Professional Documents

Culture Documents

Metal Casting: 1.1 Overview of Casting Technology

Uploaded by

Hassan MahmoodOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Metal Casting: 1.1 Overview of Casting Technology

Uploaded by

Hassan MahmoodCopyright:

Available Formats

1

METAL CASTING

CHAPTER CONTENTS

1.1

1.3

Overview of Casting Technology

Definitions

Casting nomenclature

Heating and pouring

Solidification and cooling

Casting Processes

Expandable mold casting

Permanent mold casting

Casting quality

1.1

OVERVIEW OF CASTING TECHNOLOGY

1.2

Definitions

Casting is a process in which molten metal flows into a mold where it solidifies in the shape of the mold

cavity. The part produced is also called casting.

Advantages

Complex shapes

Net-shape ability

Very large parts

Variety of metals

Mass production

Poor accuracy

Poor surface

Disadvantages Internal defects

Mechanical properties

Environmental impact

Casting technology involves the next steps:

Mold preparation

Metal heating

Pouring

Cooling

Processing

Selection of castings of various

materials, shapes, and sizes

Casting nomenclature

The figure in the right shows the nomenclature of mold and castings in sand casting.

Casting nomenclature

Metal Casting

Valery Marinov, Manufacturing Technology

Pouring cup

The pouring cup, downsprue, runners, etc., are known as the

mold gating system, which serves to deliver the molten metal to all

sections of the mold cavity.

Downsprue

Gates to casting

Runner

Runner extension

Runner well

Downsprue well

Heating and pouring

Gating system in sand casting

Heating

The total heat required is estimated as the sum of

Heat to raise the temperature to the melting point

Heat of fusion

Heat to raise the molten metal temperature to the temperature of pouring

Pouring

Major factors affecting the pouring action

Pouring temperature

Pouring rate

Turbulence

Some important equations in pouring:

Velocity of the liquid metal at the base of the sprue:

2 gh

Gravitational acceleration constant

Volumetric flow rate:

Sprue height

Q = vA

Castings cross-sectional area

Mold filling time:

MFT = V/Q

Mold cavity volume

Fluidity

Fluidity is a measure of the capability of a metal to flow into and

to fill the mold before freezing. It defines to the great extend the

quality of casting.

Factors affecting fluidity:

Pouring temperature

Metal composition

Heat transfer to the surroundings

Viscosity of the liquid metal

Standard testing method

Pouring cup

Downsprue

Limit of flow

before freezing

Spiral mold

In the foundry practice, test for fluidity is carried out for each ladle just before pouring the molten

metal into the mold

Valery Marinov, Manufacturing Technology

Metal Casting

Solidification and cooling

Solidification of metals

Pure metals solidify at a constant temperature equal to their freezing point

Most alloys freeze over a temperature range

Solidification time

Chvorinovs rule

TST

Cm

V

A

TSTtotal solidification time

Cmmold constant

Vvolume of the casting

Asurface area of the casting

nconstant, usually n=2

Example:

Calculate the total solidification time for a 10/100/200-mm steel plate if Cm = 0.2 min/mm2

Solution:

Metal Casting

Valery Marinov, Manufacturing Technology

Shrinkage

Directional solidification

By a proper design of the casting

By external and internal chills

Riser design

Several riser designs are used in practice as shown in the figure.

The riser must remain molten until

after the casting solidifies.

The Chvorinovs Rule is used to calculate the risers dimensions.

Riser design

Open

Side

Riser

Casting

Riser

Possible types and positions

for risers in sand casting

Mold

Riser

Top

Blind

Casting

Mold

Mold

Riser

Casting

Casting

Mold

You might also like

- Thixoforming: Semi-solid Metal ProcessingFrom EverandThixoforming: Semi-solid Metal ProcessingGerhard HirtNo ratings yet

- FUNDAMENTALS OF METAL CASTING (Autosaved)Document45 pagesFUNDAMENTALS OF METAL CASTING (Autosaved)İREM TaşlıNo ratings yet

- Fundamentals of Metal CastingDocument39 pagesFundamentals of Metal CastingYASHFEEN AYUBBNo ratings yet

- Fundamentals of Metal CastingDocument45 pagesFundamentals of Metal CastingsuntharNo ratings yet

- Valery Marinov, Manufacturing TechnologyDocument168 pagesValery Marinov, Manufacturing TechnologyAbir Roy100% (3)

- Ch10 Casting Fund WileyDocument38 pagesCh10 Casting Fund WileyAbdur Rahman SultanNo ratings yet

- Fundamentals of Metal Casting: Overview of Casting Technology Heating and Pouring Solidification and CoolingDocument37 pagesFundamentals of Metal Casting: Overview of Casting Technology Heating and Pouring Solidification and CoolingSachin RanaNo ratings yet

- Valery Marinov Manufacturing Technology PDFDocument168 pagesValery Marinov Manufacturing Technology PDFMostafa Adil50% (2)

- Chapter Ten - Fundamental of Metal CastingDocument35 pagesChapter Ten - Fundamental of Metal CastingWael W. AlsousNo ratings yet

- Casting in Manufacturing ProcessesDocument106 pagesCasting in Manufacturing ProcessesAhsan MukhtarNo ratings yet

- Foundry and Casting OperationDocument176 pagesFoundry and Casting OperationABHINAV KUMAR ROY100% (26)

- L5-Fundamentals of Metal CastingDocument22 pagesL5-Fundamentals of Metal CastingKhayrulIslamNo ratings yet

- Fundamentals of Metal Casting: Overview of Casting Technology Heating and Pouring Solidification and CoolingDocument40 pagesFundamentals of Metal Casting: Overview of Casting Technology Heating and Pouring Solidification and Coolingalemu170No ratings yet

- Introduction To CastingDocument16 pagesIntroduction To CastingOkari100% (1)

- Lecture 2 - Manufacturing Processes - Fundamentals of Metal Casting and Casting Design - DR Bilal AhmadDocument99 pagesLecture 2 - Manufacturing Processes - Fundamentals of Metal Casting and Casting Design - DR Bilal Ahmadjawad khalidNo ratings yet

- 3 1and3 2Document110 pages3 1and3 2MPRajNo ratings yet

- 2nd Class Notes 17.01Document48 pages2nd Class Notes 17.01EDISON OCHIENGNo ratings yet

- Metal Casting: Weeks 1 - 2Document125 pagesMetal Casting: Weeks 1 - 2obvertNo ratings yet

- Manufacturing Processes Ch.4 (10 and 11) CastingDocument143 pagesManufacturing Processes Ch.4 (10 and 11) Castingashoku24007No ratings yet

- Metal Casting Lectures NotesDocument125 pagesMetal Casting Lectures NotesSabir AliNo ratings yet

- Metal Casting: Compiled By: Norliana Mohd AbbasDocument34 pagesMetal Casting: Compiled By: Norliana Mohd AbbasAziful AimanNo ratings yet

- 1st Class 13.01.2020Document18 pages1st Class 13.01.2020EDISON OCHIENGNo ratings yet

- Fundamentals of Metal Casting: - Overview of Casting Technology - Heating and Pouring - Solidification and CoolingDocument35 pagesFundamentals of Metal Casting: - Overview of Casting Technology - Heating and Pouring - Solidification and Coolingb0zzch4No ratings yet

- Foundry CourseDocument62 pagesFoundry CoursePradip Gupta0% (1)

- Casting Lecture NoteDocument12 pagesCasting Lecture NoteHARIMETLYNo ratings yet

- Chapter 10 Casting IDocument38 pagesChapter 10 Casting IMinhaj UllahNo ratings yet

- Overview of Casting TechnologyDocument5 pagesOverview of Casting TechnologySK Kushwah RajputNo ratings yet

- Casting Processes: March 2020Document26 pagesCasting Processes: March 2020Bhavin DesaiNo ratings yet

- Metal Casting I: Manufacturing ProcessesDocument36 pagesMetal Casting I: Manufacturing Processesavinash 879No ratings yet

- Peleburan & Pengecoran Logam: (Ir. Abrianto Akuan, MT.)Document48 pagesPeleburan & Pengecoran Logam: (Ir. Abrianto Akuan, MT.)b0zzch4No ratings yet

- Fundamentals of Metal Casting: 1. Overview of Casting Technology 2. Heating and Pouring 3. Solidification and CoolingDocument32 pagesFundamentals of Metal Casting: 1. Overview of Casting Technology 2. Heating and Pouring 3. Solidification and CoolingAkash GuptaNo ratings yet

- Fundamentals of Metal CastingDocument18 pagesFundamentals of Metal CastingtmcoachingcentreNo ratings yet

- Manu Fact Ech Lecture 2 and 3Document125 pagesManu Fact Ech Lecture 2 and 3Sasi aeroNo ratings yet

- Casting Processes CompleteDocument49 pagesCasting Processes CompleteRavi KumarNo ratings yet

- IE 337 W10 Lecture 7.casting 1Document48 pagesIE 337 W10 Lecture 7.casting 1linkinunNo ratings yet

- Lec 2castingpdfDocument26 pagesLec 2castingpdfHải TrầnNo ratings yet

- Metal Casting Dies: Thoguluva Raghavan VijayaramDocument4 pagesMetal Casting Dies: Thoguluva Raghavan VijayaramcombinationcoffeeNo ratings yet

- Unit - 1 Metal Casting Processes-NVRDocument287 pagesUnit - 1 Metal Casting Processes-NVRPrashon GNo ratings yet

- Chapter 5Document14 pagesChapter 5Phuc Truong DucNo ratings yet

- Factors Affecting CastingDocument6 pagesFactors Affecting CastingMuhammad BilalNo ratings yet

- Surface & Sub Surface Control of Cast Iron ComponentsDocument22 pagesSurface & Sub Surface Control of Cast Iron ComponentsAditya PratapNo ratings yet

- Casting - Lec 2.2Document17 pagesCasting - Lec 2.2Ahmed MahmoudNo ratings yet

- Solidification Analysis in Continuous Casting Process - Barman TambunanDocument11 pagesSolidification Analysis in Continuous Casting Process - Barman TambunanBarman TambunanNo ratings yet

- GATEMfg LatestDocument210 pagesGATEMfg LatestniteshNo ratings yet

- Casting: 2.810 Prof. Timothy GutowskiDocument65 pagesCasting: 2.810 Prof. Timothy GutowskiRoberto LaurindoNo ratings yet

- Fundamentals of Metal Casting: Overview of Casting Technology Heating and Pouring Solidification and CoolingDocument30 pagesFundamentals of Metal Casting: Overview of Casting Technology Heating and Pouring Solidification and Coolingchincha chuNo ratings yet

- Casting Manufacturing Processes Fundamentals of Metal Casting Metals For CastingDocument47 pagesCasting Manufacturing Processes Fundamentals of Metal Casting Metals For CastingarobaidiNo ratings yet

- Casting ProcessesDocument48 pagesCasting ProcessessumikannuNo ratings yet

- Metal CastingDocument22 pagesMetal CastingANKIT RAJNo ratings yet

- GATE MFG LatestDocument210 pagesGATE MFG LatestRanjan Kumar PathakNo ratings yet

- Chapter10 PDFDocument42 pagesChapter10 PDFJayson SmithNo ratings yet

- Basic of Metal CastingDocument80 pagesBasic of Metal CastingJayant ChaudhariNo ratings yet

- Casting PDFDocument48 pagesCasting PDFsanjay_lingotNo ratings yet

- Manufacturing Processes-I (TA 201A) : 6 Credit CourseDocument44 pagesManufacturing Processes-I (TA 201A) : 6 Credit Coursejamessupermann1No ratings yet

- Enme 331-Fundamentals of CastingDocument48 pagesEnme 331-Fundamentals of CastingAhmed AbdulrhmanNo ratings yet

- Metal-Casting Processes and EquipmentDocument48 pagesMetal-Casting Processes and EquipmenttemesgenNo ratings yet

- 3.1 Casting ProcessDocument4 pages3.1 Casting Processزينب عبد الخالق كاملNo ratings yet

- Introduction to the Physical Metallurgy of WeldingFrom EverandIntroduction to the Physical Metallurgy of WeldingRating: 3 out of 5 stars3/5 (2)

- Ngineering Rogramme Ohort Emester Odule Ssignment OF Fluid DrivesDocument2 pagesNgineering Rogramme Ohort Emester Odule Ssignment OF Fluid DrivesTasnim ArifNo ratings yet

- Inventor and Its Applications Chapter 1: Introduction To Autodesk InventorDocument4 pagesInventor and Its Applications Chapter 1: Introduction To Autodesk InventorTasnim ArifNo ratings yet

- Darshan R. Kanjiya: KSKV Kachchh UniversityDocument31 pagesDarshan R. Kanjiya: KSKV Kachchh UniversityTasnim ArifNo ratings yet

- Solved Numericals On Heat Conduction and Extended Heat SurfaceDocument20 pagesSolved Numericals On Heat Conduction and Extended Heat SurfaceTasnim ArifNo ratings yet

- Heat ExchangerDocument26 pagesHeat ExchangerTasnim Arif100% (2)

- Applications and Processing of CeramicsDocument17 pagesApplications and Processing of CeramicsTasnim Arif100% (1)

- Me e 211 Handouts 09Document8 pagesMe e 211 Handouts 09Tasnim ArifNo ratings yet

- Earthing & Bonding SystemDocument6 pagesEarthing & Bonding Systemsaravana3kumar3ravicNo ratings yet

- QADDCO ISO CertificateDocument2 pagesQADDCO ISO CertificateShaiju EbrahimNo ratings yet

- Gang-Nail Connectors - How They Work Gang-Nail Truss SystemDocument5 pagesGang-Nail Connectors - How They Work Gang-Nail Truss SystemAnonymous acaD5VNo ratings yet

- Piping Spec (24-08-2017)Document7 pagesPiping Spec (24-08-2017)Muhammad Moeed AlamNo ratings yet

- Codigos de ErroresDocument31 pagesCodigos de ErroresItseed CorcaNo ratings yet

- Lecture 9 Life Cycle AssessmentDocument18 pagesLecture 9 Life Cycle AssessmentAmmar SafwtNo ratings yet

- Experiment 3 Filtration-Grp. 5Document20 pagesExperiment 3 Filtration-Grp. 5Claudine Valdez100% (1)

- Hydrocor Type 3 and Type 106 TDS May 08Document2 pagesHydrocor Type 3 and Type 106 TDS May 08Indrayadi AbdillahNo ratings yet

- ME6601 QbsdfwsdfsDocument8 pagesME6601 QbsdfwsdfsvivekzzNo ratings yet

- Metal Nanoparticles For Catalysis Advances and ApplicationsDocument284 pagesMetal Nanoparticles For Catalysis Advances and ApplicationsMoreno MarcatiNo ratings yet

- Дизельные электростанции EMSADocument52 pagesДизельные электростанции EMSABrizmotorsNo ratings yet

- Duo FlexDocument8 pagesDuo FlexIsaac Martínez AlcocerNo ratings yet

- Subject - Machine Design - : Topic - Spur GearDocument10 pagesSubject - Machine Design - : Topic - Spur GearRohit GhulanavarNo ratings yet

- Metal WindowsDocument21 pagesMetal Windowsshubhankar mishraNo ratings yet

- Spairality of Weft Knit FabricDocument5 pagesSpairality of Weft Knit FabricObak Prithibi100% (1)

- Machine Guarding StandardDocument68 pagesMachine Guarding StandardDave CNo ratings yet

- PERTAMINA COMPATIBILITY TEST Method PDFDocument27 pagesPERTAMINA COMPATIBILITY TEST Method PDFm_asad_a50% (2)

- Zeodent 117 enDocument2 pagesZeodent 117 enJNo ratings yet

- T3000CS2264744 - 0 Calculation - Blast Wall SupportsDocument104 pagesT3000CS2264744 - 0 Calculation - Blast Wall SupportsnpwalNo ratings yet

- Green Cosmos AKS Lining PDFDocument8 pagesGreen Cosmos AKS Lining PDFMeng WaiNo ratings yet

- Design A Hybrid Solar BicycleDocument32 pagesDesign A Hybrid Solar Bicycleakash100% (1)

- Manual Triplex PumpDocument45 pagesManual Triplex PumpSalineñoApasionado100% (1)

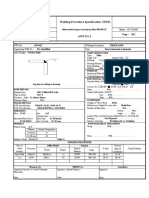

- Welding Procedure Specification (WPS) : Date: 2017/04/09Document1 pageWelding Procedure Specification (WPS) : Date: 2017/04/09akalNo ratings yet

- Uj440I Jaw Crusher Pioneering Solutions For You: Technical SpecificationDocument2 pagesUj440I Jaw Crusher Pioneering Solutions For You: Technical SpecificationMeth MalimouNo ratings yet

- Timber Examples - TeddsDocument19 pagesTimber Examples - TeddsTom KwoNo ratings yet

- CR800 Hybrid Low ResDocument8 pagesCR800 Hybrid Low RestappannNo ratings yet

- Assesment of Textile Dyeing Units and ZLD at Tirupur - CPCB PDFDocument87 pagesAssesment of Textile Dyeing Units and ZLD at Tirupur - CPCB PDFVishal Duggal100% (1)

- History Additive ManufacturingDocument7 pagesHistory Additive ManufacturingbrunosipodNo ratings yet

- Chapter 28 Abrasive Machining PDFDocument43 pagesChapter 28 Abrasive Machining PDFMat MatttNo ratings yet