Professional Documents

Culture Documents

Fig P11-06 REV

Uploaded by

Fernando Pauli PradoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fig P11-06 REV

Uploaded by

Fernando Pauli PradoCopyright:

Available Formats

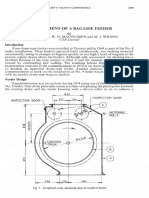

DESIGN OF MACHINERY 3rd Ed.

by ROBERT L. NORTON

reed

McGraw-Hill 2004

water-jet orifice

incoming

threads

(warp)

"shot" thread (weave)

cloth

crank

coupler

in

laybar

rocker

4-bar linkage

(a) Warp, weave, laybar, reed, and laybar drive for a water-jet loom

coupler

8.375"

in

crank

2"

beat-up

force

reed

laybar

reed

beat-up force

540 lb

r = 3.75"

inertia

force

ground

9.625"

@ 43

500 rpm

laybar

inertia

force

rocker

7.187"

(b) Linkage, laybar, reed, and dimensions

accelerations

4 169

in/sec2

7 834

in/sec2

(c) Acceleration on laybar and force on reed

FIGURE P11-6

Problem 11-13 - Fourbar linkage for laybar drive, showing forces and accelerations on laybar

11-13

Figure P11-6 shows a water jet loom laybar drive mechanism driven by a pair of Grashof

crank rocker fourbar linkages. The crank rotates at 500 rpm. The laybar is carried

between the coupler-rocker joints of the two linkages at their respective instant centers

I3,4. The combined weight of the reed and laybar is 29 lb. A 540-lb beat-up force from

the cloth is applied to the reed as shown. The steel links have a 2 x 1 in uniform cross

section. Find the forces on the pins for one revolution of the crank. Find the torque-time

function required to drive the system.

These problems are suited

to solution using Mathcad,

Matlab, or TKSolver

equation solver programs.

In most cases, your solution

can be checked with

program FOURBAR.

You might also like

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsFrom EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsNo ratings yet

- United States Patent (19) (11) Patent Number: 4,727,781: Yuehui Et Al. (45) Date of Patent: Mar. 1, 1988Document31 pagesUnited States Patent (19) (11) Patent Number: 4,727,781: Yuehui Et Al. (45) Date of Patent: Mar. 1, 1988Siul OtreborNo ratings yet

- Wrap Thesis Revell 1983Document247 pagesWrap Thesis Revell 1983Hans WolfNo ratings yet

- Design of Machine Members-2Document2 pagesDesign of Machine Members-2Vibin KrishnaNo ratings yet

- Desarrollo de Un Alimentador de BagazoDocument4 pagesDesarrollo de Un Alimentador de BagazoWilliam VillarrealNo ratings yet

- 07a60304 - Dynamics of MachineryDocument8 pages07a60304 - Dynamics of MachineryRajaganapathy GanaNo ratings yet

- Permanent Magnet Bias, Homopolar Magnetic Bearings For A 130 KW-HR Composite FlywheelDocument8 pagesPermanent Magnet Bias, Homopolar Magnetic Bearings For A 130 KW-HR Composite FlywheelAnonymous f3oWRCJNo ratings yet

- Amelunxen, P, Bagdad Concentrator Process Control UpdateDocument6 pagesAmelunxen, P, Bagdad Concentrator Process Control UpdateGuadalupe EMNo ratings yet

- NACA - High-Speed Kaman Rotochute - 1954Document20 pagesNACA - High-Speed Kaman Rotochute - 1954Anton EdigerNo ratings yet

- Hirsch Ocean EngineeringDocument6 pagesHirsch Ocean EngineeringsiswoutNo ratings yet

- Fpe Winter 2017Document2 pagesFpe Winter 2017Rushabh PatelNo ratings yet

- Propeller Design and Two-Speed Gearboxes: - . - With Partigular Reference To Tugs and TrawlersDocument12 pagesPropeller Design and Two-Speed Gearboxes: - . - With Partigular Reference To Tugs and Trawlersannastama.ameNo ratings yet

- Artigo de MancaisDocument11 pagesArtigo de MancaisAndré MenezesNo ratings yet

- Flywheels - Theory of Machines PDFDocument13 pagesFlywheels - Theory of Machines PDFSandip Ghosh100% (1)

- HarringtonDocument26 pagesHarringtonMaximNo ratings yet

- Ship Assist and Escort Winches For Dynamic Seas The ARR Winch For Crowley Maritime Tug RESPONSEDocument15 pagesShip Assist and Escort Winches For Dynamic Seas The ARR Winch For Crowley Maritime Tug RESPONSEYao WeiNo ratings yet

- Speed Boat DevelopmentsDocument18 pagesSpeed Boat DevelopmentsGermán AguirrezabalaNo ratings yet

- Effect of Blades Number To Performance of Savonius Water Turbine in Water PipeDocument4 pagesEffect of Blades Number To Performance of Savonius Water Turbine in Water PipeAri PrasetyoNo ratings yet

- Bilel Et Al.Document10 pagesBilel Et Al.بلال بن عميرهNo ratings yet

- Manual Actuators For Use With Large Size Butterfly ValvesDocument5 pagesManual Actuators For Use With Large Size Butterfly Valvesmarsha.fsdNo ratings yet

- Fatigue Life Assessment of Screw Blades in Screw Sand Washing Machine Under Extreme LoadDocument7 pagesFatigue Life Assessment of Screw Blades in Screw Sand Washing Machine Under Extreme LoadArie WirantoNo ratings yet

- Gme Assignments Ekg Part-1Document22 pagesGme Assignments Ekg Part-1ArunNo ratings yet

- National Advisory Committee For AeronauticsDocument26 pagesNational Advisory Committee For Aeronauticscepheid_luNo ratings yet

- Comparison of Heald Frame Motion Generated by Rotary Dobby and Crank & Cam Shedding MotionsDocument6 pagesComparison of Heald Frame Motion Generated by Rotary Dobby and Crank & Cam Shedding MotionsKannan KumarNo ratings yet

- TP SeismicRetrofitPiersSupportedBatteredPilesDocument10 pagesTP SeismicRetrofitPiersSupportedBatteredPilesciscoNo ratings yet

- 1 s2.0 037604219500001F MainDocument52 pages1 s2.0 037604219500001F MainSubooh ZaidiNo ratings yet

- Em Ii - Ict-IiDocument2 pagesEm Ii - Ict-IiYokeshNo ratings yet

- Turbine Calculation For Hydro Power PlantDocument6 pagesTurbine Calculation For Hydro Power Plantajay vikrantNo ratings yet

- Worksheet 323Document5 pagesWorksheet 323duraiprakash83No ratings yet

- Tula's Institute, Dhoolkot, DehradunDocument2 pagesTula's Institute, Dhoolkot, Dehradunanadinath sharmaNo ratings yet

- Horse PowerDocument42 pagesHorse PowerKYAWNo ratings yet

- MENG - 331 - Spring 2019-2020 - TUTORIAL PROBLEMSDocument66 pagesMENG - 331 - Spring 2019-2020 - TUTORIAL PROBLEMSİREM Taşlı100% (1)

- PROPULSION E-Motors 300609-014459 PDFDocument59 pagesPROPULSION E-Motors 300609-014459 PDFScott_B4U100% (1)

- Fluidfilm Bearing AprilDocument8 pagesFluidfilm Bearing AprilTravis SkinnerNo ratings yet

- Document FileDocument68 pagesDocument Fileso100% (1)

- MI30013 Machinery For Mining MA 2016Document2 pagesMI30013 Machinery For Mining MA 2016SunilNo ratings yet

- International Moth HydrofoilDocument20 pagesInternational Moth HydrofoilMorgan Rook100% (1)

- Experience With Torsional Vibration at Reciprocating CompressorsDocument14 pagesExperience With Torsional Vibration at Reciprocating CompressorsÏmŗäņPŗïņċëNo ratings yet

- MixDocument19 pagesMixfreakameNo ratings yet

- Comber: Construction Design of A Nipper in Comber MachineDocument7 pagesComber: Construction Design of A Nipper in Comber Machinemahmuda chowdhuryNo ratings yet

- FM Qpaper Nit Raipur Mech 5th SemDocument10 pagesFM Qpaper Nit Raipur Mech 5th SemShashi Bhushan PatelNo ratings yet

- REE 6031 Tutorial 1Document5 pagesREE 6031 Tutorial 1Eng Maboshe Charles Namafe0% (1)

- The Influence of Granular Vortex Motion On The Volumetric PerformanceDocument12 pagesThe Influence of Granular Vortex Motion On The Volumetric PerformancelarosemaximeNo ratings yet

- R (Flilit ( (:: Machine DrawingDocument2 pagesR (Flilit ( (:: Machine DrawingMayur DhanokarNo ratings yet

- Case Study WindflowDocument17 pagesCase Study Windflowrcmomesso9942No ratings yet

- Beat Up MechanismsDocument69 pagesBeat Up MechanismszameershahNo ratings yet

- Dynamics Lab Manual - ME6511Document66 pagesDynamics Lab Manual - ME6511vinothNo ratings yet

- A Novel Design of Composite Water Turbine Using CFDDocument6 pagesA Novel Design of Composite Water Turbine Using CFDNung NingNo ratings yet

- A Novel High-Performance Magnetic GearDocument3 pagesA Novel High-Performance Magnetic GearGanesh B NairNo ratings yet

- Problems s3Document3 pagesProblems s3zangue billy james67% (3)

- The Prediction of Helicopter Rotor Hover Performance Using A Prescribed Wake AnalysisDocument56 pagesThe Prediction of Helicopter Rotor Hover Performance Using A Prescribed Wake AnalysiszmajchekNo ratings yet

- Oil Whirl Whip PDFDocument9 pagesOil Whirl Whip PDFTravis SkinnerNo ratings yet

- Speed Boat Developments From The Past Into The FutureDocument15 pagesSpeed Boat Developments From The Past Into The Futurebrizzolara100% (1)

- 2008 Experience With Rotor-Stator Interactions in High Head Francis RunnerDocument10 pages2008 Experience With Rotor-Stator Interactions in High Head Francis RunnerAlexandre TrudelNo ratings yet

- Hiren Sem II (180111203)Document22 pagesHiren Sem II (180111203)hirenNo ratings yet

- BEM Theory Adaptation Taking Into Account The Wind Speed Vertical Gradient For Wind Turbines of High Class Part 2 Numerical Analysis of The Aerodynamic InteractionDocument9 pagesBEM Theory Adaptation Taking Into Account The Wind Speed Vertical Gradient For Wind Turbines of High Class Part 2 Numerical Analysis of The Aerodynamic InteractionJulian GenovNo ratings yet

- Diamec 262 Crawler Underground Electric 6991 0777 01Document4 pagesDiamec 262 Crawler Underground Electric 6991 0777 01gemin0204100% (1)

- A Machine For Interactive Fatigue TestinDocument11 pagesA Machine For Interactive Fatigue Testinshah nauman100% (1)

- Analyzing Vibration Parameters of A Modern High-Sp PDFDocument8 pagesAnalyzing Vibration Parameters of A Modern High-Sp PDFrony silvaNo ratings yet

- Fig P7-24 PDFDocument1 pageFig P7-24 PDFFernando Pauli PradoNo ratings yet

- Figure P3-4: Design of Machinery Robert L. NortonDocument1 pageFigure P3-4: Design of Machinery Robert L. NortonFernando Pauli PradoNo ratings yet

- Fig P11-01Document2 pagesFig P11-01Fernando Pauli PradoNo ratings yet

- Fig P3-03 PDFDocument1 pageFig P3-03 PDFFernando Pauli PradoNo ratings yet

- Prob 10-28 ValvulaDocument1 pageProb 10-28 ValvulaFernando Pauli PradoNo ratings yet

- Fig P2-16Document1 pageFig P2-16Fernando Pauli PradoNo ratings yet

- Fig P2-08 PDFDocument1 pageFig P2-08 PDFFernando Pauli PradoNo ratings yet

- Fig P2-08 PDFDocument1 pageFig P2-08 PDFFernando Pauli PradoNo ratings yet

- Follower: Design of Machinery Robert L. NortonDocument1 pageFollower: Design of Machinery Robert L. NortonFernando Pauli PradoNo ratings yet

- Design of Machinery Robert L. Norton: 3Rd Ed. by © Mcgraw-Hill 2004Document1 pageDesign of Machinery Robert L. Norton: 3Rd Ed. by © Mcgraw-Hill 2004Fernando Pauli PradoNo ratings yet

- Fig P2-18 PDFDocument1 pageFig P2-18 PDFFernando Pauli PradoNo ratings yet

- Y y Y Y Y: Design of Machinery Robert L. NortonDocument1 pageY y Y Y Y: Design of Machinery Robert L. NortonFernando Pauli PradoNo ratings yet

- 26 D 64 All Dimensions in MM: FIGURE P10-1Document1 page26 D 64 All Dimensions in MM: FIGURE P10-1Fernando Pauli PradoNo ratings yet

- Driveshaft: Design of Machinery Robert L. NortonDocument1 pageDriveshaft: Design of Machinery Robert L. NortonFernando Pauli PradoNo ratings yet

- Design of Machinery Robert L. Norton: 3Rd Ed. by © Mcgraw-Hill 2004Document1 pageDesign of Machinery Robert L. Norton: 3Rd Ed. by © Mcgraw-Hill 2004Fernando Pauli PradoNo ratings yet

- Design of Machinery Robert L. Norton: 3Rd Ed. by © Mcgraw-Hill 2004Document1 pageDesign of Machinery Robert L. Norton: 3Rd Ed. by © Mcgraw-Hill 2004Fernando Pauli PradoNo ratings yet

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseFrom EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseRating: 4.5 out of 5 stars4.5/5 (51)

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityFrom EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityNo ratings yet

- Pilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CFrom EverandPilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CNo ratings yet

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionFrom EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionRating: 4.5 out of 5 stars4.5/5 (3)

- Damages on Pumps and Systems: The Handbook for the Operation of Centrifugal PumpsFrom EverandDamages on Pumps and Systems: The Handbook for the Operation of Centrifugal PumpsRating: 4.5 out of 5 stars4.5/5 (2)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- Hybrid Electric Vehicles: Principles and Applications with Practical PerspectivesFrom EverandHybrid Electric Vehicles: Principles and Applications with Practical PerspectivesNo ratings yet

- Bulk Material Handling: Practical Guidance for Mechanical EngineersFrom EverandBulk Material Handling: Practical Guidance for Mechanical EngineersRating: 5 out of 5 stars5/5 (1)

- Geotechnical Engineering Calculations and Rules of ThumbFrom EverandGeotechnical Engineering Calculations and Rules of ThumbRating: 4 out of 5 stars4/5 (17)

- Machinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionFrom EverandMachinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionNo ratings yet

- The Geometrical Tolerancing Desk Reference: Creating and Interpreting ISO Standard Technical DrawingsFrom EverandThe Geometrical Tolerancing Desk Reference: Creating and Interpreting ISO Standard Technical DrawingsRating: 4.5 out of 5 stars4.5/5 (10)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchFrom EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchRating: 4 out of 5 stars4/5 (10)

- Practical Machinery Vibration Analysis and Predictive MaintenanceFrom EverandPractical Machinery Vibration Analysis and Predictive MaintenanceRating: 4.5 out of 5 stars4.5/5 (10)

- Machinery Failure Analysis Handbook: Sustain Your Operations and Maximize UptimeFrom EverandMachinery Failure Analysis Handbook: Sustain Your Operations and Maximize UptimeRating: 3.5 out of 5 stars3.5/5 (4)

- The Laws of Thermodynamics: A Very Short IntroductionFrom EverandThe Laws of Thermodynamics: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (10)

- Three Laws of Nature: A Little Book on ThermodynamicsFrom EverandThree Laws of Nature: A Little Book on ThermodynamicsRating: 4.5 out of 5 stars4.5/5 (10)

- Insulation Co-ordination in High-voltage Electric Power SystemsFrom EverandInsulation Co-ordination in High-voltage Electric Power SystemsRating: 4.5 out of 5 stars4.5/5 (5)