Professional Documents

Culture Documents

LM2500 Family of Products PDF

LM2500 Family of Products PDF

Uploaded by

abelsgOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LM2500 Family of Products PDF

LM2500 Family of Products PDF

Uploaded by

abelsgCopyright:

Available Formats

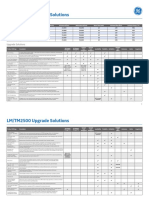

ISO performance based on natural gas with

water injection to 25 ppmvd NOx.

LM2000

18,000

9,900

134

927

NOx/CO

LM2500

22,000

9,465

149

990

NOx/CO

LM2500+

30,500

8,850

191

960

NOx/CO

Gas-DLE

25/25

25/25

25/25

Gas or Liquid-Water

25/75, 42/68

25/50, 42/30 25/60, 42/60

Gas-Steam

25/74

25/30

25/138

3,600

16

6

3,600

16

6

3,600

17

6 or 2

Power Output (kWe)

Heat Rate LHV (Btu/kWe-Hr)

Exhaust Flow (lbs/sec)

Exhaust Temperature (0F)

Emissions (ppmvd)

LM2500

Gas Turbine

Power Turbine Speed (rpm)

No. of Compressor Stages

No. of Turbine Stages

Technology

Service

Derived from the CF6 family of aircraft engines used on wide body jet liners,

the LM2500 family is a hot-end drive, two-shaft gas generator with free power

turbine. Thermal efficiencies are from 34% to 40%.

Baseload Power Capabilities of 18 - 32 MW ISO

Unsurpassed Reliability Exceeding 99%

Three Models with a High Degree of Parts Commonality

GE Aero Energy is the worlds largest aeroderivative

service provider, with a global network of field service

offices and fully equipped depots. A wide range of products and services are offered for the LM2500+, LM2500,

and LM2000 Industrial, Cogeneration, and Oil & Gas

operators, including:

Experience

GE Aero Energy offers three models in the LM2500 family of products:

LM2500+

Providing More Than 30 MW ISO

Power Generation, Marine and Mechanical Drive Applications

Available in a 6-stage or 2-stage Power Turbine Configuration

Level IV depot repair and overhaul capability

in Houston, Texas; Rheden, The Netherlands,

and Agotnes, Norway

Conversions, Modifications and Upgrades

(CM&U) designed to enhance the efficiency,

power output and reliability of the LM2500,

such as Exhaust Flow Enhancer, Wet/Dry Low

Emissions (DLE) Upgrades; Inlet Conditioning,

Fuel Conversions, Remote Monitoring and

Diagnostics, among many others

Spare or Lease Engine Options

Engine Exchange Programs

Rotable Hot Section and Module

Exchange Programs

Wide Variety of Contractual or Long-Term

Service Agreements

LM2500

Produces in Excess of 22 MW ISO

Operates at 3000 or 3600 rpm Without a Gearbox

Optional Steam Injection (STIG) for Power Enhancement

This comprehensive product offering, combined with

GE Aero Energys commitment to reduced depot and

outage turn times, results in substantial life cycle cost

savings for the plant owner/operator.

Maintaining a high degree of commonality with its flight-tested forerunners,

the LM2500 family continues to build its reputation as the most reliable

industrial gas turbine generator in its class.

40 Million Operating Hours

More than 2,000 units

End-users: Mechanical Drive and Power Generation for

Industrial Plants, Pipelines, Platforms and Marine Ships

Configurations: Simple-cycle, Cogeneration and Combined-Cycle

Innovation

LM2000

Capable of 18 MW ISO

Extended Maintenance Intervals

LM2500 60Hz Output and Heat Rate

9,900

25,000

OUTPUT (kW)

9,700

21,000

9,600

19,000

9,500

17,000

9,400

15,000

9,300

120

20

40

60

80

100

HEAT RATE (Btu /kW)

9,800

23,000

0 ft, 60% RH, 4/6 in H20 inlet/exhaust loss on natural gas

with water injection to 25ppmvd NOx water inj.

AMBIENT ( F)

LENGTH

686 x

WIDTH

149 x

HEIGHT

STANDARD 60HZ LM2500

GENERATOR PACKAGE

OPTIONAL EQUIPMENT

AND SERVICES

Gas Turbine

Generator Options

> TEWAC

> Voltages: 12.47kV

> Enclosure

> Fault Protection

Fuel System

> Liquid

Water Injection or DLE

> Dual

Water Injection or DLE

> Gas

Water or Steam Injection or DLE

> Filters

Control System

> 10 minute start

> Black start

> Continuous Emission Monitoring

> Remote Display

> Control House

> Motor Control center

Lube Oil System

> Air to Oil Coolers

> First Fill Lubricants

Winterization

Remote Monitoring and Diagnostics

Pulse Air Filter

Inlet Conditioning

> Evaporative Cooling

> Chilling

> Heating

16 Stage Axial Compressor

> 1st 6 Stages are VIGV

> Horizontal Split Casing

> 20:1 Compression Ratio

> 103 lb/s Nominal Inlet Mass Flow

Annular Combustor

> 30 Nozzles Gas Fuel, Water Injection for NOx Control

6 Stage Power Turbine

Generator

Continuous Duty 13.8kV, 0.85 PF

2 pole, 3 Phase Brushless Exciter

WPII Weather Protected

Voltage Regulator/Neutral Side Protection CTs

NEMA Class F Insulation & B Temperature Rise

Package

24V and 125V DC Batteries

90dBA Near Field Design

Barrier Inlet Air Filters

Electro-hydraulic Start System

Class I Div 2 Group D Class Electrical System

Digital Control System with a Human Machine Interface (HMI)

Turbine and Generator Lube Oil System with Simplex Shell

and Tube Coolers

Turbine Factory Tested

On/Off-line Water Wash

1 Year Parts/Service Warranty

Package Familiarization Training

Electronically Transmitted Drawings

Startup Technical Assistance

295

You might also like

- GE Frame 7FA Gas Turbine OffLine Water Wash ProcedureDocument18 pagesGE Frame 7FA Gas Turbine OffLine Water Wash ProcedurePetrovich10100% (1)

- Software EngineeringDocument129 pagesSoftware EngineeringGuruKPO93% (28)

- CatalogoPGT25 PDFDocument4 pagesCatalogoPGT25 PDFshihabjamaan100% (5)

- Gek105162 Operating InstructionDocument72 pagesGek105162 Operating InstructionMiguel Francisco Goytia100% (1)

- LM 2500Document12 pagesLM 2500pramodtryNo ratings yet

- LM2500+ Shutdown SequencesDocument6 pagesLM2500+ Shutdown Sequencesrenzobermudez89No ratings yet

- List of Illustrations: Lm6000 PD Gek 105061 Ge Industrial Aeroderivative Gas TurbinesDocument4 pagesList of Illustrations: Lm6000 PD Gek 105061 Ge Industrial Aeroderivative Gas TurbinesJHONNATTAN RODRIGUEZNo ratings yet

- 02 Fuel Change-Over GAS To LIQUIDDocument2 pages02 Fuel Change-Over GAS To LIQUIDJaroslav Kuruc100% (1)

- DLN2 6+Document10 pagesDLN2 6+Ubair Kazi100% (2)

- Generator VOL 8ADocument18 pagesGenerator VOL 8AEmadAlhosien Alhosien100% (1)

- LM6000 Gas Fuel Spec.Document11 pagesLM6000 Gas Fuel Spec.cdbeardsall100% (2)

- TM2500 Main Equipment Scope of SupplyDocument4 pagesTM2500 Main Equipment Scope of Supplyzhangj5No ratings yet

- 2020 WTUI - LM2500 Breakout Session - Virtual Conference Version - FINAL - 062420Document30 pages2020 WTUI - LM2500 Breakout Session - Virtual Conference Version - FINAL - 062420Daniil SerovNo ratings yet

- CT Inspection IntervalsDocument19 pagesCT Inspection IntervalsSantiago67% (3)

- Fuel Control Requirements: Fuel Scheduling at Steady State OperationDocument11 pagesFuel Control Requirements: Fuel Scheduling at Steady State OperationDenis Jimenez100% (2)

- GE TM2500 PowerPlant Build ListDocument16 pagesGE TM2500 PowerPlant Build Listbayu_sukmaperdanaNo ratings yet

- DP Operations Risk Management Tools (CAMO-ASOG) Rev EDocument10 pagesDP Operations Risk Management Tools (CAMO-ASOG) Rev EflegreoNo ratings yet

- Lifting & Rigging ProceduresDocument32 pagesLifting & Rigging ProceduresBrunoro DantasNo ratings yet

- Introducing The TM2500+Document19 pagesIntroducing The TM2500+Urip S. Setyadji100% (1)

- LM 2500 PlusDocument2 pagesLM 2500 Plusalexandr_popov_2No ratings yet

- Lm2500 InstrumentationDocument4 pagesLm2500 InstrumentationDenis JimenezNo ratings yet

- 04 - LM2500 OverviewDocument27 pages04 - LM2500 OverviewLudovic LeroyNo ratings yet

- Lm2500 IntroDocument4 pagesLm2500 IntroDenis JimenezNo ratings yet

- Starting Gas TurbineDocument3 pagesStarting Gas Turbineanup_nair100% (2)

- 2012 WTUI Conference LM2500 Breakout Session March 18-21, 2012Document100 pages2012 WTUI Conference LM2500 Breakout Session March 18-21, 2012ferrerick100% (3)

- TM2500 and TM2500+ Intro PagesDocument24 pagesTM2500 and TM2500+ Intro Pagesavryone0% (1)

- Theory Lm2500. Principios Basicos de OperacionDocument25 pagesTheory Lm2500. Principios Basicos de OperacionHunab379100% (1)

- CPM - Ap - Lm6000-Ind-024 (1) 2009Document64 pagesCPM - Ap - Lm6000-Ind-024 (1) 2009Victor Nahun ReyesNo ratings yet

- Ger4250 LM2500G4Document12 pagesGer4250 LM2500G4Denis JimenezNo ratings yet

- Ger 4217 ADocument30 pagesGer 4217 Atehranqom100% (2)

- PDFDocument124 pagesPDFEmanuel Conde100% (1)

- LM TM2500 Upgrade Solutions PDFDocument2 pagesLM TM2500 Upgrade Solutions PDFLibyanManNo ratings yet

- lm2500 LubesupplyDocument3 pageslm2500 LubesupplyDenis Jimenez100% (2)

- Siemens GTDocument8 pagesSiemens GThbalu007No ratings yet

- Gas Turbine MaintenanceDocument11 pagesGas Turbine Maintenancemoinuddinmohdyusuf100% (4)

- SBLM2500 Ind 217Document5 pagesSBLM2500 Ind 217Daniil SerovNo ratings yet

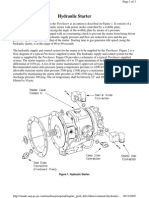

- Figure 1. Hydraulic StarterDocument3 pagesFigure 1. Hydraulic StarterDenis JimenezNo ratings yet

- GEA31503e PGP Product E-Catalog 2015 R10Document47 pagesGEA31503e PGP Product E-Catalog 2015 R10juagamsar100% (1)

- Lm2500 DescripDocument2 pagesLm2500 DescripDenis Jimenez100% (1)

- Pages From GEK105059Document29 pagesPages From GEK105059phoenix609No ratings yet

- المواد المرمزة والمطلوبة ترميزها بملف واحدDocument247 pagesالمواد المرمزة والمطلوبة ترميزها بملف واحدMahdi HassanNo ratings yet

- 073 - TM2500 FoundationDocument2 pages073 - TM2500 FoundationDanang RahadianNo ratings yet

- Gek105060 File0060 PDFDocument12 pagesGek105060 File0060 PDFHelton OliveiraNo ratings yet

- Sobreprecio 18MM: TM2500 de EPS A DerwickDocument33 pagesSobreprecio 18MM: TM2500 de EPS A DerwickTomás LanderNo ratings yet

- GT6B FoundamentalDocument53 pagesGT6B FoundamentalThanapaet RittirutNo ratings yet

- TM2500 Student ManualDocument391 pagesTM2500 Student ManualFreddy CiresNo ratings yet

- LM6000Document2 pagesLM6000Carlos J Alvarado M100% (2)

- 9e Turbine Gea16035b 9e GT HRDocument1 page9e Turbine Gea16035b 9e GT HRFedor Bancoff.No ratings yet

- Dynamics Characteristics: Figure 1. LM2500-PE Estimated Load Rejection Transient PerformanceDocument3 pagesDynamics Characteristics: Figure 1. LM2500-PE Estimated Load Rejection Transient PerformanceDenis JimenezNo ratings yet

- TM2500 and TM2500+ Intro Pages-2Document24 pagesTM2500 and TM2500+ Intro Pages-2abelsg100% (2)

- TM2500 GEN8 Mobile Gas Turbine: Key Features and BenefitsDocument1 pageTM2500 GEN8 Mobile Gas Turbine: Key Features and BenefitsIvan RinconNo ratings yet

- 9e PDFDocument12 pages9e PDFgayani100% (2)

- Lm2500 LubricationDocument2 pagesLm2500 LubricationDenis Jimenez100% (2)

- GE Aeroderivative Product and Services SolutionsDocument16 pagesGE Aeroderivative Product and Services SolutionsCory TurnerNo ratings yet

- Mars 100 PlantDocument9 pagesMars 100 PlantabelsgNo ratings yet

- Contracts ManagementDocument87 pagesContracts Managementarabi2222No ratings yet

- Monta LM25+DLE Retrofit Jul-22-2011 R0Document62 pagesMonta LM25+DLE Retrofit Jul-22-2011 R0Aitor Garcia RoviraNo ratings yet

- Detailed Hot Section Mapping of Siemens SGT 600 PDFDocument19 pagesDetailed Hot Section Mapping of Siemens SGT 600 PDFfrdnNo ratings yet

- G3516 (975 Ekw 1218 kVA)Document7 pagesG3516 (975 Ekw 1218 kVA)Antwon CharlesNo ratings yet

- g3520c Natural Gas For 1950Document6 pagesg3520c Natural Gas For 1950Shahzad AliNo ratings yet

- 3512 1275 kVA Prime Low BSFC - EMCP4 - EU PDFDocument6 pages3512 1275 kVA Prime Low BSFC - EMCP4 - EU PDFAashish MoyalNo ratings yet

- Cat C175-16 - Jul 2010Document6 pagesCat C175-16 - Jul 2010Lei YinNo ratings yet

- 3516B TaDocument6 pages3516B TaGeovanny Chasi PesantezNo ratings yet

- Sap PLM User Interface Intuitive and FlexibleDocument29 pagesSap PLM User Interface Intuitive and FlexibleAnonymous b3yPOhzNo ratings yet

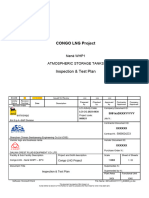

- Inspection & Test Plan TemplateDocument11 pagesInspection & Test Plan Templatefanghao5345No ratings yet

- Accounting Management SystemDocument64 pagesAccounting Management Systemnilesh50% (2)

- Kinetics and Mechanism of Chlorination of Acetanilide and Substituted Acetanilides by Chloramine-TDocument7 pagesKinetics and Mechanism of Chlorination of Acetanilide and Substituted Acetanilides by Chloramine-TWintoloNo ratings yet

- Rules For The Classification Naval Ships Part A - Classification and Surveys - Chapter 1 Al 5 - NR 483.A1 DT R01 E - 2011-11Document114 pagesRules For The Classification Naval Ships Part A - Classification and Surveys - Chapter 1 Al 5 - NR 483.A1 DT R01 E - 2011-11Marlon Alejandro Arboleda TapiaNo ratings yet

- HAAS VR11B MillOperManualDocument292 pagesHAAS VR11B MillOperManuallastowlNo ratings yet

- TLS PDFDocument36 pagesTLS PDFAmrita KhatriNo ratings yet

- Electrical Engineering PortalDocument25 pagesElectrical Engineering Portalraul_bsuNo ratings yet

- CRM Web 81Document404 pagesCRM Web 81Sriram KrishnarajuNo ratings yet

- Avoid Outbound Delivery Splitting in SAP EWM: Published On September 30, 2020Document6 pagesAvoid Outbound Delivery Splitting in SAP EWM: Published On September 30, 2020MUNAFF ACUMENNo ratings yet

- BBS 2015.1 - UK Part 1 PDFDocument109 pagesBBS 2015.1 - UK Part 1 PDFAugustin MacoveiNo ratings yet

- Presentation 1Document24 pagesPresentation 1Dinesh KumarNo ratings yet

- ISO 27002 Compliance Guide: 1 Detailed Controls Mapping 2 About Rapid7 7Document8 pagesISO 27002 Compliance Guide: 1 Detailed Controls Mapping 2 About Rapid7 7tpradeeptechNo ratings yet

- Technical Properties - Roofings - AgtexDocument3 pagesTechnical Properties - Roofings - Agtexplaner_manNo ratings yet

- Preparation Exam API 510:N°02 QuestionsDocument2 pagesPreparation Exam API 510:N°02 QuestionskorichiNo ratings yet

- 85 Irish Woodturners Guild Issue 85 PROOF 2Document64 pages85 Irish Woodturners Guild Issue 85 PROOF 2George T GallagherNo ratings yet

- Demco Butterfly Valves BrochureDocument44 pagesDemco Butterfly Valves BrochureOndRechTacLetMovNo ratings yet

- PA 32R 301 301T SaratogaDocument6 pagesPA 32R 301 301T SaratogaZawy Alkazawy100% (1)

- Chap 005Document17 pagesChap 005John BroganNo ratings yet

- Review of Literature-Car FinancingDocument5 pagesReview of Literature-Car FinancingRaj Kumar50% (4)

- CSMCRI Technician 25062013Document4 pagesCSMCRI Technician 25062013Vijay KumarNo ratings yet

- De MantraDocument4 pagesDe Mantraanishokm2992No ratings yet

- 2012 Crystal Catalog - International (Metric)Document228 pages2012 Crystal Catalog - International (Metric)CrystalFountainsNo ratings yet

- Jamcet Attendance MGMTDocument16 pagesJamcet Attendance MGMTJilly ArasuNo ratings yet

- Tugas ADSIDocument2 pagesTugas ADSITarkiman0% (1)

- 4.1 ProcurementDocument48 pages4.1 Procurementlidya50% (2)

- Miller - Joint Design and Weld TypeDocument8 pagesMiller - Joint Design and Weld Typed_beachboyzNo ratings yet