Professional Documents

Culture Documents

Project Execution Plan Procedure Coal Bin

Uploaded by

Arie MahendraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Project Execution Plan Procedure Coal Bin

Uploaded by

Arie MahendraCopyright:

Available Formats

PROCEDURE

PT. TUBAN STEEL WORK

Fabricator&Engineering Service

Rev. No

: 0

Page No

: 1 of 41

PROJECT EXECUTION PLAN

CLIENT

PT. SEMEN GRESIK (PERSERO) Tbk.

PROJECT NAME

TUBAN IV PROJECT

OUR PO NO

OUR WO NO

0

Rev. No

Doc. No

Issued For Bidding

Date Of Issue

Status

Pekerjaan Pabrikasi & Ereksi Struktur Baja Belt Conveyor 649 BC03

Cement Loading Lokasi Pelsus Semen Gresik Di Tuban

Prepared

by

Reviewed Approved

by

by

PROCEDURE

Doc. No

Rev. No

: 0

Page No

: 2 of 41

PT. TUBAN STEEL WORK

Fabricator&Engineering Service

TABULATION OF REVISED PAGES

3

SHEET

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

1

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

REVISIONS

2 3 4

REMARK

5

SHEET

TABLE OF CONTENT

COVERING SHEET

TABULATION OF REVISED PAGES

TABLE OF CONTENT

Pekerjaan Pabrikasi & Ereksi Struktur Baja Belt Conveyor 649 BC03

Cement Loading Lokasi Pelsus Semen Gresik Di Tuban

0

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

1

X

X

X

X

X

X

X

X

X

X

X

REVISIONS

2 3 4

REMARK

5

.333

PROCEDURE

1.

Doc. No

Rev. No

: 0

Page No

: 3 of 41

PURPOSE................................................................................................................6

PT. TUBAN STEEL WORK

Fabricator&Engineering Service

2.

SCOPE...................................................................................................................6

3.

DEFINITION..............................................................................................................7

3.1.

Project Execution Plan (PEP)..............................................................................................................................

3.2.

Front End Schedule.............................................................................................................................................

3.3.

Project Schedule.................................................................................................................................................

3.4.

Resources...........................................................................................................................................................

3.5.

Project Budget.....................................................................................................................................................

3.6.

Project Cost.........................................................................................................................................................

3.7.

Cost Control........................................................................................................................................................

3.8.

Current Budget....................................................................................................................................................

3.9.

Posted Cost.........................................................................................................................................................

3.10. Committed Cost..................................................................................................................................................

3.11.

Total Expense.....................................................................................................................................................

3.12. Actual Cost.........................................................................................................................................................

3.13. Total Actual.........................................................................................................................................................

3.14. Forecast to Go....................................................................................................................................................

3.15. Estimated at Completion.....................................................................................................................................

3.16. Work Package or Summary................................................................................................................................

3.17. Work Unit, known as Master Schedule...............................................................................................................

3.18. Work Item............................................................................................................................................................

3.19. Work Step or Work Sequence............................................................................................................................

3.20. Progress.............................................................................................................................................................

3.21. Baseline..............................................................................................................................................................

4.

REFERENCE............................................................................................................9

Pekerjaan Pabrikasi & Ereksi Struktur Baja Belt Conveyor 649 BC03

Cement Loading Lokasi Pelsus Semen Gresik Di Tuban

PROCEDURE

5.

Doc. No

Rev. No

: 0

Page No

: 4 of 41

DETAIL PROJECT EXECUTION PLAN PROCEDURE.........................................................10

PT. TUBAN STEEL WORK

5.1. General..............................................................................................................................................................

10

Fabricator&Engineering

Service

5.2. Project Management & Control Scheme...........................................................................................................10

5.2.1.

Duty & Responsibility........................................................................................................................10

5.2.2.

Project Communications....................................................................................................................12

5.2.3.

Project Document Control..................................................................................................................13

5.2.4.

Documents Distribution Procedure for Approval to Company..........................................................14

5.3. QA / QC Management Plan............................................................................................................................... 14

5.3.1.

QA Management Plan........................................................................................................................14

5.3.2.

QC Management Plan........................................................................................................................21

5.4. Financial Management Plan..............................................................................................................................24

5.4.1.

Introduction........................................................................................................................................24

5.4.2.

Scheme of Roll and Financial Management......................................................................................25

5.4.3.

Financial Function..............................................................................................................................26

5.5. Risk Management Plan..................................................................................................................................... 27

5.5.1.

Introduction........................................................................................................................................27

5.5.2.

Scheme of Project Risk Management................................................................................................27

5.6. Surveying Plan.................................................................................................................................................. 27

5.6.1.

Introduction........................................................................................................................................27

5.6.2.

Access Route For Installation...........................................................................................................27

5.7. Management Plan............................................................................................................................................. 27

5.7.1.

Engineering Organization...................................................................................................................27

5.7.2.

Engineering Communication..............................................................................................................28

5.7.3.

Document Control..............................................................................................................................28

5.8. Procurement Management Plan........................................................................................................................29

5.8.1.

Introduction........................................................................................................................................29

5.8.2.

Job Description...................................................................................................................................29

5.9. Logistic Management Plan................................................................................................................................ 30

5.9.1.

Job Description...................................................................................................................................30

5.9.2.

Inventory Control...............................................................................................................................30

5.9.3.

Warehouse..........................................................................................................................................30

5.9.4.

Outdoor Warehouse............................................................................................................................31

5.10. Labor Recruitment & Labor Relation Plan........................................................................................................31

5.10.1. Hiring and Releasing Policies............................................................................................................31

5.10.2. Discipline and Disciplinary Policies..................................................................................................31

5.10.3. Disciplinary Action Policies...............................................................................................................31

5.10.4. Based on the grade of discipline punishment, such as :.....................................................................32

5.10.5. Remuneration Policy..........................................................................................................................32

5.10.6. Contract employment consideration...................................................................................................32

5.10.7. Severance Pay Policy.........................................................................................................................32

5.10.8. Plan to Hire Local Labor....................................................................................................................33

5.11.

Health, Environmental and Safety Management Plan......................................................................................33

Pekerjaan Pabrikasi & Ereksi Struktur Baja Belt Conveyor 649 BC03

Cement Loading Lokasi Pelsus Semen Gresik Di Tuban

PROCEDURE

Doc. No

Rev. No

: 0

Page No

: 5 of 41

5.12. Security Plan..................................................................................................................................................... 33

5.12.1. Task of Securities...............................................................................................................................33

PT. TUBAN STEEL WORK

5.12.2. Facility................................................................................................................................................33

Fabricator&Engineering

Service

5.12.3. Location..............................................................................................................................................34

5.12.4. Job Description...................................................................................................................................34

5.13. Mobilization of Equipment and Manpower........................................................................................................34

5.14. Construction Management Plan.......................................................................................................................34

5.14.1. Introduction........................................................................................................................................34

5.14.2. Job Description...................................................................................................................................34

5.14.3. Project construction schedule.............................................................................................................35

5.14.4. Construction Control Schedule..........................................................................................................35

5.14.5. Construction Coordination.................................................................................................................35

5.15. Demobilization of Equipment and Manpower...................................................................................................35

5.16. Front End Schedule.......................................................................................................................................... 36

5.17. Project Schedule............................................................................................................................................... 36

5.18. Resources Plan................................................................................................................................................ 36

5.19. Project Budget.................................................................................................................................................. 37

5.20. Projected Cash Flow......................................................................................................................................... 38

5.21. Project Procedures........................................................................................................................................... 39

5.21.1. Prepare Project Execution Procedure Check List..............................................................................39

5.21.2. Prepare Project Procedures.................................................................................................................39

1. PURPOSE

This project execution plan prepared for Pekerjaan Pabrikasi & Ereksi Struktur Baja Belt Conveyor 649 BC03

Cement Loading Lokasi Pelsus Semen Gresik Di Tuban Project. It is intended to enhance communication and

coordination of project activities between Company and Subcontractor.

The Company is PT SEMEN GRESIK (PERSERO)

The contractor is PT. Tuban Steel Work

This procedure serves as a project guideline for all parties to achieve effective and efficient project

implementation. The primary uses of the project plan are to document planning assumptions and decisions, to

Pekerjaan Pabrikasi & Ereksi Struktur Baja Belt Conveyor 649 BC03

Cement Loading Lokasi Pelsus Semen Gresik Di Tuban

PROCEDURE

Doc. No

Rev. No

: 0

Page No

: 6 of 41

facilitate communication among stakeholders, and to document approved scope, cost and schedule baseline.

This

procedure

PT. TUBAN

STEEL

WORK describes the basic and method to be used in controlling the cost through out the project

Fabricator&Engineering

period, to Service

detect the variance by identifying potential problem and delay as early as possible. This procedure

describes the basis and method to be used in controlling the schedule throughout the project period, to detect

the variance by identifying potential problem and delay as early as possible.

2. SCOPE

This procedure covers detail of Project Execution Plan based on the latest project information. This document

is developed to enhance communication and coordination between the participants and/or the company. It

establishes project execution plant with the following item:

Project Management and Project Control scheme

Engineering Management Plan

Procurement Management Plan

Logistic Management Plan

Construction Management Plan

Labor Recruitment & Labor Relation Plan

Front End Schedule

Project Schedule

Resources Plan

Project Budged

Project Cash Flow

Project Procedure

Data Collection

Input Data into Report

Varian Analysis

Corrective Action

Budget Revision

Update Current Budget

Update Total Expense To Date

Update Total Actual To Date

Calculate Forecast To Go

Update Estimate at Completion

Update Project Cash Flow

Update Project Balance

This Procedure also covers :

Pekerjaan Pabrikasi & Ereksi Struktur Baja Belt Conveyor 649 BC03

Cement Loading Lokasi Pelsus Semen Gresik Di Tuban

PROCEDURE

Doc. No

Rev. No

: 0

Page No

: 7 of 41

Initiation is to determine a baseline for controlling the schedule for engineering, procurement,

construction

PT. TUBAN STEEL

WORK and overall activities, including the progress measurement.

Fabricator&Engineering Service

Data collection is to collect progress and/or status report from engineering, procurement and

construction.

Progress Monitoring is to calculate the progress for engineering, procurement, construction and overall

project.

Varian Analysis is to analyze the difference between plan and actual of every discipline and its impact to

project completion date.

Corrective Action is to perform necessary steps attempting to recover any schedule delay by means of

expediting, accelerating, fast tracking, adding resources.

Forecast the final completion date is to estimate the end date of project completion based on the current

progress achievement by means of CPM scheduling technique or bar charting.

Recovery Schedule is to develop a revised project schedule after the fact that the current progress

achievement slipped the project completion date, using CPM scheduling and cost optimation technique.

Resource Forecasting is to calculate the resource requirement needed to accomplish the remaining

activities.

Re-planning is to revise the project schedule in case there is a major change in scope impacting the

project completion date

Reporting is to prepare updates reports by summarizing the project progress into the reporting format

3. DEFINITION

3.1.

Project Execution Plan (PEP)

Contains the formal approved document used to guide both project execution and project control in

achieving the project objective and goal, which are determined, by the Company and Subcontractor

PM concerning the quality, cost and schedule aspect as per agreement.

3.2.

Front End Schedule

Detail planned dates for performing activities, used as a project baseline tool. (attached in technical

document).

3.3.

Project Schedule

The detail-planned dates for performing activities and the planned dates for meeting milestone, used

as a project control tool.

3.4.

Resources

The manpower, equipment and material required for project in achieving its objective and

implementation.

Pekerjaan Pabrikasi & Ereksi Struktur Baja Belt Conveyor 649 BC03

Cement Loading Lokasi Pelsus Semen Gresik Di Tuban

PROCEDURE

3.5.

Doc. No

Rev. No

: 0

Page No

: 8 of 41

Project Budget

PT. TUBAN STEEL The

WORK

real cost for implementing the project, which comes from contract price minus overhead cost,

Fabricator&Engineering Service

profit, marketing expenses, corporate cost and contingencies, approved by Vice President and

Operation Manager.

3.6.

Project Cost

The cost required for project implementation.

3.7.

Cost Control

A process of keeping cost within the bounds of budget or standard based upon work actually

performed, including monitoring actual versus budget, variance analysis, integrated cost/schedule

reporting, progress analysis and corrective action.

3.8.

Current Budget

A valid budget at a point in time.

3.9.

Posted Cost

Cost of work completed to date.

3.10.

Committed Cost

Cost of work committed to be done.

3.11.

Total Expense

Posted cost plus committed cost.

3.12.

Actual Cost

Actual cost of work committed to be done to date.

3.13.

Total Actual

Posted cost plus actual cost.

3.14.

Forecast to Go

Predicted cost for finishing the remaining work.

3.15.

Estimated at Completion

Total expense cost plus forecasted to go.

Pekerjaan Pabrikasi & Ereksi Struktur Baja Belt Conveyor 649 BC03

Cement Loading Lokasi Pelsus Semen Gresik Di Tuban

PROCEDURE

3.16.

Doc. No

Rev. No

: 0

Page No

: 9 of 41

Work Package or Summary

PT. TUBAN STEEL The

WORK

project deliverable at the lowest level of Work Breakdown Structure contains several activities

Fabricator&Engineering Service

with main key date(s) in monthly basis. The work package could also be treated as a milestone to

achieve the target at a certain time.

3.17.

Work Unit, known as Master Schedule

Contains all major activity sequences and interdependencies using PERT method, showing the

critical path and floats in weekly basis.

3.18.

Work Item

Support to level-1 work unit that covers all activities using PERT method, showing the critical path

and floats in daily basis.

3.19.

Work Step or Work Sequence

Support to level 2 Work Item and is the lowest level of project activities in daily basis to measure the

progress. Some projects have more detail than work step, depending on the type and complexity of

the project. The more detail level needs more effort to control.

3.20.

Progress

Actual work completed divided by total scope of work. Physical progress measurement is determined

on monthly basis at the monthly cut off date for all specific work units and for the overall work, the

weight of each specific work unit being proportional to its cost value

3.21.

Baseline

The original plan ( a project work package or an activity ) plus or minus approved changes. Usually

used with a modifier (e.g., cost baseline, schedule baseline, performance measurement baseline).

4. REFERENCE

These procedure developed refer to the following document :

Quality Manual

Project Management Guideline Procedure

Project Execution Plan Procedure

Project Schedule Control Procedure

Project Progress Report Procedure

Project Change Management Procedure

Pekerjaan Pabrikasi & Ereksi Struktur Baja Belt Conveyor 649 BC03

Cement Loading Lokasi Pelsus Semen Gresik Di Tuban

PROCEDURE

Doc. No

Rev. No

: 0

Page No

: 10 of 41

5. DETAIL PROJECT EXECUTION PLAN PROCEDURE

PT. TUBAN STEEL WORK

Fabricator&Engineering

Service

5.1.

General

Upon completion of Internal Kick off meeting, Project Manager (PM) and project team coinciding with

the preparation of Client Kick off meeting will review and complete the Project Execution Plan (PEP),

to ensure its completeness and accuracy for field implementation. In case of limited time to prepare

both Client Kick off meeting and PEP, PM should attempt to accelerate the preparation work.

The schedule described in contract document is defined as Master Schedule and become the original

summarized schedule (level 2 or 3). The amount stated in the contract is known as Contract Price.

The real cost for implementing the project named project budget, is the contract price minus

overhead cost, profit, marketing expenses, corporate cost and contingencies.

5.2.

Project Management & Control Scheme

For executing of this project the Project Director will act as the representative of board management

to arrange a Project Management which will be responsible for execution the project

5.2.1.

Duty & Responsibility

Due to the wide scope as well as technical challenges, the subcontractor intends to

implements a project organization task force. By this organization all resources needed

to accomplish project will be assigned full time in strict accordance their rule and

responsibility for successful of project. Set up a project organization and its

responsibility as following.

Project Manager : who is the number one manager in this project has responsibilities as follows:

Review and complete the Project Execution Plan

Collect all information related to the Project Execution Plan

Subcontractor contact person / decision maker related to the project

Review and approve Front End Schedule

Review and approve Project Schedule

Review and approve Resources Plan

Complete, review and approve Project Execution Plan Check List

Review and approve Project Plan according to procedure approval process

Monitoring and control of the project cost

Implementation of the project according to the schedule

Liaison with the Company and obtaining necessary information from the owner and

vendors and feeding in the engineering, procurement and construction section

Coordination developing and compiling all project documents as per the agreed documents

list and coordinating with the Company for approval of all relevant documents

Pekerjaan Pabrikasi & Ereksi Struktur Baja Belt Conveyor 649 BC03

Cement Loading Lokasi Pelsus Semen Gresik Di Tuban

PROCEDURE

PT. TUBAN STEEL WORK

Fabricator&Engineering Service

Doc. No

Rev. No

: 0

Page No

: 11 of 41

Coordination mobilizing requires for maintaining schedule

Coordination Procurement of all items

Coordination Implementing all sub subcontractors

Coordination Resolving conflicts

Coordination Archiving correspondences

Review and approve the monthly cost summary report

Provide variance analysis and determine necessary corrective action

Review and approve the proposal budget revision

Approve the Project Control System

Approve the re-planning schedule

Manage project in day to day

Project Control Manager : who is a manager that has almost all of the project information has

responsibility as follows:

Coordinate Preparing summarize Front End Schedule

Coordinate Preparing summarize Project Schedule

Coordinate Update summarize Resources Plan

Coordinate Update summarize Project Budget

Coordinate Preparing Projected Cash Flow

Coordinate Scheduler and Reporting

Collect all information related to the PEP

Coordinate Prepare detail Front End Schedule

Coordinate Prepare detail Project Schedule

Update manpower, material and equipment plan (detail resources plan)

Update detail Project Budget

Review and complete Project Execution Procedure Check List

Coordinate Preparing and finalizing Project Procedure according to procedure approval

process

Determine the schedule recovery and re-schedule, together with Project Manager

Ensure that all on-going projects are within the schedule

Provide variance analysis and recommend necessary corrective action

Review the proposal budget revision

Update project cash flow

Update project balance

Project Control Engineer : who is the supporting engineer to Project Control Manager has

responsibility as follows:

Pekerjaan Pabrikasi & Ereksi Struktur Baja Belt Conveyor 649 BC03

Cement Loading Lokasi Pelsus Semen Gresik Di Tuban

PROCEDURE

PT. TUBAN STEEL WORK

Fabricator&Engineering Service

Doc. No

Rev. No

: 0

Page No

: 12 of 41

Input data into monthly cost summary report and project cost status report

Provide variance analysis and recommend necessary corrective action

Prepare budget revision

Update current budget

Update total expense to date

Update total actual to date

Calculate forecast to go

Update estimate at completion

Review the contract and determine the Project Control System such as level of activities,

weight value and progress measurement

Collect the data and other reports regarding the progress and schedule control

Calculate the progress percentage for engineering, procurement and all work discipline

Review the difference between plan and actual, analyze constraints and its impact to

project schedule

5.2.2.

Prepare forecast and/or recovery schedule, resource forecast, re-planning and reporting

Responsible to the integrity and maintenance of the primary project file

Project Communications

5.2.2.1.

Introduction

This section is implemented for correspondence between Company and Subcontractor.

5.2.2.2.

Company correspondence

All formal correspondence to Company will be by Subcontractor transmittal letter.

Drawing submittals, design information submittal, and project progress report will be

prepared by all project section.

5.2.2.3.

Internal Correspondence

For correspondence regarding progress and schedule, subcontractor and vendors will

correspond directly with Project Manager and provide carbon copy to Site Manager.

For correspondence regarding technical design matter, quality control and start-up and

performance testing, subcontractor and vendors will correspond directly with the

Engineering Manager and provide carbon copy to Project Manager.

5.2.2.4.

Distribution Procedure for Correspondence

Due to the tight schedule for this project and the length time required for delivery by

regular mail services, correspondence will generally be either by facsimile or express

courier service. Project delay due to delay in delivery of documents will be responsibility

of the sender.

Pekerjaan Pabrikasi & Ereksi Struktur Baja Belt Conveyor 649 BC03

Cement Loading Lokasi Pelsus Semen Gresik Di Tuban

PROCEDURE

5.2.2.5.

PT. TUBAN STEEL WORK

Fabricator&Engineering Service

Doc. No

Rev. No

: 0

Page No

: 13 of 41

Telephone Communications

Others may use telephone communication to transmit information or to further the

consideration of information. Telephone conversations are not conclusive in them and

must be documented by telephone memoranda if the communication has an official or

significant status. It is not necessary to assign log number to telephone memoranda.

Telephone memoranda will be prepared and distributed to the parties involved in the

telephone discussion with copies to other parties, as required.

5.2.3.

Project Document Control

5.2.3.1.

Introduction

Project documents to be controlled include official project correspondence, memoranda,

calculations, drawings, design specifications, test records, manufacturer's material

certifications, manufacture's drawing and other such records. Document control

procedures are based on the project file system developed under the supervision of

Project Control.

5.2.3.2.

Administration

Project Control shall serve as the central point of project document control and shall

process or supervise the processing of documents from outside sources as well as

documents generated from consortium internal distribution or transmitted by

Subcontractor to outside sources. The activities include receiving, application of file

numbers, distributing, expediting and releasing all project documents.

5.2.3.3.

Documents Receipt

Documents may be received from outside sources such as Company, subcontractor and

vendors.

5.2.3.4.

Document Identification

All project mail, including faxes telegrams and package shall be delivered to Project

Control as incoming documents. Project Control shall process the original copy of each

incoming document, other than documents submitted in multiple copies (proposal,

instruction manual, etc.) and the transmittal letter or form for documents submitted in

multiple copies.

Processing shall include stamping document with the project routing stamp, dating the

receipt, marking the appropriate file number and indicating action and information

parties in the space provide on the routing stamp, and making required copies for action

and information parties. All documents should use numbering system as per attachment

5.2.3.5.

Project Management Review

Project Control shall forward the action copy of the non-technical and commercial

documents to Project Manager who will review the document package. He will pay

Pekerjaan Pabrikasi & Ereksi Struktur Baja Belt Conveyor 649 BC03

Cement Loading Lokasi Pelsus Semen Gresik Di Tuban

PROCEDURE

Doc. No

Rev. No

: 0

Page No

: 14 of 41

particular attention that the proper file numbers are assigned and the correct party is

PT. TUBAN STEEL WORK

Fabricator&Engineering Service

designated. The complete document package shall be returned to Project Control for

transmittal of the action and information copies, and filling of the original documents.

Project Control shall forward the action copy of the technical documents to Engineering

Manager who is assigned and the correct party is designated. The complete document

package shall be returned to Project Control for transmittal of the action and information

copies, and filling of original documents.

5.2.3.6.

Responsible Action Party

The copy of documents transmitted to the responsible action party shall be marked with

the word ACTION and route directly to the action party. The responsible action party is

responsible to review the document and provide the action as required. The responsible

action party may make further distribution of copies for action to one or more of the

project team or other personnel.

5.2.3.7.

Project Reference Documents

Documents having only temporary significance or which are used for reference purpose

in general will not be filled in the project file.

5.2.3.8.

Outgoing Documents

Project Control shall process all outgoing correspondence. Processing shall include

verification of file numbers, preparation of documents for mailing, completion of

Subcontractor internal distribution and distribution of copies to the project file, with

appropriate copies to subcontractor, other parties and Subcontractor Site Manager.

5.2.3.9.

Manuscripts and Preliminary Drafts

Manuscripts and preliminary draft of specifications, reports and other such documents

will not normally be maintained in the project files.

5.2.4.

Documents Distribution Procedure for Approval to Company

Each consortium member shall be responsible for getting approval to own drawing from

Company through Subcontractor Engineering Manager. When distribute the drawing

packet to Company, each consortium member or Supplier shall send a copy of the

drawing to Project Control for drawing control.

Pekerjaan Pabrikasi & Ereksi Struktur Baja Belt Conveyor 649 BC03

Cement Loading Lokasi Pelsus Semen Gresik Di Tuban

PROCEDURE

5.3.

Doc. No

Rev. No

: 0

Page No

: 15 of 41

QA / QC Management Plan

PT. TUBAN STEEL WORK

Fabricator&Engineering Service

5.3.1.

QA Management Plan

5.3.1.1.

Introduction

The subcontractor will issue Project Quality Assurance Plan to assure all material,

equipment, fabrication and installation process fulfill the project requirement by referring

to the Quality System requirement. The Document is model of Project Quality Plan that

will be used by subcontractor during perform The Project.

5.3.1.2.

Purpose

This document will describe The Quality System, and subcontractor to assure the

Project requirement will do activities and Quality Standard will be fulfilled. Referring to

The Quality System of subcontractor will develop Project Quality Plan.

5.3.1.3.

Terminology

Vendor : The companies that appointed by subcontractor and approved by

subcontractor/company to supply part of product and perform part of subcontractor

scope of work or services for this project purpose.

5.3.1.4.

Quality Requirement

5.3.1.4.1. Management Responsibilities

Organization chart will be developed base on project scope of work requirement.

Responsibilities of each member explained as follows :

Quality Control / Quality Assurance Division Manager

as Management

representative together with Project Manager should evaluate the Project

system effectiveness; ensuring that complain have been taken up and The

Quality Requirement have been fulfilled. Another responsibility of QA/QC

Division Manager is:

Perform Quality Audit

Evaluate vendor or sub vendor Quality System.

Project Manager has responsibilities to perform The Project Quality

Management System, and ensuring that all quality activities by refer to the

Quality Procedure have been implemented by all Departments, approve the

Project Quality Plan that have been prepared by QA/QC Manager, lead

project review meeting to ensure that all quality problems have been

responded and follow up by related departments.

Pekerjaan Pabrikasi & Ereksi Struktur Baja Belt Conveyor 649 BC03

Cement Loading Lokasi Pelsus Semen Gresik Di Tuban

PROCEDURE

Doc. No

Rev. No

: 0

Page No

: 16 of 41

Project Quality Assurance / Quality Control Manager has responsibilities to

prepare The Project Quality Plan, evaluate the project execution by survey,

PT. TUBAN STEEL WORK

Fabricator&Engineering Service

audit or review and assist of Project Manager in project review meeting that

attended by Department Manager. Project review meeting will evaluate:

Implementation of Quality System and project requirement.

Evaluate of corrective action request, and all non-conformity.

With relevant department discuss about corrective action to be taken.

Project QA/QC Manager under controlled by Project Manager will report The

Project Quality System implementation to QA/QC Division Manager.

Department Manager have responsibilities to issue the procedures that will

be used to support their activities, ensure that implementation of these

procedures have been in line with Project Quality Plan.

Site Manager has responsibilities to implement The Project Quality

Management System and ensure that all quality activities on construction

phase have been implemented by refer to the relevant procedure.

5.3.1.4.2.

Commitment Management

Management of subcontractor has a commitment to produce qualified products

through:

Communication is one of importance think to fulfill the customer requirement

base on the government regulations.

5.3.1.5.

Define quality policy and objective.

Conduct management review.

Assure the availability of resources.

Define management representative.

Quality System

Project Quality Assurance Plan will be supported by management procedure and

detailed by relevant procedures, describe regulation of process control of each

department activities. During performed this project, Project Quality Assurance Plan and

Management Procedure will be controlled by Project Quality Assurance/ Quality Control

Manager (Project QA/QC Manager), Project QA/QC Manager and relevant Department

Manager will develop Project Quality Assurance Plan and relevant procedures.

Pekerjaan Pabrikasi & Ereksi Struktur Baja Belt Conveyor 649 BC03

Cement Loading Lokasi Pelsus Semen Gresik Di Tuban

PROCEDURE

5.3.1.6.

PT. TUBAN STEEL WORK

Fabricator&Engineering Service

Doc. No

Rev. No

: 0

Page No

: 17 of 41

Contract Review

During perform this Project, Engineering Manager will be supported by relevant

Department Manager, have responsibilities to review and verify engineering design

changes. The changes related to the construction activities will be reviewed and

clarified by Site Manager. The clarifications of the changes include all aspect, and not

limited to the commercial aspect, schedule of project, and etc. Project Manager should

approve all deviation or the changes item.

5.3.1.7.

Design Control

5.3.1.7.1.

Responsibilities

Engineering Manager has responsible to control all engineering activities.

5.3.1.7.2.

Interface Design Control

Engineering Manager will controlled interfacing design with other party and or

authorize party. Project Engineering Manager identify the items or documents that

will interface and the document that should be approved by company.

5.3.1.7.3.

Input Design

Engineering Manager will control and develop all design information from

company, vendor, authorize party and assure that only up to date information will

be used and distributed to relevant department. Design criteria will be fixed refer

to contract requirement and specification.

5.3.1.7.4.

Out put Design

Out put design will produce approved of documents, specification drawing,

procedures and calculation sheet and another work sheet. Quality Assurance/

Quality Control Department will review out put design to make sure that the

designs have been:

Fulfill out put design requirement.

Insist of acceptance criteria

Conform with regulation

Identify specific characteristic

Engineering Manager will approve the design out put to make sure the design

procedure have been followed and approved by authorized personnel and

distributed to other related departments.

Pekerjaan Pabrikasi & Ereksi Struktur Baja Belt Conveyor 649 BC03

Cement Loading Lokasi Pelsus Semen Gresik Di Tuban

PROCEDURE

PT. TUBAN STEEL WORK

Fabricator&Engineering Service

5.3.1.7.5.

Doc. No

Rev. No

: 0

Page No

: 18 of 41

Design Verification

Project Engineering Manager has responsibilities to control and develop the

design verification. The important items that should be confirmed during design

verification are:

5.3.1.7.6.

Safety System of equipment

Accuracy of material take off

Accessibility / operation ability

Construction ability

Design Change Control

Project Engineering Manager will control design changes. Project Engineering

Manager will review and make sure that design change effects have been

observed by relevant department and design change not deviate from project

contract requirement.

5.3.1.7.7.

Field Design Change

Field Engineer will control design change at site. The effect that caused by design

change will be evaluated by Field Engineer and will be reported to Engineering

Manager.

5.3.1.8.

Document Control

Each administration department will control correspondence document. Engineering

Manager will control technical document as drawing, procedure, vendor technical

document. All Department Manager should ensure that only latest revision document or

procedure that will be used as work reference, if prior revision document being used as

reference, this document should be marked Void .

5.3.1.9.

Procurement and Sub Contracted

Procurement Manager will control procurement activities and Site Manager will control

Sub Subcontractor.

5.3.1.9.1.

Vendor or Sub Subcontractor Audit

Procurement department select vendor or sub subcontractor from company

vendor list. Vendor or sub subcontractor will be proposed to the company for

approval. Vendor or sub subcontractor audit based on their capabilities and

experiences.

Pekerjaan Pabrikasi & Ereksi Struktur Baja Belt Conveyor 649 BC03

Cement Loading Lokasi Pelsus Semen Gresik Di Tuban

PROCEDURE

5.3.1.9.2.

Doc. No

Rev. No

: 0

Page No

: 19 of 41

Quality requirement of vendor or sub subcontractor

All vendor or sub subcontractors should keep the quality requirement as

PT. TUBAN STEEL WORK

Fabricator&Engineering Service

mentioned on purchase order. Vendor or sub subcontractor Quality Plan could

be developed by refer to Subcontractor Quality Plan and or contract

requirement.

5.3.1.9.3.

Data for procurement and sub contract

Requisition Document and another supporting document as technical

specification, quality system requirement, test specification, acceptance

criteria, inspection and test plan, instruction sheet to vendor will be controlled

by:

Identify department that will be responsible to prepare, review or approve

these documents including revised document.

5.3.1.9.4.

Review the relevant document prior publishes purchase order.

Bid. Evaluation

Bid evaluation, purchase order and sub subcontractor were controlled by

consider;

Ensuring that bid document have been conformed with requisition

requirement document

Pre evaluation, to ensure that vendor or sub subcontractor have been

qualified and selected refer to approved vendor list.

Clarify unclear condition of bid evaluation, prior purchase order or sub

subcontractor document published.

5.3.1.10.

Material and Equipment Supplied by Company

Materials or equipments that supplied by company will be verified quality and quantities

conform to the quality requirement specification. By refer to the Receiving Material

Procedure, and all non-conformity or damages will be reported to company.

5.3.1.11.

Inspection and Test

To ensure project activities meet customer requirements, subcontractor will submit The

Inspection and Test Plan. It is subcontractor guideline to perform activities Inspection

and Test.

5.3.1.11.1.

Organization

Inspection activities will be performed by personnel that have been qualified

and controlled by Quality Assurance / Quality Control Department.

5.3.1.11.2.

Inspection and Test Plan

Pekerjaan Pabrikasi & Ereksi Struktur Baja Belt Conveyor 649 BC03

Cement Loading Lokasi Pelsus Semen Gresik Di Tuban

PROCEDURE

Doc. No

Rev. No

: 0

Page No

: 20 of 41

Inspection and Test Plan will be fitted to identify detail items of inspection

PT. TUBAN STEEL WORK

Fabricator&Engineering Service

activities will be done by vendor or sub subcontractor, subcontractor,

Company, third party or government representative, especially for Hold

Points and Witness Point. This document is as vendor or sub subcontractor

references to perform inspection and test.

5.3.1.11.3.

Shop Inspection Procedure

Quality Assurance / Quality control Manager will supervise all inspection

activities for material/equipment, and review inspection report to ensure that all

purchase order requirement and Project specification have been fulfilled.

Having ensured the all inspection items have been done, and the material /

equipment conform to the specification, Quality Assurance / Quality control

Manager or his representative will publishes Inspection Release Notice

(IRN).

IRNs copy will be given to traffic Department for packaging and

shipping preparation.

5.3.1.11.4.

Receiving Material Inspection

Quality Assurance / Quality Control Manager and Logistic Manager will arrange

and supervise inspection activities during receiving material on site to identify

and check the material or equipment condition.

Inspection result will be

recorded and reported to Site Manager. Non-conformity was found during

receiving material process will be reported to Project Engineering Manager for

take corrective action.

5.3.1.11.5.

Inspection and Test on Construction Phase

Inspection activities will be performed on site will be arranged and controlled by

Quality Assurance / Quality Control Manager. All Inspection activities between

sub subcontractor, subcontractor, company and other parties will be identified

and clarified on Inspection and Test Plan; Including clarify Hold Point and

Witness Point. Non-conformance item that found during inspection will be

controlled by relevant procedure.

5.3.1.11.6.

Final Inspection

Inspection and Test of each system will be done by refer to the inspection

planning. Result of inspection should be evaluated to the customer

requirement specification. Final Inspection will be performed after equipment

and/or system completely erected and it become document to release precommissioning.

5.3.1.11.7.

Inspection and Test Report

Pekerjaan Pabrikasi & Ereksi Struktur Baja Belt Conveyor 649 BC03

Cement Loading Lokasi Pelsus Semen Gresik Di Tuban

PROCEDURE

Doc. No

Rev. No

: 0

Page No

: 21 of 41

Inspection report of fabrication and procurement process will be controlled by

Quality Assurance / Quality Control Manager. Inspection Report of construction

PT. TUBAN STEEL WORK

Fabricator&Engineering Service

5.3.1.12.

process will be controlled by Quality Assurance / Quality Control Manager.

Inspection/Test Equipment and Measurement Instrument Control

All equipment that will be used during inspection, test and measurement should be

calibrated, identify and preserve as relevant procedure. Subcontractor, Vendor or sub

subcontractor should do all activities mentioned above.

5.3.1.13.

Control of Non Conforming Items

Project Engineering Manager have responsible to control and prepare corrective action

plan for non-conformance item of vendor equipment. Project engineering Manager will

control non-conformance item during construction. Project Engineering Manager will

arrange these activities after receiving non-conformity report:

Review Report

Find source of non conformance and make corrective action

Reported non conformance to company as required

Supervise execution of corrective action.

Control of design change for repair as design change procedure.

Quality Assurance / Quality Control Manager will arrange these activities mentioned

below:

5.3.1.14.

Review and perform the relevant Inspection item of the corrective action.

Ensure that corrective action will be finished.

Corrective Action

Quality Assurance / Quality Control Manager will identify the condition that cause of

deviation to the Project Quality.

Quality Assurance / Quality Control Manager will arrange the meeting to find sources

and fix the plant to avoid this condition will be happened.

5.3.1.15.

Storage, Packaging and Shipping

Packaging / shipping Procedure or method should be provided to ensure all material

and equipment was controlled and avoids material damage or loose. All material should

be good packaging for shipping/delivery or storage in certain period and provided with

complete document. Logistic Manager or assigned personnel is responsible to control

those material or equipment. Without completed requirement document material or

equipment prohibited bringing out from the warehouse.

5.3.1.16.

Quality Report

Quality Report Document will be given to the company as Project requirement.

Pekerjaan Pabrikasi & Ereksi Struktur Baja Belt Conveyor 649 BC03

Cement Loading Lokasi Pelsus Semen Gresik Di Tuban

PROCEDURE

5.3.1.17.

PT. TUBAN STEEL WORK

Fabricator&Engineering Service

Doc. No

Rev. No

: 0

Page No

: 22 of 41

Quality Audit

Quality audit for internal subcontractor organization or vendor / sub subcontractor, will

be planed and controlled by Quality Assurance / Quality Control Manager. Result of

audit will be documented by Quality Assurance / Quality Control Manager and reported

to Division QA/QC Manager.

5.3.2.

QC Management Plan

5.3.2.1.

Introduction

Quality Assurance / Quality Control Department will prepare Quality Control guidance of

material and equipments inspection that will be used during fabrication and repair work.

5.3.2.2.

Purpose

Project Quality Control Plan describe work methods and inspection activities as

mentioned on Quality Project requirement. Project Quality control Plan, Inspection &

Test Plan and Quality Control procedure will be prepared to provide inspection activities

as mentioned below:

Arrange

inspection

activities

between

Vendor,

Subcontractor,

Contractor,

Government and third party during fabrication, construction phase and certification

process.

Perform inspection and test, internal or witnessed by company during fabrication or

construction phase.

Ensure all test equipments, measurement instruments that will be used during

inspection in valid calibration period

Perform certification of equipments that required certificate from authorize party or

Government.

5.3.2.3.

Preserve inspection and test report including non-conformity report.

Terminology

Any terminology related to QC Management plan described as follows :

Vendor : The company that appointed by subcontractor and approved by company

to supply part of product, performed part of subcontractor scope of work or

services for this project purpose.

Third Party: Subcontractor subcontracted inspection company approved and

appointed to act on behalf of Migas.

5.3.2.4.

Responsibility

Responsibility each member described as follows :

Quality Assurance / Quality Control Manager has responsible:

Ensure that Project Quality Control Plan conform to quality project requirement.

Pekerjaan Pabrikasi & Ereksi Struktur Baja Belt Conveyor 649 BC03

Cement Loading Lokasi Pelsus Semen Gresik Di Tuban

PROCEDURE

Doc. No

Rev. No

: 0

Page No

: 23 of 41

Quality Assurance / Quality Control Department representative to make coordination

with another department during perform the project.

PT. TUBAN STEEL WORK

Fabricator&Engineering Service

Inspector : Perform Quality Control activities as mentioned on the Inspection and Test

Plan, including internal test and inspection or witnessed by company, prepare and

review inspection and test record.

Document Control : To assist and support Quality Assurance / Quality Control Manager

in the administration and documentation matter.

5.3.2.5.

Supporting Procedures of Project Quality Control Plan

For guidance of implementation Project Quality Control Plan during phase procurement

fabrication and erection, Quality Assurance / Quality Control Department will provide

with Quality Control procedure as follow:

Inspection and Test Plan

WPS/PQR & WPQT

Another Procedure if required

5.3.2.6.

Inspection Activities

During performed of inspection activities, SUBCONTRACTOR will refer to The

Inspection and Test Plan, Customer Requirement.

5.3.2.6.1.

Inspection and Test Plan

Inspection and test plan will describe inspection and test activities during

construction and commissioning phase.

Main activities of site inspection and test are:

Documented all site inspection was performed by subcontractor and

submitted to the company for approval.

Arrange inspection between subcontractor and company.

Ensure welder personal and NDE operator that involved in this project and

were certified.

Collect all inspection and test data as electrical equipment, instrument

equipment, mechanical equipment, civil work, piping, isolation painting etc.

Ensure all measurement equipments to be used for inspection in valid

period of calibration.

Control and monitor schedule on site, for non-destructive test, radiography

and post weld heat treatment (if required) activities.

Support of HES Department to implement their program as during welding

process, non destructive test, radiography test, post weld heat treatment,

especially to handle and storage of radio active material.

Pekerjaan Pabrikasi & Ereksi Struktur Baja Belt Conveyor 649 BC03

Cement Loading Lokasi Pelsus Semen Gresik Di Tuban

PROCEDURE

Doc. No

Rev. No

: 0

Page No

: 24 of 41

Verification of inspection result, documented of test result and reported to

the company.

PT. TUBAN STEEL WORK

Fabricator&Engineering Service

Perform the inspection meeting with sub subcontractor and / or company if

any problems were found during previous inspection activities.

Inform to the company, Inspection schedule that should be attend by

company (witness point).

SUBCONTRACTOR will prepare welding procedure specification for welder

qualification and should be approved by migas.

5.3.2.6.2.

Control of Non Conformity Report

Non-conformity is damage, shortage of material, poor quality of material or deviation of

work that not conform to specification, drawing as project contract specification. Control

activities of non-conformity should refer this description.

Non-conformity report

If Inspector or supervisor found non-conformance item, the construction

process should be stopped and should prepare non-conformity report and (if

required) attached picture and reported.

Non-conformity will be controlled with list of non-conformity.

Corrective Action Plan

Based on this non-conformity report, subcontractor will propose corrective

action to the company with two categories,

Use-as-Is

Non-conformity of material or construction process permitted to continue

during deviation in line with the specification.

Repair / rework

Repair / rework was caused by design mistake, non-conformity

design with project specification.

Repair / rework should be done if there are difference with

relevant specification.

Repair / rework was need , for pressure vessel that have been

tested on shop.

Subcontractor will propose corrective action to get company

approval.

Design change request

If during construction process found the items cannot be done, or will obstruct

to another facilities, so the construction process will deviate from approval

drawing, the subcontractor will propose the design change to get company

approval.

Pekerjaan Pabrikasi & Ereksi Struktur Baja Belt Conveyor 649 BC03

Cement Loading Lokasi Pelsus Semen Gresik Di Tuban

PROCEDURE

5.3.2.7.

PT. TUBAN STEEL WORK

Fabricator&Engineering Service

5.4.

Doc. No

Rev. No

: 0

Page No

: 25 of 41

Inspection Report

The subcontractor will use inspection / test form as applied procedure during inspection

activities at shop and site project

Financial Management Plan

5.4.1.

Introduction

The aim of emphasize of the Roll and Financial Management plan is to formulate and

recommend steps to be taken by the Project Manager related to the Integrated Tank Repair

Project, particularly to the preparation of planning, implementation and control. The formulation

of financial management plan could be described as follow.

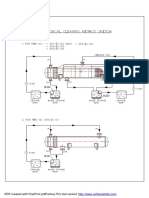

G OAL

5.4.2.

Scheme of Roll and Financial Management

Successful of Project Execution

FINANCIAL VISION

To Support Project Execution

FINANCIAL MISSION

To Provide Working Capital / Financing

For Project Execution

FIGURE SCHEME OF

ROLL AND FINANCIAL

MANAGEMENT

S T R AT E G Y

Professionalisme of

Man Power

Efficiently

Organization

Increase of Service

Competences &

Integrity

Structure and System

Procedure

(Simplification)

Keep on Target / Goal

Keep on Volume

Keep on Schedule

Pekerjaan Pabrikasi & Ereksi Struktur Baja Belt Conveyor 649 BC03

Cement Loading Lokasi Pelsus Semen Gresik Di Tuban

FINANCIAL FUNCTION

PROCEDURE

Doc. No

Rev. No

: 0

Page No

: 26 of 41

PT. TUBAN STEEL WORK

Fabricator&Engineering Service

5.4.3.

Financial Function

FINANCIAL FUNCTION

SINKIND FUND

FUND ALLOCATION

PERFORMANCE MANAGEMENT

TOTAL PROJECT PLANNING

COST CONTROL

PERFORMANCE MANAGEMENT

SYSTEM AND PROCEDURE

Cash Receiving

Cash Disbursement

Material Receiving

SYSTEM ARRANGEMENT PLAN

Sub Contractor Receiving

Investment Receiving

IMPLEMENTATION

BUDGET

Import Price Calculation

Shipment

Maintenance

Material Usage

Overhead Application

Finish Good

PROJECT MASTER BUDGET

Delivery of Good / Project

Progress Delivery Invoicing

Credit Note

Intern Progress

Closing Order

Overhead Cost Breakdown

PROJECT OPERATIONAL BUDGET

Project Site Cost Breakdown

BASED ON SECTION BUDGET

of Adjustment

Pekerjaan Pabrikasi & Ereksi Struktur Baja BeltMemo

Conveyor

649 BC03 / Correction

IMPLEMENTATION

REALIZATION

Q: Master Design

Detail Design

Shop Drawing

C: Matl Cost

Labour Cost

FOH Cost

Progress, Etc

Cement Loading Lokasi Pelsus Semen Gresik Di Tuban

D: (Delivery)

Progress of

Good Delivery

PROJECT CASH FLOW

RISKS

CONTROL

Comply

with Spec

of Quality

Comply

with

Project

Budget

Comply

with

Project

Schedule

PROCEDURE

Doc. No

Rev. No

: 0

Page No

: 27 of 41

PT. TUBAN STEEL WORK

Fabricator&Engineering Service

ADJUSTMENT/REPLANNING

OF BUDGET TO MEET THE

QCD TARGET

NO

CONTROL

/ RESULT

QCD =

PLAN

YES

QCD =

PLANNING

5.5.

Risk Management Plan

5.5.1.

Introduction

The successful of project implementation is depend in to how to manage the risk's during project

execution, so this risks project Management plan is to provide a management to take any

necessary action based on some factors such as:

5.5.2.

Unit price factor

Work volume ( BQ ) factor

Work Schedule factor

Exchange rate factor

Damage factor

Scheme of Project Risk Management

See description figure in the attachment

Pekerjaan Pabrikasi & Ereksi Struktur Baja Belt Conveyor 649 BC03

Cement Loading Lokasi Pelsus Semen Gresik Di Tuban

PROCEDURE

5.6.

Doc. No

Rev. No

: 0

Page No

: 28 of 41

Surveying Plan

PT. TUBAN STEEL WORK

Fabricator&Engineering Service

5.6.1.

Introduction

Surveying plan is all activity that will be done at site before design engineering works is started.

The activity in order to get all data that will be used engineering calculation, transportation

planning, choice of type equipment and others civil works planning.

5.6.2.

Access Route for Installation

All access route for workers and equipment shall be checked and provide new if necessary.

Transportation by big and long car to bring all heavy equipment to site shall be checked the

availability space to take around.

5.7.

Management Plan

5.7.1.

Engineering Organization

Engineering Manager shall manage all engineering activities within this project

and responsible to Project Manager.

Discipline Engineer

Engineer shall do the design each discipline under the coordination of Lead Discipline

Engineer.

Field Engineer

Field Engineer shall support construction activities, accommodate all modification done on

site and implemented those modifications to marked drawings will informed to Discipline

Engineer through Engineering Manager.

Draftsman

Draftsman shall make the drawing and coordinated by Discipline Engineer.

5.7.2.

Engineering Communication

This section is implemented for communication among engineering sub-sections. All formal

correspondence with company and other will be by Project Manager transmittal letter.

Engineering Manager will conduct daily meeting to solve problem among sub-sections moreover

in interfacing problem. In case of small problem, Engineers may precede a coordination meeting

among and copy carbon shall be forward to engineering manager.

5.7.3.

Document Control

Administration

Document Control officer also shall act as the central point of engineering document as

well as documents generated from internal subcontractor or transmitted by Company.

Pekerjaan Pabrikasi & Ereksi Struktur Baja Belt Conveyor 649 BC03

Cement Loading Lokasi Pelsus Semen Gresik Di Tuban

PROCEDURE

Doc. No

Rev. No

: 0

Page No

: 29 of 41

The activities include receiving, application of file number, distributing, expediting and

PT. TUBAN STEEL WORK

Fabricator&Engineering Service

releasing all engineering documents to assure that the document will receiving by

related section in same version.

Documents Receipt

Documents may be received from outside sources such as Company and NA or others.

Document Identification

All engineering mail, including e-mail, telecopy, telegrams and package shall be

identified.

The Document Control shall process the original copy of each incoming document, other than

documents submitted in multiple copies (proposal, instruction manual, etc.) and the

transmittal letter or form for documents submitted in multiple copies.

Identifying shall include stamping document with the engineering routing stamp, dating the

receipt, marking the appropriate file number and indicating action and information parties in

the space provide on the routing stamp, and making required copies for action and

information parties. All documents should use numbering system as per attachment

Engineering Management Review

Document Control shall forward the action copy of documents to the Engineering

Manager who will review the document package. He will pay particular attention that the

proper file numbers are assigned and distribution to the related party.

The complete document package shall be returned to the Engineering Planning &

Control for re-routing and filling of the original documents, also distributing if necessary.

Document Traffic

The copy of documents transmitted to the responsible action party shall be marked with

the word ACTION and route directly to the action party.

The responsible engineer is responsible to review the document and provide the action

as required. The responsible engineer could get additional information from other Lead

engineer under coordination of the engineering manager.

Engineering Reference Documents

Documents having only temporary information or which are used for reference purpose

in general will not be filed in the engineering file.

Outgoing Documents

Pekerjaan Pabrikasi & Ereksi Struktur Baja Belt Conveyor 649 BC03

Cement Loading Lokasi Pelsus Semen Gresik Di Tuban

PROCEDURE

Doc. No

Rev. No

: 0

Page No

: 30 of 41

Document Control shall record and forward documents include verification of file

numbers, preparation of documents for mailing, completion of Engineering internal

PT. TUBAN STEEL WORK

Fabricator&Engineering Service

distribution and distribution of copies to the engineering file.

Manuscripts and Preliminary Drafts

Manuscripts and preliminary draft of specifications, reports and other such documents

will not normally be maintained in the project files.

5.8.

Procurement Management Plan

5.8.1.

Introduction

In order to achieve the aim of project, the procurement section shall be divided into four

sub sections as on organization chart.

5.8.2.

Job Description

The aim of this written job description is to clarify all jobs and duties to avoid confusion and

overlap among procurement section.

Procurement Manager

Procurement Manager has responsible for the procurement of all material,

equipment, electrical and instrumentation as required.

Procurement Manager shall manage all procurement activities and responsible

for all material supplied has bought and ready for installation and construction.

Procurement Manager shall sign all correspondence of procurement activities.

Purchasing Officer

Material requisition for quotation to vendor for sourcing.

Evaluation, clarification and negotiation of quotation with vendor.

Issuing LOI or P/O and inform to QC and traffic for preparing.

Verification of vendor invoice.

Traffic & Expediting

Expediting of purchase requisition material or equipment.

Inventory of the delivery point.

Arranging of the transportation and material handling.

Issuing the packaging & transportation method.

Reporting of expediting report.

Pekerjaan Pabrikasi & Ereksi Struktur Baja Belt Conveyor 649 BC03

Cement Loading Lokasi Pelsus Semen Gresik Di Tuban

PROCEDURE

PT. TUBAN STEEL WORK

Fabricator&Engineering Service

5.9.

Doc. No

Rev. No

: 0

Page No

: 31 of 41

Monitoring of arrival material or equipment.

Issuing transportation schedule and volume.

Issuing cargo insurance.

Logistic Management Plan

5.9.1.

Job Description

Logistic Manager has responsible for inventory control of material, tools, consumable, and

equipment start from receiving materials etc, up to storage at warehouse.

Warehousing of the material etc, could be indoor / outdoor.

5.9.2.

Inventory Control

Inventory control is arrangement of method material, tools, consumable and equipment in

storage to support site activities I e :

Arrangement of arrival / shipment material schedule according to

Master Schedule including preparation of the storage plan.

Preparing progress control of receiving material etc according to

procurement schedule.

Arrangement material, tools and consumables storage system

both indoor and outdoor warehouse.

Classification of special material etc to be storage at special rack /

box.

Controlling the quantities of materials / consumables as the

necessity to be report weekly

5.9.3.

To minimize waste of material

Warehouse

Indoor warehouse is storage place to protect of material, tools and consumables from weather to

prevent material from damage or corrosive.

All material, tools etc should be identified base on its type & size, prior stored on the racks or put

on the floor according to storage system at warehouse as below

Equipment for large size as panels, pumps, generator power, fittings etc should be stored on the

floor indoor and its gave distance from the floor around 15 cm.

Inflammable material as chemical liquid, painting, gas bottles should be stored at special place.

5.9.4.

Outdoor Warehouse

Outdoor warehouse is open storage place which will use for storing large size of raw material as

pipe, fittings, material profile, cable etc.

Pekerjaan Pabrikasi & Ereksi Struktur Baja Belt Conveyor 649 BC03

Cement Loading Lokasi Pelsus Semen Gresik Di Tuban

PROCEDURE

Doc. No

Rev. No

: 0

Page No

: 32 of 41

Placement of raw material in outdoor warehouse to be prevent contact with ground and its gave

distance around 20 cm from the ground.

PT. TUBAN STEEL WORK

Fabricator&Engineering Service

5.10.

Labor Recruitment & Labor Relation Plan

5.10.1. Hiring and Releasing Policies

Hiring Policies / a need of contract labor at project will be based on:

Requirement of manpower for specific project especially workers.

The skill or unskilled labor available at near project area.

The contract system will be written in the KKWT form according to the Depnaker

regulation.

Releasing Policies

Labor contract duration is depending upon project time schedule and releasing of contract

employment shall follow applicable Depnaker regulations.

Time of contract employment may be terminated by any in-disciplines which counted at

least three (3) times of written warning.

5.10.2. Discipline and Disciplinary Policies

Discipline is a part of project successful, therefore, in order to keep it Subcontractor have to

conduct the following but not limited to :

The discipline regulation (PHDK) shall be socialized by the subcontractor to all

employee

All employee have to fill the absence time card when get in or out of the

office/project area.

Records time of work

Using ID Card

Using Uniform

5.10.3. Disciplinary Action Policies

Any indiscipline will be punished verbally, give notification up to termination of

contract for easy or heavy indiscipline action and un-honorable of labor relationship

breaking if needed.

For example abuse prevention programs where Subcontractor recognizes that

alcohol and drugs are a potential safety hazard within the workplace and as such it is

forbidden for any person to possess, or be under the influence of alcohol or non