Professional Documents

Culture Documents

Quality Astm A 105: Lucefin Group

Quality Astm A 105: Lucefin Group

Uploaded by

Edison FonsecaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Quality Astm A 105: Lucefin Group

Quality Astm A 105: Lucefin Group

Uploaded by

Edison FonsecaCopyright:

Available Formats

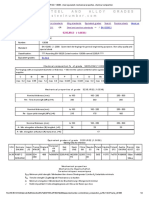

Quality

ASTM A 105

Technical card

According to standards

Number

ASTM A 105M - 05

Lucefin Group

Chemical composition

C%

max

0,35

Si%

Mn%

0,10-0,35

0,60-1,05

P%

max

0,035

S%

max

0,040

Cu%

max

0,40

Ni%

max

0,40

Cr%

max

0,30

Mo%

max

0,12

V%

max

0,08

Nb%

max

0,02

The sum of copper (Cu), chromium (Cr), nickel (Ni) and molybdenum (Mo) should not exceed 1,00%

The sum of chromium (Cr) and molybdenum (Mo) should not exceed 0,32%

For each reduction of 0,01% under max carbon value (0,35), it is admitted a 0,06% increase of manganese over its max value (1,05%)

up to 1,35%

On request, this steel grade may be supplied Calcium (Ca) treated

Min Al content 0,020% (to be certified)

Carbon Equivalent CE = C + Mn/6 + (Cr + Mo + V)/5 + (Ni + Cu)/ 15 max 0,47

Temperature C

Hot-forming

Normalizing .

Quenching

Tempering

Stress-relieving

1150-850

843-927

air cooling

880-930

oil / polymer water

593

air cooling

50 under the temperature of

tempering

Soft

annealing

700

air cooling

Normalizing

and Tempering

843-927 air

593 air

Isothermal

annealing

860 furnace

cooling to

660, then air

Pre-heating welding

250

AC1

AC3

Stress-relieving

after welding (PWHT)

590 furnace cooling

MS

Mf

Mechanical properties

Forged values as reference Heat treatments must guarantee the reported values ASTM A 105M - 05

all dimension

Testing at room temperature (longitudinal)

mm

R

Rp 0.2%

A% L

A% T

C% L

C% T

N/mm2 min

N/mm2 min.

min.

min.

min.

min.

T

485

250

22

30

Forged over 4540 Kg may be ordered according to ASTM A 266/A 266M 03a

all dimension

R

Rp 0.2%

A%

A% T

mm

N/mm2 min.

min.

min.

N/mm2

T

415-585

205

23

20

C% L

min.

38

C% T

min.

30

Kv

J min.

HB

max

187

Kv

J min.

HB

121-170

T= max heat-treated thickness. Test specimen should correspond to the T

Minimum values at high temperatures

Rp 0.2 N/mm2

248

228

C

38

93

219

149

212

204

Mechanical properties ( longitudinal testing) LUCEFIN experience

Heat treatment

product test at R

Rp 0.2

mm

C

N/mm2 N/mm2

Normalizing 920 C

90

+20

603

485

Normalizing 920 C

90

+400

312

217

Normalizing 900 C

240

+20

578

417

Normalizing 900 C

240

+400

506

248

Normalizing 900 C

400

+20

470

309

Normalizing 900 C

400

+400

424

206

Quenched end tempered 95

+20

579

403

Quenched and tempered 95

+400

520

325

Natural

90

+20

580

400

EUROPE EN

ITALY UNI

CHINA GB

GERMANY DIN

C21

202

260

190

316

A

%

30

C-Z

%

69.5

Kv 0 C

J

56-64-57

32.4

63.8

111-136-133

39.2

69.0

181-222-220

35.6

68.6

210-203-207

28.0

63.0

20-18-18

FRANCE AFNOR

U.K. B.S.

184

343

178

371

Kv -18 C Kv -46 C product

J

J

Hot-rolled

Hot-rolled

Hot-rolled

Hot-rolled

Forged

Forged

Hot-rolled

Hot-rolled

14-12-12 10-8-8

Hot-rolled

RUSSIA GOST

20G

USA AISI/SAE

A 105

You might also like

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Astm C856Document16 pagesAstm C856Jad Louis100% (2)

- Steel Tubes: See Notes !Document5 pagesSteel Tubes: See Notes !amit kumar sarkarNo ratings yet

- A434Document3 pagesA434alirioNo ratings yet

- 05 Askeland ChapDocument10 pages05 Askeland ChapWeihanZhang100% (2)

- Asme Section Ii A-2 Sa-815 Sa-815mDocument10 pagesAsme Section Ii A-2 Sa-815 Sa-815mdavid perezNo ratings yet

- PIPE SpecificationDocument5 pagesPIPE SpecificationNilesh GohelNo ratings yet

- S235jr Carbon SteelDocument2 pagesS235jr Carbon Steelcheligp1981No ratings yet

- Egg Crate Grills SampleDocument3 pagesEgg Crate Grills SamplempwasaNo ratings yet

- Item 13. Codo SCH-80 A234 - 783Document1 pageItem 13. Codo SCH-80 A234 - 783ELMER CHILON MINCHANNo ratings yet

- BS Bolt MaterialDocument1 pageBS Bolt MaterialKamlesh LuharNo ratings yet

- Valvula Mariposa Danais 150Document15 pagesValvula Mariposa Danais 150Oscar CherroNo ratings yet

- Minfc930 Astm A322 Grade 4140Document3 pagesMinfc930 Astm A322 Grade 4140Muthazhagan SaravananNo ratings yet

- Insulation PDS & MSDS PDFDocument11 pagesInsulation PDS & MSDS PDFsmartayaz1987No ratings yet

- Asme Sa 213 Grade t92 TubesDocument1 pageAsme Sa 213 Grade t92 TubesFerroPipENo ratings yet

- ASTM 재질분류표Document106 pagesASTM 재질분류표오덕환Oh Duckhwan100% (1)

- ASTM A536 Ductile Iron Castings Tensile Requirements PDFDocument1 pageASTM A536 Ductile Iron Castings Tensile Requirements PDFTheOne Yasir100% (1)

- GIC Pressure GaugeDocument2 pagesGIC Pressure GaugeSUSOVAN BISWASNo ratings yet

- Monel 400Document16 pagesMonel 400amr kouranyNo ratings yet

- European Steel and Alloy Grades: S235JRG2 (1.0038)Document2 pagesEuropean Steel and Alloy Grades: S235JRG2 (1.0038)farshid KarpasandNo ratings yet

- Service Bulletin 8-12-109hDocument16 pagesService Bulletin 8-12-109hexergicNo ratings yet

- Certificado Copla SW 2Document1 pageCertificado Copla SW 2juan aguilarNo ratings yet

- ASTM A213 T22 ASME SA213 T22 Specification - 3 PDFDocument6 pagesASTM A213 T22 ASME SA213 T22 Specification - 3 PDFbagus asmoroNo ratings yet

- C43Document1 pageC43rudramansingh123No ratings yet

- Din 17100Document4 pagesDin 17100Sheby SandyNo ratings yet

- Dasco 10-18Document9 pagesDasco 10-18Ahmed Azad100% (1)

- Egg Crate: Product InformationDocument5 pagesEgg Crate: Product Informationntt_121987No ratings yet

- Astm A216Document3 pagesAstm A216Ruth Sarai YañezNo ratings yet

- S275JR PDFDocument1 pageS275JR PDFEmrahCayboylu100% (1)

- Mud Gas Separator For Gas ServiceDocument2 pagesMud Gas Separator For Gas ServiceKapwell LimitedNo ratings yet

- 1.9.1.2-ALCRO - Arc Sprayed Iron-Chrome-Aluminum WireDocument4 pages1.9.1.2-ALCRO - Arc Sprayed Iron-Chrome-Aluminum WirechonubobbyNo ratings yet

- DIN Flange 2502-2503 PDFDocument2 pagesDIN Flange 2502-2503 PDFHeru Agus SetyawanNo ratings yet

- A 488A 488M 01 Welding Qualifications of Procedures and Personnel PDFDocument16 pagesA 488A 488M 01 Welding Qualifications of Procedures and Personnel PDFshakeelahmadjsrNo ratings yet

- ASTM Comparison PDFDocument1 pageASTM Comparison PDFRaja HoneNo ratings yet

- GasFluxWelding PDFDocument72 pagesGasFluxWelding PDFjuandajdjNo ratings yet

- Douglas Chero Catalogue Valve 6-2003Document89 pagesDouglas Chero Catalogue Valve 6-2003Yurizki LhzNo ratings yet

- Mag General Business: Mill Test CertificateDocument1 pageMag General Business: Mill Test CertificateRaul SebastiamNo ratings yet

- ASTM Standard For Pipe and FittingDocument7 pagesASTM Standard For Pipe and FittingHtet Aung ZayNo ratings yet

- KTM - Eb11 Eb12 Eb21 Eb22Document12 pagesKTM - Eb11 Eb12 Eb21 Eb22psycloneses100% (1)

- Certificado de Calidad Brida WN SCH-80 2.5Document1 pageCertificado de Calidad Brida WN SCH-80 2.5Jackelin MayraNo ratings yet

- Astm A192 Asme Sa192 PDFDocument4 pagesAstm A192 Asme Sa192 PDFWil Vasquez C100% (1)

- Material QuivalentDocument4 pagesMaterial QuivalentUma SankarNo ratings yet

- Metric DIN 933 Hexagon Head Cap Screws / Bolts Full Thread: Visit Our For Product AvailabilityDocument5 pagesMetric DIN 933 Hexagon Head Cap Screws / Bolts Full Thread: Visit Our For Product AvailabilityRodolfo MartinezNo ratings yet

- A270 PDFDocument5 pagesA270 PDFHansSarmientoNo ratings yet

- RJR PMMTDocument16 pagesRJR PMMTArun PrasadNo ratings yet

- Ampliflow T-Boost Ssfly000029-Ena4Document2 pagesAmpliflow T-Boost Ssfly000029-Ena4carburoNo ratings yet

- ASTM A572 Grade 50 Plate: AnalysisDocument2 pagesASTM A572 Grade 50 Plate: Analysisdaniel moreno jassoNo ratings yet

- Presentation Rekuluvo Counter-Flow Air Preheater Technologie" Gea-Ecoflex GMBH Dr.-Ing. Olivier BrasseurDocument29 pagesPresentation Rekuluvo Counter-Flow Air Preheater Technologie" Gea-Ecoflex GMBH Dr.-Ing. Olivier BrasseurdeepchotiNo ratings yet

- LCM ValvesDocument40 pagesLCM ValvesAlexa Harper100% (1)

- ASHRAE Terminology - Complete ListDocument298 pagesASHRAE Terminology - Complete Listwado11No ratings yet

- Astralloy-V: Abrasion and Impact Resistant, Air Hardened Wear SteelDocument2 pagesAstralloy-V: Abrasion and Impact Resistant, Air Hardened Wear SteelJRodengineerNo ratings yet

- Chemical and Mechanical PropertiesDocument5 pagesChemical and Mechanical PropertiesAristotle MedinaNo ratings yet

- Din 10140Document3 pagesDin 10140Diego CamargoNo ratings yet

- ASTM A210 Seamless Boiler and Superheater Tubes PDFDocument5 pagesASTM A210 Seamless Boiler and Superheater Tubes PDFPAULNo ratings yet

- Stainless Steel 316Document1 pageStainless Steel 316Bungsu ZamzamNo ratings yet

- Certificado Calidad-Codo SCH40Document1 pageCertificado Calidad-Codo SCH40ALENo ratings yet

- Quality: Astm A 105Document1 pageQuality: Astm A 105lavius_mNo ratings yet

- 1 4571a316ti69Document2 pages1 4571a316ti69Admir TalicNo ratings yet

- 1330 Crni Mo 831Document2 pages1330 Crni Mo 831sajay_suryaNo ratings yet

- 1 4305a30365Document2 pages1 4305a30365skidanjeNo ratings yet

- Astm A350 LF2Document1 pageAstm A350 LF2anjangandak2932100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- CLS Aipmt 19 20 XII Che Study Package 1 Level 1 Chapter 1Document20 pagesCLS Aipmt 19 20 XII Che Study Package 1 Level 1 Chapter 1ShubanghiNo ratings yet

- Chemical Reactions PDFDocument80 pagesChemical Reactions PDFJohnRenzoMolinarNo ratings yet

- D5298 Curva Característica Do SoloDocument6 pagesD5298 Curva Característica Do SoloDenny SantanaNo ratings yet

- US Navy Course NAVEDTRA 14019 - Aviation Structural Mechanic E 1 & CDocument152 pagesUS Navy Course NAVEDTRA 14019 - Aviation Structural Mechanic E 1 & CGeorges100% (2)

- 805AA Flexor 5 SAE 100 R5: Wire BraidDocument1 page805AA Flexor 5 SAE 100 R5: Wire BraidRodrigo Pessoa VespaNo ratings yet

- Hydrocarbons - Types, Classification, Properties, Preparation, UsesDocument26 pagesHydrocarbons - Types, Classification, Properties, Preparation, UsesAnand GautamNo ratings yet

- Sulfonation With Sulfur TrioxideDocument4 pagesSulfonation With Sulfur TrioxideRashid SaleemNo ratings yet

- PRODUKKOMERSIALDocument3 pagesPRODUKKOMERSIALAngga Afrian PradikaNo ratings yet

- Microflex-93-260 Pds MyDocument2 pagesMicroflex-93-260 Pds Mysimbua72No ratings yet

- Rolling FrictionDocument19 pagesRolling FrictionPavan Kumar NarendraNo ratings yet

- FGDocument9 pagesFGSelvaRajNo ratings yet

- Experiment 6Document9 pagesExperiment 6trusdale chazzNo ratings yet

- Click To Edit Master Subtitle StyleDocument16 pagesClick To Edit Master Subtitle StyleMUHAMMAD AKRAMNo ratings yet

- AlkysafeDocument9 pagesAlkysafeNabeel ShaukatNo ratings yet

- Smog Free Tower: NAME: Nooranqawi ID: 1170884 Chem438Document6 pagesSmog Free Tower: NAME: Nooranqawi ID: 1170884 Chem438noor anqNo ratings yet

- Powell (1983) - Ductile Anchor Bolts For Tall ChimneysDocument11 pagesPowell (1983) - Ductile Anchor Bolts For Tall Chimneystimur sibaevNo ratings yet

- TPTG620 - Teaching Practice (Long Term) : Assignment Lesson Plan (Fall 2020) Total Marks: 20 - +instructionsDocument6 pagesTPTG620 - Teaching Practice (Long Term) : Assignment Lesson Plan (Fall 2020) Total Marks: 20 - +instructionsnisar aliNo ratings yet

- Errata For Atkins' Chemical Principles 5th EditionDocument2 pagesErrata For Atkins' Chemical Principles 5th EditionRonald LNo ratings yet

- History of ElectricityDocument27 pagesHistory of Electricitysyeed0% (1)

- 7 Duval TrianglesDocument35 pages7 Duval Triangleszarchiwin050% (1)

- Review UASDocument6 pagesReview UASkarenNo ratings yet

- Q2 Lesson 1Document43 pagesQ2 Lesson 1Sheena AragoNo ratings yet

- Christie DorflingDocument13 pagesChristie DorflingFrancisco Javier Alarcón GarridoNo ratings yet

- Indiko Brochure - ENDocument4 pagesIndiko Brochure - ENklinik mmNo ratings yet

- FT Lab Manual27-12-17 PDFDocument48 pagesFT Lab Manual27-12-17 PDFJay JoshiNo ratings yet

- Chemistry QuestionsDocument32 pagesChemistry QuestionsSiddharthGuptaNo ratings yet

- Dna Model Rubric: Level of ProficiencyDocument1 pageDna Model Rubric: Level of ProficiencyMichelle BaguioNo ratings yet

- Insulin ELISA Kit (INS) : Images PublicationsDocument9 pagesInsulin ELISA Kit (INS) : Images PublicationsAlma TubungNo ratings yet