Professional Documents

Culture Documents

2 Piles Cap Design Example

Uploaded by

Silvanus ChepkocheiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2 Piles Cap Design Example

Uploaded by

Silvanus ChepkocheiCopyright:

Available Formats

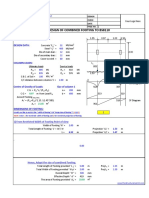

Project Job Ref.

ENG. GRD. CHEPKOCHEI SILVANUS Structural Elements Design ~Jan22 #2203J

Section Sheet no./rev.

EBK: B12891

RC Pile Cap Design 1

IAENG: 264642 Calc. by Date Chk'd by Date App'd by Date

S CHEPKOCHEI 16-Jan-2022

RC PILE CAP DESIGN (BS8110:PART1:1997)

Loaded width - x 2 Pile Cap, height h

e

ex

b

P1 x P2 e

Pile Cap Design – Truss Method

Design Input - 2 Piles - With Eccentricity

Number of piles; N=2

ULS axial load; Fuls = 1600.0 kN

Characteristic axial load; Fchar = 1100.0 kN

Pile diameter; = 400 mm

Pile spacing; s = 1000 mm

Eccentricity from centroid of pile cap; ex = 90 mm

The characteristic load in pile, 1 is; Fchar_pile_1 = Fchar (s/2 - ex)/s = 451.0 kN

The characteristic load in pile, 2 is; Fchar_pile_2 = Fchar (s/2 + ex)/s = 649.0 kN

Pile cap overhang ; e = 200 mm

Overall length of pile cap; L = s + + 2 e = 1800 mm

Overall width of pile cap; b = + 2 e = 800 mm

Overall height of pile cap; h = 500 mm

Dimension of loaded area; x = 400 mm; (parallel to pile cap)

Cover

Concrete grade; fcu = 35.0 N/mm2

Nominal cover; cnom = 30 mm

Tension bar diameter; Dt = 16 mm

Link bar diameter; Ldia = 12 mm

Depth to tension steel; d = h – cnom - Ldia - Dt/2 = 450 mm

Pile Cap Forces

Maximum compression within pile cap; Fc = max(Fc1, Fc2) = 1277.1 kN

Maximum tension within pile cap; Ft = max(Ft1, Ft2) = 860.1 kN

Compression In Pile Cap - Suggested Additional Check

Check compression diagonal as an unreinforced column, using a core equivalent to pile diameter

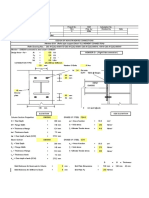

Project Job Ref.

ENG. GRD. CHEPKOCHEI SILVANUS Structural Elements Design ~Jan22 #2203J

Section Sheet no./rev.

EBK: B12891

RC Pile Cap Design 2

IAENG: 264642 Calc. by Date Chk'd by Date App'd by Date

S CHEPKOCHEI 16-Jan-2022

Compressive force in pile cap; Pc = 0.4 fcu 2/4 = 1759.3 kN

PASS Compression

Cl. 3.8.4.3

Tension In One Truss Member

Characteristic strength of reinforcement; fy = 500 N/mm2

Partial safety factor for strength of steel; ms = 1.15

Required area of reinforcement; As_req = Ft /(1/ms fy) = ;1978; mm

Provided area of reinforcement; As_prov = Ast = 2011 mm2

Tension capacity of truss member; Pt = (1/ms fy) As_prov = ;874.2; kN

PASS Tension

Cl. 3.11.4.2

Max / Min Areas Of Reinforcement

Minimum area of tension steel; Ast_min = kt Ac = 520 mm2

Maximum area of tension steel; Ast_max = 4 % Ac = 16000 mm2

Area of tension steel provided OK

Cl. 3.12.6 & Table 3.25

Shear

Applied shear stress

Shear force pile 1; V1 = Fuls_pile_1 = 656.0 kN

Shear force pile 2; V2 = Fuls_pile_2 = 944.0 kN

Width of pile cap shear plane; bv = min( b, 3 ) = 800 mm

Shear stress pile 1; v1 = V1/(bv d) = 1.82 N/mm2

Shear stress pile 2; v2 = V2/(bv d) = 2.62 N/mm2

Allowable shear stress; vallowable = min ((0.8 N1/2/mm) (fcu ), 5 N/mm2 ) = 4.73 N/mm2

Shear stress - OK

Cl. 3.4.5.2

Design concrete shear strength

Determine concrete shear strengths on the sections at distance / 5 inside face of each pile:

Cl. 3.11.4.3 & fig. 3.23

Shear stress - BS8110-1:1997 Table 3.8;

vc_25 = 0.79 r1/3 max(0.67, (400 mm/d)1/4) 1.0 N/mm2 / 1.25 = 0.51 N/mm2

Enhanced shear stress - Cl. 3.4.5.8 & fig. 3.5; vc = vc_25 ( min(fcu, 40 N/mm2 )/25 N/mm2 )1/3 = 0.57 N/mm2

av_1 = min(2 d, max(s/2 + ex - /2 + /5- x/2, 0.1 mm)) = 270 mm

av_2 = min(2 d, max(s/2 - ex - /2 + /5- x/2, 0.1 mm)) = 90 mm

Concrete shear strength - Case 1; vc_enh_1 = min( vallowable , 2 d vc / av_1 ) = 1.88 N/mm2

Concrete shear strength - Case 2; vc_enh_2 = min( vallowable , 2 d vc / av_2 ) = 4.73 N/mm2

Concrete shear strength - OK, no links reqd. for case 1

Concrete shear strength - OK, no links reqd. for case 2

Table 3.16

Note: If no links are provided, the bond strengths for PLAIN bars must be used in calculations for anchorage and lap lengths.

Cl. 3.12.8.3

Clear Distance Between Bars In Tension (Cl 3.12.11.2.4)

Bar spacing;

spacingbars = max( 0mm, (b- 2 (cadopt + Ldia) - Dt)/(Lnt - 1) - Dt) = 62 mm

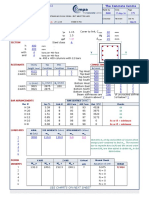

Project Job Ref.

ENG. GRD. CHEPKOCHEI SILVANUS Structural Elements Design ~Jan22 #2203J

Section Sheet no./rev.

EBK: B12891

RC Pile Cap Design 3

IAENG: 264642 Calc. by Date Chk'd by Date App'd by Date

S CHEPKOCHEI 16-Jan-2022

Maximum allowable spacing; spacingmax = min((47000 N/mm)/fs, 300 mm) = 143 mm

Minimum allowable spacing; spacingmin = hagg + 5 mm = 25 mm

Bar spacing OK

Clear Distance Between Face Of Beam And Tension Bars (Cl 3.12.11.2.5)

Distance to face of beam; Distedge = cadopt + Ldia + Dt/2 = 50 mm

Design service stress in reinforcement; fs = 2 fy As_req /(3 As_prov b) = 328.0 N/mm2

Max allowable clear spacing; Spacingmax = min((47000 N/mm)/fs, 300 mm) = 143 mm

Max distance to face of beam; Distmax = Spacingmax /2 = 72 mm

Max distance to beam edge check - OK

Anchorage Of Tension Steel

Anchorage factor; factor =38

Type of lap length; lap_type ="tens_lap"

Type of reinforcement; reft_type = "def2_fy500"

Minimum radius; rbar = 32 mm

Minimum end projection; Pbar = 130 mm

Minimum anchorage length or lap length req’d; Ltable 3.27 = factor Dt = 608 mm

Check anchorage length to cl. 3.12.9.4 (b); Lcl. 3.12.9.4 = 12 Dt + d/2 = 417 mm

Required minimum effective anchorage length; La = max(Ltable 3.27, Lcl. 3.12.9.4) = 608 mm

Check minimum radius required on bend

Note that the bars must extend at least 4D past the bend

Force per bar at bend; Fbt = Ft / Lnt = 86.0 kN

Edge bar centres; sext = cadopt + Dt = 46 mm

Edge maximum allowable bearing stress; fbt_max_ext = 2 fcu / ( 1 + 2(Dt / sext )) = 41.28 N/mm2

Internal bar centres; sint = spacingbars + Dt = 78 mm

Internal maximum allowable bearing stress; fbt_max_int = 2 fcu / ( 1 + 2(Dt / sint )) = 49.60 N/mm2

Design max allowable bearing stress; fbt_max = min(fbt_max_ext, fbt_max_int) = 41.28 N/mm2

Minimum radius required; rmin = max(rbar, Fbt /(fbt_max Dt)) = 130.2 mm

Minimum radius of bend required = 130 mm

Deflection Check (Cl 3.4.6)

Redistribution ratio; b = 1.0

Design service stress in tension reinforcement; fs = 2 fy As_req /(3 As_prov b) = 328.0 N/mm2

Modification for tension reinforcement;

factortens = min( 2, 0.55 + (477 N/mm2 - fs)/(120 (0.9 N/mm2 + Ft /(bd )))) = 0.928

Modified span to depth ratio; modfspan_depth = factortens basicspan_depth = 18.6

Span of pile cap for deflection check; Ls = 1000 mm

Actual span to depth ratio; actualspan_depth = Ls /d = 2.22

PASS - Deflection

You might also like

- As Per RCC Design (B.C. Punmia) Page 184 Example 7.6 Design of Cantilever ChajjaDocument32 pagesAs Per RCC Design (B.C. Punmia) Page 184 Example 7.6 Design of Cantilever ChajjajaffnaNo ratings yet

- TCC81 Foundation PadsDocument1 pageTCC81 Foundation PadsReetesh0% (1)

- Boundary Wall Design - Final For RFCDocument10 pagesBoundary Wall Design - Final For RFCShubham KhareNo ratings yet

- Pedestal DesignDocument2 pagesPedestal DesignRamadanNo ratings yet

- Lip C Purlin (KNL)Document8 pagesLip C Purlin (KNL)KTMONo ratings yet

- Base Plate Design Prokon PDFDocument8 pagesBase Plate Design Prokon PDFmsiddiq1No ratings yet

- Footing Design According To BS8110 CodeDocument4 pagesFooting Design According To BS8110 CodeMohit VatsNo ratings yet

- Structural Design 50M SST - Medium Duty - Zone Ii, Exposure C Rev. No. 00 F0736Document39 pagesStructural Design 50M SST - Medium Duty - Zone Ii, Exposure C Rev. No. 00 F0736Henj MirasolNo ratings yet

- WALLPRES ExcavationDocument11 pagesWALLPRES ExcavationShekh Muhsen Uddin AhmedNo ratings yet

- Pedestal Design For Pedestal Marked As "P3" (500 MM X 400 MM)Document3 pagesPedestal Design For Pedestal Marked As "P3" (500 MM X 400 MM)NAYAN RANPURANo ratings yet

- Combined FootingDocument31 pagesCombined Footingalbert_pathNo ratings yet

- Cantilever Retaining Wall Example - PDF EurocodeDocument14 pagesCantilever Retaining Wall Example - PDF Eurocodepatrick chegeNo ratings yet

- Combined Footing DesignDocument3 pagesCombined Footing DesignThe Structural WorldNo ratings yet

- Beam DesignDocument7 pagesBeam DesignKasi ViswanathanNo ratings yet

- 11 CulvertDesign v22Document2 pages11 CulvertDesign v22Lee See VoonNo ratings yet

- AngleDocument7 pagesAngleNguyễnTúSơnNo ratings yet

- Spreadsheets To BS 8110 Etc: Advisory Group Grid Line 2 RC 01-Apr-2014 95 CHG R68Document14 pagesSpreadsheets To BS 8110 Etc: Advisory Group Grid Line 2 RC 01-Apr-2014 95 CHG R68jaffnaNo ratings yet

- Single Box Culvert Structural Design 1.5m X 1.5mDocument28 pagesSingle Box Culvert Structural Design 1.5m X 1.5mAYEDNo ratings yet

- Slender Column - Sway Frame - ACI 318-08 Reinforced Concrete Design Example HassounDocument8 pagesSlender Column - Sway Frame - ACI 318-08 Reinforced Concrete Design Example HassounMike2322100% (1)

- 1.1 Subject Information: Statical Calculation For Masonry Abutment DesignDocument10 pages1.1 Subject Information: Statical Calculation For Masonry Abutment DesignabadittadesseNo ratings yet

- Design of Rectangular Combined Footing Supporting Two Axially Loaded ColumnsDocument3 pagesDesign of Rectangular Combined Footing Supporting Two Axially Loaded ColumnsThirdie LerajeNo ratings yet

- Design of Strap Footing PDFDocument3 pagesDesign of Strap Footing PDFVasanthakumarNo ratings yet

- Neral & Staad Diag.Document130 pagesNeral & Staad Diag.IkramNo ratings yet

- Design of Isolated Footing With Vertical Load Only - According To ACI 318M-99Document1 pageDesign of Isolated Footing With Vertical Load Only - According To ACI 318M-99mahmoud IbrahemNo ratings yet

- ANCHOR - REINFORCEMENT (Metric)Document10 pagesANCHOR - REINFORCEMENT (Metric)Tarek AbulailNo ratings yet

- Moment Connection Beam Column Is Bs Section For Is800Document27 pagesMoment Connection Beam Column Is Bs Section For Is800Ramesh SelvarajNo ratings yet

- Design of Double Pilecap: Design For Axial Load and MomentDocument16 pagesDesign of Double Pilecap: Design For Axial Load and MomentMidhun BabuNo ratings yet

- Retaining Wall DesignDocument6 pagesRetaining Wall Designdocument123456789100% (1)

- Retaining Wall Analysis & Design (BS8002 - 1994)Document10 pagesRetaining Wall Analysis & Design (BS8002 - 1994)IKNo ratings yet

- Combined Footing Design (Strap Final)Document22 pagesCombined Footing Design (Strap Final)Engineeri TadiyosNo ratings yet

- SpreadsheetDocument7 pagesSpreadsheetChan Kin CheungNo ratings yet

- Pad Foundation With Two Columns ExampleDocument10 pagesPad Foundation With Two Columns ExampleakankwasaNo ratings yet

- PAEC2017 - Slab On Grade InvestigationDocument2 pagesPAEC2017 - Slab On Grade InvestigationSayavi Nicole Sayavi NickNo ratings yet

- Column Design With ExcelDocument47 pagesColumn Design With ExcelMatiur Rahman BasumNo ratings yet

- Chequer Platform-Flat Bar Design - L 1.112m - SDL 10kpaDocument1 pageChequer Platform-Flat Bar Design - L 1.112m - SDL 10kpaGOHNo ratings yet

- Pile Cap Design - ColumnsDocument7 pagesPile Cap Design - ColumnsJule LobresNo ratings yet

- Punching Shear StandardDocument4 pagesPunching Shear StandardjanethNo ratings yet

- Larsen & Toubro Limited: ECC Division - EDRCDocument11 pagesLarsen & Toubro Limited: ECC Division - EDRCNitesh SinghNo ratings yet

- Design of PurlinsDocument10 pagesDesign of PurlinsFranklyn GenoveNo ratings yet

- SHS 100x100x5t BP-02Document3 pagesSHS 100x100x5t BP-02Win ThanNo ratings yet

- 3.3.1 Retaining WallDocument31 pages3.3.1 Retaining WallNeil SonNo ratings yet

- Link Containment Reinforcement (Walls BS 8110)Document1 pageLink Containment Reinforcement (Walls BS 8110)dhanya1995No ratings yet

- TCC53 Column DesignDocument18 pagesTCC53 Column DesignTemesgenAbiyNo ratings yet

- Footing BiaxialDocument33 pagesFooting BiaxialSanthoshkumar RayavarapuNo ratings yet

- Pad Footing Design ExampleDocument6 pagesPad Footing Design ExampleGautam PaulNo ratings yet

- Inputs 1.1 Material Properties: Design of Masonry Retaining WallDocument16 pagesInputs 1.1 Material Properties: Design of Masonry Retaining WallEskinderNo ratings yet

- 20d-Stepped Masonry Retaining Wall-Stability CheckDocument6 pages20d-Stepped Masonry Retaining Wall-Stability CheckParthiban Arivazhagan100% (1)

- Vent Stack Foundation CalDocument11 pagesVent Stack Foundation CalBenedict OgbaghaNo ratings yet

- Design of Water TankDocument30 pagesDesign of Water TankDeepthi ReddyNo ratings yet

- Ruj.: Kod: Subjek: No Helaian: Ruj. Lukisan: Disemak Tarikh: Direkabentuk Oleh: ProjekDocument5 pagesRuj.: Kod: Subjek: No Helaian: Ruj. Lukisan: Disemak Tarikh: Direkabentuk Oleh: ProjekHafiz Budean RahmanNo ratings yet

- Fin Plate To Column Flange - LRFDDocument23 pagesFin Plate To Column Flange - LRFDkalpanaadhiNo ratings yet

- Wind CalculatorDocument12 pagesWind Calculatorilyasmd7No ratings yet

- Calculation For Moment Connection - Type ADocument15 pagesCalculation For Moment Connection - Type ANitesh SinghNo ratings yet

- Concrete ColumnDocument3 pagesConcrete ColumnDaniella AlvesNo ratings yet

- Base Slab Design - RampDocument6 pagesBase Slab Design - RampSuresh Mahalingam100% (1)

- Purlin DesignDocument6 pagesPurlin DesignAnonymous mcHqIfbnV1No ratings yet

- Pile Cap Design at AbutmentDocument4 pagesPile Cap Design at AbutmentAzwani Abdullah100% (1)

- Pile Rebar DesignDocument4 pagesPile Rebar DesignprakashNo ratings yet

- 6.1 Sun ShadeDocument46 pages6.1 Sun ShadeEr Mohd NoshadNo ratings yet

- Anchor Bolt BiAxialDocument10 pagesAnchor Bolt BiAxialALPHYL BALASABASNo ratings yet

- HL Paper1Document32 pagesHL Paper1Brandon PARDNo ratings yet

- Fayoum University Faculty of Engineering Mechanical Department Fluid Mechanics (1), SheetDocument2 pagesFayoum University Faculty of Engineering Mechanical Department Fluid Mechanics (1), SheetMo 16No ratings yet

- Preparation and Evaluation Ofmyoconductive Ecg GelDocument3 pagesPreparation and Evaluation Ofmyoconductive Ecg GelpgeneraliNo ratings yet

- Design of ScaffoldingDocument9 pagesDesign of ScaffoldingdfdgggNo ratings yet

- Egg Drop Background InformationDocument3 pagesEgg Drop Background Informationapi-332369217No ratings yet

- Fraunhofer Diffraction Through A Thin Wire and Babinet's PeincipleDocument19 pagesFraunhofer Diffraction Through A Thin Wire and Babinet's PeincipleShwetaNo ratings yet

- Revamping of The PCS Nitrogen 03 Plant in Trinidad: Elizabeth West-ToolseeDocument7 pagesRevamping of The PCS Nitrogen 03 Plant in Trinidad: Elizabeth West-Toolseevaratharajan g rNo ratings yet

- Steam Turbine ModelDocument19 pagesSteam Turbine ModelRoberto ZuñigaNo ratings yet

- Physics 9 Icse Sample Paper 5Document5 pagesPhysics 9 Icse Sample Paper 5Study in an easy wayNo ratings yet

- Drying Stages During The Heating of High-Alumina, Ultra-Low-Cement Refractory CastablesDocument4 pagesDrying Stages During The Heating of High-Alumina, Ultra-Low-Cement Refractory CastablesAnthony MarasiganNo ratings yet

- Co ReDocument11 pagesCo ReAbdallah ElsaidNo ratings yet

- Ochsner 2008 Carbon Dioxide Heat Pipe in ConjuncDocument6 pagesOchsner 2008 Carbon Dioxide Heat Pipe in ConjuncHugo PeresNo ratings yet

- UTCHEM Tech Doc PDFDocument256 pagesUTCHEM Tech Doc PDFpasha khanNo ratings yet

- Previouspaper UKPSC Civil Engineering Paper IDocument46 pagesPreviouspaper UKPSC Civil Engineering Paper INitesh KumarNo ratings yet

- S06-All Examples 2upDocument5 pagesS06-All Examples 2upAvinash MeenaNo ratings yet

- The Chemistry Tribology: Friction, Lubrication and WearDocument70 pagesThe Chemistry Tribology: Friction, Lubrication and WearJicheng PiaoNo ratings yet

- AP Government GATE Online Classes: Day-10 (04.06.2020) Dr. R. Srikanth Professor ANITS-VisakhapatnamDocument74 pagesAP Government GATE Online Classes: Day-10 (04.06.2020) Dr. R. Srikanth Professor ANITS-VisakhapatnamRajmangal NishadNo ratings yet

- Atomic StructureDocument4 pagesAtomic StructureThea GermanNo ratings yet

- VDM® Alloy 625 - Nickel Iron Alloy - MatmatchDocument4 pagesVDM® Alloy 625 - Nickel Iron Alloy - MatmatchRaznovrsni KutakNo ratings yet

- Wellstream Flexibles StudentDocument204 pagesWellstream Flexibles StudentVictor HiromatsuNo ratings yet

- Assignment QuestionDocument15 pagesAssignment QuestionPratik WalimbeNo ratings yet

- (De Gruyter Textbook) Tadros, Tharwat F. - Polymeric Surfactants Dispersion Stability and Industrial Applications (2017) - Libgen - LiDocument288 pages(De Gruyter Textbook) Tadros, Tharwat F. - Polymeric Surfactants Dispersion Stability and Industrial Applications (2017) - Libgen - LishaziaNo ratings yet

- Scaling Laws & Microfabrication: MECH 466 Microelectromechanical SystemsDocument20 pagesScaling Laws & Microfabrication: MECH 466 Microelectromechanical Systemsamrut mulayNo ratings yet

- Chapter 2 (Mcmurry - 9th Edition)Document60 pagesChapter 2 (Mcmurry - 9th Edition)Paolo NaguitNo ratings yet

- Combined Stresses and Mohr'S Circle: James Doane, PHD, PeDocument41 pagesCombined Stresses and Mohr'S Circle: James Doane, PHD, Pesalem gergiNo ratings yet

- The Inhibitive Effect of Hexamethylenetetramine On The Acid Corrosion of SteelDocument10 pagesThe Inhibitive Effect of Hexamethylenetetramine On The Acid Corrosion of Steelhadi ebrahimfathNo ratings yet

- Solvent ExtractionDocument39 pagesSolvent ExtractionDeoga Nax LiverpoolNo ratings yet

- Lecture 3 CVDDocument43 pagesLecture 3 CVDSam StideNo ratings yet

- Safety Valve NotesDocument12 pagesSafety Valve NotesNikhilSinghNo ratings yet

- TDS Molylube SF 100 Semi Synthetic Open Gear Lubricant PDFDocument3 pagesTDS Molylube SF 100 Semi Synthetic Open Gear Lubricant PDFGilmer CaceresNo ratings yet