Professional Documents

Culture Documents

Overhead Crane Operator Checklist: Hoist

Uploaded by

HamzaNoumanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Overhead Crane Operator Checklist: Hoist

Uploaded by

HamzaNoumanCopyright:

Available Formats

Overhead Crane

Operator Checklist

N/A= Needs Attention

OK

Hoist

#1-Check hoisting speeds and brakes for proper operation.

#2-Without load, run hoist to upper limit to insure that limit shuts down hoisting operation.

Check lower limit if equipped.

#3-Check load cable/chain for damage or wear.

#4-Check safety latch for proper operation.

#5-Check load hook for proper rotation and deformation.

#6-Check load block sheave/pocket wheel for easy rotation.

#7-Check lifting attachments for damage or wear.

Trolley

#8-Check trolley speeds and travel for proper operation.

#9-If equipped check travel limits for proper operation.

#10-If equipped check brakes for proper operation.

Bridge

#11-Check bridge speeds and travel for proper operation.

#12-Check bridge brakes for proper operation.

#13-If equipped check travel limits for proper operation.

Misc.

#14-Check warning bells, horns, lights for proper operation.

#15-Pendant station sealed from dirt and moisture.

#16-Directional labels on pendant station/radio legible.

#17-Operator warning label legible.

#18-Strain relief cable or chain supporting pendant.

Information

Crane Capacity

Crane ID

Certification Expiration Date

Crane Description

Department/Location

List problems:

Operator/Designated Employee

Shift

Date

Please refer to the owners manual for all operator inspection

requirements. This listing only covers the basics. Depending on

the equipment design or complexity of the equipment a more

thorough inspection may be required. Again, always check the

owners manual.

Advanced Overhead Crane

Member Since 1986

1-800-413-2103

aocs@verizon.net

www.advancedoverheadcrane.com

N/A

You might also like

- Mobile Crane Load Test Report FormDocument4 pagesMobile Crane Load Test Report FormBayuo2k100% (3)

- Lifting Tools & TacklesDocument44 pagesLifting Tools & Tacklesbalajirajasekaran100% (2)

- Crane, Rigging & LiftingDocument100 pagesCrane, Rigging & LiftingMarlon Arq100% (13)

- Winch Safety TrainingDocument27 pagesWinch Safety Trainingaymenmoataz100% (1)

- Overhead Crane Study 1Document12 pagesOverhead Crane Study 1shahrilmr6934No ratings yet

- Overhead and Gantry CranesDocument3 pagesOverhead and Gantry CranesCesar NietoNo ratings yet

- Loading Dock Safety ChecklistDocument4 pagesLoading Dock Safety ChecklistMochammad Nur Hidayat50% (2)

- Omm DP50N CT28CDocument48 pagesOmm DP50N CT28Casri novhandi100% (2)

- Helicopter Maneuvers Manual: A step-by-step illustrated guide to performing all helicopter flight operationsFrom EverandHelicopter Maneuvers Manual: A step-by-step illustrated guide to performing all helicopter flight operationsRating: 5 out of 5 stars5/5 (1)

- MCBU - Lifting & Rigging Questions and AnswersDocument15 pagesMCBU - Lifting & Rigging Questions and AnswersBhaiJan59No ratings yet

- Safety Training Cranes and HoistsDocument89 pagesSafety Training Cranes and HoistsJose Antonio García Ruíz100% (3)

- The Crane, Hoist and Monorail Alliance: Safety Tips Sheet No. 2: Pre-Operational Equipment Check of Cranes and HoistsDocument1 pageThe Crane, Hoist and Monorail Alliance: Safety Tips Sheet No. 2: Pre-Operational Equipment Check of Cranes and HoistsUmangtarangNo ratings yet

- EOT Crane Safety KilburnDocument26 pagesEOT Crane Safety KilburnOnkar NikamNo ratings yet

- Cranes, Rigging and BanksmanDocument61 pagesCranes, Rigging and BanksmanAdelCh100% (3)

- Overhead Crane Operator Safety ManualDocument36 pagesOverhead Crane Operator Safety ManualakhilakaNo ratings yet

- Examination ProcedureDocument2 pagesExamination ProcedureArshad ParambilNo ratings yet

- Overhead Crane SafetyDocument23 pagesOverhead Crane SafetyBv Rao50% (2)

- Crane Safety InstructionsDocument8 pagesCrane Safety InstructionsAnil kumarNo ratings yet

- New Air Hoist Practices and Procedures Updated 8.16.2012Document21 pagesNew Air Hoist Practices and Procedures Updated 8.16.2012QHSE Manager100% (1)

- Crane Safety Guidance ManualDocument11 pagesCrane Safety Guidance Manualmadhurikiro1995No ratings yet

- 400 Bad Request 400 Bad Request Nginx/1.2.7Document6 pages400 Bad Request 400 Bad Request Nginx/1.2.7muthuswamy77No ratings yet

- The Crane, Hoist and Monorail Alliance: Safety Tips Sheet No. 2: Pre-Operational Equipment Check of Cranes and HoistsDocument1 pageThe Crane, Hoist and Monorail Alliance: Safety Tips Sheet No. 2: Pre-Operational Equipment Check of Cranes and Hoistsmariae2No ratings yet

- 1631617166934-EOT Maintenance PDFDocument16 pages1631617166934-EOT Maintenance PDFMohd Haidi100% (1)

- Overhead CranesDocument50 pagesOverhead CraneshamzanusratNo ratings yet

- Overhead Crane: Maintenance ProgramDocument3 pagesOverhead Crane: Maintenance ProgramMuhammad RafiNo ratings yet

- Chain Block ManualDocument3 pagesChain Block ManualPhan Van Loi0% (1)

- Safe LiftingDocument22 pagesSafe LiftingMahmoud Abdallah67% (3)

- Crane & Hoist Inspection ProgramDocument12 pagesCrane & Hoist Inspection ProgramAltayeb Yassin0% (2)

- Pre Use and Monthly Inspection Checklist For Overhead Cranes and HoistsDocument1 pagePre Use and Monthly Inspection Checklist For Overhead Cranes and HoistsAnsarNo ratings yet

- Safe Slinging PracticesDocument2 pagesSafe Slinging PracticesKrish VetriselvamNo ratings yet

- Hoist and Jib Crane Safety InspectionDocument3 pagesHoist and Jib Crane Safety InspectionSamsung Joseph0% (1)

- Daily Check (English Version) .PpsDocument12 pagesDaily Check (English Version) .PpsYe Min HtikeNo ratings yet

- Airframe Essay QuestionsDocument12 pagesAirframe Essay QuestionsRaul DeonarainNo ratings yet

- OSHA Man Basket User ManualDocument9 pagesOSHA Man Basket User Manualwalid EttihNo ratings yet

- 9.1.4 Admasco Rig Move Procedure PDFDocument52 pages9.1.4 Admasco Rig Move Procedure PDFkhaled100% (2)

- The Single Most Important Precaution in Rigging and Hoisting Is To Determine Load Weight Before Attempting Any LiftDocument19 pagesThe Single Most Important Precaution in Rigging and Hoisting Is To Determine Load Weight Before Attempting Any LiftBinoy GopinathanNo ratings yet

- Chain Slings Inspection Best PracticeDocument11 pagesChain Slings Inspection Best PracticeMohana RangeshNo ratings yet

- THE BASIC CRANE OPERATION AND RIGGING SAFETY Hand Outs A4Document21 pagesTHE BASIC CRANE OPERATION AND RIGGING SAFETY Hand Outs A4RosalyNo ratings yet

- Lesson Rigging SafetyDocument14 pagesLesson Rigging Safetymister pogiNo ratings yet

- Instructions For The Safe Use Of: Travelling Girder TrolleysDocument2 pagesInstructions For The Safe Use Of: Travelling Girder TrolleysMuhammad Umair RasheedNo ratings yet

- Articulated Boom Truck Student ManualDocument35 pagesArticulated Boom Truck Student ManualErc Nunez VNo ratings yet

- Welcome To G.T.S.C Gulf Technical & Safety Training CenterDocument49 pagesWelcome To G.T.S.C Gulf Technical & Safety Training CenterOussama Ouardani100% (1)

- Mewp Inspection ProcedureDocument1 pageMewp Inspection ProcedureArshad ParambilNo ratings yet

- Rotary Aro14 - Smo14 Owners ManualDocument8 pagesRotary Aro14 - Smo14 Owners ManualCarlos Alberto100% (1)

- Course Material For Rigger-Latest - Final CHVR 2010Document138 pagesCourse Material For Rigger-Latest - Final CHVR 2010Tarek Ahmed100% (1)

- D O C F O C: Aily Perator Hecklist OR Verhead RanesDocument3 pagesD O C F O C: Aily Perator Hecklist OR Verhead RanesberatcansuNo ratings yet

- Forklift OperationDocument5 pagesForklift OperationcrespoNo ratings yet

- Safe Work Practices - CraneDocument22 pagesSafe Work Practices - CranepentianNo ratings yet

- 07 FD Overhead Crane SafetyDocument18 pages07 FD Overhead Crane SafetyJimmy TanNo ratings yet

- F&T Inc.: Overhead Crane SafetyDocument18 pagesF&T Inc.: Overhead Crane SafetybimaNo ratings yet

- Crane - Banksman TrainingDocument21 pagesCrane - Banksman TrainingProfessional TrustNo ratings yet

- Title: 9801 High-Impact Crane Safety: Length: 18 Minutes Production Year: 1998 Program SynopsisDocument2 pagesTitle: 9801 High-Impact Crane Safety: Length: 18 Minutes Production Year: 1998 Program Synopsisg665013No ratings yet

- Crane Operation ChecklistDocument4 pagesCrane Operation ChecklistOkky PoerwantoNo ratings yet

- Overhead CraneDocument18 pagesOverhead Craneemail2yogeshshindeNo ratings yet

- EHS OP 09 03 Procedure For ForkliftsDocument11 pagesEHS OP 09 03 Procedure For ForkliftsLim YpteruNo ratings yet

- How To Drive On A Motorway: Including Highway Code rules for the motorwayFrom EverandHow To Drive On A Motorway: Including Highway Code rules for the motorwayNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Best Practices in Machinery InstallationDocument2 pagesBest Practices in Machinery InstallationHamzaNoumanNo ratings yet

- Helium Leak Detector Vs Pressure Decay Leak DetectionDocument2 pagesHelium Leak Detector Vs Pressure Decay Leak DetectionHamzaNoumanNo ratings yet

- The ABC of NDTDocument5 pagesThe ABC of NDTHamzaNoumanNo ratings yet

- Acceptance Criteria of Weld Defects As Per Different CodesDocument17 pagesAcceptance Criteria of Weld Defects As Per Different CodesShubham ShuklaNo ratings yet

- H Hole MesaurmentDocument2 pagesH Hole MesaurmentHamzaNoumanNo ratings yet

- 2005 Nondestructive Testing GuideDocument8 pages2005 Nondestructive Testing GuideHamzaNoumanNo ratings yet

- Balance Plot FormDocument1 pageBalance Plot FormHamzaNoumanNo ratings yet

- Bayyinat ArticleDocument4 pagesBayyinat ArticleHamzaNoumanNo ratings yet

- Nbo-Tc NewDocument24 pagesNbo-Tc NewHamzaNoumanNo ratings yet

- Confirmation - Check-InDocument1 pageConfirmation - Check-InHamzaNoumanNo ratings yet

- Shift 2 Schedule (Sept 12 - Sept 20 '22)Document1 pageShift 2 Schedule (Sept 12 - Sept 20 '22)HamzaNoumanNo ratings yet

- Certificate of Completion: Hafiz NomanDocument1 pageCertificate of Completion: Hafiz NomanHamzaNoumanNo ratings yet

- Fluid Handling System PriceDocument2 pagesFluid Handling System PriceHamzaNoumanNo ratings yet

- MC LiftRigBestPractices Poster 11X17Document1 pageMC LiftRigBestPractices Poster 11X17HamzaNoumanNo ratings yet

- Unit Conversion All in OneDocument7 pagesUnit Conversion All in OneSuyenthan SathishNo ratings yet

- 7 22 2022 Mech - 19596Document1 page7 22 2022 Mech - 19596HamzaNoumanNo ratings yet

- Congratulations On Your Completion: Hamza NomanDocument1 pageCongratulations On Your Completion: Hamza NomanHamzaNoumanNo ratings yet

- Cylinder Test-Certification-ProceduresDocument3 pagesCylinder Test-Certification-ProceduresHamzaNoumanNo ratings yet

- Contract Extension of Hafiz Hussain 2021Document2 pagesContract Extension of Hafiz Hussain 2021HamzaNoumanNo ratings yet

- Onboarding Checklist IGDocument1 pageOnboarding Checklist IGHamzaNoumanNo ratings yet

- Sr. No. Description Unit: Workshop / Garage Craft IssuesDocument14 pagesSr. No. Description Unit: Workshop / Garage Craft IssuesHamzaNoumanNo ratings yet

- Advance Cash For Cricket PitchDocument1 pageAdvance Cash For Cricket PitchHamzaNoumanNo ratings yet

- Manpower Workshop Garage CraftDocument7 pagesManpower Workshop Garage CraftHamzaNoumanNo ratings yet

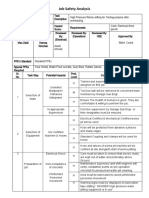

- JSA For Woma Jet TestingDocument2 pagesJSA For Woma Jet TestingHamzaNoumanNo ratings yet

- D Level Safety Meeting Quality Checklist - RevisedDocument1 pageD Level Safety Meeting Quality Checklist - RevisedHamzaNoumanNo ratings yet

- Scaffolding: Submitted By, Akhilesh.A Production Operator (TR), Forbes Bumiarmada LimitedDocument42 pagesScaffolding: Submitted By, Akhilesh.A Production Operator (TR), Forbes Bumiarmada LimitedHamzaNoumanNo ratings yet

- Mechanical Workshop: Inspection & Test PlanDocument4 pagesMechanical Workshop: Inspection & Test PlanHamzaNoumanNo ratings yet

- Incident / Injury Occurrence Report Part A:: Form No: SAF/2/001 Date Prepared: 29 / 09 / 08 Revision: 00Document2 pagesIncident / Injury Occurrence Report Part A:: Form No: SAF/2/001 Date Prepared: 29 / 09 / 08 Revision: 00HamzaNoumanNo ratings yet

- PC Help Desk Form: Pakarab Fertilizers Ltd. MultanDocument1 pagePC Help Desk Form: Pakarab Fertilizers Ltd. MultanHamzaNoumanNo ratings yet