100% found this document useful (2 votes)

3K views4 pagesWork Holding Devices

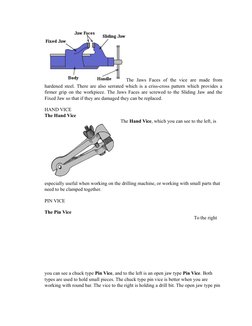

1. The document describes various work holding devices used in metalworking, including drill press vices, bench vices, hand vices, and pin vices.

2. It provides details on bench vices, including recommended heights and jaw materials. Buttress threads are described as withstanding heavy thrust.

3. The document also briefly covers related tools like V-blocks, angle plates, and types of files for metalworking. Files are classified by length, shape, cut, and coarseness.

Uploaded by

Keith Tanaka MagakaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

100% found this document useful (2 votes)

3K views4 pagesWork Holding Devices

1. The document describes various work holding devices used in metalworking, including drill press vices, bench vices, hand vices, and pin vices.

2. It provides details on bench vices, including recommended heights and jaw materials. Buttress threads are described as withstanding heavy thrust.

3. The document also briefly covers related tools like V-blocks, angle plates, and types of files for metalworking. Files are classified by length, shape, cut, and coarseness.

Uploaded by

Keith Tanaka MagakaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

- Work Holding Devices: Describes various devices used for holding workpieces in place during machining, including specifics on drill press vice and bench vice.

- Cutting Tools: Covers the tools used for shaping and cutting materials, including file types and levels of coarseness.