Professional Documents

Culture Documents

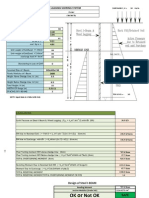

Lamp Post Foundation Design

Lamp Post Foundation Design

Uploaded by

erikaren85Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lamp Post Foundation Design

Lamp Post Foundation Design

Uploaded by

erikaren85Copyright:

Available Formats

Project

Client

Location

Design of Lamp Post Foundation

Loadings

Dynamic Pressure, qs =

0.29

kN/m

0.613 Vs

Vs =

21.70

m/s

VbS1S2S3

Vb =

35

m/s

S1 =

1

1+0.001s

S2 =

0.62

City Area

S3 =

1

Permanent

Lamp Post Width, B =

0.27

m

Panel Height, L =

12

m

Cf =

0.6

Table 14

Horizontal Wind Load, w =

0.05

kN/m

CfqsB (Lamp Post)

Lamp Post Wt., PL =

4.4

kN

Lamp wt., Pw =

0.12

kN

Lamp Arm, La =

4

m

Horizontal Wind Load, wb =

0.20

kN

qBbLb

Length of Banner, Lb =

3.5

m

1.2

m

Width of Banner, Bb =

Moment Arm, A =

6

m

Overturning Moment Check (Parallel to Lamp)

Overturning Moment, Mo =

3.85

kN-m

wL/2 + PwLa

Footing Width, B =

0.5

m

Footing Length, L =

1.6

m

Footing Depth, D =

1.3

m

Concrete Density, =

24

kN/m3

Concrete Weight, Cw =

24.75

kN

[BL-/4(0.15)]D

Resisting Moment, Mr =

7.32

kN-m

(Cw+PL+Pw)(B/2)

FOS =

1.90

Mr/Mo

Overturning Moment Check (Perpendicular to Lamp)

Overturning Moment, Mo =

4.55

kN-m

wL/2 + wbA

Footing Width, B =

0.5

m

Footing Length, L =

1.6

m

Footing Depth, D =

1.3

m

Concrete Density, =

24

kN/m3

Concrete Weight, Cw =

24.75

kN

[BL-/4(0.15)]D

Resisting Moment, Mr =

23.41

kN-m

(Cw+PL+Pw)(L/2)

FOS =

5.15

Mr/Mo

Base Plate Design

Plate Width, bp =

400

mm

Plate Length, lp =

400

mm

Plate Thickness, tp =

20

mm

Plate Yield Strength, pyp =

265

N/mm

Concrete Strength, fcu =

40

N/mm

Edge Distance, e =

38

mm

300

mm

Bolt Distance, s =

16

Bolt Diameter, db =

mm

Hole Diameter, dh =

18

mm

db+2

Minimum Spacing and Edge Distance of Bolt

Minimum Spacing, smin =

40

mm

2.5db

<s

Minimum Edge Distance, emin =

22.5

mm

1.25dh

<e

Determine Plate Thickness

w=

24

N/mm

0.6fcu

Mu =

6931200

N-mm

wbpe/2

Sx =

26155.47

mm

Mu/pyp

tp =

19.81

mm

6Sx/b

Bolt Design

2

Bolt Qty, nt =

4

Bolt Qty, ns =

Tension Force on bolt, Tb =

21.21

kN

M/s

0.79

Shear Force, Fh =

kN

Tension Force per Bolt, Pt =

10.61

kN

Tb/n

Shear Force per Bolt, Fs =

0.20

kN

Fh/ns

Made by

LHC

Checked

LHC

Date

19/3/2016

Revision

-

Page

Job No.

-

Reference

BS 6399-2

2.1.2.1

OK

OK

400mm

400mm

300mm

OK

OK

6.2.1.1

OK

4.13.2.2

Project

Client

Location

Made by

LHC

Checked

LHC

Date

19/3/2016

Revision

-

Page

Job No.

-

Shear Area of Bar, Av =

Yield Strength, ps =

Pv =

157

160

15.07

mm

N/mm

kN

psAv

OK

4.2.3

Tensile Strength, pt=

Pnom =

240

30.14

N/mm

kN

0.8Avpt

OK

6.3.4.2

Combine Shear and Tension

Fs/Ps + Ft/Pnom 1.4

0.36

Anchorage Length Design (Cast-In Bar)

l=

119.15

mm

Ft =

10.61

kN

fb =

1.77

N/mm

=

0.28

fcu =

40

N/mm

e =

16

mm

Weld Design

Force on weld, Fw =

19.95

kN

Weld Size, a =

4

mm

Weld Strength, ws =

0.22

kN/mm

Weld Length, Lw =

471.24

mm

Weld Capacity, PT =

362.85

kN

K=

1.25

Loadings

M=

3.85

kN-m

Ground pressure, qu =

57.70

kN/m

Ultimate Bearing Capacity

FILL

q1 =

307.58

kN/m

=

30

degree

c' =

0

kN/m

Dry Density, y =

9

kN/m

Nc =

37.20

Nq =

22.50

Ny =

19.70

kN/m

qa =

102.53

F.S. =

3

Bending Check

qu =

80.78

kN/m

w=

80.78

kN/m/m

M=

25.85

kN-m

L=

0.80

m

depth, d =

1236

mm

Conc. Cover, cnom =

40

mm

16

mm

Bar Size, db1 =

Bar Spacing, s =

100

mm

width, b =

500

mm

fcu =

40

N/mm

fy =

460

N/mm

k=

0.001

z=

1.00

d

z=

1174

mm

x=

137

mm

As =

55

mm

Aspro =

1005

mm

Asmin =

845

mm

Shear Check

V=

65

kN

vc =

0.40

N/mm

100As/bd =

0.16

400/d =

1.00

ym =

1.25

Vc =

499

kN

OK

Fs/fbpie

Pt

fcu

6.3.4.4

BS8110

3.12.8.3

3.12.8.4

Table 3.26

db

M/D

Table 37

0.15

0.7awsLw

OK

6.8.7.3

6M/LB

c'Nc + yDNq + 0.5yBNy

GIBR

GIBR

GIBR

Table 12.1

Table 12.1

Table 12.1

qu/F.S

>qu

OK

Table 12.1

Table 12.1

Table 12.1

wL/2

L/2

D-(cnom+db1/2)

M/bdfcu

0.5+0.25-(k/0.9)

0.95d

d-z/0.45

M/0.87fyz

(/4)db(b/s) >As

0.0013bD

<Aspro

Compression bar not required

wL

0.84(100As/bd)1/3(400/d)1/4(fcu/30)1/3/ym

<3

<1

vcdb

Table 3.1

3.4.4.4

OK

OK

OK

Use 1

Links not required

Table 3.9

You might also like

- Structural Computation AnalysisDocument16 pagesStructural Computation Analysisjeromefamadico90% (20)

- Lifting Hook For Precast SegmentDocument1 pageLifting Hook For Precast Segmenteric bargas100% (5)

- Perhitungan Kekuatan Pile Cap Kode Pondasi F2: A. Data Pondasi Tiang BorDocument9 pagesPerhitungan Kekuatan Pile Cap Kode Pondasi F2: A. Data Pondasi Tiang BorPuji Kurniawan100% (5)

- Combined Footing Design BS8110Document1 pageCombined Footing Design BS8110dantevarias83% (6)

- Single Pile Cap DesignDocument2 pagesSingle Pile Cap DesignVishal Nanavare0% (1)

- Design of Light Pole FoundationDocument2 pagesDesign of Light Pole Foundationabhinav100% (2)

- Project: Design:: Bukit Keteri Pg3 Strip FootingDocument4 pagesProject: Design:: Bukit Keteri Pg3 Strip FootingazwanNo ratings yet

- ES2 HoardingDocument1 pageES2 Hoardingerikaren85No ratings yet

- Slab With OpeningDocument16 pagesSlab With OpeningTomislav Šimag100% (1)

- Punching Shear StandardDocument4 pagesPunching Shear StandardjanethNo ratings yet

- Strip Footing 3 Columns Bsi 8110 - 2Document11 pagesStrip Footing 3 Columns Bsi 8110 - 2Magdy Bakry100% (3)

- Wind Loads Calculation BS6399Document3 pagesWind Loads Calculation BS6399jeddij100% (1)

- Pile Cap DesignDocument35 pagesPile Cap Designعصام السامرائي100% (2)

- Waler Wall Connection Design TemplateDocument1 pageWaler Wall Connection Design TemplateArjun RajaNo ratings yet

- Design of DomeDocument5 pagesDesign of DomeAmarjeet SinghNo ratings yet

- Slope Mass Rating: 8 N269.8 90 Mechanical/BlastingDocument3 pagesSlope Mass Rating: 8 N269.8 90 Mechanical/Blastingerikaren85No ratings yet

- ES2 HoardingDocument1 pageES2 Hoardingerikaren85No ratings yet

- 10.0m LIGHTING POLES - Concrete Design BS8110Document7 pages10.0m LIGHTING POLES - Concrete Design BS8110Nicoleta cristianNo ratings yet

- Foundation Design of Lamp PostDocument1 pageFoundation Design of Lamp PostMayank Agrawal100% (1)

- Footing Design According To BS8110 CodeDocument4 pagesFooting Design According To BS8110 CodePre SheetNo ratings yet

- Design - Bs CodeDocument2 pagesDesign - Bs CodeAnonymous Nn7XhD100% (1)

- Flat Slab ExcelDocument50 pagesFlat Slab ExcelJEFFY JACOB100% (1)

- Pile Set Calculation Dated 07-May-2018Document4 pagesPile Set Calculation Dated 07-May-2018hauzhiNo ratings yet

- Wall DesignDocument13 pagesWall DesignAnantPawarNo ratings yet

- Isolated Footing Design Example and Excel SheetDocument7 pagesIsolated Footing Design Example and Excel SheetAmjid AfridiNo ratings yet

- ManholeDocument2 pagesManholeTukuboya MTaufanNo ratings yet

- Cable Trench Desiign Report 26.04.2020 PDFDocument50 pagesCable Trench Desiign Report 26.04.2020 PDFkkgcNo ratings yet

- Footing Design According To BS8110 CodeDocument4 pagesFooting Design According To BS8110 CodeMohit VatsNo ratings yet

- Flood Lighting PoleDocument8 pagesFlood Lighting PoleMayuresh KudveNo ratings yet

- Dynamic Calculation For Retaining WallDocument6 pagesDynamic Calculation For Retaining WallSabrina ImloulNo ratings yet

- Pile Cap DesignDocument28 pagesPile Cap Designpwd2007No ratings yet

- Punching Shear CalculationDocument18 pagesPunching Shear CalculationNayeemuddin Khaja100% (2)

- 2 Piles Cap Design bs8110Document3 pages2 Piles Cap Design bs8110Faizal ImranNo ratings yet

- Bsae PlateDocument12 pagesBsae PlatesallymazeeraNo ratings yet

- 16 PoleDocument2 pages16 PoleMario Sajulga Dela CuadraNo ratings yet

- Sepakat Setia Perunding SDN BHD: Design InformationDocument6 pagesSepakat Setia Perunding SDN BHD: Design InformationAfiq SyahmiNo ratings yet

- Deviated Pile Cap DesignDocument10 pagesDeviated Pile Cap Designirmreza68No ratings yet

- Crack Width BS 8110Document2 pagesCrack Width BS 8110nhulugallaNo ratings yet

- ECM CalcsDocument25 pagesECM Calcsundf25No ratings yet

- Pile Spacing From Center To Center Should Not Exceed 3 Times The Pile Diameter and BS 8110 Part 1 Clause 3.11.4 Should AppliedDocument3 pagesPile Spacing From Center To Center Should Not Exceed 3 Times The Pile Diameter and BS 8110 Part 1 Clause 3.11.4 Should AppliedHafiz Kamarudin100% (1)

- Lintel DesignDocument3 pagesLintel DesignPrashant HuddarNo ratings yet

- 10m R.C BEAM DESIGNDocument3 pages10m R.C BEAM DESIGNchris100% (1)

- Punching ShearDocument14 pagesPunching Shearshamen amarasekaraNo ratings yet

- Foundation 2Document333 pagesFoundation 2akem mig100% (1)

- Shoring Depth CalculationDocument11 pagesShoring Depth CalculationUpali KarunarathneNo ratings yet

- Foundation Design For 30m TowerDocument52 pagesFoundation Design For 30m TowerTam Eng SunNo ratings yet

- Shoring SystemDocument3 pagesShoring SystemJason RoyNo ratings yet

- Design Shear Resistance (Beams EC2)Document2 pagesDesign Shear Resistance (Beams EC2)dhanya1995No ratings yet

- Cantilever BeamDocument4 pagesCantilever BeamWaheed AhmadNo ratings yet

- 9m Pole FDN Design 18.2.2015Document2 pages9m Pole FDN Design 18.2.2015faizankhan23No ratings yet

- 2 Piles Cap Design ExampleDocument3 pages2 Piles Cap Design ExampleSilvanus ChepkocheiNo ratings yet

- Fencing Oman With Block Footing - 03072013Document20 pagesFencing Oman With Block Footing - 03072013RAJENDRA PRASADNo ratings yet

- Weldgrp - Weld Group Analysis ProgramDocument16 pagesWeldgrp - Weld Group Analysis ProgramemoriderNo ratings yet

- Retaining Wall DesignDocument5 pagesRetaining Wall DesignbharatNo ratings yet

- Pile EccentricityDocument8 pagesPile EccentricitySiongyung KongNo ratings yet

- T208 Bored Pile Design - XLSXDocument3 pagesT208 Bored Pile Design - XLSXerikaren85No ratings yet

- Structural Design and Computations: Certified By: ApprovedDocument13 pagesStructural Design and Computations: Certified By: ApprovedJesusAntonioJugosNo ratings yet

- Design of Rectangular Footing Col Edge 3Document28 pagesDesign of Rectangular Footing Col Edge 3Shaikh Muhammad AteeqNo ratings yet

- Roof Beam DesignDocument68 pagesRoof Beam DesignUlasi IfeanyiNo ratings yet

- Continuous BeamsDocument450 pagesContinuous BeamssreenivasaeeNo ratings yet

- Structural Computation: Phase 7-A Block 17 Lot 04 Orchard & Residential Estate, Salitran, Dasmariñas, CaviteDocument9 pagesStructural Computation: Phase 7-A Block 17 Lot 04 Orchard & Residential Estate, Salitran, Dasmariñas, CaviteEdward Jade EmolagaNo ratings yet

- 230kV DS Foundation DesignDocument5 pages230kV DS Foundation Designelkhalfi100% (1)

- Slope Mass RatingDocument4 pagesSlope Mass Ratingerikaren85No ratings yet

- Noise Barrier DesignDocument1 pageNoise Barrier DesignPorky Cunanan BargasNo ratings yet

- UTP CalculationDocument1 pageUTP Calculationerikaren85No ratings yet

- Bolt CapacityDocument2 pagesBolt Capacityerikaren85No ratings yet

- DES0079Document2 pagesDES0079erikaren85No ratings yet

- Staad Pro Solid ManualDocument3 pagesStaad Pro Solid Manualerikaren850% (1)

- Concrete Pressure On Vertical FormworkDocument8 pagesConcrete Pressure On Vertical Formworkerikaren85No ratings yet

- T208 Bored Pile Design - XLSXDocument3 pagesT208 Bored Pile Design - XLSXerikaren85No ratings yet