Cerri E., Evangelista E., Spigarelli S., Bianchi P.: Evolution of

microstructure in a modified 9Cr-1Mo steel during short term creep,

Materials Science and Engineering, A245 (1998) 285-292

11

Haarmann K., Vaillant J.C., Bendick W., Arbab A.: The T91/P91

Book, Vallourec & Mannesmann Tubes, 1999

12

Ule B.: Toplotna obdelava jeklene litine s povi{ano mejo plasti~nosti, Livarski vestnik, 4 (1983) 127-132

MATERIALI IN TEHNOLOGIJE 36 (2002) 6

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Steam Generators 2Document33 pagesSteam Generators 2gbharathreddysNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Fracture Toughness of The Heat Affected Zone in Girth WeldsDocument7 pagesFracture Toughness of The Heat Affected Zone in Girth Weldsmahmoud_allam3No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Method For Mechanical Properties EvaluationDocument5 pagesMethod For Mechanical Properties Evaluationmahmoud_allam3No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Study of Ductile-Brittle Transition Temperature of 9Cr-1Mo SteelsDocument2 pagesStudy of Ductile-Brittle Transition Temperature of 9Cr-1Mo Steelsmahmoud_allam3No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Furnaces and RefractoriesDocument36 pagesFurnaces and Refractoriesengkassem100% (5)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- PICKLING Gel FOR STAILESS STEEL PdsDocument2 pagesPICKLING Gel FOR STAILESS STEEL Pdsmahmoud_allam3No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- 1english Reg Final Nov 2010 PDFDocument367 pages1english Reg Final Nov 2010 PDFmahmoud_allam3No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Code Case 2891 U-2 CerDocument1 pageCode Case 2891 U-2 Cermahmoud_allam3No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Journal Modified 9% CR Steels For AdvancedDocument6 pagesJournal Modified 9% CR Steels For Advancedmahmoud_allam3No ratings yet

- Nitrogen Purging For Stainless SteelDocument4 pagesNitrogen Purging For Stainless Steelmahmoud_allam3No ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- ASME New Code Case LetterDocument1 pageASME New Code Case Lettermahmoud_allam3No ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Projects Follow UpDocument1 pageProjects Follow Upmahmoud_allam3No ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Passivating Gel For Stainless SteelDocument2 pagesPassivating Gel For Stainless Steelmahmoud_allam3No ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Request For Code CaseDocument2 pagesRequest For Code Casemahmoud_allam3No ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Code Case 2891 U-2 CerDocument1 pageCode Case 2891 U-2 Cermahmoud_allam3No ratings yet

- Color Metallurgy of Cast IronDocument13 pagesColor Metallurgy of Cast Ironmahmoud_allam3No ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Hidada Process EquipmentsDocument4 pagesHidada Process Equipmentsmahmoud_allam3No ratings yet

- Presentation For WeldingDocument31 pagesPresentation For Weldingmahmoud_allam3No ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Color Metallurgy of Cast IronDocument13 pagesColor Metallurgy of Cast Ironmahmoud_allam3No ratings yet

- Welding of P91Document11 pagesWelding of P91mahmoud_allam3100% (1)

- Heat Treatment of 9 CRDocument12 pagesHeat Treatment of 9 CRmahmoud_allam3No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 16-2819 Welders InterpretationDocument1 page16-2819 Welders Interpretationmahmoud_allam3No ratings yet

- Assessment of Welding ConsumablesDocument17 pagesAssessment of Welding Consumablesmahmoud_allam3No ratings yet

- Aluminim WPSDocument5 pagesAluminim WPSmahmoud_allam3No ratings yet

- Aluminim WPSDocument2 pagesAluminim WPSmahmoud_allam3No ratings yet

- Welding of P91Document10 pagesWelding of P91mahmoud_allam3No ratings yet

- 10 1 1 161 3015Document7 pages10 1 1 161 3015rinshadNo ratings yet

- Aluminim WPSDocument2 pagesAluminim WPSmahmoud_allam3No ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Aluminim WPSDocument5 pagesAluminim WPSmahmoud_allam3No ratings yet

- Aluminim WPSDocument2 pagesAluminim WPSmahmoud_allam3No ratings yet

- Behavior of Fastened and Adhesively Bonded Composites Under Mechanical and Thermomechanical LoadsDocument165 pagesBehavior of Fastened and Adhesively Bonded Composites Under Mechanical and Thermomechanical LoadsAlaa ElsisiNo ratings yet

- Comprative Study of Enset and Banana FiberDocument7 pagesComprative Study of Enset and Banana FiberbiniyamNo ratings yet

- 1 s2.0 0045794992902696 MainDocument11 pages1 s2.0 0045794992902696 MainsakhirNo ratings yet

- API 579 IntroductionDocument6 pagesAPI 579 IntroductionNiraj KumarNo ratings yet

- Arp CatalogDocument55 pagesArp Catalogjzaw65No ratings yet

- Polymers For Advanced Techs - 2019 - Liu - Three Dimensional Printing of Poly Lactic Acid Bio Based Composites WithDocument13 pagesPolymers For Advanced Techs - 2019 - Liu - Three Dimensional Printing of Poly Lactic Acid Bio Based Composites WithTIop outNo ratings yet

- Bieniawski - Mechanism of Brittle Fracture of Rock - Part I PDFDocument14 pagesBieniawski - Mechanism of Brittle Fracture of Rock - Part I PDFGuilherme AndersonNo ratings yet

- Best Practice For The Assessment of Defects in Dents and Gouges PDFDocument26 pagesBest Practice For The Assessment of Defects in Dents and Gouges PDFSharbel WgNo ratings yet

- 1985-Review of Cracking of Partially Prestressed Concrete Member Canadian Journal of Civil EngineeringDocument8 pages1985-Review of Cracking of Partially Prestressed Concrete Member Canadian Journal of Civil EngineeringChan Dara KoemNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Boron FibresDocument21 pagesBoron FibresKishore Kumar RajendiranNo ratings yet

- 2017-APFIS Conference - Strengthening Concrete Columns Using NSM CFRP LaminatesDocument4 pages2017-APFIS Conference - Strengthening Concrete Columns Using NSM CFRP LaminatesThanoon AlmarwasyNo ratings yet

- Srisailam Boillaert MasonDocument8 pagesSrisailam Boillaert MasonzuenboNo ratings yet

- Failure Analysis of Economizer PDFDocument6 pagesFailure Analysis of Economizer PDFhangmann169No ratings yet

- Iacs W-22 2004Document15 pagesIacs W-22 2004Guilherme de BarrosNo ratings yet

- NozzlePRO 14.1NewFeatures-2019ReleaseDocument13 pagesNozzlePRO 14.1NewFeatures-2019ReleasedelitesoftNo ratings yet

- CNG Tank DevelopmentDocument98 pagesCNG Tank Developmentjunrey paracuellesNo ratings yet

- Recent Development of High-Strength and Tough Welding Consumables For Offshore StructuresDocument8 pagesRecent Development of High-Strength and Tough Welding Consumables For Offshore StructuresDiNo ratings yet

- Cutting Tool Technology - Mubashir UsmanDocument26 pagesCutting Tool Technology - Mubashir UsmanM.FakharNo ratings yet

- Mechanical Properties of Material: Definition and Example (Notes & PDF)Document5 pagesMechanical Properties of Material: Definition and Example (Notes & PDF)Мария ЮжаковаNo ratings yet

- Demonstrations and ExperimentsDocument57 pagesDemonstrations and ExperimentsJoão Morgado100% (1)

- 2005 Failure Analyis of M16 BoltDocument9 pages2005 Failure Analyis of M16 BoltCharles PowellNo ratings yet

- Study Report On Implications of UnbondednessDocument19 pagesStudy Report On Implications of UnbondednessFatima tuz ZohraNo ratings yet

- Pabuç-Burç Elemanlarında Çevrimsel Yük Altında Meydana Gelen Titreşimli Aşınma Hasarının Deneysel Ve Nümerik Olarak IncelenmesiDocument108 pagesPabuç-Burç Elemanlarında Çevrimsel Yük Altında Meydana Gelen Titreşimli Aşınma Hasarının Deneysel Ve Nümerik Olarak Incelenmesimustafa sertNo ratings yet

- A Review On Hydrogen Embrittlement Risk Based Inspection 1688970506Document31 pagesA Review On Hydrogen Embrittlement Risk Based Inspection 1688970506Pranav PramodNo ratings yet

- Inconel 738 PropiedadesDocument9 pagesInconel 738 PropiedadesEmad A.AhmadNo ratings yet

- Hull Inspection Assessment - SolutionsDocument6 pagesHull Inspection Assessment - SolutionsHashem GamNo ratings yet

- 06structure of Hardened ConcreteDocument39 pages06structure of Hardened ConcretesonofalexanderNo ratings yet

- 1965 - Cook - The Failure of RockDocument15 pages1965 - Cook - The Failure of RockIgnasi AliguerNo ratings yet

- Contamination of Composite Resin by Glove Powder and Saliva Contaminants: Impact On Mechanical Properties and Incremental Layer DebondingDocument8 pagesContamination of Composite Resin by Glove Powder and Saliva Contaminants: Impact On Mechanical Properties and Incremental Layer DebondingclaudiaNo ratings yet

- 1.5.3.3.1 Paper 2007 - SPE-107474-MS Borehole Stability (Geomechanics) Modeling and Drilling Optimization PracticesDocument9 pages1.5.3.3.1 Paper 2007 - SPE-107474-MS Borehole Stability (Geomechanics) Modeling and Drilling Optimization Practicescapl930No ratings yet

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetFrom EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetRating: 4.5 out of 5 stars4.5/5 (10)

- To Engineer Is Human: The Role of Failure in Successful DesignFrom EverandTo Engineer Is Human: The Role of Failure in Successful DesignRating: 4 out of 5 stars4/5 (138)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansFrom EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansNo ratings yet

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsFrom EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNo ratings yet

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansFrom EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansRating: 4.5 out of 5 stars4.5/5 (21)

- Geotechnical Engineering Calculations and Rules of ThumbFrom EverandGeotechnical Engineering Calculations and Rules of ThumbRating: 4 out of 5 stars4/5 (17)