Professional Documents

Culture Documents

R-7505-01. TBA Pipe Bend Form

R-7505-01. TBA Pipe Bend Form

Uploaded by

AdvisOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

R-7505-01. TBA Pipe Bend Form

R-7505-01. TBA Pipe Bend Form

Uploaded by

AdvisCopyright:

Available Formats

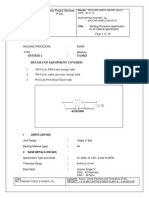

STAR ENERGY (Kakap) Ltd.

KRA South Gas Development Subsea Tie-in

TECHNICAL BID ANALYSIS

TRIPATRA - SARKU CONSORTIUM

Project

: KRA South Gas Development Subsea Tie-in

Doc. No

Job. No

: 9444

Rev

Client

: STAR ENERGY (Kakap) Ltd.

Date

Subject

: TBA for Pipe Bend

Sheet

NO

I.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

COMPONENT

PIPE BEND 90 DEG

Size

Outer Diameter

Wall Thickness

Quantity

Pipe Process Manufacture

Bend Process Manufacture

End Preparation

Material

Yield Strength

Tensile Strength

Hardness

Charpy V-Notch

Elongation

NACE MR 0175

Carbon Equivalent

Pcm

YS/TS

Bend Radius

Bend Degrees

Length of Tangent

Out of Roundness

Wall Thk. After forming

Pipe Dia. After Forming

Origin

Manufacturer

Delivery Time

Delivery Point

EVALUATION RESULT

28

29

30

REQUIREMENT

Schedule

Technical

Recommendation

TRIPATRA - SARKU CONSORTIUM

File : 335578730.xls

NPS 6 Inch

6.625 Inch

0.432 Inch

4 EA

SMLS

HFIB

Bevelled End

API 5L X-65

Min 65,000 Psi

Max 87,000 Psi

Min 77,000 Psi

Max 110,000 Psi

Max 99 HRB (HV 248)

Min 28 Ft-Lbs (38 Joule)

Min 18 %

None

0.40 for 65ksi

0.44 for 80ksi

0.22 for 65ksi

0.25 for 80ksi

0.92

Max

3D

90 DEG

2 Feet

Max

2 1/2 % of Pipe Dia.

Min

0.389 Inch

Max 6.8 Inch

BETA INTERNATIONAL, INC

Quote

Compliance

STAR ENERGY (Kakap) Ltd.

: KRA-2X-A-05-R-7505

: 01

: 5 January 2006

: 1 of 2

REMARKS

TRIPATRA - SARKU CONSORTIUM

File : 335578730.xls

KRA South Gas Development Subsea Tie-in

STAR ENERGY (Kakap) Ltd.

KRA South Gas Development Subsea Tie-in

TECHNICAL BID ANALYSIS

TRIPATRA - SARKU CONSORTIUM

Project

: KRA South Gas Development Subsea Tie-in

Doc. No

: KRA-2X-A-05-R-7505

Job. No

: 9444

Rev

: 01

Client

: STAR ENERGY (Kakap) Ltd.

Date

: 5 January 2006

Subject

: TBA for Pipe Bend

Sheet

: 2 of 2

NO

II.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

COMPONENT

PIPE BEND 45 DEG

Size

Outer Diameter

Wall Thickness

Quantity

Pipe Process Manufacture

Bend Process Manufacture

End Preparation

Material

Yield Strength

Tensile Strength

Hardness

Charpy V-Notch

Elongation

NACE MR 0175

Carbon Equivalent

Pcm

YS/TS

Bend Radius

Bend Degrees

Length of Tangent

Out of Roundness

Wall Thk. After forming

Pipe Dia. After Forming

Origin

Manufacturer

Delivery Time

Delivery Point

EVALUATION RESULT

28

29

30

REQUIREMENT

Schedule

Technical

Recommendation

TRIPATRA - SARKU CONSORTIUM

File : 335578730.xls

NPS 6 Inch

6.625 Inch

0.432 Inch

2 EA

SMLS

HFIB

Bevelled End

API 5L X-65

Min 65,000 Psi

Max 87,000 Psi

Min 77,000 Psi

Max 110,000 Psi

Max 99 HRB (HV 248)

Min 28 Ft-Lbs (38 Joule)

Min 18 %

None

0.40 for 65ksi

0.44 for 80ksi

0.22 for 65ksi

0.25 for 80ksi

0.92

Max

3D

45 DEG

2 Feet

Max

2 1/2 % of Pipe Dia.

Min

0.389 Inch

Max 6.8 Inch

BETA INTERNATIONAL, INC

Quote

Compliance

REMARKS

You might also like

- Technical Bid Analysis: STAR ENERGY (Kakap) LTDDocument1 pageTechnical Bid Analysis: STAR ENERGY (Kakap) LTDAdvisNo ratings yet

- Output Report For Bullet Tank PDFDocument1 pageOutput Report For Bullet Tank PDFOmil RastogiNo ratings yet

- About UsDocument32 pagesAbout UsSubbu Ram PNo ratings yet

- Development of CNG CompressorDocument81 pagesDevelopment of CNG CompressorMuhammad AsimNo ratings yet

- Technology Base For The ACR Fuel ChannelsDocument52 pagesTechnology Base For The ACR Fuel ChannelsMahmood KhanNo ratings yet

- BK - TNG 001 TS PI SP 001 Piping Material Specification Rev.1Document45 pagesBK - TNG 001 TS PI SP 001 Piping Material Specification Rev.1Kev Tra100% (1)

- Concast WPS - REV-01Document28 pagesConcast WPS - REV-01meena34No ratings yet

- Surge Tank 25m3Document1 pageSurge Tank 25m3cbcyouthygnNo ratings yet

- BK TNG 001 TS PI SP 001 - Piping Specification - Rev 2Document45 pagesBK TNG 001 TS PI SP 001 - Piping Specification - Rev 2Kev TraNo ratings yet

- Aterial Specification & All Thickness CalculationDocument35 pagesAterial Specification & All Thickness CalculationPanjiUte100% (1)

- TSC PT. Wijaya KaryaDocument6 pagesTSC PT. Wijaya KaryatofaNo ratings yet

- TSC PT. Wijaya KaryaDocument6 pagesTSC PT. Wijaya KaryatofaNo ratings yet

- TSC PT. Wijaya KaryaDocument6 pagesTSC PT. Wijaya KaryatofaNo ratings yet

- Pipeline CoatingsDocument29 pagesPipeline Coatingstrpac100% (3)

- Volime II of II Pipeline - JP KennyDocument199 pagesVolime II of II Pipeline - JP Kennyabhi_luvme03100% (1)

- 008-MS For Prefabrication of CS, TT & CN Pipe Spools PDFDocument23 pages008-MS For Prefabrication of CS, TT & CN Pipe Spools PDFKöksal PatanNo ratings yet

- Di Pipes AuhDocument22 pagesDi Pipes AuhMaged SamirNo ratings yet

- Abdul Khaliq CV As A QC SupervisorDocument6 pagesAbdul Khaliq CV As A QC SupervisorMNo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- 500 SP PIP 018 Rev C (Check Valve)Document13 pages500 SP PIP 018 Rev C (Check Valve)anwar01No ratings yet

- Above Ground Piping Wall Thickness CalculationsDocument9 pagesAbove Ground Piping Wall Thickness CalculationsFarid TataNo ratings yet

- LNTDocument25 pagesLNTAnshik JainNo ratings yet

- Success of STAR-CCM+ Application in The Design Process of Modern Gas Turbine 0Document23 pagesSuccess of STAR-CCM+ Application in The Design Process of Modern Gas Turbine 0sb aliNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- Inspection Test PlanDocument3 pagesInspection Test PlanSharique Ali50% (2)

- ITP PlanDocument3 pagesITP PlandhasdjNo ratings yet

- Manufacturing Process of Tower PartsDocument29 pagesManufacturing Process of Tower PartssAuRaBhNo ratings yet

- Design Calculation For Pipe SupportsDocument200 pagesDesign Calculation For Pipe Supportssanggytha100% (1)

- D 100 Mda WHP Bem 004 Tbe PipeDocument30 pagesD 100 Mda WHP Bem 004 Tbe PipeAdvisNo ratings yet

- Price Summary Sheet: Currency (Baht) 1.direct Work Cost Offer Price Cost ItemDocument11 pagesPrice Summary Sheet: Currency (Baht) 1.direct Work Cost Offer Price Cost Itemchompink6900No ratings yet

- SampleDocument8 pagesSamplearavindNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- الخليجDocument10 pagesالخليجmohamedNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- Drilling Services OverviewDocument70 pagesDrilling Services OverviewMahmoud Abd El-Razik100% (1)

- s22 Gantry Design Report Rev01Document43 pagess22 Gantry Design Report Rev01RaviNo ratings yet

- Ga & Data Sheet of Cooling Tower - 03.02.16 PDFDocument9 pagesGa & Data Sheet of Cooling Tower - 03.02.16 PDFAniket Roy100% (1)

- Convention Center Structural CalculationsDocument2,776 pagesConvention Center Structural CalculationsGiho Kim0% (1)

- TBE For UG Knock Out Drum - Draft For Rev.C1Document22 pagesTBE For UG Knock Out Drum - Draft For Rev.C1pragatheeskNo ratings yet

- TBE Pumps CP 16Document21 pagesTBE Pumps CP 16ivomNo ratings yet

- 4635 5 SPC 111 Rev0 (Piping Colors)Document5 pages4635 5 SPC 111 Rev0 (Piping Colors)Anonymous NupAudbjjNo ratings yet

- Dev-Aad-mp-sp-jpk-1058 Rev b2 Welding and NDT of Cs Linepipe To Bs 4515-1 (2004)Document77 pagesDev-Aad-mp-sp-jpk-1058 Rev b2 Welding and NDT of Cs Linepipe To Bs 4515-1 (2004)AdvisNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- T-25-2018-00-Pe-Das-1048 - Rev-2 - Datasheet For Sight GlassDocument3 pagesT-25-2018-00-Pe-Das-1048 - Rev-2 - Datasheet For Sight Glassvinoj chandranNo ratings yet

- Inspection and Test Plan - General Civil Works at Adr&Ruwais RefineryDocument4 pagesInspection and Test Plan - General Civil Works at Adr&Ruwais RefineryJithesh.k.sNo ratings yet

- Capability Dl&tocument For Process Platforms PDFDocument72 pagesCapability Dl&tocument For Process Platforms PDFSunil SinghNo ratings yet

- Piping Design BasisDocument26 pagesPiping Design BasisAnjani Prabhakar100% (4)

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- Above Ground Piping Wall Thickness CalculationsDocument7 pagesAbove Ground Piping Wall Thickness Calculationslutfi awn100% (1)

- SPG CAL 50 008 A4 Calculation Genset FoundationDocument11 pagesSPG CAL 50 008 A4 Calculation Genset FoundationOmar PerpatihNo ratings yet

- PantechSteel CatalogueDocument36 pagesPantechSteel Cataloguejok1974No ratings yet

- Structural Fabrication SpecificationDocument18 pagesStructural Fabrication Specificationravirawat15No ratings yet

- 006-MS For Purging of Stainless Steel PDFDocument18 pages006-MS For Purging of Stainless Steel PDFKöksal PatanNo ratings yet

- MM ZTK 1B WPX MEC DTS 0013 Rev.C1 Diesel Oil Filter With InternalDocument9 pagesMM ZTK 1B WPX MEC DTS 0013 Rev.C1 Diesel Oil Filter With Internalpragatheesk100% (1)

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- MD PV ASME v0.1Document35 pagesMD PV ASME v0.1rizalramaNo ratings yet

- Pipeline and Energy Plant Piping: Design and TechnologyFrom EverandPipeline and Energy Plant Piping: Design and TechnologyRating: 5 out of 5 stars5/5 (2)

- Proceedings of the 2014 Energy Materials Conference: Xi'an, Shaanxi Province, China, November 4 - 6, 2014From EverandProceedings of the 2014 Energy Materials Conference: Xi'an, Shaanxi Province, China, November 4 - 6, 2014No ratings yet

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionFrom EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionRating: 4.5 out of 5 stars4.5/5 (16)

- VAI-ME-SPC-111 Pipe Insulation Technical Specification - Rev ADocument8 pagesVAI-ME-SPC-111 Pipe Insulation Technical Specification - Rev AAdvis100% (1)

- MT Op PWHT 001Document15 pagesMT Op PWHT 001Advis100% (1)

- Wmg-pl-cp-0001 Sales Gas Pipeline Execution ProcedureDocument28 pagesWmg-pl-cp-0001 Sales Gas Pipeline Execution ProcedureAdvis100% (1)

- Mto Piping Balance of Material Phase I Stage 2 - 1st BatchDocument4 pagesMto Piping Balance of Material Phase I Stage 2 - 1st BatchAdvis100% (2)

- Olokola Gas Supply Project Pipeline Feed: Constructability StudyDocument22 pagesOlokola Gas Supply Project Pipeline Feed: Constructability StudyAdvisNo ratings yet

- 01 P 3 005 Rev B ConstructabilityDocument16 pages01 P 3 005 Rev B ConstructabilityAdvis100% (1)

- IDBE-WO-YPZZZ-En0001 Onshore Construction Execution Plan, Rev 0Document56 pagesIDBE-WO-YPZZZ-En0001 Onshore Construction Execution Plan, Rev 0Advis100% (2)

- Induction Bends - COPIDocument12 pagesInduction Bends - COPIAdvis100% (1)

- 01-P-1-007 Pipeline Construction Spec Rev ADocument42 pages01-P-1-007 Pipeline Construction Spec Rev AAdvis100% (2)

- Olokola Gas Supply Project Pipeline Feed: Constructability StudyDocument22 pagesOlokola Gas Supply Project Pipeline Feed: Constructability StudyAdvisNo ratings yet

- PPLN PL Dat 1 545b 27 00 Ds For Barred Tee Rev.01Document12 pagesPPLN PL Dat 1 545b 27 00 Ds For Barred Tee Rev.01AdvisNo ratings yet

- Kepodang BP Muriah - Spec For Welding WMSS LinepipeDocument15 pagesKepodang BP Muriah - Spec For Welding WMSS LinepipeAdvisNo ratings yet

- Technical Bid EvaluationDocument3 pagesTechnical Bid EvaluationAdvisNo ratings yet

- Hot Induction Bend - SSWJ PGNDocument12 pagesHot Induction Bend - SSWJ PGNAdvisNo ratings yet

- Pipeline OnshoreDocument29 pagesPipeline OnshoreAdvis100% (3)

- Barred TeesDocument1 pageBarred TeesAdvisNo ratings yet

- Technical Bid Analysis: STAR ENERGY (Kakap) LTDDocument1 pageTechnical Bid Analysis: STAR ENERGY (Kakap) LTDAdvisNo ratings yet

- 05-3300-01-W-01-009 Pipeline Welding and NDT Spec (Onshore) Rev P2Document17 pages05-3300-01-W-01-009 Pipeline Welding and NDT Spec (Onshore) Rev P2AdvisNo ratings yet

- GL-SP-Q-604 Rev.0 Specification For WeldingDocument15 pagesGL-SP-Q-604 Rev.0 Specification For WeldingAdvis100% (1)

- Dev-Aad-mp-sp-jpk-1058 Rev b2 Welding and NDT of Cs Linepipe To Bs 4515-1 (2004)Document77 pagesDev-Aad-mp-sp-jpk-1058 Rev b2 Welding and NDT of Cs Linepipe To Bs 4515-1 (2004)AdvisNo ratings yet

- COPI - Welding Spec For Flowlines To API 1104-1999Document12 pagesCOPI - Welding Spec For Flowlines To API 1104-1999AdvisNo ratings yet

- Fabrication of Hot Bends - Technical Bid Evaluation Rev BDocument2 pagesFabrication of Hot Bends - Technical Bid Evaluation Rev BAdvis100% (1)

- Technical Bid EvaluationDocument3 pagesTechnical Bid EvaluationAdvisNo ratings yet

- Welding and NDTDocument51 pagesWelding and NDTAdvis67% (3)

- P.T. Raga Perkasa Ekaguna Tender Evaluation - Technical: GeneralDocument2 pagesP.T. Raga Perkasa Ekaguna Tender Evaluation - Technical: GeneralAdvisNo ratings yet

- Welding and NDTDocument51 pagesWelding and NDTAdvis67% (3)

- D 100 Mda WHP Bem 004 Tbe PipeDocument30 pagesD 100 Mda WHP Bem 004 Tbe PipeAdvisNo ratings yet