Professional Documents

Culture Documents

KilnFiringChart PDF

KilnFiringChart PDF

Uploaded by

Paulie Salgado DelaParra0 ratings0% found this document useful (0 votes)

2 views1 pageOriginal Title

KilnFiringChart.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

2 views1 pageKilnFiringChart PDF

KilnFiringChart PDF

Uploaded by

Paulie Salgado DelaParraCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

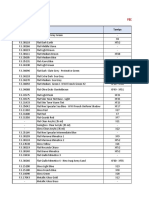

KILN FIRING CHART

Firing converts ceramic work from weak greenware into a strong, durable form. As the temperature in a kiln

rises, many changes take place in the clay; and understanding what happens during the firing can help you avoid

problems.The following chart provides highlights of what happens when firing clay.

Temperature

C

F

Color

Cone

(approx.)

14

13

12

11

9

7

5

4

2

1

04

05

06

07

08

010

012

013

015

016

017

018

019

020

021

022

1400

2552

Brilliant white

1300

2372

White

1200

2192

Yellow-white

Yellow

1100

2012

1000

1832

Yellow-orange

Orange

Red-orange

900

1652

800

1472

700

1292

600

1112

Cherry red

Dull red

Dark red

Dull red glow

500

932

400

752

300

572

Black

200

392

100

212

Copyright 2005 The American Ceramic Society

Event

End of porcelain range

End of stoneware range

End of earthenware (red clay) range

Between 1100-1200C, mullite and cristobalite (two types of

silica) form when clay starts converting to glass. Clay and

ceramic particles start to melt together and form crystals.

These changes make the material shrink as it becomes more

dense. Soaking (holding the end temperature) increases the

amount of fused matter and the amount of chemical action

between the fluxes and the more refractory materials.

Between 800-900C sintering begins. This is the stage

where clay particles begin to cement themselves together to

create a hard material called bisque.

Between 300-800C, the temperature must be raised steadily and ample air must be present to permit the complete burning of carbonaceous materials (impurities in the clay along

with paper, wax, etc.). After 800C, the clay surface will start

to seal off, trapping unburned carbonaceous materials and

sulfides, which could cause bloating and black coring.

Quartz inversion occurs at 573C. When clay is refired for a

glaze firing, quartz crystals change from an alpha () crystal

structure to a beta () crystal structure. The inversion is

reversed on cooling. This conversion creates stresses in the

clay so temperature increase and decrease must be slow to

avoid cracking the work.

Between 480-700C chemical water (referred to as water

smoke) is driven off.

Upon cooling, cristobalite, a crystalline form of silica found in

all clay bodies, shrinks suddenly at 220C. Fast cooling at this

temperature will cause ware to crack.

Water boils and converts to steam. Trapped water will cause

clay to explode so all water should be evaporated below

100C. Begin a firing by keeping the kiln below 100C until all

water has evaporated.

www.potterymaking.org

You might also like

- PDF Ce Refractory Concrete e 2 2014Document10 pagesPDF Ce Refractory Concrete e 2 2014cristian villegasNo ratings yet

- Options For The Future of CementDocument11 pagesOptions For The Future of CementDIAZCORDOBANo ratings yet

- Cimprogetti Kilns & Firing SystemsDocument20 pagesCimprogetti Kilns & Firing SystemsKalai SelvanNo ratings yet

- Transformers #1 (1984) Hundred Penny Press Edition PreviewDocument9 pagesTransformers #1 (1984) Hundred Penny Press Edition PreviewGraphic Policy100% (1)

- CastableDocument8 pagesCastableManindra SinghNo ratings yet

- Bricks and Shapes 2Document6 pagesBricks and Shapes 2nay den100% (1)

- Refractory DetailDocument23 pagesRefractory Detailsunil_supeda0% (1)

- Installation With Mortar - Umlauf 2015 PDFDocument18 pagesInstallation With Mortar - Umlauf 2015 PDFvũ minh tâmNo ratings yet

- Installation With Mortar - Umlauf 2015Document18 pagesInstallation With Mortar - Umlauf 2015Moud SaklyNo ratings yet

- Insulation - Filippich 2015Document22 pagesInsulation - Filippich 2015vũ minh tâmNo ratings yet

- 35-Castables With MgO-SiO2-Al2O3 As Bond PhaseDocument11 pages35-Castables With MgO-SiO2-Al2O3 As Bond PhaseAnky FadharaniNo ratings yet

- Rotary Lime Kiln PDFDocument3 pagesRotary Lime Kiln PDFKroya HunNo ratings yet

- RA SiC T CM EC PDFDocument2 pagesRA SiC T CM EC PDFDaniel RicartNo ratings yet

- MMC Clinker CoolerDocument4 pagesMMC Clinker CoolerAlbar BudimanNo ratings yet

- Коротк Нотатки Про Хемiю ЦементiвDocument33 pagesКоротк Нотатки Про Хемiю ЦементiвCementarNo ratings yet

- Engineering: General CatalogDocument37 pagesEngineering: General CatalogzsmithNo ratings yet

- 2011-RHI Bulletin 1Document9 pages2011-RHI Bulletin 1Bagas Prasetyawan Adi NugrohoNo ratings yet

- Refractory Use and Consumption in North American Cement IndustryDocument33 pagesRefractory Use and Consumption in North American Cement IndustrygldiasNo ratings yet

- Coating RingsDocument8 pagesCoating RingsIrshad HussainNo ratings yet

- 76-Microsilica-Gel Bond Castables For Rapid Heat-UpDocument12 pages76-Microsilica-Gel Bond Castables For Rapid Heat-UpJagadeesh GuttiNo ratings yet

- Fdocuments - in Process Problems Trouble Shooting in Cement KilnDocument13 pagesFdocuments - in Process Problems Trouble Shooting in Cement Kilnmahendra senNo ratings yet

- UnitDocument78 pagesUnitMohammed Khalid HakeemNo ratings yet

- Kiln Book ENDocument30 pagesKiln Book ENPéricles Ferreira LeiteNo ratings yet

- Perillex Bricks PDFDocument3 pagesPerillex Bricks PDFMuntandwe georgeNo ratings yet

- 12 Mr. Christensen, Nosering Case StoryDocument20 pages12 Mr. Christensen, Nosering Case StoryJunaid MazharNo ratings yet

- Ultra Tech Cement TadipatriDocument18 pagesUltra Tech Cement TadipatriAshutosh SinghNo ratings yet

- Refractory Bricks: Ce8391 Construction MaterialsDocument22 pagesRefractory Bricks: Ce8391 Construction MaterialsrangaNo ratings yet

- Refrateck SolutionsDocument8 pagesRefrateck SolutionsMagesh Kumar0% (1)

- Kiln Shell Corrosion PDFDocument29 pagesKiln Shell Corrosion PDFfatamorgganaNo ratings yet

- The Use of Coal As Fuel For Cement Rotary KilnDocument23 pagesThe Use of Coal As Fuel For Cement Rotary KilnDheo Ebhee LouVeNo ratings yet

- SOx Emmissions Absortion FLSDocument14 pagesSOx Emmissions Absortion FLSMartha Carolina Gomez MartinezNo ratings yet

- New Developments in Monolithic ProductsDocument59 pagesNew Developments in Monolithic Productsmahreza189100% (1)

- ABC Cooler Inlet PDFDocument4 pagesABC Cooler Inlet PDFSushant GuptaNo ratings yet

- MonolithicRefractory PDFDocument2 pagesMonolithicRefractory PDFmevaNo ratings yet

- Refractory Product Catalogue - VINAREF - EnglishDocument34 pagesRefractory Product Catalogue - VINAREF - EnglishBao Quoc NguyenNo ratings yet

- Cement PDFDocument70 pagesCement PDFhamza2k19No ratings yet

- Firing of Porcelain TilesDocument5 pagesFiring of Porcelain TilesRajarshi Dionysus BhattacharyyaNo ratings yet

- Thermo and Mechanical Stress Modelling Kiln Outlet DesignDocument5 pagesThermo and Mechanical Stress Modelling Kiln Outlet Designjoe_kudoNo ratings yet

- RHI MagnesitaDocument2 pagesRHI MagnesitaMauricio MessiNo ratings yet

- Ball Mill Inspection - Chap 1Document6 pagesBall Mill Inspection - Chap 1Min MCLNo ratings yet

- 2 Introduction-Refractories ApresentaçãoDocument11 pages2 Introduction-Refractories ApresentaçãoBrunoNo ratings yet

- Refractory Thickness in Rotary KilnDocument3 pagesRefractory Thickness in Rotary KilnDileepSaragadamNo ratings yet

- Cement Industry: Monolithic Concept Solutions ForDocument16 pagesCement Industry: Monolithic Concept Solutions ForAndreNo ratings yet

- Cement: Cabaluna, John Patrick Omandam, Wayne Rabanes, Ian MarDocument44 pagesCement: Cabaluna, John Patrick Omandam, Wayne Rabanes, Ian MarJay AbeladaNo ratings yet

- Raw Meal Susp PDFDocument48 pagesRaw Meal Susp PDFemadsabriNo ratings yet

- Presentation - Cement - GenDocument40 pagesPresentation - Cement - Genpacoto livingstoneNo ratings yet

- Kiln Operation ManualDocument25 pagesKiln Operation ManualLeulNo ratings yet

- Unit 2 - CementDocument55 pagesUnit 2 - CementSaharsha GadariNo ratings yet

- Manufacture Process of Cement: 1. Mixing of Raw MaterialDocument11 pagesManufacture Process of Cement: 1. Mixing of Raw MaterialLhance BabacNo ratings yet

- Different Shaft Kiln For Lime ManufacturerDocument13 pagesDifferent Shaft Kiln For Lime ManufactureranjnaNo ratings yet

- 2 3LimeKilnChemistryEffectsonOperationsDocument10 pages2 3LimeKilnChemistryEffectsonOperationsDamme Haulion SidabutarNo ratings yet

- Some Questions and Answers of CEMENT Rotary KilnDocument4 pagesSome Questions and Answers of CEMENT Rotary KilnSalud Y SucesosNo ratings yet

- Test For Properties of Cement: Physical & ChemicalDocument4 pagesTest For Properties of Cement: Physical & ChemicalmuqeetNo ratings yet

- PDF ST Nanobond e - 04 2019.en.22Document8 pagesPDF ST Nanobond e - 04 2019.en.22Henry Sunarko100% (1)

- Bull Nose Ref FailureDocument1 pageBull Nose Ref FailurejagrutNo ratings yet

- Atox Coal MillDocument8 pagesAtox Coal MillLijosh JamesNo ratings yet

- Concrete Technology: 18CV44 Sem:IVDocument56 pagesConcrete Technology: 18CV44 Sem:IVsnehaNo ratings yet

- How Mixing Affects The Rheology of Refractory Castables - Part IIDocument25 pagesHow Mixing Affects The Rheology of Refractory Castables - Part IIVinh Do ThanhNo ratings yet

- Operacion 44Document44 pagesOperacion 44Nelly Isabel Narvaez PachecoNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Dust Suppression System Cat.16755926Document2 pagesDust Suppression System Cat.16755926Albar BudimanNo ratings yet

- Effects of Dust Suppression On Conveyor Belting: TechtipsDocument3 pagesEffects of Dust Suppression On Conveyor Belting: TechtipsAlbar BudimanNo ratings yet

- Long Filter BagDocument1 pageLong Filter BagAlbar BudimanNo ratings yet

- Effect of Clinker Composition On GrindingDocument5 pagesEffect of Clinker Composition On GrindingAlbar Budiman100% (1)

- Hydraulic Thrust DeviceDocument2 pagesHydraulic Thrust DeviceAlbar Budiman100% (6)

- Kiln DryingDocument20 pagesKiln DryingIndera Pradana100% (1)

- Kiln Out LetDocument2 pagesKiln Out LetSamehibrahemNo ratings yet

- Jentoft Calcination 311003Document70 pagesJentoft Calcination 311003Albar BudimanNo ratings yet

- Basic Kiln Manual - For A - B - C KilnsDocument24 pagesBasic Kiln Manual - For A - B - C KilnsAlbar BudimanNo ratings yet

- Kiln Emergency YSDocument50 pagesKiln Emergency YSNelly Isabel Narvaez PachecoNo ratings yet

- Hydraulic Thrust DeviceDocument2 pagesHydraulic Thrust DeviceAlbar Budiman100% (6)

- MMC Clinker CoolerDocument4 pagesMMC Clinker CoolerAlbar BudimanNo ratings yet

- Language For PresentationsDocument13 pagesLanguage For PresentationsVo Dinh Quy (K17 CT)No ratings yet

- 6 Pulp Drying and Stock PreparationDocument57 pages6 Pulp Drying and Stock PreparationsersehNo ratings yet

- Guessing Game 2Document10 pagesGuessing Game 2ariefNo ratings yet

- EmissividadeDocument1 pageEmissividadefabricioemarcal8304No ratings yet

- Hydrarchy - GasworksDocument2 pagesHydrarchy - GasworksnicolaceliawrightNo ratings yet

- Coletânea Autores InstrumentosDocument20 pagesColetânea Autores InstrumentosSergio Miguel MiguelNo ratings yet

- 3 Surfer Van Amigurumi Pattern Caloca CroDocument37 pages3 Surfer Van Amigurumi Pattern Caloca CroDanielly Alexandre100% (1)

- Musica para DescargarDocument2 pagesMusica para DescargarEdwinOmarRosarioLeonNo ratings yet

- University of Pamplona Anglophone Literature: Analysis of A PlayDocument2 pagesUniversity of Pamplona Anglophone Literature: Analysis of A PlayAdriana SuarezNo ratings yet

- Kodak Tmax Data SheetDocument30 pagesKodak Tmax Data SheetNate CochraneNo ratings yet

- Basic Woodworking TextDocument76 pagesBasic Woodworking Textstaticfactory9281100% (3)

- Tourist Attractions in FranceDocument5 pagesTourist Attractions in Francemark balisnomoNo ratings yet

- Metodo de Iluminación Escénica MccandlessDocument152 pagesMetodo de Iluminación Escénica MccandlessCruzada Cristiana Marco FidelNo ratings yet

- Paint Vendor Conversion ChartsDocument71 pagesPaint Vendor Conversion ChartsLucy Barnett100% (1)

- TDS Swimming Pool-20210213Document1 pageTDS Swimming Pool-20210213Nicholson Vhenz UyNo ratings yet

- Art Appreciation OrientationDocument10 pagesArt Appreciation OrientationJashley Nicole HernandezNo ratings yet

- United World CollegeDocument50 pagesUnited World CollegeDIPAK VINAYAK SHIRBHATENo ratings yet

- Angelique Brickner: Ceramics Annual of America CatalogueDocument2 pagesAngelique Brickner: Ceramics Annual of America Catalogueklimt1No ratings yet

- Essay 2 TopicDocument3 pagesEssay 2 Topicapi-234940939No ratings yet

- Cultural Analysis EssayDocument1 pageCultural Analysis Essayariacom1No ratings yet

- Kenpo Vs American KenpoDocument12 pagesKenpo Vs American Kenpomarrow.0.ferretNo ratings yet

- Mars Ravelo DyesebelDocument2 pagesMars Ravelo DyesebelElfa Mae LibanonNo ratings yet

- Ba BSC Semester IIDocument177 pagesBa BSC Semester IIVansham AggarwalNo ratings yet

- Art EssayDocument2 pagesArt Essayrtrsgxp7fsNo ratings yet

- Stylistics Seminar 3Document8 pagesStylistics Seminar 3Тая РыжакNo ratings yet

- Dogma 95 EnglezaDocument96 pagesDogma 95 EnglezaSilvia IonescuNo ratings yet

- Bode and Museum Display 1996Document12 pagesBode and Museum Display 1996FranciscoNo ratings yet

- Juki DP 2100Document44 pagesJuki DP 2100Jose ÑañezNo ratings yet

- Icewear CreationDocument7 pagesIcewear CreationIpsita SahuNo ratings yet