Professional Documents

Culture Documents

Comments 1

Comments 1

Uploaded by

nimish.aquamarine0 ratings0% found this document useful (0 votes)

9 views1 pageThis document discusses the design of structural splices for a building. It notes that:

1) The middle section would be a separate piece bolted on site to accommodate tolerances between pieces welded at the factory.

2) Splice plates at connections must have slotted holes to allow for 10mm of movement from factory tolerances.

3) Bracing connections will now be made with welds at crossbeam flanges instead of connectors, to simplify assembly with spliced pieces.

Original Description:

Comments

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses the design of structural splices for a building. It notes that:

1) The middle section would be a separate piece bolted on site to accommodate tolerances between pieces welded at the factory.

2) Splice plates at connections must have slotted holes to allow for 10mm of movement from factory tolerances.

3) Bracing connections will now be made with welds at crossbeam flanges instead of connectors, to simplify assembly with spliced pieces.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views1 pageComments 1

Comments 1

Uploaded by

nimish.aquamarineThis document discusses the design of structural splices for a building. It notes that:

1) The middle section would be a separate piece bolted on site to accommodate tolerances between pieces welded at the factory.

2) Splice plates at connections must have slotted holes to allow for 10mm of movement from factory tolerances.

3) Bracing connections will now be made with welds at crossbeam flanges instead of connectors, to simplify assembly with spliced pieces.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

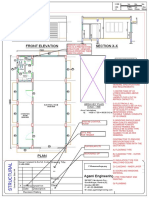

Splice 1

3750

tHE MIDDLE PART IS A

SEPARATE PIECE, THAT

WOULD BE BOLTED AT

SITE.

max. overhang

2500

CHL04

tHESE 2 PIECES WOULD

BE WELDED AT

FACTORY AND BROT IN

TO SITE. SPLICE PLATE

WOULD HAVE TO ADMIT

A TOLERANCE OF 10MM

AT SITE.

CH03

CHL04

CHL04

THESE DIAGONALS WUD

BE A SHORTER LENGTH

AND HAVE DIFFERENT

MEMBER IDENTI NO.

CHL04

SUBASSEMBLY 3

Scale 1:50

Splice 1

Splice 2

5000

SIMILAR THING

HAPPENING HERE.

2500

1250

1230

CHL06

CHL06

SPLICE

DET at 'E'

sO WHAT DOES THIS IMPLY

FOR THE CONNECTIONS?

THE BRACING CONNECTORS

GO AWAY, MOST REPLACED

BY WELDS.

1) SPLICE FOR THE

CROSSBEAM HAS TO HAVE A

SLOTTED HOLE TO ADMIT

TOLERANCE FROM SITE TO

FACTORY. SEE THIS SKETCH.

THE SLOT SHOULD ALLOW

10MM MOVEMENT OF BOLT

CHL06

STIFFNER PLATE

CHL06

CROSSBEAM

SUBASSEMBLY 1

Scale 1:50

WELDED BRACE

Splice 2

Splice 3

2500

2) THE BRACING WELDS NOW

HAPPEN AT THE CROSS BEAM

FLANGES

sEE IF ALL THREE

DIAGONALS CAN BE

MADE EQUAL IN LENGTH

SO THAT IT IS THE SAME

MEMBER. THEY SHUD

NOT FALL ON THE

SPLICE PLATE

1250

CHL05

CROSSBEAM

CHL05

DET at 'H'

CHL05

CHL05

SUBASSEMBLY 2

STRAIGHT MIDDLE BRACE

BOLTED

Scale 1:50

THE MIDDLE MEMBER IS

A DIFFERENT MEMBER

NO AS ITS LENGTH IS

DIFF.

You might also like

- BMC 1100 & 1300 Workshop ManualDocument324 pagesBMC 1100 & 1300 Workshop ManualMichael Carnell94% (17)

- Halliburton Sand Control MCS Closing SleeveDocument41 pagesHalliburton Sand Control MCS Closing SleevePither ZuritaNo ratings yet

- RCPC Detail and PCCP Joint Details PDFDocument1 pageRCPC Detail and PCCP Joint Details PDFShammir Tabayag MangidaNo ratings yet

- Coil Circuiting - SerpentineDocument8 pagesCoil Circuiting - Serpentinebruce1312100% (1)

- Pugh PDFDocument13 pagesPugh PDFRandall Marsh100% (1)

- Design Calculations For Foundations For A Solar MMSDocument13 pagesDesign Calculations For Foundations For A Solar MMSnimish.aquamarineNo ratings yet

- DBR-Steel LadderDocument35 pagesDBR-Steel Laddernimish.aquamarineNo ratings yet

- Basics For Supervision 1Document7 pagesBasics For Supervision 1Geo PazhayattilNo ratings yet

- Aa 036007 001Document1 pageAa 036007 001narutothunderjet216No ratings yet

- Radial Thrust BRG Case StudiesDocument14 pagesRadial Thrust BRG Case StudiesRajagopal100% (1)

- MO Paper Nov 2019Document2 pagesMO Paper Nov 2019Bhavik YoganandiNo ratings yet

- MSE 227 Chapter 8 HWDocument1 pageMSE 227 Chapter 8 HWjosewilliam85No ratings yet

- BalaiDocument20 pagesBalaimyvi317No ratings yet

- Iv RepotDocument16 pagesIv Repotneethurj9No ratings yet

- Lesson 5: Current Requirements (Circular Magnetization)Document7 pagesLesson 5: Current Requirements (Circular Magnetization)kevin desaiNo ratings yet

- CardsDocument15 pagesCardsFernando EscalanteNo ratings yet

- Cabana Plc. TestDocument3 pagesCabana Plc. TestNathan yemaneNo ratings yet

- TGSL Concentric 26Document17 pagesTGSL Concentric 26Daniel UngureanuNo ratings yet

- TGSL ConcentricDocument16 pagesTGSL ConcentricAli SarıaltınNo ratings yet

- TGSL Concentric 18Document17 pagesTGSL Concentric 18Daniel UngureanuNo ratings yet

- Suspension FactorsDocument2 pagesSuspension FactorsManu PantNo ratings yet

- 6.1 Leakage Flux and Leakage InductanceDocument29 pages6.1 Leakage Flux and Leakage InductancePrema ElizabethNo ratings yet

- LV Resin Cable Joints 4 Core XLPE & PILC SWA, 185sqmm 300sqmm InstallationDocument3 pagesLV Resin Cable Joints 4 Core XLPE & PILC SWA, 185sqmm 300sqmm Installationalitopan9900No ratings yet

- Closed-Book Practice-Ch 07 (2016!12!24)Document8 pagesClosed-Book Practice-Ch 07 (2016!12!24)JuanNo ratings yet

- Tube Settler Leaflet Rev 2Document6 pagesTube Settler Leaflet Rev 2Rabindra SinghNo ratings yet

- Alco ComponentDocument76 pagesAlco Componenttamolisandip1No ratings yet

- An Old Quality Lesson From Failure of A New Heat ExchangerDocument15 pagesAn Old Quality Lesson From Failure of A New Heat ExchangerassurendranNo ratings yet

- CHTE471 Tutorial 2Document3 pagesCHTE471 Tutorial 2JabuNo ratings yet

- Duct Pressure Loss Calculations For Air - Handling Units: Tersam UtilityDocument10 pagesDuct Pressure Loss Calculations For Air - Handling Units: Tersam UtilityVipul HodawdekarNo ratings yet

- Braze Weld TechnicalDocument7 pagesBraze Weld TechnicalimupathanNo ratings yet

- Fire Fighting Building B O QDocument10 pagesFire Fighting Building B O QJurie_sk3608No ratings yet

- Reinforced Concrete Slabs: Civil Engineering DepartmentDocument18 pagesReinforced Concrete Slabs: Civil Engineering DepartmentUlyssis ManalogNo ratings yet

- Tutorial Last AnswerDocument9 pagesTutorial Last AnswerEswaran ManakorNo ratings yet

- Capilary Tube For Ac and RefrigeratorDocument4 pagesCapilary Tube For Ac and RefrigeratorJoko SubagyoNo ratings yet

- Functional Design ReportDocument10 pagesFunctional Design Reportnevin KhedooNo ratings yet

- Review QuestionsDocument2 pagesReview QuestionsMinh Nguyễn AnhNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityprince.patelNo ratings yet

- BeamsDocument33 pagesBeamsGintokiNo ratings yet

- Study of Circuit Breakers: Mini ProjectDocument28 pagesStudy of Circuit Breakers: Mini ProjectSekhar ChejarlaNo ratings yet

- Capillary Tube Inst-Tubing PDFDocument4 pagesCapillary Tube Inst-Tubing PDFEduardoNo ratings yet

- Babani-Crystal Set ConstructionDocument16 pagesBabani-Crystal Set ConstructionRonLayton100% (2)

- DistortionDocument62 pagesDistortionManzar KhanNo ratings yet

- Lec11 PDFDocument21 pagesLec11 PDFARIJIT ROYNo ratings yet

- Q.1 Which Welding Technique You Would Adopt To Weld The Vertical Seams of TwoDocument38 pagesQ.1 Which Welding Technique You Would Adopt To Weld The Vertical Seams of Twoquiron2010No ratings yet

- Notes:: 6"-12" PIPE Flowline Removable AnchorDocument1 pageNotes:: 6"-12" PIPE Flowline Removable Anchornarutothunderjet216No ratings yet

- WRN STD 105Document1 pageWRN STD 105Conifer YuNo ratings yet

- Owner Michael Calistrat and Associates Missouri City, TexasDocument8 pagesOwner Michael Calistrat and Associates Missouri City, Texasjhchung111100% (1)

- Difference Between Metalizer K5000 & K5ExpertDocument15 pagesDifference Between Metalizer K5000 & K5Expertsajid100% (1)

- 5 - Sieve Tray DesignDocument61 pages5 - Sieve Tray DesignM.H vafaeiNo ratings yet

- DistortionDocument62 pagesDistortionSharad AtraheNo ratings yet

- REINFORCED CONCRETE I-Lecture5Document15 pagesREINFORCED CONCRETE I-Lecture5BAHJAT MUSHTAHANo ratings yet

- Front Elevation Section A-A: Hard Rock Tower FoundationDocument1 pageFront Elevation Section A-A: Hard Rock Tower FoundationkoklenderNo ratings yet

- Experimental Study On Vortex FlowDocument34 pagesExperimental Study On Vortex FlowSai SudheerNo ratings yet

- The Norton CarburetorDocument3 pagesThe Norton Carburetorbill_wattNo ratings yet

- Diesel Engines 4Document4 pagesDiesel Engines 4Thiet PhamNo ratings yet

- A New System of Alternating Current Motors and Transformers and Other EssaysFrom EverandA New System of Alternating Current Motors and Transformers and Other EssaysRating: 5 out of 5 stars5/5 (1)

- Beam Schedule: General NotesDocument1 pageBeam Schedule: General Notesnimish.aquamarineNo ratings yet

- S-Bd85-A-101-Ugt Details - R6Document1 pageS-Bd85-A-101-Ugt Details - R6nimish.aquamarineNo ratings yet

- 1 - STEEL STAIRCASE GA DRAWING1.dwgDocument1 page1 - STEEL STAIRCASE GA DRAWING1.dwgnimish.aquamarineNo ratings yet

- 3 - Ga Drawing 3 of 3Document1 page3 - Ga Drawing 3 of 3nimish.aquamarineNo ratings yet

- Sec Aa: Staircase Details: 16 Ø at 180 C/C Starter BarsDocument1 pageSec Aa: Staircase Details: 16 Ø at 180 C/C Starter Barsnimish.aquamarineNo ratings yet

- Glass Thickness From TrosifolDocument2 pagesGlass Thickness From Trosifolnimish.aquamarineNo ratings yet

- 1 - Ga Drawing 1 of 3Document1 page1 - Ga Drawing 1 of 3nimish.aquamarineNo ratings yet

- Neropoxy266 MIO HB Coating GreyDocument2 pagesNeropoxy266 MIO HB Coating Greynimish.aquamarine0% (1)

- Bhoom Settingout NP-NIMISH-PCDocument1 pageBhoom Settingout NP-NIMISH-PCnimish.aquamarineNo ratings yet

- Part Per Table Per Row: Side View Front View 3D ViewDocument1 pagePart Per Table Per Row: Side View Front View 3D Viewnimish.aquamarineNo ratings yet

- Pune Rooftop GA DrawingDocument1 pagePune Rooftop GA Drawingnimish.aquamarineNo ratings yet

- 3 - L Column A1Document1 page3 - L Column A1nimish.aquamarineNo ratings yet

- 1 - General Arrangement DrawingDocument1 page1 - General Arrangement Drawingnimish.aquamarineNo ratings yet

- Request For Anchor Design For Technoarc: Nimish PrabhukhanolkarDocument2 pagesRequest For Anchor Design For Technoarc: Nimish Prabhukhanolkarnimish.aquamarineNo ratings yet

- Nerothane 1000Document1 pageNerothane 1000nimish.aquamarine0% (1)

- Neropoxy HB Zinc Phosphate PrimerDocument1 pageNeropoxy HB Zinc Phosphate Primernimish.aquamarineNo ratings yet

- COVID-19: Advisory and Plan of ActionDocument7 pagesCOVID-19: Advisory and Plan of Actionnimish.aquamarineNo ratings yet

- Concept Report For BuildingDocument13 pagesConcept Report For Buildingnimish.aquamarineNo ratings yet

- DBR - Delhi GPODocument16 pagesDBR - Delhi GPOnimish.aquamarineNo ratings yet

- Adequacy Check For Existing FootingsDocument3 pagesAdequacy Check For Existing Footingsnimish.aquamarineNo ratings yet

- Structural Design: ProjectDocument24 pagesStructural Design: Projectnimish.aquamarineNo ratings yet

- Engineering: Reference DrawingsDocument1 pageEngineering: Reference Drawingsnimish.aquamarineNo ratings yet

- Structural Design CAlculationsDocument12 pagesStructural Design CAlculationsnimish.aquamarineNo ratings yet

- Fixed Tilt Structures DesignDocument8 pagesFixed Tilt Structures Designnimish.aquamarineNo ratings yet

- Solar Mounting StructuresDocument7 pagesSolar Mounting Structuresnimish.aquamarineNo ratings yet

- Commercial Bldg. at Poman, VASAI: Description REV DateDocument1 pageCommercial Bldg. at Poman, VASAI: Description REV Datenimish.aquamarineNo ratings yet

- Front Elevation Section X-X: Area Key PlanDocument1 pageFront Elevation Section X-X: Area Key Plannimish.aquamarineNo ratings yet

- Fixed Tilt Important Considerations in StructuresDocument14 pagesFixed Tilt Important Considerations in Structuresnimish.aquamarineNo ratings yet