Professional Documents

Culture Documents

IS 3370-1956 Part2

IS 3370-1956 Part2

Uploaded by

akshat chauhanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IS 3370-1956 Part2

IS 3370-1956 Part2

Uploaded by

akshat chauhanCopyright:

Available Formats

t

IS : 3370 ( Part II ) - 1965

( RealYhmed 1991)

Indian Standard

( Reaffirmed 1999 )

CODE OF PRACTKE FOR

CONCRETE STRUCTURES FOR THE

STORAGE OF LIQUIDS

PART II

REINFORCED

CONCRETE

STRUCTURES

Tenth Reprint FEBRUARY 1992

( Incorporating

Amendment

No. 1 )

UDC 621.642:666.982

t

@ Copyright 1976

BUREAU

MANAK

OF INDIAN

BHAVAN,

9 BAHADLJB

STANDARDS

SHAH

ZAFAB

MARG

NEW DELHI lloo(n

Gr 4

August 1976

I.

, .i

IS : 3370 ( Part II ) - 1965

Indian Standard

CODE OF PRACTICE FOR

CONCRETE STRUCTURES FOR THE

STORAGE OF LIQUIDS

PART II

Cement

REINFORCED

and Concrete

CONCRETE

Sectional

STRUCTURES

Committee,

BDC 2

Rc~resenting

Chairman

SRRI K. K. NABIBIAR

The Concrete

Association

of India,

Bombay

Mcm bus

Srr~r N. H. MoHILB ( Afternate to

Shri k. k. Nambia;

)

M. N. Dastur & Co ( Pvt ) Ltd. Calcutta

SARI K. F. ANTIA

Engineer-in-Chiefs

Branch, Army Headquarters

COL G. I~KNJAMIN

SNXI K. S. MEHANDRU ( Altarnatr 1

Bhakra & Beas Designs Organization,

New Delhi

SrfRI P. S. RRATNAQAR

Central

Water h Power Commission

( Ministry

of

Drr I. C. Dos M. PAIS CUDDOU

Irrigation

& Power )

SHRI Y. K. MLJRTIIY( Alfwnatc )

In personal capacity ( Dutt Niwiwb-r,27 Laburnam Road,

SAXI N. D. -DAVTARY

Bombay 7 )

Central Public Works Department,

New Delhi

SHRI N. G. DEWAN

SUPERINTENDINCA

ENQINIPER,

LNDCIRCLE ( Alternate )

The Associated Cement Companies Ltd, Bombay

DR R. R. HATTIAN~ADI

SHRI V. N. PAI ( Alternate )

Geological

Survev of India, Calcutta

SHRI P. C. HAZRA

&

Standards

Organization

Designs

DIRECTOR STANDARDS Research.

JOINT

( Ministry of Railways

)

(B&S)

DEPUTY DIRECTOR STANDARDS ( B & S ) ( AknatC

)

S. B. Joshi & Co Ltd, Bombay

SRRI S. B. JOSRI

;.nS;$ovcrnmrnt

Cement Factory! Churk

SIiRI M. M LAL

Road

Research

Instltutc

( CSIR),

e

Poor S. R. MEHRA

New Delhi

DR R. K. GHOSH ( Afternatr )

National Test House, Calcutta

SHRI S. N. MUKERJI

SERI N. C. SENQUPTA( Altcrnatr )

( Continued on page 2 )

BUREAU

MANAK

OF

BHAVAN,

INDIAN

STANDARDS

9 BAHADUR

SHAH

NEW DELHI

110002

ZAFAR

MARG

IS : 3370 ( Part II ) - 1965

~Continlled

frompage1 )

Representing

Members

Institution of Engineers ( India ) Calcutta

National

Buildings

Organization

( Ministry

of

Works & Housing )

SRRI RABINDER SIN~H ( Afternatc )

Central

Building

Research

Institute

( CSIR ),

PROS G. S. RAXASWAMY

Roorkc e

SHRI M. G. TIYEANKAR ( Altarnate )

Gammon Indja Ltd; Bombay

SERI T. N. S RAO

SHRI S. R. PINREIRO( &am&

)

Martin Burn Ltd: Calcutta

REPRU~NTATIVE

Dalmia Cement ( Bharat ) Ltd. Calcutta

SERI NIHAR CEANDRA ROY

Central Hoard of Irrigation & Power, New Delhi

SECRETARY

Indian Roads Congress, New Delhi

DR BH. SUBBARAJU

Roads Wing, Ministry of Transport

SHRI J. M. TKEHAN

SHRI N. H. KE~WANI ( Alfcrnafr )

Director, BIS ( Ex-o$icio Member ) I

DR H. C. VZSVEEVARAYA,

Deputy Director ( Civ Engg )

SHRI ERACA A. NADIRSHAH

SEEI C. B. PATEL

SecreLary

SRRI Y. R. TANEJA

Extra Assistant Director ( Civ Engg ), ,BlS

Concrete Subcommittee,

BDC 2 : 2

Conoener

SH~I S. B. JOSHI

S. B. Joshi & Co Ltd, Bombay

Members

Engineer-in-Chiefs

Branch, Army Headquarters

Central Water & Power Commission ( Ministry of

Irrigation 82 Power )

SHRI Y. K. MURTHY ( Alternate )

Designs

& Standards

Organization

D;~BVT,YSy~~~~~~

STANDARDS Research,.

( Muustrv of Railways )

Engineering Research Department, Hyderabad

DIRECTOR

Dcpartmexit,

Government

01

Public

Works

SERI V. N. GUNAJI

Maharashtra

National Buildings Organization ( Ministry of Works

SHRI M. A. HAPEEZ

& Housing )

SHRI B. S, SHIVAYURTHY ( Alternote )

Central Water & Power Commission ( Ministry o

Saab C. L. HONDA

Irrigation & Power )

Geological Survey of India, Calcutta

SHRI P. C. HAZRA

The Concrete Association of India, Bombay

SEEI K. K. NAMBIAR

SHRI C. L. N. IYEN~AR ( Altenznte )

Centr$hyad

Research Institute

( CSIR ), New

DE M. L. PURI

SHRI N. H. BHAQWANANI

Da I. C. DOS M. PAIS CUDDOW

Central

Building

Roorkce

SIIRI M. G. TAMHANKAR ( Alkrnatr )

PBO~ G. S. RAMASWAMY

Research

Institute

( CSIR )

( continued on page 1st

IS : 3350 ( Part

II ) - 1965

Indian Standard

CODE OF PRACTICE FOR

CONCRETE STRUCTURES

FOR THE

STORAGE OF LIQUIDS

PART II

REINFORCED

0.

CONCRETE

STRUCTURES

FOREWORD

0.1 This Indian Standard

( Part II ) was adopted by the Indian Standards Institution

on 19 November

1965, after the draft finalized by the

Cement and Concrete

Sectional

Committee

had been approved by the

CivilEngineering

Division Council.

0.2 The need for a code covering

the design and construction

of reinforced concrete

and prestresscd

concrete

structures

for the storage

of

liquids has been long felt in this country.

So far, such structures have

been designed to varying standards

adapted

from the recommendations

af the Institution

of Civil Engineers and of the Portland

Cement

Assoziation with the result that the resultant

structures

do not possess a

uniform guaranteed

margin of safety and dependability.

Moreover,

the

design and construction

methods in reinforced

concrete

and prestressed

concrete

are influenced

by the prevailing

construction

practices,

the

physical properties of the material and the climatic conditions.

The need

was, therefore,

felt to lay down uniform requirements

of structures for the

In order to fulfil this need, formulation

of this Indian

storage of liquids.

Standard

code of practice

for the storage of liquids ( IS : 3370 ) was

This part [ IS : 3370 ( Part II )-19651 deals with reinforced

undertaken.

Three other parts of the code are the following:

concrete structures.

Part I General

Part III

requirements

Prestressed

Part IV Design

concrete

structures

tables

0.3 Although

the provisions of this code cover mainly structures

for the

storage of liquids, the general provisions of this code,may also be applied,

with such modifications

as found necessary, to suit the special conditions

in the design of reinforced concrete and prestressed concrete structures for

the conveyance

of liquids such as aqueducts and superpassages.

0.4 While the common methods of design and construction

have been

covered in this code, design of structures

of special forms or in unusual

IS I 3370 ( Part II ) - 1965

circumstances

should be left to the judgement

of the engineer and in such

cases special systems of design and construction

may be permitted

on

production

of satisfactory

evidence

regarding

their adequacy

and safety

by analysis or test or by both.

0.5 In this standard

it has been assumed that the design of liquid retaining

structures,

whether of plain, reinforced

or prestressed concrete, is entrusted to a qualified engineer and that the executron

of the work is carried

out under the direction

of an experienced

supervisor.

0.6 All requirement

of IS : 456-1964* and IS : 134%1960f,

they apply, shall be deemed to form part of this code except

wise laid down in this code.

in so faf as

whereother-

0.7 The Sectional

Committee

responsible

for the .preparation

of this

standard

has taken into consideration

the views of engineers

and technologists and has related the standard

to the practices followed in the

Due weightage has also been given to the need for

country in this fi:ld.

international

co-ordination

among the standards

prevailing

in different

These considerations

led the Sectional Committee

countries of the world.

to derive assistance

from published

materials

of the following organiza., tions:

British Standards

Institution,

Institution

of Civil Engineers,

Portland

Cement

Association,

London,

Chicago,

and

USA.

0.8 For the purpose of deciding whether a particular

requirement

of this

standard

is complied

with, the final value, observed or calculated,

expressing the result of a test or analysis, shall be rounded off in accordance

with IS : 2-1960$.

The number

of significant

places retained

in the

rounded off value should be the same as that of the specified value in this

standard.

ld SCOPE

1.1 This standard

( Part 11 ) lays down the requirements

applicable

specifically to reinforced concrete structures for the storage of liquids, mainly

These requirements

ate in addiiion

to the general requirements

water.

laid down in IS : 3370 ( Part I )-19655.

*Code of practice for plain and reinforced concrete ( second raoision ).

+Codc of practice for prestrcsscd concrete.

SRules for rounding.off numerical values ( rmised ).

@Zodeof practice for concrete 8tructurcs for the storage of liquids: Part I Genenl

requirements.

IS : 3370 ( Part II ) - 1965

1.2 This code does not cover the requirements for reinforced and prestressed concrete structures for storage of hot liquids and liquids of low

viscosity and high penetrating power like petrol, diesel ,oil, etc.

Special

problems of shrinkage arising in the storage of non-aqueous

liquid

and the measures necessary where chemical

attack is possible,

are

also not dealt with. The recommendations,

however, may generally be

applicable to the storage at normal temperatures of aqueous liquids and

solutions which have no detrimental action on concrete and steel or where

sufficient precautions are taken to ensure protection of concrete and steel

from damage due to action of such liquids as in the case of sewage.

2. GENERAL

REQUIREMENTS

2.1 Design and construction of reinforced concrete liquid retaining structures shall comply with the requirements of IS : 3370 ( Part I j-1965+.

3. DESIGN

3.1 General - Provisions shall be made for conditions of stresses that

may occur in accordance with principles of mechanics, recognized methods

of design and sound engineering practice. In particular, adequate consideration shall be given to the effects of monolithic construction in the

assessment of bending moment and shear.

3.1.1 Before taking up the detailed design, the designer should satisfy

himself on the correct estimation of loads and on the adequate statical

equilibrium of the structure, particularly in regard to safety against overturning of overhanging members; in the latter case the general arrangement should be such that statical equilibrium should be satisfied even

when the overturning moment is doubled.

3.2 Basis of Design

3.2.1 General basis of design shall be in line with the recommendations

of IS : 456-1964t except where otherwise specified in this code. The parts

of the structure neither in contact with the liquid on any face nor enclosing the space above the liquid, as in case of staging of a water tower,

shall be designed in accordance with the requirements of IS : 456-1964t.

3.2.2 Design of .members other than those excluded by 3.2.1 shall be

based on consideration of adequate resistance to cracking as well as adequate strength.

Calculation of stresses shall be based on the following

*Code of practice for concrete structures for the storage of liquids: Part

requirements.

tCode of practice for plain and reinforced concrete ( second revision).

5

I General

IS t 3370 ( Part

II ) - 1965

assumotio:rs

addition

in

to the

generaiassumptions

given

in IS : 456-

1964:

a)

In calculations

for both flcxure and direct tension

( or combination of both ) relating

to resistance

to cracking,

the concrete

is

capable of sustaining

limited tensile stress, the whole section of

concrete

including

the cover, together

with the reinforcement

being taken into account.

b)

The total shear stress given by the following

exceed the value given

in 3.3.1 whatever

provided:

Total shear stress = - Q

b jd

equation

shall not

the reinforcement

where

Q = total shear,

b

= breadth,

and

,

jd = lever arm.

c) In strength

calculations

the concrete

has no tensile

strength.

3.2.3 Plain Concrete Structures - Plain concrete

members

of reinforced

concrete

liquid retaining

structures

may be designed against structural

failure by allowing tension in plain concrete as per the permissible

limits

for tension in bending

specified in IS : 456-1964.

This will automatically

take care of failure due to cracking.

However, nominal reinforcement

in

accordance

with the requirements

of IS : 456-1964* shall be provided for

plain concrete structural

members.

3.3 Permissible

Stresses

in Concrete

3.3.1 For Resistance to CrackingFor calculations

relating to the resistance

of members

to cracking,

the permissible

stresses in tension

( direct and

due to bending ) and shear shall conform to the values specified in Table

1. The permissible

tensile stresses due tobending

apply to the face of the

In members less than 225 mm thick

member in contact with the liquid.

and in contact

with the liquid on one side, these permissible

stresses in

bending

apply also to the face remote from the liquid.

the permissible

3.3.2 For Strcn@h Calculations - In strength calculations,

concrete stresses shall be in accordance

with 8 of IS : 456-1964*.

Where

the calculated

shear stress in concrete alone exceeds the permissible value,

reinforcement

acting in conjunction

with diagonal

compression

in the

concrete shall be provided to take the whole of the shear.

*Code of practice

for plain and reinforced

concrete ( second rcuirion ).

IS : 3370 ( Part II ) - 1965

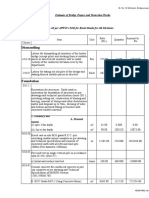

1 PERMlSSIBLE

TABLE

RELATING

CONCRETE

STRESSES

IN CALCULATIONS

TO RESISTAi%CE

TO CRACKING

( Clause 3.3.1 )

GRADE

PIsR3IIssIlII.I~: S1I~I.SSI.:R

kg/cm2

~-_-_-h-_--_._~

Tension Dt~e

Direct

to Bendin;;

Tension

cm CONCRETE

M

M

M

M

M

M

150

200

250

YOO

350

400

3.4 Permissible

11

12

13

15

16

17

Stresses

Sniwn

== ( Q/hjd)

15

17

15

17

20

22

24

22

:!,

27

18

19

in Steel

arc assumctl

3.4.1 For Resistance to Cracking - When steel and concrete

to act together for checking the tensile stress in concrete for avoidance

of

cracks, the tensile stress in the steel will be limited by lhe rcquircment

that the permissible tensile stress in the concrete

is not excccdcd;

so the

tensile stress in steel shall be equal to the product of modular ratio of

steel and concrete,

and the corresponding

allowable

tensile stress in

concrete.

3.3.2 For Strength Calculations - For strength calculations,

the permissible

stresses in steel reinforcement

shall be as given in Table 2.

3.5 Stresses Due to Drying Shrinkage or Temperature

Change Stresses due to drying shrinkage or temperature

change may he ignored

provided that:

a)

the permissible

exceeded.

stresses specified

b)

adequate

precautions

are taken to avoid cracking

of concrete

during the construction

period and until the reservoir is put into

use.

c)

the recommendations

of this code [see IS : 3370 ( Part I )-1365* ]

as regards the provisions of joints and for suitable sliding layer

beneath the reservoir are complied with, or the reservoir is to be

used only for the storage of water or aqueous liquids at or neai

ambient

temperature

and the circumstances

are such that the

concrete will never dry out.

*Code of practice for concrete

requirements.

in 3.3 and 3.4

structures for the storage

arc

of liquids:

not

otherwise

Part I General

IS : 3370 ( Part II ) - 1965

TABLE

PERMISSIBLE

STRESSES

IN STEEL REINFORCEMENT

STRENGTH

CALCULATIONa

.FOR

( Cfausc 3.4.2 )

PERMISSIBLE STRESSES IN kg/ems

c----.-*-_------~

Plain Round Mild

High Yield Strength

Steel Bars ConformDeformed

Bars

ing to Grade 1 of

Conforming

to

IS : 432 ( Part I )IS : 1786-19li6t

or

IS : 1139-1966~

1966

TYPF.OFSTRERS

IN STEEL

REINFORCEMENT

SL

No.

(3)

(4)

1 150

1 500

of

1 150

1 500

b) On-f:lccaway

from liquid for

members

less than 225 mm

1 150

I 500

c) On face away from liquid for

members 225 mm or more in

thickness

1 250

1 900

1 150

1 500

or

1 250

1 750

in columns

load

I 250

1 750

(1)

i)

ii)

Tensile stress in members

direct tension

Tensile

bending:

a)

iii)

stress

On liquid

members

Tensile

ment:

a)

srrcss

Compressive

subjected

retaining

NOTE-Stress

face

in shear

reinforccless

mcmbrrs

225

in thickness

stress

to direct

in

members

mcmbcrs

For

225 mm thickness

b) For

more

iv)

in

under

limitations

than

mm

for

liquid

retaining

faces

shall

also

apply

to

the

placed

in

following:

a) Other

faces within

225 mm of the liquid

retaining

b) Outside

or external

faces of struc1urcs

away

water logged soils up to the level of the highest

face.

from the liquid

but

subsoil water level.

*Specification

for mild steel and medium

tensile steel bars and hard-drawn

steel wire

for concrete

reinforcement:

Part 1 Mild steel and medium

tensile steel bars ( second

froision ) .

tSpccification

for cold twisted steel bars for concrete

reinforcement

( wised ).

SSprcification

for hot rolled mild steel, medium

tensile steel and high yield strength

steel deformed

bars for concrete

reinforcement

( rcuisrd ).

3.5.1 Shrinkage stresses may, however, be required to be calculated

cases, when a shrinkage coefficient bf 300 X lOa may be

assumed.

in special

IS : 3370 ( Part II ) - 1965

3.512 When the shrinkage stresses are allowed, the permissible

stresses,

tensile stresses in concrete ( direct and bending ) as given in Table 1 may

be increased by 33b percent.

3.5.3 Where reservoirs

are protected

with an internal

impermeable

lining, consideration

should be given to the possibility of concrete eventually

drying out.

Unless it is established

on the b&is of tests or

crack

bridging

properties,

experience

that

the lining

has adequate

allowance for the increased ef&ct of drying shrinkage should be made in

the design.

4.

FLOORS

4.1 Provisions

of Movement

Jointc

vided in accordance

with 8 of IS : 3370

- Movement

jointsshall

( Part I )-1965*.

be pro-

4.2 Floors

of Tanks Resting

on Ground - If the tank is resting

directly over ground, floor may be constructed

of concrete with a nominal

percent;ige

of reinforcement

( smaller than the minimum specifird in 7 )

provided

it is cert,lin

that the ground

will carry the. load

without

appreciable

subsidence in any part and that the concrete floor is cast in

panels with sides not more than 4.5 metrcs with contraction

or expansion

joints between.

In such cases a screed or concrete

layet not less than

75 mm thick shall first be placed on the ground and covered with a sliding

layer of bitumen

paper or other suitable material

to destroy the bond

between the scrced and floor concrete.

In normal circumstances

the screedlayer

shall be of grade not weaker

where injurious soils or aggressive

than M 100 specified in IS : 456-19647,

water are expected, the screed layer shall be of grade not weaker than M

150 specified in IS : +j6-1964t

and if necessary a sulphate resisting or

other special cerhent should be used.

4.3 Floors of *auks Resting on Supports - If the tank is supported

on walls or other similar supports, the floor slab shall be designed as floors

in buiidings for bending moment,s due towater load and sslf weight. The

worst conditions

of loadings may not be those given in 9.3 of IS : 4561964?, since water level extends over all spans in normal

construction

except in the case of multi-cell tanks, these will have to be determined

by

the designer in each particular

case.

4.3.1 When the floor is rigidly connected to the walls ( as is grnerally

the case ) the bending

moments at the junction

between the walls and

floor shall be taken into account in the design of floor together

with any

direct forces transferred

to the floor from the walls or from the floor to the

wall due to the suspension of the floor from the wall.

*Code of practice for concrete structures

requirements.

tCode of practice

for the storage of liquids: Part I General

for plain and reinforced

9

concrete

( second rruirim ).

ii

f

IS : 3370 ( Part II ) - 1965

If tht: \v.rlls art: Il,)rl-motlolitllic

with the floor slab, such as in cases

wvi!II~*m:~v(:~r~t:!lt joilrts h;tve been providctl

between

the floor slabs and

w iii%,, tlrc fh)or shall be d:signcd

only for the vertical

loads on the floor.

4.3.2 III continuous

T-beams

or L-beams

with ribs on the side remote

~I.OIII tlr(, li(luitl, the tension

in concrete

on the liquid

side at the face of

till- sapports

shall not exceed the permissible

stresses for controlling

cracks

in cl)rrcrcte.

The width of the slab given in 9.2.2 of IS : 456-1964*

shall

be made the basis for calculation

of the rcsistancc

to cracking

of T-beam,

L-beam

sections

at supports.

4.3.3 The floor slab may besuitably

tied to&e~~vaIlsby

reinforcement

bars proprrly

embedded

in both the slab and the walls.

In such cases no

separate

beam ( curved or straight

) is necessary

under the wall, provided

the wall of the rank itself is designed

to act as a beam over the supports

under it.

4.3.4 Si~mctimes

it rn;ry hc economical

to provide

the floors of circular

tarlks in the shape

of dome.

In such casts the dome shall be designed

for the vertical

load of the liquid over it and the ratio of its rise to its

diameter

shall

Ix 30 adjrrsrccl that the stress&in

the tlomr

are, as far as

possible, wholly

comprcssivc.

The, dome shall be supported

at its bottom

on the rirlg ?lram which

shall be designed

for resultant

circumferential

tension

in addition

to vertical

loads.

5. WALLS

5.1

Provision

of Joints

5.1.1 Sliding jkints at the Base of the Wall - Where it is desired to allow

the walls to cspuid

or contract

separatrlv

from the floor, or to prevent

moments

at the base of tlte wall owing to fixity to the fl&or, sliding

joints

may be emuloycd.

5.1.1.1 Consitlrrations

affecting

the Spacing

of vertical

movement

joints arc discussed

in 8 of IS : 3370 ( Part I )-1965t.

While

the majority of these joints

may be of the partial

or complete

contraction

type,

sufficient

joints

of the expansion

type should

be provided

to satisfy the

rrquiremcnts

of 8 of IS : 3370 ( Part I )-19657.

5.2

Prqmure

on Walls

5.2.1 In liquid rct:lining

structures

with fixed or floating covers, the gas

pressure

cl~v~~lc~l~cd ahove

liquid

surface

shall be added

to the liquid

pressure.

-*r:ndr: of practice: fr,r plain and rrinforced concrete ( second reaisiotl ).

+~Adc of prar.:icc fol conc~c~c structures

for the

storage of liquids:

Part I General

IS : 3370

( Part

PI ) - 1965

5.2.2 When the wall of liquid retaining

structure

is built in ground

or

has earth embanked

against

it, the effxt

of earth pressure

shall be taken

into account

as discussed

in 4 of IS : 3370 ( Part I )-1965*.

5.3 Walls of Tanks Rectangular

or Polygonal

in Plan - While

designing

the walls

of rectangular

or polygonal

concrete

tanks,

the

following

points should be borne in mind:

In plane walls, tbc liquid pressure

is resisted

by both vertical

and

horizontal

bcndillg

moments.

An estimate

should be made of the

proportion

of the pressure

resisted by bending

mclments

in the

The

direct

horizontal

tens&n

vertical

and

horizor,tal

planes.

caused by the direct pull due to water pressure

on end walls should

be added to that resulting

from horizontal

bending

moment.

On

liquid rrtaining

faces, the tensile stresses

due to the combination

of direct horizontal

tension

and bending

action

shall satisf)J the

fLJllowing condition:

where

t

t

Calculated

= Permissible

(set =

Table

1 ),

Calculated

direct tensile stress in concrete,

direct

tensile

stress

in

concrete

tensile

stress

due

to bending

( see

in concrete,

an d

Get

b)

Permissible

Table

1 ).

tensile

stress

due to bendir.g

in concrete

( see

At the vertical

edges <where the walls of a reservoir

are rigidly

joined,

horizontal

reinforcement

and haunch

bars should

be provided

to resist the horizontal

bending

moments,

even if the Ivalls

are designed

to withstand

the whole

load as vertical

beams

or

cantilever

without

lateral supports.

c) In the case of rectangular

or polygonal

tanks,

the side walls act

as two way slabs, whrreby

the wall is continued

or restrained

in

the horizontal

direction,

fixed or hinged

at the bottom

and hinged

or free at the top.

The walls thus act as thin plates subject

to

triangular

loading

and with boundary

conditions

varying

between

full restraint

and free edge.

The analysis

of moment

and forces

may be made on the basis of any recognized

method.

However,

moment

coefficients,

for boundary

conditions

of wall panels

fog

some common

cases are given in IS : 3370 ( Part IV )-1967t

of

this code for general

guidance.

*Code of practice

requirements.

_

tCode of practice

for concrete

structures

for the

for concrete

structures

for the storage

tables.

ii

storage

of liquids:

of liquids:

Part

Part

I General

IV Design

IS : 3370 ( Part II ) - 1965

5.4 Walls

cal tanks,

of

Cylindrical

the following

Tanks

points

should

While designing

be borne in mind:

walls of cylindri-

Walls of cylindrical

tanks are either cast monolithically

with the

base or are set in grooves and key ways ( movement

joints ). In

either case deformation

of the wall under the influence of liquid

pressure is restricted at and above the base.

Consequently,

only

part of the triangular

hydrostatic

load will be carried by ring

tension and part of the load at the bottom will be supported

by

cantilever

action.

b)

It is difficult to restrict rotation or settlement

of the base slaband

it is advisable

to provide vertical

reinforcemeut

as if the walls

were fully fixed at the base, in addition

to the reinforcement

required to resist horizontal

ring tension for hinged at base conditions of walls, unless the appropriate

amount of fixity at the base

is established

by analysis with due consideration

to the dimensions of the base slab, the type of joint between the wall and slab

and, where applicable,

the type of soil supporting

the base slab.

5.4.1 Coefficients

for

tension and vertical moments

_ .

_. ring

^

conditions

CJf

thr walls for some common

cases are given

( Part IV )-1967* for general guidance.

for ~different-_

in Is : 3370

6. ROOFS

6.1 Provision of Movemtnt

Joints - To avoid the possibility of sympathetic cracking,

it is important

to ensure that movement

joints in the

roof correspond

with those in walls if roof and walls are monolithic.

If,

however,

provision

is made by means of a sliding jnint for movement

between

the roof and the wall, correspondence

of joints

is nc,t so

important.

structures

should be

6.2 Loading - Fixed covers of liquid retaining

designed for gravity loads, such as the weight of roof slab, earth cover, if

any, live loads, and mechanical

equipment.

They should also be designed

for upward load if the liquid retaining

structure

is subjected

to internal

gas pressure.

6.2.1 A superficial

load sufficient to ensure safety with the unequal

intensity

of loading which occurs during the placing of the earth cover

should be allowed for in designing roofs.

The engineer

should specify a

loading under these temporary

conditions,

which should not be exceeded.

In designing the roof, allowance should be made for the temporary

condition of some spans loaded and other spans unloaded,

even though in the

final state the load may be small and evenly distributed.

*Code of

Design tables.

practice for cbncrcte

structurer

12

for the storage of liquids:

Part

IV

IS : 3370 ( Part II ) - 1965

6.3 Water-Tightness

- In case of tanks intended for the storsge of water

for domestic purposes, the roof must be made water-tight.

This may be

achirved

bv limiting the stresses as for the rest of the tank or by the use

of the covciing of waterproof

membrane

or by providing slopes to ensure

adequate drainage.

6.4 Protection

Against

provided to the lmderside

condensation.

Corrosion

- Protective

measures

shall

be

of the roof to prevent it from corrosion due to

7. DETAILING

7.1

Minimum

Reinforcement

7.1.1 The minitnum reinforcement

in walls, floors and roofs in each of

two directions

at right angles shall have an area of O-3 percent of the

concrete

section in that direction

for sections up to 100 mm thick.

For

sections

of thickness

greater than 100 mm and less than 450 mm the

minimum

reinforcement

in each of the two directions

shall be linearly

reduced from 03 percent for 100 mm thick section to 0 2 percent

for

450 mm thick section.

For sections of thickness greater than 450 mm,

minimum

reinforcement

in each of the two directions

shall be kept at

0.2 percent.

In concrete

sections of thickness 225 mm or greater, two,

layers of reinforcing

steel shall be placed one near each face of the section

to make up the minimum reinforcement

specified in this clause.

7.1.1.1

The minimum

reinforcement

specified

in

decreased

by 20 percent in case of high yield strength

conforming

to IS : 1786-1966*

or IS : 1139-1966t.

7.1.1

may

be

deformed

bars

7.1.2 In special circumstances

( scu 4.2 ) fl:)or slabs may be constructed

In no

with percentage

of reinforcrment

less than that specified above.

case the percentage

of reinforcement

in any member shall be less than

that specified in IS : 456-1964:.

7.2

Minimum

Cover

to Reinforcement

7.2.1 For liquid faces of parts of members

either in contact with the

liquid or enclosjng the space above the liquid ( such as inner faces of roof

slab ), the minimum cover to all reinforcement

should be 25 mm or the

In the presence of sea

diameter

of the main bar, whichever is greater.

water and soils and water of corrosive character

the cover should be increased by 12 mm but this additional cover shall not be taken into account

for design calculations.

Specification for cold twisted steel bars for concrete reinforcement ( reoisrd ).

tipeclfication for hot rolled mild steel, medium trnsile steel and high yield rtrength

steel deformed bars for concrete rcmforcement ( revised ).

*Code of practice for plain and reinforced concrete ( second r&ion ).

13

IS : 3370 ( Part II) - 1965

7.2.2

For

faces

neither. in contact

above the liquid,

1964*.

away from the liquid and for parts of the structure,

with the liquid on any face nor enclosing

the space

the cover shall conform to the requirements

of IS : 456--

7.3 Size of Bars, Distance Between Bars, Laps and Bends - Subject

to the requirements

of 7.3.1 and 7.3.2, details regarding

reinforcement

such as size of bars, distance between bars, laps and bends in bars, and

fixing of bars shall comply with the provisions of IS : 456-1964*

and

IS : 2502-1963T.

bars, the local stresses on

7.3.1 Bends in Bars - In bends in reinforcing

concrete may be increased to three times the value pe.rmitted in 3.3.2 for

concrete in direct compression.

is.

7.3.2 Laps in Bars - Bars should be lapped only when such practice

Where laps are used they should be designed in accordance

unavoidable.

with the relevant requirements

of IS : 456-1964.

*&de of practice for plain and reinforced concrete ( second revision ).

vodc of practice for bending and fixiig of bars for concrete reinforcement.

14

IS : 3370 ( Part II ) - 1965

[ Continuad from page ? )

Representing

Members

SHRI T. N. S. RAO

Sum S. R. ~INHRlllO

: Alternate

SUPAILINTENDINO

ENOINEER, END

CIRCLE

SHW

0.

P. GOEL

( Alfernale )

SRRI J. M. TR~HAN

SHRI R. P. SIKKA ( Altcrnare )

.DR H. C, VI~DSVAILAYA

Srr~tr II. T. YAN

Gammon

India Ltd, Bombay

)

Central Public Works Department

Roads

Ministry

of

Transport

Indian

Standards

Institution

Braithwaite

Burn & Jcssop

Calcutta

Panel for Concrete

SIrRl S. B. JOSHI

.SHILI 1~. K. N.wsr.41~

Da H. C. VISVWVARAYA

Wing,

Construction

Codes, BDC 2 : 2 : 1

S. B. Joshi & Co Ltd, Bombay

The eoncrete

Association

of India,

India Standards Institution

Bombay

CO Ltd

BUREAU

OF

INDIAN

STANDARDS

Headquarters:

Manak Ehavan, 9 Bahadur Shah Zafar Marg. NEW DELHI 110002

Telephones: 331 01 31, 331 13 75

Telegrams: Manaksanstha

( Common to all Offices )

Regional Offices:

Central : Manak Bhavan, 9 Bahadur Shah Zafar Marg,

NEW DELHI 110002

*Eastern : l/14 c. I. -. Scheme VII M, V. I. P. Road,

Maniktola, CALCUTTA 700054

Northern : SC0 445-446, Sector 35-C,

CHANDIGARH

160036

Southern

: C. I. T. Campus, MADRAS

600113

TWestern : Manakalaya, E9 MIDC, Marol, Andheri

BOMBAY 400093

Telephone

331 01 31

I 331 13 75

36 24 99

21843

I 3 1641

41 24 42

41 25 19

I 41 2916

( East ), 6 32 92 95

Branch Offices:

2 63 48

IPushpak, Nurmohamed Shaikh Marg, Khanpur,

AHMADABAD

380001

I 2 63 49

SPeenya Industrial Area 1st Stage, Bangalore Tumkur Road 38 49 55

BANGALORE 560058

38 49 56

I

Gangotri Complex, 5th Floor, Bhadbhada Road, T. T. Nagar,

667 16

BHOPAL 462003

5 36 27

Plot No. 82/83. Lewis Road. BHUBANESHWAR 751002

5315. Ward No. 29, R.G. Barua Road, 5th Byelane,

3 31 77

GUWAHATI 781003

23 1083

5-8-56C L. N. Gupta Marg ( Nampally Station Road ),

HY DEPABAD 500001

6 34 71

R14 Yudhister Marg. C Scheme, JAIPUR 302005

( 6 98 32

117/418

B Sarvodaya Nagar, KANPUR 208005

{ ;:

Patliputra Industrial Estate, PATNA 800013

T.C. No. 14/1421. Universitv P.O.. Palayam

TRIVANDRUM

695035

inspection Offices ( With Sale Point ):

Pushpanjali, First Floor, 205-A West High Court Road,

Shankar Nagar Square. NAGPUR 440010

Institution of Engineers ( India ) Building, 1332 Shivaji Nagar,

PUNE 411005

z; ss

5 24 35 t \

*Sales Office in Calcutta is at 5 Chowringhse Approach, P. 0. Princep 27 68 00

Street. Calcutta 700072

tseles Office

in Bombay is al Noveltv

Chambers,

Grant Road, 89 66 28

Bombav 400007

$Sales Office in Bangalore is at Unity Building, Narasimharajs Square, 22 36 71

Bangalore 560002

Reprography

/

Unit

BIS,

New

Delhi,

India

c

_

AMEF!DNENT No. 2

/+Gusr 1981

TO

IS:337O(Part 2)-1965 CODE OF W4CTICE FOR CONCRETE

STRUCTURES FOR THE STORAGE OF L It&IDS

PART 2

REINFORCED CONCRETE

Alteration

-w-w-

STRUCTURES

.

(Rzge 3, clause 0.3; - Ebbstitute the follouiIlg

for the existing clause:

'0.3 Altbughth e provisions of this code cover mainly

structures for the storage of liquids, the general

requirements given in Part 1 of this codemaygenerally

apply to the design of reinforced concrete and

prestressed concrete structures for the conveyance of

liquids, such as aqueducts and superplssages; the other

kequiranents given in the code may al= be applied with

appxqriate modifications.'

(mc

2)

Reprography Unit, BIS, New Delhi, India

You might also like

- IS 2911-Part-4Document17 pagesIS 2911-Part-4Prabhakaran S100% (1)

- Presentation For Structural Audit Report To Residential Co-Op. Housing Societies by - CSR Consultant and AssociatesDocument113 pagesPresentation For Structural Audit Report To Residential Co-Op. Housing Societies by - CSR Consultant and AssociatesCSR Consultant and AssociatesNo ratings yet

- Internship 2019Document59 pagesInternship 2019ArjunRathodNo ratings yet

- Explanatory Examples For Ductile Detailing of RC Buildings: Dr. R. K. IngleDocument68 pagesExplanatory Examples For Ductile Detailing of RC Buildings: Dr. R. K. IngleSatish Kumar100% (1)

- IS 2911 Part 1 Sec 4 - 2010Document27 pagesIS 2911 Part 1 Sec 4 - 2010Susmita PandaNo ratings yet

- Guideline Notes For RCC WorkDocument10 pagesGuideline Notes For RCC Workvikas WaghmareNo ratings yet

- IRC-40-2002 Road Bridge (Masonry) PDFDocument52 pagesIRC-40-2002 Road Bridge (Masonry) PDFNorendro KangjamNo ratings yet

- M20 M25 M30 Ultratech PPC Sikaplast 2009 NS 28daysDocument13 pagesM20 M25 M30 Ultratech PPC Sikaplast 2009 NS 28daystalabirachp siteNo ratings yet

- IS 2911 Part 2-Pages-4,8-19Document13 pagesIS 2911 Part 2-Pages-4,8-19Harsh TiwariNo ratings yet

- BoqDocument24 pagesBoqDilshad AhemadNo ratings yet

- Course File RCC I Spring 2017newwwwDocument15 pagesCourse File RCC I Spring 2017newwwwMuhammad MurtazaNo ratings yet

- 9.1 Formwork Notes-1Document4 pages9.1 Formwork Notes-1RahulSinghRajput100% (2)

- Calculation of Quantity of Cement Mortar in Brickwork and PlasterDocument2 pagesCalculation of Quantity of Cement Mortar in Brickwork and PlasterYathish1430% (1)

- Design of Concrete Bridges: Praveen NagarajanDocument18 pagesDesign of Concrete Bridges: Praveen NagarajanSSNo ratings yet

- Structural Stability Report-SrinagarDocument24 pagesStructural Stability Report-SrinagarOM Pandey100% (1)

- E DSR 18 09 2018Document1,482 pagesE DSR 18 09 2018mashaKNo ratings yet

- Types and Causes of Deterioration of Steel StructureDocument24 pagesTypes and Causes of Deterioration of Steel Structuresnehakudale21100% (1)

- 2911 3Document44 pages2911 3rambinodNo ratings yet

- Retaining Walls - Optimal DesignDocument10 pagesRetaining Walls - Optimal DesignSwapnil KNo ratings yet

- Approved Guidelines For Evaluation of ProposalsDocument13 pagesApproved Guidelines For Evaluation of ProposalsAbdullah Al JubayerNo ratings yet

- Earthwork & Engineering Backfilling MaterialsDocument47 pagesEarthwork & Engineering Backfilling MaterialsAHMAD YAGHINo ratings yet

- Indian Code On Crack GoodDocument79 pagesIndian Code On Crack GoodJibonGhoshPritomNo ratings yet

- NPTEL Concrete Engg and Tech Problem and Solved AnswersDocument5 pagesNPTEL Concrete Engg and Tech Problem and Solved AnswerssuranjanacNo ratings yet

- Indian Standard: Code of Practice FOR Design and Construction Pile Foundations OFDocument44 pagesIndian Standard: Code of Practice FOR Design and Construction Pile Foundations OFKhushaliNo ratings yet

- Panchakanya Structural SteelDocument5 pagesPanchakanya Structural Steelkabira12No ratings yet

- Working Draft of Combined Piled-Raft Foundation, Doc - CED 43 (196) WDDocument19 pagesWorking Draft of Combined Piled-Raft Foundation, Doc - CED 43 (196) WDKedarNo ratings yet

- Project PDFDocument36 pagesProject PDFMable MathewNo ratings yet

- 2911 (Part 4) 2013Document16 pages2911 (Part 4) 2013Sangram keshari bejaNo ratings yet

- Rock Anchors Are Used Primarily For Resisting Uplift ForcesDocument4 pagesRock Anchors Are Used Primarily For Resisting Uplift Forcesjaswant_agrim_325313No ratings yet

- Detail Design and Analysis of Earthquake PDFDocument59 pagesDetail Design and Analysis of Earthquake PDFSabih Hashim Alzuhairy100% (1)

- Project Report Modify PDFDocument24 pagesProject Report Modify PDFTasmay EnterprisesNo ratings yet

- Lkèkkj.K Iksvzysam Lhesav Fof'Kf"V: HKKJRH EkudDocument13 pagesLkèkkj.K Iksvzysam Lhesav Fof'Kf"V: HKKJRH EkudKRamana ReddyNo ratings yet

- Is 7784 2 3 1996 PDFDocument13 pagesIs 7784 2 3 1996 PDFmanoj_structureNo ratings yet

- Design of Steel STAADDocument61 pagesDesign of Steel STAADPrashant Sunagar100% (2)

- Design of Steel Structures-DeepaDocument13 pagesDesign of Steel Structures-DeepaSai Albet BillaNo ratings yet

- ESRDocument30 pagesESRAjayvidyanand SharmaNo ratings yet

- Building-materials-Lab - ManualDocument18 pagesBuilding-materials-Lab - ManualMaulik Panseriya100% (1)

- Condition Assessment and Rehabilitation of Structures (CARS-2017)Document3 pagesCondition Assessment and Rehabilitation of Structures (CARS-2017)abcd efghNo ratings yet

- Retaining Wall With Relief SlabDocument7 pagesRetaining Wall With Relief Slabrajivkannan100% (2)

- Design of Concrete Structures: Amit Das Department of Civil Engineering I.I.T BombayDocument57 pagesDesign of Concrete Structures: Amit Das Department of Civil Engineering I.I.T BombayKC Paguinto100% (1)

- Is 9640 1980 SPT Sampler PDFDocument15 pagesIs 9640 1980 SPT Sampler PDFmitnathNo ratings yet

- Methodology of Leakage Treatment at Z4-896 PDFDocument2 pagesMethodology of Leakage Treatment at Z4-896 PDFEngr. MahmudNo ratings yet

- Method of Statement - Junction ChamberDocument9 pagesMethod of Statement - Junction ChamberLaksri JayathilakeNo ratings yet

- Code of Practice For Design and Construction of Raft FoundationsDocument26 pagesCode of Practice For Design and Construction of Raft FoundationsZiya Ul Haq SagriNo ratings yet

- Amendment No. 1 September 2017 TO Is 13920: 2016 Ductile Design and Detailing of Reinforced Concrete Structures Subjected To Seismic Forces Code of PracticeDocument6 pagesAmendment No. 1 September 2017 TO Is 13920: 2016 Ductile Design and Detailing of Reinforced Concrete Structures Subjected To Seismic Forces Code of PracticeParchuri PraveenNo ratings yet

- Bill of QuantityDocument14 pagesBill of QuantityAshok KcNo ratings yet

- Underground Works in VietNam-B.DDocument42 pagesUnderground Works in VietNam-B.Dapi-3714473No ratings yet

- Shear Wall Design Manual: IS 456:2000 and IS 13920:1993Document98 pagesShear Wall Design Manual: IS 456:2000 and IS 13920:1993soumyadeep194784250% (1)

- Strengthening of RC Column With Externally Bonded Steel BarsDocument5 pagesStrengthening of RC Column With Externally Bonded Steel BarsInternational Journal of Innovative Science and Research Technology100% (1)

- ST5001 Maintenance and Rehabilitation of StructuresDocument2 pagesST5001 Maintenance and Rehabilitation of Structurescharvi shiny100% (1)

- Notes All Civil Eng. Subjects-1.pdf - 1Document315 pagesNotes All Civil Eng. Subjects-1.pdf - 1Srikanth BhaskaraNo ratings yet

- Analysis and Design of Multi Storyed Building by Using Staad ProDocument6 pagesAnalysis and Design of Multi Storyed Building by Using Staad ProarjunNo ratings yet

- Crack Width by Bs8110Document2 pagesCrack Width by Bs8110Mohammed100% (1)

- A Review Study On The Behaviour of Black Cotton Soil With Bamboo Fibre PDFDocument3 pagesA Review Study On The Behaviour of Black Cotton Soil With Bamboo Fibre PDFVikram NikhilNo ratings yet

- Water Retaining Structure Design Hand Book - TRFIDocument25 pagesWater Retaining Structure Design Hand Book - TRFInrnnadig100% (1)

- Association of Structural and Geotechnical Consulting EngineersDocument9 pagesAssociation of Structural and Geotechnical Consulting EngineersHIVETECHNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- IS 3370 (Part 3) 1967 R 1999Document14 pagesIS 3370 (Part 3) 1967 R 1999Nayag Singh100% (1)

- Indian Standard: Code of Practice For Concrete Structures For The Storage of LiquidsDocument27 pagesIndian Standard: Code of Practice For Concrete Structures For The Storage of LiquidsSughanyaa VeNo ratings yet

- IS 3370 Part 3Document15 pagesIS 3370 Part 3SourabhAdikeNo ratings yet

- IS 4995 (Part 2) 1974Document25 pagesIS 4995 (Part 2) 1974Nagaraju ChintaNo ratings yet

- Is 8640 1977 R 1995Document13 pagesIs 8640 1977 R 1995Nagaraju ChintaNo ratings yet

- IS 4031 - Part15Document8 pagesIS 4031 - Part15Nagaraju ChintaNo ratings yet

- IS 4031 - Part12Document3 pagesIS 4031 - Part12Nagaraju ChintaNo ratings yet

- IS 4031 - Part11Document3 pagesIS 4031 - Part11Nagaraju ChintaNo ratings yet

- IS 2911 (Part 1 Section 4) 1984 R 2002Document31 pagesIS 2911 (Part 1 Section 4) 1984 R 2002Nagaraju ChintaNo ratings yet

- IS 4031 - Part10Document5 pagesIS 4031 - Part10SourabhAdikeNo ratings yet

- IS 2185 (Part 3) 1984Document18 pagesIS 2185 (Part 3) 1984Nagaraju ChintaNo ratings yet

- Is 1948 1961 R 1996Document21 pagesIs 1948 1961 R 1996Nagaraju Chinta100% (4)

- AP General Equilibrium Free Response QuestionsDocument5 pagesAP General Equilibrium Free Response QuestionsCynNo ratings yet

- Fundamentals of PetrophysicsDocument24 pagesFundamentals of PetrophysicsPyaso YoboneNo ratings yet

- Worksheet On Static ElectricityDocument3 pagesWorksheet On Static ElectricityShiny NivolyaNo ratings yet

- Stance 161 - Valves For Special ChemicalsDocument5 pagesStance 161 - Valves For Special ChemicalsPhyu Mar Thein KyawNo ratings yet

- Cellulose Nanofiber Extraction From Unbleached Kraft Pulp For Paper StrengtheningDocument17 pagesCellulose Nanofiber Extraction From Unbleached Kraft Pulp For Paper StrengtheningDr. XucruteNo ratings yet

- Module 4 - Laying of Underground Cables - T&GDocument42 pagesModule 4 - Laying of Underground Cables - T&GDeepak100% (2)

- Jet-Lube 21 Waterwell Drill Rod CompoundDocument1 pageJet-Lube 21 Waterwell Drill Rod CompoundDon HowardNo ratings yet

- MDPE Final TutorialDocument4 pagesMDPE Final Tutoriallata sinsinwarNo ratings yet

- REMA TIP TOP PerformanceGrip 70Document1 pageREMA TIP TOP PerformanceGrip 70dedison_rNo ratings yet

- Pipe Support BasisDocument4 pagesPipe Support BasisBabyface888No ratings yet

- Dismantling: Estimate of Bridge Proper and Protection WorksDocument11 pagesDismantling: Estimate of Bridge Proper and Protection WorksHoque joynulNo ratings yet

- Compressed Gas Cylinder SafetyDocument36 pagesCompressed Gas Cylinder Safetysaid1175No ratings yet

- Presentation Nutrient Uptaked by Plant RootsDocument60 pagesPresentation Nutrient Uptaked by Plant RootsHasbullah ZawawiNo ratings yet

- Casting Powders KemproDocument12 pagesCasting Powders KemproBhoomaiah SunkenapalliNo ratings yet

- Mil HDBK 205a PDFDocument81 pagesMil HDBK 205a PDFpedroNo ratings yet

- B 92 - B 92M - 11Document3 pagesB 92 - B 92M - 11phaindikaNo ratings yet

- Comminution Course - 2016Document392 pagesComminution Course - 2016clucero9100% (1)

- Principle: Foaming Tendency & Stability of Lubricating OilsDocument2 pagesPrinciple: Foaming Tendency & Stability of Lubricating OilsKamruzaman MiahNo ratings yet

- Geochemistry in Petroleum Exploration - AugDocument44 pagesGeochemistry in Petroleum Exploration - AugShivamTiwariNo ratings yet

- Reinforced Concrete Beam DesignDocument8 pagesReinforced Concrete Beam DesignLindy Kho100% (1)

- Phy2 11 - 12 Q3 0101 FD 1Document16 pagesPhy2 11 - 12 Q3 0101 FD 1Earl Clyde BañezNo ratings yet

- Skin TonesDocument15 pagesSkin Tonesanuyasane9776No ratings yet

- Non-Linear Finite Element Analysis of Light Gage Steel Shear DiapDocument346 pagesNon-Linear Finite Element Analysis of Light Gage Steel Shear DiapAlonso Aguilar Salas100% (1)

- 426 Thod CodDocument10 pages426 Thod CodNur AishaNo ratings yet

- DS 9303 e OWAtecta Installation Guide 121400Document40 pagesDS 9303 e OWAtecta Installation Guide 121400DianaNo ratings yet

- ASTM D4984 CO2 en Gas NaturalDocument3 pagesASTM D4984 CO2 en Gas Naturalfamturbo0% (1)

- Formulasi Sediaan ParenteralDocument47 pagesFormulasi Sediaan ParenteralThania RaniNo ratings yet

- Worksheet 1 - MenesesDocument2 pagesWorksheet 1 - MenesesDarwin MenesesNo ratings yet

- ASME CODE Requirements - Heat ExchangerDocument9 pagesASME CODE Requirements - Heat ExchangerJithin FrancizNo ratings yet

- Core Cutter TestDocument2 pagesCore Cutter Testsita ram JatNo ratings yet