Professional Documents

Culture Documents

Am Am VM VM V V LW: ME488/588 Machining Costs Homework Problem Cylinder Plate

Uploaded by

Sathisha MkOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Am Am VM VM V V LW: ME488/588 Machining Costs Homework Problem Cylinder Plate

Uploaded by

Sathisha MkCopyright:

Available Formats

ME488/588 Machining Costs Homework Problem

Cylinder

10/28/03

Plate

Am

Vm

V

density

Weight

v-HSS

v-B.Carb

ps

4

24

144

6

Steel lc

0.28

40.75

19.2

52.9

1.1

load/un

engage (s)

setup (s)

addit. Setup

batch size

t1

39.6

30

5400

0

3000

71.4

39.6

30

5400

0

3000

71.4

6.4 s

3.2 s

HSS

Carbide

18.8

6.8

12.9 s

6.0 s

tmp -Maching time (min power)

Pm

5

tmp

586.6

126.3 s

Pm

tmp

3

528.0

192.0 s

density

Weight

vf-HSS

vf-B.Carb

ps

9.4 sq in

18.8 cu in

125.7 cu in

Am

Vm

V

lw

Steel al. Alum. al.

0.31

0.10 lb/cu in

38.97

12.57 lb

23.7

176

96

352

1.3

0.28 hp/(in3/min)

t1 - Non-Productive time

load/un

52.9

engage (s)

10

setup (s)

1800

addit. Setup

0

batch size

2400

t1

63.65

tmc - Maching time (min cost)

HSS

47.6

Carbide

11.8

31.9

10

1800

0

2400

42.65

Cpo - Production costs

M'

30 $/hr

M 0.008333 $/s

HSS

5.42

1.41 $/part

Carbide

5.42

1.41 $/part

CB - Material Cost

cost/wt

CB

0.75

29.23

1.93 $/lb

24.26 $/part

C - total/part

34.64

25.67 $/part

sq in

cu in

cu in

in

Zinc. al.

0.23 lb/cu in

33.12 lb

28

60.1

0.4 hp/(in3/min)

M'

35 $/hr

M 0.0097222 $/s

HSS

5.83

2.56 $/part

Carbide

5.83

2.56 $/part

cost/wt

CB

0.42

17.12

1.50 $/lb

49.68 $/part

22.94

52.24 $/part

You might also like

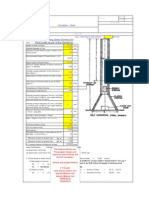

- Design of Steel Chimney and RCC Foundation As Per Indian Code 22052014Document12 pagesDesign of Steel Chimney and RCC Foundation As Per Indian Code 22052014Ahmad Badsha Quadri58% (19)

- Machine Design Elements and AssembliesFrom EverandMachine Design Elements and AssembliesRating: 3.5 out of 5 stars3.5/5 (2)

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Materials Data for Cyclic Loading: Aluminium and Titanium AlloysFrom EverandMaterials Data for Cyclic Loading: Aluminium and Titanium AlloysRating: 1 out of 5 stars1/5 (1)

- Pressure Vessel THCK CalcDocument8 pagesPressure Vessel THCK Calcmkchy12100% (1)

- Proper Bolt Axial Tightening ForceDocument1 pageProper Bolt Axial Tightening ForcePrabhu SelvaRajNo ratings yet

- 2400 Tema DCDocument7 pages2400 Tema DCMasoodMiyanNo ratings yet

- Hamt K: 1 Basic ParameterDocument7 pagesHamt K: 1 Basic ParameterVenkatesha HebbarNo ratings yet

- PV Elite 2013 Sp3 Licensee: Isgec Filename: Pe-1668 75 - Hydro Asme Ts Calc: Case: 1 12:08P Apr 2,2014Document8 pagesPV Elite 2013 Sp3 Licensee: Isgec Filename: Pe-1668 75 - Hydro Asme Ts Calc: Case: 1 12:08P Apr 2,2014Mayank MittalNo ratings yet

- 05 04 Chap GereDocument12 pages05 04 Chap GereDipNdra SharmaNo ratings yet

- Column IR Ratio CalculationsDocument7 pagesColumn IR Ratio CalculationsRajesh GangwalNo ratings yet

- Anchor Chair Design CheckDocument5 pagesAnchor Chair Design CheckHomer SilvaNo ratings yet

- Corbel DesignDocument6 pagesCorbel DesignMisqal A IqbalNo ratings yet

- RC Tie Beam DesignDocument10 pagesRC Tie Beam DesignSujay Santra67% (3)

- Proper Bolt Axial Tightening Force and Proper Tightening TorqueDocument1 pageProper Bolt Axial Tightening Force and Proper Tightening Torquecmms88No ratings yet

- Phase II-B SpecificationsDocument19 pagesPhase II-B SpecificationsanasgiNo ratings yet

- Asme Calculation For Renewal-A-317-Id Based - Rev-2Document29 pagesAsme Calculation For Renewal-A-317-Id Based - Rev-2ariya100% (1)

- Required Thicknesses of Pipe or Tube Per Asme B31.3-2010 Process Piping CodeDocument1 pageRequired Thicknesses of Pipe or Tube Per Asme B31.3-2010 Process Piping CodeZoebairNo ratings yet

- 13 One Way Ribbed SlabDocument24 pages13 One Way Ribbed SlabKhalil FanousNo ratings yet

- Det-8 Ub533x210x92Document4 pagesDet-8 Ub533x210x92ihpeterNo ratings yet

- Total Middle East New Bitumen Terminal in TlbuDocument25 pagesTotal Middle East New Bitumen Terminal in TlbuAnupam Jana100% (2)

- Vdi2230e 2014Document10 pagesVdi2230e 2014bennyfergusonNo ratings yet

- Bolt Shear and Tension Capacity To AAMA-TIR-A9Document1 pageBolt Shear and Tension Capacity To AAMA-TIR-A9KhoonShihHsienNo ratings yet

- Footing Design F 1Document8 pagesFooting Design F 1prabhuNo ratings yet

- RCC Design SheetsDocument40 pagesRCC Design SheetsIbrahim El SharNo ratings yet

- RCC Design SheetsDocument40 pagesRCC Design SheetsAnonymous 9iK0i8h0dPNo ratings yet

- Design Calculations For V2703 Rev 0Document9 pagesDesign Calculations For V2703 Rev 0Dilip KatekarNo ratings yet

- Saddle Reaction Summary - For Empty CaseDocument12 pagesSaddle Reaction Summary - For Empty CasesridharNo ratings yet

- Cummins c2750d5b Data SheetDocument3 pagesCummins c2750d5b Data Sheetbambang ismailNo ratings yet

- RCC Design SheetsDocument40 pagesRCC Design SheetsAnonymous nwByj9L100% (2)

- Compress Report For Pressure VesselDocument394 pagesCompress Report For Pressure VesselgaurangNo ratings yet

- BeamDocument4 pagesBeamAnkit SuriNo ratings yet

- TWI Current Practice For Welding P92 PDFDocument13 pagesTWI Current Practice For Welding P92 PDFpipedown456100% (1)

- Astm A106 Ts EnglDocument4 pagesAstm A106 Ts EnglxaviereduardoNo ratings yet

- Thermo-Kinetics Thermowell Calculation Program: Company: Tag #: Project No: Date: RevDocument14 pagesThermo-Kinetics Thermowell Calculation Program: Company: Tag #: Project No: Date: Revvazzoleralex6884No ratings yet

- Tank DesignDocument152 pagesTank Designnkmishra99100% (1)

- Bolt Strength PDFDocument1 pageBolt Strength PDFSilambarasi MurugesanNo ratings yet

- RE - Max 17 17 MM, Graphite Brushes, 4.5 Watt: Article NumbersDocument1 pageRE - Max 17 17 MM, Graphite Brushes, 4.5 Watt: Article NumbersJose CarlosNo ratings yet

- ASME SpreaderBar CalcsDocument5 pagesASME SpreaderBar Calcsganesh100% (1)

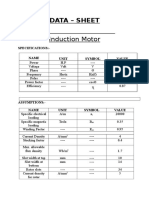

- Design of A Squirrel Cage Induction Motor: Data - SheetDocument7 pagesDesign of A Squirrel Cage Induction Motor: Data - SheetSovanSurNo ratings yet

- Design OF Doubly Reinforced BeamDocument4 pagesDesign OF Doubly Reinforced BeamRam LangheNo ratings yet

- Shape Memory Alloy Actuators: Design, Fabrication, and Experimental EvaluationFrom EverandShape Memory Alloy Actuators: Design, Fabrication, and Experimental EvaluationNo ratings yet

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsFrom EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNo ratings yet

- Case Studies in Mechanical Engineering: Decision Making, Thermodynamics, Fluid Mechanics and Heat TransferFrom EverandCase Studies in Mechanical Engineering: Decision Making, Thermodynamics, Fluid Mechanics and Heat TransferRating: 5 out of 5 stars5/5 (2)

- Joining of Polymer-Metal Hybrid Structures: Principles and ApplicationsFrom EverandJoining of Polymer-Metal Hybrid Structures: Principles and ApplicationsSergio T. Amancio FilhoNo ratings yet

- Stress in ASME Pressure Vessels, Boilers, and Nuclear ComponentsFrom EverandStress in ASME Pressure Vessels, Boilers, and Nuclear ComponentsNo ratings yet

- Cyclic Plasticity of Engineering Materials: Experiments and ModelsFrom EverandCyclic Plasticity of Engineering Materials: Experiments and ModelsNo ratings yet

- Printer Compatibility List: Print Server Model Printer Manufacture Printer ModelDocument20 pagesPrinter Compatibility List: Print Server Model Printer Manufacture Printer ModelpchakkrapaniNo ratings yet

- Ash Land DetailsDocument1 pageAsh Land DetailspchakkrapaniNo ratings yet

- Piping Material Selection TableDocument1 pagePiping Material Selection TablepchakkrapaniNo ratings yet

- Jumping Math!: Grade 1Document1 pageJumping Math!: Grade 1pchakkrapaniNo ratings yet

- Manuals Type3Document365 pagesManuals Type3pchakkrapani100% (1)

- Welding Terms & DefinitionsDocument42 pagesWelding Terms & DefinitionspchakkrapaniNo ratings yet

- Obtaining Contents in DVDDocument1 pageObtaining Contents in DVDpchakkrapaniNo ratings yet

- Hitachi CalibrationDocument3 pagesHitachi CalibrationpchakkrapaniNo ratings yet

- Calibre User Manual, The - Kovid GoyalDocument2 pagesCalibre User Manual, The - Kovid GoyalpchakkrapaniNo ratings yet

- Design For Assembly WorksheetDocument1 pageDesign For Assembly WorksheetpchakkrapaniNo ratings yet

- Instrument Calibration ProcedureDocument7 pagesInstrument Calibration ProceduremullanjiNo ratings yet

- Calculating Electrical CostsDocument1 pageCalculating Electrical CostspchakkrapaniNo ratings yet

- Vendors 820Document28 pagesVendors 820pchakkrapaniNo ratings yet

- Setting Rings: Total Solution For Thread GaugingDocument1 pageSetting Rings: Total Solution For Thread GaugingpchakkrapaniNo ratings yet

- c006b QDocument54 pagesc006b QpchakkrapaniNo ratings yet