Professional Documents

Culture Documents

Leak Testing Methodologies PDF

Leak Testing Methodologies PDF

Uploaded by

apply19842371Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Leak Testing Methodologies PDF

Leak Testing Methodologies PDF

Uploaded by

apply19842371Copyright:

Available Formats

Leak Testing Methodologies

LEAK TESTING METHODOLOGIES

Different methods can be used for leak testing:

-

Ultrasonic measurement

Bubble test

Pressure decay

Vacuum decay test or pressure rise test

Helium sniff

Helium spray

Helium accumulation

Helium leak detection through vacuum systems

ULTRASONIC MEASUREMENT

Any type of leak emits a sound and, depending on the size of the leak, the frequency

of the leak can be higher or lower. Very small leaks emit a sound with a frequency

which is too high for our ears to detect so an ultrasonic leak detector is used in this

case.

Ultrasonic leak detectors are generally hand held devices which are used with a pair

of headphones, a meter, a sensitivity adjustment, a nozzle and some level of

software. More complex systems can be used when it is necessary to automate the

process in a production environment for example, where more leak detection points

are potentially present.

This method is not reliable in complex systems where ultrasonic sounds can be

produced by multiple leaks but other sources too, which do not necessarily imply a

leak (background noise). Also, the leak rate cannot be measured, but only estimated

based on the frequency of the emitted sound.

The sensitivity of the instrument is rather low as well, as it can reliably detect leaks

only up to10-2 mbarlitre/sec.

For these reasons, this method is suited to finding large leaks, but it is not

recommended for the fine leaks in a production environment.

Tel.: (UK): +44 (0)161 866 88 60 - (US): +1 734 4874566

info@vac-eng.com

www.vac-eng.com

Leak Testing Methodologies

BUBBLE TEST

This method consists of pressurising the component (usually with dry air or nitrogen),

submerging it into a water tank and watching for escaping bubbles.

A leak in the component will produce a bubble stream, which can be less or more

intense depending on the size of the leak itself. The size of the bubble will also

depend on this factor.

The theoretical sensitivity of this method is about 10-4 mbarlitre/sec, however the

real sensitivity is lower (10-3 mbarlitre/sec)

as it is influenced by factors like illumination

conditions, water turbidity, unit location and

placement and water movement.

Besides, this method is not reliable as:

-

the

leak

size

cannot

be

easily

quantified

-

component requires drying after test

extensive floor space required

low throughputs

expensive to operate due to high labour costs (operators are required to look

for bubbles)

high dependency on the reliability of the operator

problems with bubbles (these can get trapped in the component structure, or

they are not produced because the leak is too small, false bubbles can be

produced by air trapped in the component structure during its immersion in

water, etc.)

possible par contamination

unpleasant working conditions (water can wet floors, operators, etc.)

operational and maintenance costs (cleaning the water, lighting, etc.)

Tel.: (UK): +44 (0)161 866 88 60 - (US): +1 734 4874566

info@vac-eng.com

www.vac-eng.com

Leak Testing Methodologies

PRESSURE DECAY

If we consider a component charged at a given

pressure, any possible leak can be associated with a

decrease

of

internal

pressure.

Therefore,

if

component needs to be leak tested, it can be first

charged (usually with dry air or nitrogen) at a set

pressure and then its pressure can be monitored for a

set amount of time. A pressure decay indicates the

presence of a leak.

This system is simple, compact and easy to use. It is

cheap, dry and it does not require an operators

judgement for its use.

The leak detection sensitivity depends on the volume of the unit to be tested (the

bigger, the more it takes to stabiles the internal pressure before monitoring it), the

pressure transducer resolution and testing time.

Moreover it presents the following disadvantages:

-

low sensitivity (down to 10-2 mbarlitre/sec)

requires long times to stabilise the pressure level before this is monitored over

time

very susceptible to environment changes (particularly temperature)

susceptible to mechanical instability (when pressurising the component its

volume can change, therefore the results can be misleading)

guarding is required for high pressures

the leak cannot be located

low throughput, especially for large components

This method can represent a good preliminary leak test to detect gross leaks before

a final automated fine leak test is carried out using helium (if a component has a

gross leak and this is not detected first with a pressure decay test, large quantities of

helium will leak out of the test unit, contaminating the system and making it

inoperable for a long time).

Tel.: (UK): +44 (0)161 866 88 60 - (US): +1 734 4874566

info@vac-eng.com

www.vac-eng.com

Leak Testing Methodologies

VACUUM DECAY TEST OR PRESSURE RISE TEST

This method works in the opposite way of the pressure decay test. It is based on the

on the evacuation of the part, and after the pressure has stabilised, any increase in

pressure caused by test media entering the part is measured.

This method is suitable only for parts which are able to withstand vacuum (thin

walled parts cannot be tested due to the danger of collapsing).

With respect to the pressure decay test, this method has the advantage of being less

sensitive to temperature changes since the internal pressure is lower than the

external atmospheric pressure.

However this solution presents the following disadvantages:

-

susceptible to surface out-gassing and liquid evaporation which affect and

limit the real sensitivity (the evaporation of traces of humidity increases the

internal pressure creating a false leak)

the pressure difference that can be applied to the component during the test

cannot be higher than 1 bar, therefore the part is not reliably tested if its

operating pressure is higher than 2bara

most importantly with this test the part is stressed in the opposite way

because the pressure is applied in the opposite direction to the operating one,

so certain leaks might close instead of opening as shown in the drawing here

below:

Although the sensitivity of this method can be around 10-2 mbarlitre/sec, it is not

recommended as a final leak test on complete assemblies for the reasons explained

above.

Tel.: (UK): +44 (0)161 866 88 60 - (US): +1 734 4874566

info@vac-eng.com

www.vac-eng.com

Leak Testing Methodologies

HELIUM SNIFF

For this method a helium sniffer is required. The component is charged with

pressurised helium and then scanned all over its surface with a helium sniffer.

Should there be a leak, this will cause an increase

in the helium concentration in the atmospheric air

mixture close to the leak point, which will be

detected by the sniffer.

This method is good as it locates the leak point,

has a high level of sensitivity (down to 10-6 mbarlitre/sec), it is compact, dry and

relatively inexpensive.

However, it presents the following disadvantages:

-

it is operator dependant

the accuracy of the leak detection depends on the speed the sniffer probe is

moved with, and on the distance between the part and the sniffer probe itself

it can be dangerous for the operator if the component is charged at high

pressures

low throughputs (manual)

repeat fails can helium contaminate the atmosphere where the test is carried

out, thus leading to unreliable results

it is a local method which allows testing of single points, therefore tested

points can have a leak below the sniffing sensitivity, but the overall leakage

may be above the acceptance limit. As a result, the test is successful, but the

part is defective.

Tel.: (UK): +44 (0)161 866 88 60 - (US): +1 734 4874566

info@vac-eng.com

www.vac-eng.com

Leak Testing Methodologies

HELIUM SPRAY

With this method, first of all the part to test is evacuated through a pumping system

integrated with a helium detector. This procedure can identify any gross leaks, which

if present, will not allow the component to reach vacuum. If this first operation is

completed successfully, then the component is sprayed with helium. Should there be

a small leak, this will allow some helium to get through inside the component. Once

some helium is inside the part, this will be quickly

sensed by the detector which can also measure

the leak rate. This method allows to locate a leak,

has a high level of sensitivity (down to 10-6

mbarlitre/sec), its compact and does not require

high pressure.

However, it presents the following disadvantages:

-

it is operator dependant

pressure orientation incorrect

multiple leaks can be masked if too close one to the other

throughputs are low if the system is used manually

Tel.: (UK): +44 (0)161 866 88 60 - (US): +1 734 4874566

info@vac-eng.com

www.vac-eng.com

Leak Testing Methodologies

HELIUM ACCUMULATION

This method requires a complete system consisting of a hermetically sealed

enclosure, a helium sensing device, and all the related pumps, connections, etc.

The component to test is first positioned within the enclosure and connected to the

couplings; then the enclosure door is closed and the component evacuated. This last

operation can identify any gross leaks, which if

present, will not allow the component to reach

vacuum.

If

this

first

operation

is

complete

successfully, then the component is charged with

helium at a pre-set pressure. At the same time the

air in the free volume of the enclosure (at

atmospheric conditions) is continuously mixed through the use of some fans,

necessary to guarantee a uniform concentration of the air within the enclosure itself.

After a set amount of time, samples of air are pumped through a helium sensor (Tguard) which measures the helium partial pressure and can detect any increase from

the initial atmospheric value therefore indicating a leak.

This method has a good level of sensitivity (down to 10-3 mbarlitre/sec subject to

enclosure size) coupled with reliable and repeatable results. No vacuum chamber is

required; therefore the cost of such a system is relatively low. Also, as the system

performances are not dependant on the temperature, this solution is highly indicated

when brazed products need to be tested, as they can be subject to the test when still

cooling right after the furnace.

The disadvantage of this solution is that it cannot locate the leak point; however a

helium sniffer can be integrated in the system allowing an operator to locate the

position of the leak.

Tel.: (UK): +44 (0)161 866 88 60 - (US): +1 734 4874566

info@vac-eng.com

www.vac-eng.com

Leak Testing Methodologies

VACUUM SYSTEMS

The typical system includes a vacuum

chamber, connected to a nitrogen supply, a

helium supply a pump group and a helium

leak detector.

The component to test is first connected to

the couplings and positioned within the

chamber. The chamber is then closed and evacuated. The component is also

evacuated but a difference between its pressure and the chamber pressure is first

created to carry out a gross leak test. If this is passed successfully then the

component is completely evacuated and subsequently backfilled with helium (or any

other tracer gas). Any leak would allow helium to escape through the component

walls to the chamber. As this is directly connected to a helium leak detector, any

possible leak is quickly sensed and indicated.

This method is characterised by a very high level of sensitivity (down to 10-8

mbarlitre/sec), quantifiable and reliable results, and the possibility to partly or fully

automate the process, integrating it directly into the manufacturing line too if

required. The system therefore does not require any operators judgement and

guarantees fast throughputs.

The only disadvantage is that this solution is more expensive than the other, thus

requires a certain level of investment. The position of the leak cannot be directly

identified, but if a manual sniffer is integrated with the system, this option is definitely

possible.

Moreover high percentages of the costs related to the use of helium can be saved by

using a Helium Recovery Unit.

Tel.: (UK): +44 (0)161 866 88 60 - (US): +1 734 4874566

info@vac-eng.com

www.vac-eng.com

Leak Testing Methodologies

Sensitivity or different leak testing methods expressed in mbarlitre/sec or cc/sec

10-10

10-9

10-8

10-7

10-6

10-5

10-4

10-3

10-2

10-1

100

10+1

Ultrasonics

Air Bubbles

Pressure Decay/Rise

Helium Accumulation

Helium Sniff

Helium Spray

Vacuum Chamber

HOW TO CHOOSE THE TEST METHOD

The correct method should be based on the following information:

-

How many points must be tested?

What is the pass/fail leak rate? (or how much time must the product last?)

What are the dimensions of the product to test?

What is the required test cycle time?

Does it have to be an automated system or manual?

What is the budget?

What is the test pressure?

Other factors which depend from application to application should be taken into

account. VES can analyse your requirements and suggest the best solution.

Tel.: (UK): +44 (0)161 866 88 60 - (US): +1 734 4874566

info@vac-eng.com

www.vac-eng.com

You might also like

- Audels Engineers and Mechanics Guide Volume 1 From WWW Jgokey ComDocument486 pagesAudels Engineers and Mechanics Guide Volume 1 From WWW Jgokey Comjdsa123100% (2)

- DK Did You Know SpaceDocument146 pagesDK Did You Know SpaceDiego Zambrano100% (6)

- Report Lube Oil FlushingDocument10 pagesReport Lube Oil Flushingmohan_krishna372No ratings yet

- Ceramic Matrix CompositeDocument10 pagesCeramic Matrix CompositeMohammed KhalidNo ratings yet

- Curso Leak DetectionDocument21 pagesCurso Leak DetectionDurgamadhaba Mishra100% (1)

- Inspection of Heat ExchangersDocument20 pagesInspection of Heat Exchangersadel100% (1)

- Bus Bar 1Document33 pagesBus Bar 1Pin Santos100% (3)

- Adyxen Leak Detection TechniquesDocument14 pagesAdyxen Leak Detection TechniquesSavij_ChouhanNo ratings yet

- Vacuum Air BrakeDocument55 pagesVacuum Air BrakeAnshul Gupta100% (1)

- Air Leak TestingDocument5 pagesAir Leak Testingkusdiyanta67% (3)

- PTS 12.21.11 Leak Testing Guidelines For SHEXDocument23 pagesPTS 12.21.11 Leak Testing Guidelines For SHEXamaher100% (1)

- Leak Test MethodDocument5 pagesLeak Test Methodmohamed100% (1)

- Electrode Classification by Aws A 5.1 PDFDocument1 pageElectrode Classification by Aws A 5.1 PDFVenkatesh NatlaNo ratings yet

- Hydrotest ProcedureDocument12 pagesHydrotest Procedurealex_feryando42100% (1)

- Fix Tube Sheet Heat Exchanger MaintenanceDocument10 pagesFix Tube Sheet Heat Exchanger MaintenanceKarthik MadhuNo ratings yet

- Chemical Cleaning of Boiler Pressure Parts As TheDocument57 pagesChemical Cleaning of Boiler Pressure Parts As TheAnonymous 1OmAQ0u3No ratings yet

- Heat Exchanger Inspection Checklist - QC, Inspection & Testing Engineering - Eng-TipsDocument2 pagesHeat Exchanger Inspection Checklist - QC, Inspection & Testing Engineering - Eng-TipsdileepNo ratings yet

- TUBE To HEADER JOINTS PDFDocument4 pagesTUBE To HEADER JOINTS PDFRiza KhanNo ratings yet

- On-Stream Leak Repair Techniques - Part 2Document2 pagesOn-Stream Leak Repair Techniques - Part 2qaisarabbas9002100% (1)

- CSEC Mathematics June 1998 P2Document12 pagesCSEC Mathematics June 1998 P2zarzsultan12100% (1)

- Air Cooler Cleaning TechniqueDocument4 pagesAir Cooler Cleaning Techniquedinakaranpatel100% (1)

- 38G - Pipeline PiggingDocument23 pages38G - Pipeline Piggingambadaeng100% (1)

- 9501-PP-QA-009 Piping Leak Test Procedure R-0Document27 pages9501-PP-QA-009 Piping Leak Test Procedure R-0Josh RuddyNo ratings yet

- PIL161 Lube Oil System Cleanliness PDFDocument3 pagesPIL161 Lube Oil System Cleanliness PDFHaryNo ratings yet

- 2013 04 ROSEN SlidesDocument29 pages2013 04 ROSEN SlidesAnonymous WCG2HjPybJ100% (1)

- Helium Leak TestingDocument21 pagesHelium Leak TestingSaut Maruli Tua Samosir100% (1)

- Flange Management Procedure FixDocument13 pagesFlange Management Procedure FixNaza Gavaputri100% (1)

- Incoming Inspection of Hot Gas PathDocument2 pagesIncoming Inspection of Hot Gas Pathshashikanth79100% (2)

- Helium Leak DetectionDocument3 pagesHelium Leak DetectionBv RaoNo ratings yet

- Helium Leak TestingDocument77 pagesHelium Leak TestingMirza Safeer Ahmad83% (6)

- Full Notes RadiographyDocument120 pagesFull Notes RadiographyNishimwe Lambert100% (1)

- Helium Leak TestDocument8 pagesHelium Leak TestHiren Panchal50% (2)

- Boiler MaintenanceDocument39 pagesBoiler MaintenanceAjay Chauhan100% (3)

- Corrosion Coupan Check ListDocument2 pagesCorrosion Coupan Check Listtrichysayee100% (1)

- Heleium Leak TestDocument20 pagesHeleium Leak TestAkbar Doha100% (1)

- Maintenance EvaluationDocument28 pagesMaintenance EvaluationPin Santos100% (1)

- Pipeline Leak Test ProcedureDocument174 pagesPipeline Leak Test ProcedureRini Puspitasari100% (3)

- PiggingDocument24 pagesPiggingJulio Cesar Galarza Lobo0% (1)

- Pressure & Leak TestingDocument18 pagesPressure & Leak TestingBilly KurniawanNo ratings yet

- Method Statement and Procedure For Calibration of Vertical Storage Tank MAY 2018Document4 pagesMethod Statement and Procedure For Calibration of Vertical Storage Tank MAY 2018tunde100% (1)

- Helium Leak Testing GuideDocument2 pagesHelium Leak Testing Guideabhishek198327100% (1)

- Inspection Report Insulation Check: Inspectors Ceri Name: Signature: Date: Gama Consortium Consortium StegDocument1 pageInspection Report Insulation Check: Inspectors Ceri Name: Signature: Date: Gama Consortium Consortium StegRamzi Zoghlami100% (1)

- The Pressure Decay Test Method PDFDocument3 pagesThe Pressure Decay Test Method PDFYew LoongNo ratings yet

- Helium Leak TestDocument1 pageHelium Leak TestvtbkNo ratings yet

- Temper Bead Welding 36036664Document9 pagesTemper Bead Welding 36036664sv1xv100% (1)

- ACHE - Installation, Erection, Start Up & Commissioning Check ListDocument2 pagesACHE - Installation, Erection, Start Up & Commissioning Check Listrahim_335162856100% (1)

- Boil Out ProcedureDocument2 pagesBoil Out Proceduremrizalygani99100% (1)

- Preservation of Coated Pipes For Long Term Storage in Tropical Environment PDFDocument8 pagesPreservation of Coated Pipes For Long Term Storage in Tropical Environment PDFNguyen Anh TungNo ratings yet

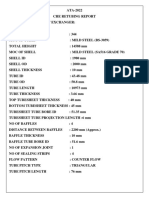

- CHE Retubing ReportDocument29 pagesCHE Retubing ReportRajesh KtrNo ratings yet

- IENCSEPRO0007-2 - General Leak Test Procedure PDFDocument9 pagesIENCSEPRO0007-2 - General Leak Test Procedure PDFCatalinNo ratings yet

- Bolt Torquing SpecialistDocument2 pagesBolt Torquing SpecialistMarkus Landington100% (1)

- Shell and Tube Corrosion and Failure DescriptionDocument6 pagesShell and Tube Corrosion and Failure DescriptionRiccardo AgnorelliNo ratings yet

- Online Leak Sealing TenderDocument10 pagesOnline Leak Sealing TenderchennaiNo ratings yet

- Pneumatic TestDocument6 pagesPneumatic TestSubbarayan SaravanakumarNo ratings yet

- Boiler Efficiency PresentationDocument13 pagesBoiler Efficiency PresentationAhmad Sabree Abdul BasitNo ratings yet

- QPR0120 Leak Testing Proc.Document3 pagesQPR0120 Leak Testing Proc.ZackTeeKeatTeongNo ratings yet

- Mechanical Boiler Inspection ReportDocument1 pageMechanical Boiler Inspection ReportAfzal pathanNo ratings yet

- TBT Welding FiresDocument4 pagesTBT Welding FiresNaiduSatyanarayanaNaiduNo ratings yet

- Innovative In-Situ Repair of A High Temperature Steam Super Heater CoilDocument13 pagesInnovative In-Situ Repair of A High Temperature Steam Super Heater Coilvaratharajan g r100% (1)

- ILI Pipeline CostDocument3 pagesILI Pipeline CostyogacruiseNo ratings yet

- Site Acceptance Test Contract No.: 537856: 863013-VPS-PQM-E-DS-0002Document16 pagesSite Acceptance Test Contract No.: 537856: 863013-VPS-PQM-E-DS-0002Andry YanuarNo ratings yet

- Water Wash Procedure For EconomizerDocument3 pagesWater Wash Procedure For EconomizerRajendra100% (1)

- Typical Acid Cleaning Procedure For Compressor LinesDocument1 pageTypical Acid Cleaning Procedure For Compressor Linesrenjithv_4No ratings yet

- Boiler & Pressure Vessel Inspection Report PDFDocument1 pageBoiler & Pressure Vessel Inspection Report PDFEslam KhamisNo ratings yet

- Asset Integrity Management A Complete Guide - 2020 EditionFrom EverandAsset Integrity Management A Complete Guide - 2020 EditionNo ratings yet

- Leak Testing MethodologiesDocument9 pagesLeak Testing MethodologiesElena-Cristina IonitaNo ratings yet

- 2.5 Tracer Gas Leak TestingDocument10 pages2.5 Tracer Gas Leak TestingNguyễn ĐạtNo ratings yet

- Unit One This or That 1Document9 pagesUnit One This or That 1sushantNo ratings yet

- Equipment Breakdown KitDocument9 pagesEquipment Breakdown KitPin SantosNo ratings yet

- Equipment BreakdownDocument1 pageEquipment BreakdownPin SantosNo ratings yet

- Pfeiffer P3 MSDSDocument7 pagesPfeiffer P3 MSDSPin SantosNo ratings yet

- Basic TransformerDocument10 pagesBasic TransformerPin SantosNo ratings yet

- 6 Workbook - FVSMDocument4 pages6 Workbook - FVSMFiorela Vanessa Santa María MundacaNo ratings yet

- Measurement of Force Torque and PressureDocument22 pagesMeasurement of Force Torque and Pressuregenius_1980No ratings yet

- 8 Class GTSO Work Sheet - 1 (BASIC CONCEPTS OF CARTOGRAPHY)Document2 pages8 Class GTSO Work Sheet - 1 (BASIC CONCEPTS OF CARTOGRAPHY)Gurrapu SudhaNo ratings yet

- Magnetic Field Experiment For Students TDocument24 pagesMagnetic Field Experiment For Students Tkaushik prajapatiNo ratings yet

- Terawins Video Display Controller Selection GuideDocument1 pageTerawins Video Display Controller Selection GuideSonic SabacNo ratings yet

- Jlhhvalue Based Questions Class-12Document16 pagesJlhhvalue Based Questions Class-12jitender8No ratings yet

- Ayurveda Perspective of Natural Drug Interaction: A Literature ReviewDocument3 pagesAyurveda Perspective of Natural Drug Interaction: A Literature ReviewBhavana GangurdeNo ratings yet

- Radiographic FilmDocument8 pagesRadiographic FilmwaelNo ratings yet

- Notification No. 20 of 2017 Central Tax RateDocument6 pagesNotification No. 20 of 2017 Central Tax RateSamrat TalukdarNo ratings yet

- Seminar Report On MemristorDocument31 pagesSeminar Report On Memristorjasil1414No ratings yet

- IBMx3650 46m1493Document264 pagesIBMx3650 46m1493kreepydanNo ratings yet

- Modular Cleaning Recipes PDFDocument8 pagesModular Cleaning Recipes PDFvalentina castilloNo ratings yet

- Codypu 03 1Document11 pagesCodypu 03 1Namik HadziibrahimovicNo ratings yet

- Latent Profile Analysis in R: A Tutorial and Comparison To MplusDocument19 pagesLatent Profile Analysis in R: A Tutorial and Comparison To MplusDaimon MichikoNo ratings yet

- On The Necessity of Sadness & Other Poems: Mikael de Lara CoDocument6 pagesOn The Necessity of Sadness & Other Poems: Mikael de Lara CoLara AntonioNo ratings yet

- RAI S ManualDocument2 pagesRAI S ManualNesil Abiera0% (1)

- Electric Motor Basics: Why Are Rotors Skewed?: by Cyndi Nyberg EASA Technical Support SpecialistDocument2 pagesElectric Motor Basics: Why Are Rotors Skewed?: by Cyndi Nyberg EASA Technical Support SpecialistsebastianNo ratings yet

- Legal Methods ProjeDocument7 pagesLegal Methods ProjeInjila ZaidiNo ratings yet

- Krishnas Final Year ProjectDocument33 pagesKrishnas Final Year ProjectVIGNESHWARAN VNo ratings yet

- NTE2389 Mosfet N CH, Enhancement Mode High Speed Switch TO220 Type PackageDocument2 pagesNTE2389 Mosfet N CH, Enhancement Mode High Speed Switch TO220 Type PackagetoroalNo ratings yet

- Secant MethodDocument5 pagesSecant MethodChiến NguyễnNo ratings yet

- Lab 3Document8 pagesLab 3Ross LevineNo ratings yet

- Rpl1 Doc1. Life Experiences RevisedDocument3 pagesRpl1 Doc1. Life Experiences Revisedmary gamboa50% (2)

- Gen Math Week 3 ModuleDocument5 pagesGen Math Week 3 ModuleJazka Abegail NavaNo ratings yet