Professional Documents

Culture Documents

MDM3051 Series Smart Transmitters

Uploaded by

Nguyễn Văn Quý0 ratings0% found this document useful (0 votes)

52 views29 pagesMDM3051 Series Smart Transmitters

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentMDM3051 Series Smart Transmitters

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

52 views29 pagesMDM3051 Series Smart Transmitters

Uploaded by

Nguyễn Văn QuýMDM3051 Series Smart Transmitters

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 29

Piancno senson Operation Manual

MDM3051 Series Smart Transmitters

MICRO SENSOR CO.,LTD. ae ee —— &

Content

Section 1 Introduction,

Section 2 Startup 3

2.1 Overview 3

2.2 Failure Mode Alarm 3

2.3 Selfest 5

2.4 Loop Test 5

Section 3 Installation 6

3.1 Mounting of Transmitter. 6

3.2 Impulse Piping 6

3.3 Mounting Requirements 8

3.4 Wiring Connecting and Power Up. e

3.5 Dangerous Locations 3

3.6 Dimension Drawings (MDM3051 GP/AP/DP/HP) 10

3.7 Typical Installation Drawings 12

Section 4 Configuration and Debugging 3

441 Menu Tree 13

4.2 MS-HART232 15

43 Locate Adjustment. 7

4.4 LCD Display 18

‘Section 5 Operation and Maintenance. 20

5.1 Brief Introduction 20

5.2 Verifying Device and Too! 20

6.3 Disassembling Process 20

5.4 Assembling Process 24

5.5 Checking and Interchanging of Components. 21

5.6 Drawings of Transmitter Components 2

Section 6 Work Principle, 23

6.1 Sensor Module 23

6.2 Electronic Circuit Board 24

Section 7 Technical Performance 25

7.1 Technical Performance 25

7.2 Performance Index... 26

7.3 Construction Index 27

Table 1 MDM3051 GP/AP/DP/HP Smart Transmitter Catalogue 28

Table 2 MDM3051 LT Catalogue. 23

Table 3 MDM3051 Optional Parts Catalogue a

App. A MS-HART232 Configuration/Debugging System Manual 32

App. B HART Characters 47

‘Our company Keeps the modification right for this,

production manual due to the updating of technology

‘and craftwork. If some information was changed, no

‘more notice wil be edited. Version: V10.01.1

MDM30SI Series Smart Transmitters Manual

Section 1 Introduction

MDM3051 series Capacitive Smart Pressure Transmitters are high-precision smart instruments

that are developed and manufactured solely by Micro Sensor Co., Ltd. Based on our research and

practice in this area for years.

MDM3051 series Capacitive Smart Transmitters are new generation smart transmitters. It applies

the sensor kernel with ROSEMOUNT® technology as well as the advanced digital technology

developed by Micro Sensor Co., Ltd. We adopt the principle of replacing analog signal ampifying

circuit and A/D conversion circuit with direct digital capacitive circuit, and meantime take the digital

‘compensation technology to compensate temperature and static pressure, which greatly improves

the measurement precision and reduces the temperature dri. The complete unit transmitter is

characterized by its small size, high reliability and long-term stability. With extremely high

performance price ratio, this series of products which have been praised by its user as “with the

performance of 3051 at the price of 1151", have become the mainstream products in the

transmitter market,

This series of products are characterized by the novel designing principle, complete specifications,

simplicity in installation and use, as well as the explosion proof safety. Its famous especially for its

high precision, small size, ight weight, easy adjustment, long-term stability, applicability in rough

conditions and perfect performance on one-way overload protection. Therefore, this series of

products enjoy high reputation in both domestic and overseas markets. This series of products in

conformity with the current “IEC” standards in China, are applicable comprehensively in many

areas, such as electrical, metallurgical, petrochemical, pharmacal and curing ete

Features

Increased flexibility and enhanced functions thanks to the application of microprocessor,

Powerful self-diagnosis capability;

Measurement Range: 0~0.2kPa‘--41.37Mpa

Basic Accuracy: 0.1; Range Ratio: 40:1;

No interaction between zero-setting and range adjustment;

Remote range, local range and zero setting,

‘Two-wire system in conformity with HART® protocol that enables digital communications

through ROSEMOUNT®275 or MS-HART375 Hand Held Terminal without interruption of the

analog output;

Built in non-losable memory:

© High stability, high precision, adjustable damping and strong abilty on one-way overload

protection;

‘© No mechanical transmission parts therefore less maintenance; sturdy and vibration proof

‘© Simple maintenance thanks to the application of all common units exchangeable: no influence

on the interchanging of the sensor andior electronic circuit board:

© Optional materials for the chaff that contacts the medium:

© Proved excellent performance and reliability,

MDMB30S1 Series Smart Transmitters Manual

MDM3081 series could be applied in various kinds of applications, such as liquid, gas and steam,

measuring the pressure (differential pressure, gauge pressure, and absolute pressure), flow as

well as liquid level. According to its wide usage, this series could be classified as.

MDM3051GP Gauge Pressure Transmitter

MDM30510P Differential Pressure Transmitter

MDM3051HP High Static Pressure Transmitter

MOM3051AP Absolute Pressure Transmitter

MDM3051LT Liquid Level Transmitter

MDM3051GP Remote Transmission Gauge Pressure Transmitter (in another manual)

MDM3051DP Remote Transmission Differential Pressure Transmitter (in another manual)

MDM3051 could be configured and calibrated by MS-HART232 Configuration/Debugging Too!

MS-HART375 Hand-Hold Terminal or ROSEMOUNT*275 Communicator Through the

‘communicator or tool, you can communicate with a transmitter from the controi room, the

transmitter site, or any other wiring terminal in the loop. MDM3051 could also be reranged by

Using the local zero and span adjustments, which is on the top of the transmitter To enable

‘communication, a resistance of at least 250 ohms must be present between the communicator

and the power supply. Before using MS-HART232 or MS-HARTS75, you should read relevant

manual carefully.

‘MDM3051 Series Smart Transmitters Manual

Section 2 Start-up

2.4 Overview

The MDM3051 may be rechecked in the laboratory or field before using, Now list the operation

process in Figure 2-1

START HERE

Bench

| ceck Swiches and Jumpers

Wire Transmiter

ower Transmiter

=

Tr Trane or Mounting

aaa)

one

Maintenance snaona

Figure 2-1 Transmitter Recheck Flowchart

2.2 Failure mode alarm

‘The MDM3051 automatically and continuously performs self-iagnostic routines If the

self-diagnostic routines detect a failure, the transmitter drives its output outside of the normal

saturation values,

How to differentiate the alarm current and the saturated current? The alarm current is happened

when the transmitter makes a mistake, and the saturated current because of the pressure beyond

the measure range. The alarm type is decided by the failure mode, and the saturated output by the

input pressure. Itll output the 21mA when the pressure is higher than the upper range jimi, in the

opposition, output the 3.9mA. The transmitter can exit the saturated status once the pressure

retums back to the normal

MDM30SI Series Smart Transmitters Manual

Removing the housing cover opposite the field terminal side, you will see the alarm jumper on the

Loo.

Figure 2-2 LCD Display

Electronic circuit board

‘Taking out the LCD display, you will see the alarm jumper on the top right corner of the electronic

board.

Figure 2-3 Electronic Circuit Board

MDM3O51 Series Smart Transmitters Masta

The transmitter will drive its output low or high based on the position of the failure mode alarm

jumper. The short jack could be set on the left (U) or right (D).

With LCD Display.

__[ NoLCD Display

LUCE Diels

Electronic board [Electronic board

Low Down(0) TDown'5)

High Down (D) | Up wu)

Up) ee +

Up (U) Down) |

The alarm jumper is position Down (D) by default. It could be reposition on the bench or in the

field,

2.3 Self-test

‘The MDM3051 automatically and continuously performs selt-test routines, and exports ihe result

by the current or HART communication,

2.4 Loop test

The loop test feature is designed to verify proper loop wiring and transmitter output, and should

only be performed after you install the transmitter. The transmitter test feature is designed to verity

that the transmitter is operating properly, and can be performed either on the bench or in the field

MDM305I Series Smart Transmitters Manual

Section 3 Installation

Measurement accuracy depends upon proper installation of the transmitter and imp

Mount the transmitter close to the process and use a minimum of piping to achieve best accuracy

Also, consider the need for easy access, personnel safety, practical field calibration, ana suitable

transmitter environment. Install the transmitter to minimize vibration, shock, and temperature

fluctuation,

3.1 Mounting of transmitter

‘There are 3 kinds optional mounting brackets for the MDM3051 series transmitter (GP, DP. AP HP

and remote transmitter). Traditional mount mode likes the figure 3-6. At first, mount the trans

fon the bracket with 4 bolts, then fix the B1~B3 brackets in the horizontal or vertica! posit

U-bolt or B2 bracket on the instrument plat with M10 bolt. For MDM051LT. it needs the mou

flange (figure 3-5)

mite

ng

MDM3051 process pressure connections on the transmitter flange are 1/4~18 NPT Flange

‘adapter unions with 1/2-14 NPT connections is benefit for taking down, User only need remove

the bolt to part the transmitter and process connection. Il increase or decrease 3mm between the

two impulse centers if tuming around the flange adapter unions, To ensure the hermetic betwee:

the flange and adapter, use the following bolt instalation procedure

1. Finger-tighten the bolt.

2. Torque the first bolt to the intial torque value using a crossing pattern

3. Torque the second bolt to the final torque value using the same

4, Torque the first bolt again to the final torque value using the same

‘The torque value is 34N + m,

‘Mounting the transmitter in any other position will shift the zero point So, should adjust the zero

Point

Note: LCD display can be rotated for easy watching.

3.2 Impulse piping

The piping between the process and the transmitter must accurately transfer the pressure to

obtain accurate measurements. The best location for the transmitter in relation to tne process pipe

depends on the process itself. Use the following guidelines to determine transmitter location and

placement of impulse piping:

+ Keep impulse pipes as short as possible.

+ Prevent sediment deposits in the impulse piping

‘+ Keep the liquid head balanced on both legs of the impulse piping

‘+ Make sure both impulse legs are the same temperature,

‘© Avoid the hot and corrosive material contact with transmitter.

MDM305t Series Smart Transmitters Manual

For gas service, slope the impulse piping at least in the vertical or 45-degree upward from the

transmitter toward the process connection. Mount the transmitter beside or above the taps so to

drain liquid into the process line.

For liquid service, slope the impulse piping at least in the horizontal or 45-degree downward from

the transmitter toward the process connection. Mount the transmitter beside or below the taps so

gases vent into the process line.

: For steam service, slope the impulse piping at least in the horizontal or 45-degree upware from ine.

transmitter toward the process connection for condensate vent into the impuise pipe.

Refer to Figure 3-1 3-2 for examples of the following mounting configurations:

Steam condition Liquid condition

Figure 3-2. Installation Exampies

1. Pressure leak

MDM3051 Series Smart Transmitters Manual

2. Rubbing loss of pressure import conduit

3. Gathered gas in liquid medium conduit

4. Gathered liquid in gas medium conduit

For the transmitter with D1 or 02 selection, place taps in side of the line. Mount drain/vent valve

{upward to allow gases to vent in Liquid Flow Measurement, and downward to allow liquids to vent

in Gas Flow Measurement. The drain/vent valve wil turn from top to bottom when flange rotated

180 degree.

There are five possible sources of error: pressure transfer, leaks, friction loss (particularly if

urging is used), trapped gas in a liquid line, liquid in a gas line

Note: For steam or other high temperature process object, the medium touch the

transmitter should not beyond the transmitter temperature limit.

3.3 Mounting requirements

‘© Use impulse pipes large enough to avoid friction effects and blockage

© Vent all gas from liquid piping legs.

© Mount the transmitter below the taps to ensure that impulse piping will remain filed with

condensate.

‘© Fill impulse lines with water to prevent steam from contacting the transmitter directly and to

ensure accurate measurement start-up.

© For steam or other elevated temperature services, it is important that temperatures at the

process flanges must not exceed the using limit.

‘© Impulse pipe should have enough intensity in high-pressure measure

3.4 Wiring connecting and power up

The transmitter terminal block is in the compartment of the electronics housing To make

connections, remove the housing cover on the side marked “FIELD TERMINALS. "(Figure 3-3).

Leff is signal terminal (PWR and COMM), right is test terminals (TEST).

Connect the lead that originates at the positive side of the power supply to the terminal marked "+"

‘and the lead that originates from the negative side of the power supply to the terminal marked "~”

Do not connect the powered signal wiring to the TEST terminals. Power could damage the test

diode if connect power to TEST directly.

Plug and seal unused conduit connections on the transmitter housing to avoid moisture

‘accumulation in the terminal side of the housing. If you do not seal the unused connections, mount

the transmitter with the electrical housing positioned downward for drainage. Install wiring with a

drip loop. Arrange the drip loop so the bottom is lower than the conduit connections and the

transmitter housing,

Use shielded twisted pairs to yield best results. Do not run signal wiring in conduit or open trays

‘

MDM30S1 Series Smart Transmitters Manual

with power wiring, or near heavy electrical equipment. You may ground the signal wiring at any

‘one point on the signal loop, or leave it ungrounded, The negative terminal of the power supply is

@ recommended grounding point. Device must be properly grounded or earthed according to local

electric codes.

The transmitter could ignore the 1V voltage fluctuate. It only uses the 100V mega-ohm meter for

circuitry check.. For 4-20mA transmitter, i's output doesn't exceed the 22mA DC

3.5 Dangerous locations

Use the following guidelines to keep the explosion-proof ability of transmitter:

‘+ Tighten the cover, no less than 6 buckles, not damage the screw thread

+ No less than 6 buckles between the sensor and electronic house. Not damage the screw

thread

‘+ Plug and seal unused conduit connections on the transmitter housing, no less than 6

buckles.

+ Ensure the seal between the circuit block and the terminal block

MDM3OS1 Series Smart Transmitters Manual

3.6 Dimension drawings (MDM3051 GP/AP/DP/HP)

Namesite

remove shan o-oo range aust ae opts

Colste space fore remot of re an cover inn)

fea. Si

“he cuit bond

‘ya -1aNeT

ng teil ice

amber wtnou eure

Measuring Range | 3,4,5

(Code)

Mimm)

Figure 3-4 Dimension

MDM3O051LT transmitter flange size and dimension drawings:

Flange size (mm)

[Bait hoie (mm)

Code _| Size | Specification | Diameter | A | 8 | C | Amount|Diameter|Oistabution dameter

[TA ) 3"? 150 [1905s [a0] 8/127} 4 | 18 | 152

Bo | 4") 150Ib 228.6 |30| 89/157) 8 | 19 | 190

C | 3"| 300 | 209.6 |a5} 66} 127 8 | 222) ta

Diane 3001b 254 | 38] 99] 157] 8 | 22.2 | 200

Nameplate

(rarove when zeoseting a age shane ar operated)

. Wiring terminal se

u

‘acon com OO Te cu

r Ar-s4NPT ior? sug inge

aoe {BNP foe ang

coupling without couping

MDM30S1 Series Smart Transmitters Manual

Figure 3-§ MDMS051LT Flange Size and Dimension

MDM3051LT Transmitter weight.

ten crater ~

quid evel

Instat fangs —~

]

Flat flange | 2" insert tube | 4" insert tube 6” insert tube

| i0.7kg

| 42) ABODE || 11.6kg 12.9kg | 13.9kg | 14.8kg

a 300Ib 11.1kg 12.1kg | 12.5kg | 12.9kg

4" 300b | 15.7kq | t7kg | 18g | 22 9g

MDM30S1 Series Smart Transmitters Manual

3.7 Typical installation drawings ,

Drawing for horizontal pipe-type

Drawing for vertical tube mounting

; eS Ey

{ SES . =

Pe

Drawing for vertical plate mounting : .

4 wept

Ht

4

eh

MDM3051 Series Smart Transmitters Manual

Section 4 Configuration and Debugging

4.1 Menu tree

MS-HART232 menu tree

[— Attribute [> Manufactor ID

Device Type

Tag

Poll Address

Information Message

Tag

Date

Describe

Offine Sensor no

Sensor ulv

Sensor liv

Sensor min span

> materia

[Sale Unt} — contgure —-> unt

| uw

ey

Damping

Online |———>} Transfer function

‘Analog Output

‘Alarm

Display

Multidop +>} Module type

Ls Module code

[-— Monitor —————+PV PV %

Current

Temperature

[comm Calibration ® Current Trim

‘> Variable Trim

Maintenance —{~ Format

|__, Additional status

[-— Propoty ——$ Manufacture ID

Device Type

Device ID ete.

Remove

Figure 4-1 MDM3051 Command Tree

MDM3O5I Series Smart Transmitters Manual

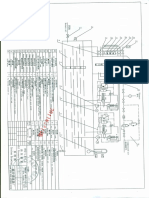

MSHART232 Debvaning/Conigution System

Note: Applied HART® communication signal, load resistance R, #2500

Figure 4-3 Field Transmitter Loop Connection

MDM30SI Series Smart Transmitters Manual

4.2 MS-HART232

4.2.1 Ready

Connect the Software Lock to your LPT

Make sure RS-232 connect with the PC serial port

Setup the MS-HART232 software

Enter the main window of MS-HART232

Set up serial port

Pall the online device

4.2.2 Configuration

If found a device, click the Right Button on the listed device to open the Device Menu.

Figure 4-4 Online Function Menu

Click the left button to choose the “Configuration”.

MDM3051 Series Smart Transmitters Manual

Figure 4-5 Status Window for range, unit and damping

‘The PV Unit command sets the process variable units to allow you to monitor your process using

the appropriate units of measure. Set the unit from the unit list box Enter the lower range value

(LRV) and the upper range value (URV) in the fields provided. Click Apply.

‘The Range Values command sets the 4 and 20 mA points (lower and upper range values). Setting

the range values to the limits of expected readings maximizes transmitter performance. Reranging

using the tool and a pressure source or process pressure is a way of reranging the transmitter

When specific 4 and 20 mA points are not known. This method changes the values of the analog 4

‘and 20 mA points. When you set the 4 mA point the span is maintained; when you set the 20 mA

point the span changes. If you set the lower range point to a value that causes the upper range

point to exceed the sensor limit, the upper range point is automatically set to the sensor limit, and

the span is adjusted accordingly.

Figure 4-6 Configuration Window for alarm and converting function

To set the minute pressure and reverse output transmitter, ts same as above. If you want to

rerange to 0~20kPa, enter the 20kPa to the lower range point and OkPa to the upper range point.

6

MDM30S1 Series Smart Transmitters Manual

‘So 20kPa is according to 4mA, OkPa to 20mA.

4.2.3 Set output

Click the Right Button on the listed device to open the Device Menu. Click the left button to choose

the “Configuration”. Select the page “Output function’

Activate the transmitter square root output or linear output

4.2.4 Zero trim

CCick the Right Button on the listed device to open the Device Menu. Click the left button to choose

the Calibration->Variable Trim’. Select the page “Compensate"

Figure 4-7 Compensation window for main variables

Azero trim is a simpler, one-point adjustment. It must be zero-based. Its useful for compensating

for mounting position effects or for zero shifts due to static pressure in differential pressure

applications.

4.3 Locate adjustment

It is also possible to rerange the transmitter using the span and zero magnistor. Remove the

Certification Label on the top of the MDM3051, hold both the span and zero buttons down

simultaneously to activate the controls.

Press the zero button for five seconds to set the 4mA point. Verify that the output is 4mA. Apply a

pressure equivalent to the higher calibrated value to the high side of the transmitter. Press the

span button for five seconds to set the 20mA point. Verity that the output is 20mA.

‘On the face of the LCD, there is the upscale/downscale switch to set the failure mode alarm signal.

MDM305I Series Smart Transmitters Manual

Zero and range adjust button

Figure 4-8 Field zero setting and range adjustment

anon

FIX py v

1.8.8.8.8 &

‘QERee

Figure 4-9 LCD multifunctional display

4.4LCD display

The Meter Options command allows you to customize the LCD display for use in your application,

You can configure the display to display the following information:

‘+ Engineering Units

+ Percent of Range

© Output current

«Temperature

MDM30SI Series Smart Transmitters Manual

4.4.4 Display PV

200.0

il

Figure 4-10 Display PV

4.4.2 Display PV%

%

sooo)

Figure 4-11 Display PV%

4.4.3 Display Current

12000

Figure 4-12 Display current

4.4.4 Display Temperature

200d |

ie

Figure 4-13 Display temperature

A.5 Display Insecurity

AdERR

Figure 4-14 Display insecurity

MDM30S1 Series Smart Transmitters Manual

Section 5 Operation and Maintenance

5.1 Brief introduction

MDM3051 almost doesn't need the maintenance for there is no mechanical pressure transfer

‘component. Please read the manual before use MDM3051

Caution:

© Be careful in operating if the measure material has the causticity or high temperature. Not

‘splash the liquid on the other component or operator from the process adapter,

© The electronics board is electrostatically sensitive; observe handling precautions for

static-sensitive components

@ The device used in calibration must be meeting the standard precision, or else It! influence

the transmitter. Please return back the transmitter to the manufactory to retrim.

5.2 Verifying device and tool

Verify device:

Standard pressure source, 24v power supply, high Precision Multi-Meter, MS-HART37S or

MS-HART232,

‘Assembly and Disassembly toot:

Screwdriver, crossing pattem etc.

5.3 Disassembly process

Caution:

‘The sensor of MDM3051LT and range 3 should not be disassembled.

© Disconnect the power source from the transmitter. Remove the bolts.

© Electrical connections are located on the terminal block in the compartment labeled "FIELD

TERMINALS.” Loosen the two small screws and pull the entire terminal block out to remove it

© Remove the housing cover opposite the field terminal side. Loosen the two captive screws

that are visible on the right and left side of the meter display,

© Loosen the two captive screws that anchor the board to the housing. Slowly pull the

electronics board out of the housing, With the two captive screws free of the transmitter

housing, only the sensor module ribbon cable holds the board to the housing

© Disconnect the sensor module ribbon cable to release the electronics board from the

transmitter.

‘The sensor module ribbon is permanent connected with the sensor. Needn't to disassembly,

Carefully tuck the cable connector completely inside of the internal shroud, Do not remove the

housing unti after you tuck the cable connector completely inside of the intemal shroud, The

shroud protects the cable from damage that can occur when you rotate the housing

Loosen the lock bolt to take down the electronic house

© Remove the flange bolts.

»

MDM30SI Series Smart Transmitters Manual

‘Scrub away the Isolating Diaphragms by soft cloth, purging by water

‘The sensor can rotate in the flange for convenience the installation,

5.4 Assembly process

5.5 Checking and interchant

Inspect all cover and housing (non-process wetted) O-rings and replace if necessary. Lightly

«grease with silicone lubricant to ensure a good seal

Ensure the 6 buckles for explore-proof of requirements.

Carefully tuck the cable connector completely inside the intemal shroud. To do so, turn the

shroud and cable counterclockwise one rotation to tighten the cable.

Lower the electronics housing onto the module. Guide the internal shroud and cable through

the housing and into the external shroud,

Turn the housing clockwise the fasten it to the module,

The housing must be no more than 6 full turn from flush with the sensor module to comply

with explosion proof requirements.

Visually inspect the Teflon sensor module O-rings. MOM3051GP9E and OE add the metal

‘support ring under it.

Install the process flange on the sensor module. To hold the process flange in place, tighten

the bolts with 20~50N + M.

Insert the electronics board into the housing, making sure that the posts from the electronics.

housing properly engage the receptacles on the electronics board. Tighten the captive

‘mounting screws,

Replace the LCD and electronics housing cover.

1g of components

Sense organ checking:

Sense organ can't repair in field. If you found damage, such as Isolating Diaphragms broken down

or cil leak, it must be changed. Ifnot, it automatically judges the status by the communication.

Electronic checking:

Self-diagnose the transmitter by the communication. If you not confirm, change the board, The

electronics board is electrostatically sensitive; observe handling precautions for static-sensitive

‘components. Retrim the transmitter to judge if il work well

No matter what the range and output, the flange, adapter, electronic housing, LCD, cover and

bracket all can be interchanged. The electronic board and sensor also interchanged, but

re-calibrate better.

a

MDM3O51 Series Smart Transmitters Manual

5.6 Drawings of transmitter components

1. Extended Cover 2. Cover O-ring 3. LCD Display 4,Electronic board § Board spaces

6.Conduit connection 7.Cettification Label 8.Terminal Block 9.Cover 10.Flange bolts

11.Process flange 12.Process O-ting 13.Sensor 14.Sensor O-ring 15.plug 16.Lock bolt

17.Electronic housing 18.Name plate 19.Drain/Vent Valve 20.Flange O-ring 21.Flange

Adapters,

22.Adapter bolts23 Flange nuts 24.Blank Flange for AP and GP Transmitters

Figure 5-1 MDM3051 GP, AP, HP components

2

MDM30S1 Series Smart Transmitters Manual

Section 6 Work Principle

‘The major component of the MDM3051 is the sensor module and the electronics housing, The

sensor module contains the oil fled sensor system (isolating diaphragms, oil fill system, and

Sensor) and the sensor electronics. The sensor electronics are installed within the sensor module

and include a temperature sensor, a memory module, and the capacitance to digital signal

Converter (C/D converter). The electrical signals from the sensor module are transmitted to the

‘output electronics in the electronics housing. The electronics housing contains the output

electronics board (microprocessor, memory module, digital to analog signal converter or DIA

converter), the local zero and span buttons, and the terminal block.

!

jane

[Comrancston

Principle Block Diagram of MDWIS05 1

Figure 6-1 MDM3051 block diagram of operation

6.1 Sensor module

‘Sense organ

For the MDM3051 design pressure is applied to the isolating

diaphragms and filled oil. The diaphragms which is the flexibility

‘component locate in the 6 room to measure the differ pressure.

Its displacement is direct proportion with the differ pressure. The

‘max displacement is 0.004inch (0.10mm). Then the oil deflects

the center diaphragm, which then changes the capacitance.

Signal processing [otaion cna Encooes by Wobding

This capacitance signal is then changed to a digital signal in the Groin of ccsny Eons

CID converter.

MDM30SI Series Smart Transmitters Manual

Temp. Sensor

The microprocessor then takes the signals from the temperature sensor and G/D converter

calculates the correct output of the transmitter.

‘Sensor memory module

‘Save the temperature compensates and sensor character data etc. It sil stores whole these data

in the EEPROM when power off. The total memory of EEPROM is 512 bytes

6.2 Electronic circuit board

Microcomputer

Microcomputer controls the work of the transmitter It inspects the pressure and temperature by

the signal processing and temperature sensor. Microcomputer also uses the data store in the

EEPROM to linearization and compensates, and takes out the pressure value that send to the D/A

conversion and HART communication. it make sure in-influence the output when interchange the

‘sensor and electronic board.

Besides these functions, microcomputer could change the output function, unit, rerange, damping

and self-diagnose.

Module Memory

‘Save the data from the location and remote trim. It still stores whole these data in the EEPROM

when power off. The total memory of EEPROM is 512 bytes.

Digital-to-Analog Signal Conversion

The signal is then sent to the D/A converter, which converts the signal back to an analog signal

Digital Communication

Supply an interface between the transmitter and MS-HART375 or MS-HART232. It superimposes

the FSK signal on the 4-20 mA output.

‘According the HART protocol, the transmitter’s poll address can be set from 0 to 15. When the

address is 0, the transmitter output the 4-20 mA with the digital signal base on HART protocol

When not 0, the transmitter fixes the current at 4 mA. There no more than 15 transmitters could be

Connected on the single loop, the pressure signal only send by the HART communication

Cause: = |

If custom change the poll address by unconsciousness or consciousness, the transmitter will |

always output 4mA, and not send analog signal again. So you should check the address when |

find the current not change with the input pressure. |

24

MDM30SI Series Smart Transmitters Manual

Section 7 Technical Performance

7.1 Technology performance

Applicable object: liquid, gas, or stream

Range: Refer to the catalogue

Cutput signal: 4-20 mA with digital signal base on the HART protocol

Power supply: 24V DC (Range from 12V~45V)

Load Characteristics:

1650

oo Nola. HART Communications requires the loaa

a 1000 - resistance to be between 250." and 100

300 -

al EE [2 Output 4-201, de onty

nom “6 TB 4-20mA de and HART communications

Load Characteriste Diagram | Operating Votage (V)

Figure 7-1 Load Characteristics

Dangerous locations:

Explosion proof dlICTS

Intrinsical safety iallCTS

Migration Characteristics:

-URL Max minus migration | Max positive migration

Figure 7-2 Migration characteristics

No matter what the output, the range doesn't exceed the sensor limit after the transfer. At lower

range point, the max positive transfer is 0.875URL and the max minus transfer is URL. Absolute

pressure and flow transmitters have no minus transfer. The positive transfer could adjust 10%

range of flow transmitter.

Temperature range

‘Medium temperature: -40~104°C

Storage temperature: -40~85°C

Operating temperature.

-40~85°C

-20~70°C (with LCD option)

Relative humilty:0~100%

as

MDM3051 Series Smart Transmitters Manual

Pressure overloads

Range lower than 6.89Mpa, apply pressure 0~13.8Mpa;

Range lower than 20.68Mpa, apply pressure 0~31.2Mpa;

Range lower than 41.37Mpa, apply pressure 0~61,45Mpa;

Volume deviation: Less than 0.16cm?

Damping

‘Adjustable 0.2~32.0s

Start-up:

35, warm-up free

7.2 Performance index

(No transfer, 316SST Isolating Diaphragms, silicon oil and other standard condition)

Range ratio: 40:1

Accuracy:

Ranges 3~6 except the AP, LT, and HP

0.1% of calibrated span from 1:1 to 10:1 of URL.

+£0,05(1+0.1URLispan)% of span for spans from 10:1 to 40-1 of URL.

Ranges 6~0 except the AP, LT, and HP

40.15% of span for spans from 1:1 to 10:1 of URL

+#0.075(1+0.1URUspan)% of span for spans from 10:1 to 40:1 of URL

Stability

40.15% of URL per 6 month

‘Ambient Temperature Effect

40.25% /55 °C of URL for zero error

40.5% /55 °C of URL for total range error

The target should be double for range 3, 9, 0

Static Pressure Effect

Zero error: (DP at linear Output)

Range 4,5: 20.25% of URL/ 13. 8MPa

Range 3,6,7,8: #0.5% of URL/ 13.8Mpa

This is system error that could be cleared by zero adjustment.

Zero error: (HP at linear Output)

ALL Range: 42.0% of URL /31.2MPa

This is system error that could be cleared by zero adjustment.

Power Supply Effect:

Less than £0,005% of calibrated span per volt.

Vibration Effect

Vibration effect is less than 40.05% of URL per g when tested 200 Hz in any axis relative,

Load Effect:

No load effect in the operation region when up the 12V power supply.

Installation Position Effect

Zero shifts up to no more than 0.25kPa, which can be calibrated out. No span effect

The measure shell tum around the flange has no effect except the LT

2%

MDM30S1 Series Smart Transmitters Manual

7.3 Construction index

Process Wetted Parts:

Process Isolating Chaff: 316 SST, Hastelloy C, Monel, Tantalum

Drain/Vent taps: 316 SST, Hastelloy C, Monel

Flange and Coupling: 316 SST, Hastelloy C, Monel

Wetted O-rings: Buna-N, Ethylene-Propylene, Viton

Non-Wetted Parts:

Fill Fluid: Silicone oil or inert oil

Bolts: Galvanized carbon steel

Electronics Housing: Low copper aluminum alloy

O-rings: Buna-N

Coating: Polyurethane

Connecting Fitting for Pressure Import

Flange 1/4-18NPT (tapered tube thread);

Coupling 1/2-14NPT (tapered tube thread)

High pressure side of LT: 3", 4" flange

Electrical Connections:

12-14 NPT conduit.

Weight

3.5kg (optional parts not included, LT is 8.9~22.9kg)

n

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- PackDocument1 pagePackNguyễn Văn QuýNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Dien Tu Cong Suat - Ebookbkmt - Removed PDFDocument498 pagesDien Tu Cong Suat - Ebookbkmt - Removed PDFNguyễn Văn QuýNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- He Thong Dieu Khien SCADA Trong He Thong Dien - Removed PDFDocument142 pagesHe Thong Dieu Khien SCADA Trong He Thong Dien - Removed PDFNguyễn Văn QuýNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Pack 1Document1 pagePack 1Nguyễn Văn QuýNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Sua Chua Quan Lai Dong Co Dien - Password - Removed PDFDocument202 pagesSua Chua Quan Lai Dong Co Dien - Password - Removed PDFNguyễn Văn QuýNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- ZCT-ZCX Series Shaft Current Monitoring Device PDFDocument5 pagesZCT-ZCX Series Shaft Current Monitoring Device PDFNguyễn Văn QuýNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- ZXZ Series Speed Measure and Control Meter PDFDocument9 pagesZXZ Series Speed Measure and Control Meter PDFNguyễn Văn QuýNo ratings yet

- D4251SS水轮机使用说明书Document29 pagesD4251SS水轮机使用说明书Nguyễn Văn QuýNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- He Thong Dieu Khien SCADA Trong He Thong Dien - Removed PDFDocument142 pagesHe Thong Dieu Khien SCADA Trong He Thong Dien - Removed PDFNguyễn Văn QuýNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- YK-103 Oil Pump Control Assembly Drawing PDFDocument12 pagesYK-103 Oil Pump Control Assembly Drawing PDFNguyễn Văn QuýNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- XWT-122C Intelligent Digital Tempurature Regulating Instrument PDFDocument12 pagesXWT-122C Intelligent Digital Tempurature Regulating Instrument PDFNguyễn Văn QuýNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- 2CY Type Gear Oil Pump Operation Instruction PDFDocument7 pages2CY Type Gear Oil Pump Operation Instruction PDFNguyễn Văn QuýNo ratings yet

- The Principle and User Manual For CVT-XX Digital Hydraulic Turbine Governor PDFDocument71 pagesThe Principle and User Manual For CVT-XX Digital Hydraulic Turbine Governor PDFNguyễn Văn QuýNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- 1250KN Load Test Hydro Cylinder PDFDocument12 pages1250KN Load Test Hydro Cylinder PDFNguyễn Văn QuýNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- DDF - Type Electric Buffterfly Valve PDFDocument8 pagesDDF - Type Electric Buffterfly Valve PDFNguyễn Văn QuýNo ratings yet

- YK-103 Oil Pump Control Assembly Drawing PDFDocument12 pagesYK-103 Oil Pump Control Assembly Drawing PDFNguyễn Văn QuýNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- ZJCQ Type Turbine Oil Purifier Operation Instruction PDFDocument15 pagesZJCQ Type Turbine Oil Purifier Operation Instruction PDFNguyễn Văn QuýNo ratings yet

- Oil Pressure EquipmentDocument13 pagesOil Pressure EquipmentNguyễn Văn QuýNo ratings yet

- Stage Suction Piping Centrifuge Pump PDFDocument15 pagesStage Suction Piping Centrifuge Pump PDFNguyễn Văn QuýNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- MDM3051 Series Smart TransmittersDocument29 pagesMDM3051 Series Smart TransmittersNguyễn Văn QuýNo ratings yet

- XWD Series Intelligent Itinerant Inspection Meter PDFDocument13 pagesXWD Series Intelligent Itinerant Inspection Meter PDFNguyễn Văn QuýNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Installation & Operation Instructions Fo 100kv Power Transformer PDFDocument28 pagesInstallation & Operation Instructions Fo 100kv Power Transformer PDFNguyễn Văn QuýNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Turck Follow Sensors PDFDocument4 pagesTurck Follow Sensors PDFNguyễn Văn QuýNo ratings yet

- Installation & Operation Instructions For 100kv Dry-Type Transformer PDFDocument9 pagesInstallation & Operation Instructions For 100kv Dry-Type Transformer PDFNguyễn Văn QuýNo ratings yet

- Instruction For Installaion and Application PumpDocument24 pagesInstruction For Installaion and Application PumpNguyễn Văn QuýNo ratings yet

- ExDrawing PDFDocument53 pagesExDrawing PDFNguyễn Văn QuýNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- HYZ Oil Pressure Tank PDFDocument12 pagesHYZ Oil Pressure Tank PDFNguyễn Văn QuýNo ratings yet

- Installation & Operation Instructions For Dry-Type Transformer PDFDocument9 pagesInstallation & Operation Instructions For Dry-Type Transformer PDFNguyễn Văn QuýNo ratings yet

- Indoor Hight Voltage Vacuum Circuit Breaker PDFDocument25 pagesIndoor Hight Voltage Vacuum Circuit Breaker PDFNguyễn Văn QuýNo ratings yet

- Ex Outline of Ex-Work Test PDFDocument17 pagesEx Outline of Ex-Work Test PDFNguyễn Văn QuýNo ratings yet

- SRE EcualizadoresDocument3 pagesSRE EcualizadoresWilson Yecit OrtizNo ratings yet

- Al811 RF Amplifier Notice SchemaDocument13 pagesAl811 RF Amplifier Notice SchemaBilles GatesNo ratings yet

- Standard Marine Navigational VocabularyDocument26 pagesStandard Marine Navigational VocabularyNaeem80% (5)

- Alga 10-500W - C-Band - Outdoor BucDocument2 pagesAlga 10-500W - C-Band - Outdoor BucGualbert Nourdine RaharimanantsoaNo ratings yet

- Low Pass Filter DesignDocument6 pagesLow Pass Filter DesignashfaqNo ratings yet

- Nero's Class: A Surreal Audio OdysseyDocument2 pagesNero's Class: A Surreal Audio OdysseyAlberto G.No ratings yet

- Flightplan 3Document45 pagesFlightplan 3AnshNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- EMF Courses and Prerequisites OverviewDocument2 pagesEMF Courses and Prerequisites OverviewPopescu AndreeaNo ratings yet

- Point To Point SDH-PDH PDFDocument2 pagesPoint To Point SDH-PDH PDFAfanNo ratings yet

- Project Enlace Santa Ana-Ues: Linkplanner PTP Installation Report 02 December 2017Document16 pagesProject Enlace Santa Ana-Ues: Linkplanner PTP Installation Report 02 December 2017Milton EspinozaNo ratings yet

- Callbook Repetoare 16 03 2020Document24 pagesCallbook Repetoare 16 03 2020Florin NicolaNo ratings yet

- 19 Pre-Emphasis and De-EmphasisDocument8 pages19 Pre-Emphasis and De-EmphasisMohamed ShabanaNo ratings yet

- DELAROSAMDocument2 pagesDELAROSAMDenisse Torizo OlanNo ratings yet

- JV33-130 160BS Operation D201887-V1.6Document206 pagesJV33-130 160BS Operation D201887-V1.6sergeiyossarianNo ratings yet

- Pulse Code Modulation and DemodulationDocument48 pagesPulse Code Modulation and DemodulationHasib PeyalNo ratings yet

- ArunDocument26 pagesArunNikhil SinghNo ratings yet

- JVC Radio ManualDocument32 pagesJVC Radio ManualmeNo ratings yet

- X-Dipole Logging Tool (XDLT) : DescriptionDocument2 pagesX-Dipole Logging Tool (XDLT) : DescriptionunduhNo ratings yet

- GOC NotesDocument14 pagesGOC NotesJohn MarkNo ratings yet

- MCQ in Noise Chapter 2 ReviewerDocument5 pagesMCQ in Noise Chapter 2 ReviewerDennis ANo ratings yet

- Phillips Service ManualDocument338 pagesPhillips Service Manualalopezcuervo100% (1)

- Dual-Band Combiner: 1710 - 2180 MHZ 2400 - 2700 MHZDocument1 pageDual-Band Combiner: 1710 - 2180 MHZ 2400 - 2700 MHZVíctor RomeuNo ratings yet

- Manual The Load & A-2 Mod 737Document13 pagesManual The Load & A-2 Mod 737Checomus PrimeNo ratings yet

- DC 800Document5 pagesDC 800Xavier TudelaNo ratings yet

- Eze Solomon Onyekachi : (B.Eng)Document2 pagesEze Solomon Onyekachi : (B.Eng)Onyekachi JackNo ratings yet

- BMED Scroll Medical Air Compressor System NFPA Instruction Book 4107900069Document100 pagesBMED Scroll Medical Air Compressor System NFPA Instruction Book 4107900069Esteban AlvarezNo ratings yet

- Fa170 Installation ManualDocument90 pagesFa170 Installation ManualGourisankar MajumderNo ratings yet

- 3.1 Intercarrier Interference in Ofdm SystemsDocument14 pages3.1 Intercarrier Interference in Ofdm SystemsSahariar Bin ShafiqueNo ratings yet

- Rules For Making Bode Plots - One Page SummaryDocument1 pageRules For Making Bode Plots - One Page SummaryMikaNo ratings yet

- What Is The Difference Between FR-4 Material and Rogers Material (Full Comparison)Document9 pagesWhat Is The Difference Between FR-4 Material and Rogers Material (Full Comparison)jackNo ratings yet