Professional Documents

Culture Documents

Using Pneumatic Conveying To Reduce Your Combustible Dust Explosion Risk

Uploaded by

Andor MolitoriszOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Using Pneumatic Conveying To Reduce Your Combustible Dust Explosion Risk

Uploaded by

Andor MolitoriszCopyright:

Available Formats

As appeared in March 2016 PBE

Copyright CSC Publishing

www.powderbulk.com

Using pneumatic conveying to reduce your

combustible dust explosion risk

Mitch Lund

Nol-Tec Systems

Combustible dust can be a severe hazard to your

plant and workers, but a pneumatic conveying

system can reduce your plants risk for a combustible dust explosion. This article explains the five

elements required for a dust explosion and shows

how a pneumatic conveying system allows you to

control those elements to reduce your plants dust

explosion risk.

ombustible dust is a critical concern for any plant

that processes and conveys bulk solid materials.

Recent changes in regulations have brought this

issue into greater focus, and the NFPA has strengthened

safety standards to prevent and mitigate explosions and

fires in plants where combustible dust is present. Several

NFPA standards pertain to combustible dust in various

individual industries, but the NFPAs intent is to have

consistent standards across industries and materials.1

Under the right circumstances, nearly any type of dust can

be combustible. Even some materials that arent normally

considered combustible can produce combustible dust.

Generally, particles smaller than 40 mesh can create a

hazard if theyre allowed to accumulate or become

airborne. Materials that produce combustible dusts

include sugar, coal, aluminum, wood, graphite, corn,

titanium, paper, and many others. Combustible dust

explosions have impacted a broad cross-section of

industries, as shown in Figure 1.

The dust explosion pentagon

Five elements are needed for a dust explosion to occur:

combustible dust, oxygen, an ignition source, dispersion

of the dust in the air, and a confined space in which the dust

cloud is contained. These five elements are called the dust

explosion pentagon, as shown in Figure 2. The first three

elements are needed to ignite a fire (or deflagration), while

the last two elements can turn that fire into an explosion. If

any one element is removed or suppressed, an explosion

cant occur.

Figure 1

Combustible dust explosions by industry

Rubber/

plastics

10%

Utility

7%

Paper

7%

Non-manufacturing

3%

Food

24%

Metal

13%

Wood

23%

Chemical

13%

Source: Combustible Dust Policy Institute

Copyright CSC Publishing

Figure 2

Dust explosion pentagon

Pneumatic conveying addresses all five dust explosion

elements and allows you more control over the elements

than typical mechanical conveying methods, such as belt,

vibratory, chain-drag, or screw conveyors or bucket

elevators. With pneumatic conveying, you can more

effectively remove elements of the dust explosion

pentagon from your process, helping you to prevent a

combustible dust explosion and meet NFPA standards.

Lets explore how pneumatic conveying allows you to

control each dust explosion element.

Avoid fueling the explosion

Combustible dust created from processing your material

provides the fuel for a dust explosion. Eliminating dust

completely can be very difficult in any conveying system,

but a pneumatic conveying system can help you minimize

this fuel source.

Dust is created when your materials particles break or

degrade during handling. Many mechanical conveying

methods tend to facilitate that breakage due to vibration

and particle-to-particle or particle-to-equipment abrasion.

Depending on your material, you may be able to use

dense-phase pneumatic conveying to minimize this

breakage and produce less dust. Unlike dilute-phase

pneumatic conveying, which uses low-pressure, highvolume air to convey material at high velocity, densephase pneumatic conveying uses high-pressure,

low-volume air to convey the material at low velocity. The

material moves through the conveying line in a series of

slugs in which theres very little interparticle abrasion or

impact with the conveying-line wall. This slug flow can be

much gentler and less abrasive on your material and create

less dust than dilute-phase pneumatic conveying.

Dust accumulation in the workspace or in your conveying

system can also provide fuel for a fire or explosion. If your

conveying system allows material to drop out of the

process stream and accumulate in the workspace or

conveying system, this accumulation can create an

explosion hazard. Unlike mechanical conveying,

pneumatic conveying offers 100 percent material

containment with no transfer points or other locations for

material to accumulate. Also, a pneumatic conveying

system can include air injection ports to add motive air

into the conveying line at points where material might be

prone to settle and accumulate. This additional airflow

keeps material moving along the conveying line and

prevents material accumulation that could fuel an

explosion.

Take oxygen out of the equation

Its difficult to imagine a way to keep oxygen out of any

bulk solids manufacturing process. Were surrounded by

it! But you dont need to eliminate oxygen completely to

prevent a dust explosion; you just need to reduce the

oxygen concentration to below your materials limiting

oxygen concentration (LOC) The LOC is the volumetric

percentage of oxygen in the conveying gas below which

combustion cannot occur. This safe oxygen level varies

greatly depending on the material but is typically less than

15 percent, as shown in Table I. Particle size is also a factor

when determining LOC. As the table shows, the LOC of

cellulose with a 51-micron median particle size is 11

percent, but the LOC of cellulose with a smaller, 22micron median particle size is just 9 percent.

Table l

Limiting oxygen concentration of common materials

(Nitrogen-air mixture)

Material

Median particle

diameter by mass

(microns)

Limiting oxygen

concentration

(percent O2)

Bread-wheat flour

60

11

Aluminum

22

Corn starch

17

Polyethylene

26

10

Cellulose

22

Cellulose

51

11

Wood flour

27

10

Brown coal

66

12

Bituminous coal

17

14

Magnesium alloy

21

Ferrosilicon magnesium alloy

17

Rubber powder

95

11

Aminophenazone

<10

Methionine

<10

12

Polyacrylonitrile

26

10

Sources: Diversified Air Systems; Fauske & Associates, LLC; NFPA

Copyright CSC Publishing

Keeping the oxygen in the conveying gas below the

materials LOC eliminates the possibility of an explosion. In

a pneumatic conveying system, this is done by inerting.

Inerting uses an inert gas, such as nitrogen, rather than air for

the conveying gas. This reduces the oxygen percentage to a

safe level and removes the dust explosion threat for the vast

majority of bulk solid materials. Inerting a mechanical

conveying system would be very difficult, however, because

a mechanical conveying system isnt completely enclosed

like a pneumatic conveying system.

Eliminate ignition sources

Ignition sources come in many forms, as shown in Figure 3.

The ignition source for a fire or explosion in a mechanical

conveying system can be anything from a spark produced by

an out-of-alignment system component to an overheating

bearing or belt. Visually monitoring your entire system to

find these potential causes of ignition can be difficult.

Pneumatic conveying eliminates the major ignition

sources, minimizing the possibility of an explosion. With

pneumatic conveying, few moving parts come into

contact with your material or other equipment. Since

theres no friction between moving components, a

pneumatic conveying system reduces the chance of

sparking and heat sources that could ignite the material.

Often, pneumatic conveying systems also incorporate

automated controls and monitoring devices, which

optimize process safety. These precision controls can

monitor the system and stop potential equipment

problems before they can develop into an ignition source.

Figure 3

Friction

9%

Fire

8%

Other

3%

Mechanical sparks

30%

With a mechanical conveying system, the surrounding air

isnt moving, so dust can hang in the air and reach dangerous

concentrations. A pneumatic conveying system encloses the

material and dust and keeps them moving, allowing you to

control the air-to-material ratio and ensure that a dangerous

dust concentration doesnt develop. This is impossible with

an open mechanical conveying system without the use of an

extensive dust collection system and sheathing.

Contain the dust cloud safely

The final element of the dust explosion pentagon is dust

cloud containment. As stated earlier, in a pneumatic

conveying system, the material is 100 percent contained,

which may seem to present a hazard. In a properly designed

system, however, that containment is controlled to

minimize your explosion risks. Pneumatic conveying

allows you to contain dust safely and collect it from the

system so it doesnt accumulate in the workspace and create

a hazard. Remember, containment is only a concern if all

other elements of the dust explosion pentagon are present. A

properly designed pneumatic conveying system can

prevent that from happening. Work with an experienced

pneumatic conveying system supplier to ensure that your

system efficiently and effectively conveys your material

while keeping your plant and workers safe.

PBE

References

Dust explosion ignition sources

Unknown/no data

11.5%

Manage your dust dispersion

Combustible dust needs to be in specific concentrations in

the atmosphere to be an explosion hazard. The NFPA has

done extensive research on combustible materials and has

developed specific formulas for calculating these

concentrations. Its important that you have your dust

tested to determine safe concentration levels for your

material and application.

1. See www.nfpa.org and www.osha.org for detailed information on

combustible dust standards and explosion prevention.

Hot surfaces

6.5%

Self-ignition

6%

For further reading

Find more information on pneumatic conveying in articles

listed under Pneumatic conveying in Powder and Bulk

Engineerings article index in the December 2015 issue or the

Article Archive on PBEs website, www.powderbulk.com.

Find more information on dust explosion prevention in

articles listed under Explosion/fire protection. (All articles

listed in the archive are available for free download to

registered users.)

Mitch Lund is a chemical engineer and product manager

for Nol-Tec Systems, Inc. (mitchlund@nol-tec.com). He

has 4 years of experience in field-testing for pneumatic

conveying system design and new product development.

Nol-Tec Systems

Electrical equipment

Welding

3.5%

5%

Smolder

spots

Static electricity

9%

9%

Lino Lakes, MN

651-780-8600

Source: OSHA

www.nol-tec.com

You might also like

- GaryJohnsonArticle PDFDocument10 pagesGaryJohnsonArticle PDFCarlos JiménezNo ratings yet

- Dust Papers 1Document129 pagesDust Papers 1jiaolei9848No ratings yet

- Frequency and Causes of Grain Dust Explosions: Oxygen, Ignition Source, Fuel, and ContainmentDocument4 pagesFrequency and Causes of Grain Dust Explosions: Oxygen, Ignition Source, Fuel, and ContainmentjosethompsonNo ratings yet

- NFPA For Dust Collection SystemDocument10 pagesNFPA For Dust Collection Systemngocbinh8x100% (1)

- Dust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesFrom EverandDust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesNo ratings yet

- Reducing The Risk of Dust Explosion Hazards: Fuel IgnitionDocument1 pageReducing The Risk of Dust Explosion Hazards: Fuel IgnitionJoãoPauloLaudaresNo ratings yet

- Reduce Hazards-Vaccum SystemDocument7 pagesReduce Hazards-Vaccum SystemChem.EnggNo ratings yet

- Dust Explosions PDFDocument34 pagesDust Explosions PDFMuthu KumarNo ratings yet

- B C F Section 4Document59 pagesB C F Section 4Saeed Ahmed Soomro100% (1)

- Dust Literature ReviewDocument6 pagesDust Literature ReviewBharat VaajNo ratings yet

- Arch Environmental Equipment, Inc.: Dust Suppression Technical HandbookDocument19 pagesArch Environmental Equipment, Inc.: Dust Suppression Technical Handbookshanmars100% (2)

- Handling Dusts and Powders Safely A Strategic Guide For Characterisation and Understanding Library PDFDocument48 pagesHandling Dusts and Powders Safely A Strategic Guide For Characterisation and Understanding Library PDFJuan Palomo (Pajarito)No ratings yet

- Whitepaper: Fire & Explosion ProtectionDocument10 pagesWhitepaper: Fire & Explosion ProtectionSrinivas PandaNo ratings yet

- Physical Sciences: Exvema Explosion Venting ManualDocument116 pagesPhysical Sciences: Exvema Explosion Venting ManualipliprensNo ratings yet

- 4 Cs of Dust Control InformationalDocument5 pages4 Cs of Dust Control Informationalabu_shofiaNo ratings yet

- Static DischargeDocument2 pagesStatic DischargeVelmurugan ElumalaiNo ratings yet

- Ergonomics N Housekeeping - Sweeping Dust & Debris Could Blow Your Safety RatingDocument12 pagesErgonomics N Housekeeping - Sweeping Dust & Debris Could Blow Your Safety RatingsingenaadamNo ratings yet

- Safety and Environmental IssuesDocument8 pagesSafety and Environmental IssuesAmirah NasirNo ratings yet

- 10-12OSHA Handbook PagesDocument6 pages10-12OSHA Handbook PagesRelene WeiNo ratings yet

- Dust ExplosionDocument4 pagesDust ExplosionAtul TripathiNo ratings yet

- Hood Types: Enclosing Hoods Are Those in Which The Source Is Either Partially or Totally Enclosed To Provide TheDocument11 pagesHood Types: Enclosing Hoods Are Those in Which The Source Is Either Partially or Totally Enclosed To Provide TheSudhakar KarnanNo ratings yet

- Guide To SpraypaintDocument7 pagesGuide To SpraypaintNurul NadirahNo ratings yet

- GAPS Guidelines: Dust Collection SystemsDocument13 pagesGAPS Guidelines: Dust Collection SystemsAsad KhanNo ratings yet

- Dust Extraction SystemDocument13 pagesDust Extraction SystemEng Tennyson SigaukeNo ratings yet

- Consideration in Dust Collection SystemDocument9 pagesConsideration in Dust Collection SystemMohammad Ali TaghdiriNo ratings yet

- Tg15 04 Dust Awareness Controls PDF enDocument4 pagesTg15 04 Dust Awareness Controls PDF enZeeshan BajwaNo ratings yet

- Avoiding Explosions by Means of Inerting SystemsDocument14 pagesAvoiding Explosions by Means of Inerting SystemsRicky Menon100% (1)

- Engineering Letter: PneumaticconveyingDocument4 pagesEngineering Letter: PneumaticconveyingMangatur SimamoraNo ratings yet

- Dust Collector DesignDocument13 pagesDust Collector DesignAekJay50% (2)

- Case Studies in Fire Safety: P.A. (Tony) EnrightDocument7 pagesCase Studies in Fire Safety: P.A. (Tony) Enrightpequenita34No ratings yet

- Training Presentation PDFDocument38 pagesTraining Presentation PDFDarko Kocic100% (1)

- HSE - Explosion ReliefDocument8 pagesHSE - Explosion ReliefridanormaNo ratings yet

- Vac U Max Sweeping Dust and Debris Could Blow Your Safety RatingDocument4 pagesVac U Max Sweeping Dust and Debris Could Blow Your Safety RatingnugiespNo ratings yet

- Combustible DustDocument11 pagesCombustible DusthalsonNo ratings yet

- CO2 Dust CollectorsDocument6 pagesCO2 Dust CollectorsJose Alfredo Rodriguez ColladoNo ratings yet

- White Paper - The Basics of Laser Fume ExtractionDocument8 pagesWhite Paper - The Basics of Laser Fume Extractionrushian65No ratings yet

- Molecular SealDocument2 pagesMolecular SealAkshat RoyNo ratings yet

- Fire and Explosion Characteristics of Powders: Vahid Ebadat, PH.DDocument7 pagesFire and Explosion Characteristics of Powders: Vahid Ebadat, PH.Dsiruslara6491No ratings yet

- Minimize Facility FlaringDocument5 pagesMinimize Facility FlaringFA AyNo ratings yet

- Cleaning A Grain Elevator: BackgroundDocument2 pagesCleaning A Grain Elevator: BackgroundНиколайNo ratings yet

- Six Considerations For Proper Dust Collection System DesignDocument9 pagesSix Considerations For Proper Dust Collection System DesignJoão CoelhoNo ratings yet

- Nyb - El-09 PDFDocument4 pagesNyb - El-09 PDFtylerstearnsNo ratings yet

- 10 Tips To Optimize Dust Collection System PerformanceDocument9 pages10 Tips To Optimize Dust Collection System PerformancePunto MühendislikNo ratings yet

- Dust Modelling Using A Combined CFD and Discrete Element FormulationDocument22 pagesDust Modelling Using A Combined CFD and Discrete Element FormulationArtur CunhaNo ratings yet

- Rotary Valve Lock Leakage SolutionsDocument8 pagesRotary Valve Lock Leakage SolutionsW MoralesNo ratings yet

- Dust Suppression of Phosphate Rock: Storage, Conveyance and ShippingDocument7 pagesDust Suppression of Phosphate Rock: Storage, Conveyance and ShippingJavier Alejandro RodriguezNo ratings yet

- What Are The Types and Causes of Fire Hazards in Textile IndustryDocument4 pagesWhat Are The Types and Causes of Fire Hazards in Textile IndustryMuhammad Asif Idrees100% (3)

- Impulse Ventilation An IntroductionDocument10 pagesImpulse Ventilation An IntroductionNupur Bhadra100% (1)

- Brochure Explosion Protection enDocument45 pagesBrochure Explosion Protection enpramodtryNo ratings yet

- 'Protecting Escape Routes - Smoke Shafts V Pressurisation' - Means of Escape - Fire Safety MagazineDocument6 pages'Protecting Escape Routes - Smoke Shafts V Pressurisation' - Means of Escape - Fire Safety MagazineAnonymous NGXdt2BxNo ratings yet

- Examing - of - The - Effectiveness - of - Ope NoDocument32 pagesExaming - of - The - Effectiveness - of - Ope Nohubo1200No ratings yet

- Hazard Analysis For Dust Handling PDFDocument8 pagesHazard Analysis For Dust Handling PDFBen banquilNo ratings yet

- Dust HazDocument8 pagesDust HazMitesh MarvaniyaNo ratings yet

- Explosion Venting RequirementsDocument6 pagesExplosion Venting Requirementsamariei_niculinaNo ratings yet

- Robertsetal ICBMH2016 ResearchandDevelopmentofAirborneDustControlTechniquesDocument9 pagesRobertsetal ICBMH2016 ResearchandDevelopmentofAirborneDustControlTechniquesFadhillah PrimanitaNo ratings yet

- Dust Suppression Practical GuideDocument20 pagesDust Suppression Practical GuideSeshupower09100% (1)

- Handbook of Air Pollution Prevention and ControlFrom EverandHandbook of Air Pollution Prevention and ControlRating: 5 out of 5 stars5/5 (2)

- Usa Tech Calculation PDFDocument35 pagesUsa Tech Calculation PDFRizwan HameedNo ratings yet

- Tut08 e Audir8 PDFDocument108 pagesTut08 e Audir8 PDFNor HidayahNo ratings yet

- What Is HeadDocument8 pagesWhat Is HeadAsan IbrahimNo ratings yet

- English Test 1Document3 pagesEnglish Test 1Andor MolitoriszNo ratings yet

- (En) Catia V5R7 Prismatic Machining BookDocument196 pages(En) Catia V5R7 Prismatic Machining BookiagomouNo ratings yet

- Neumesy Robot For NeurosurgeryDocument32 pagesNeumesy Robot For NeurosurgeryAndor MolitoriszNo ratings yet

- Silo CountyT1 DS Rev02-562791007ebe3Document2 pagesSilo CountyT1 DS Rev02-562791007ebe3Andor MolitoriszNo ratings yet

- N Leveltec L en 16 1Document4 pagesN Leveltec L en 16 1Andor MolitoriszNo ratings yet

- English Brewing and Packaging GlossaryDocument17 pagesEnglish Brewing and Packaging GlossaryAndor MolitoriszNo ratings yet

- HSG 232Document77 pagesHSG 232ozgurturunc4No ratings yet

- DS AC0920 en Co 37362Document10 pagesDS AC0920 en Co 37362Andor MolitoriszNo ratings yet

- DENWEL Carboblender v16bDocument2 pagesDENWEL Carboblender v16bAndor MolitoriszNo ratings yet

- DIN CatalogDocument60 pagesDIN CatalogAndor MolitoriszNo ratings yet

- 41759Document6 pages41759Andor MolitoriszNo ratings yet

- Alfa Laval Brew 301Document4 pagesAlfa Laval Brew 301Andor MolitoriszNo ratings yet

- Pid Legend PDFDocument1 pagePid Legend PDFSocMed Dtk UI0% (1)

- Supports For Pipelines 1758uk 7-03-15 PDFDocument46 pagesSupports For Pipelines 1758uk 7-03-15 PDFAndor MolitoriszNo ratings yet

- English Brewing and Packaging GlossaryDocument17 pagesEnglish Brewing and Packaging GlossaryAndor MolitoriszNo ratings yet

- Cpmu C11Document4 pagesCpmu C11Andor MolitoriszNo ratings yet

- Cable and Chain Drag Conveyor BrochuresDocument12 pagesCable and Chain Drag Conveyor BrochuresAndor MolitoriszNo ratings yet

- Roller Mill Crusher SkioldDocument4 pagesRoller Mill Crusher SkioldAndor MolitoriszNo ratings yet

- Towards The Lights-Out Brewery: A Brewer's View of AutomationDocument5 pagesTowards The Lights-Out Brewery: A Brewer's View of AutomationAndor MolitoriszNo ratings yet

- Beer Recovery ArticleDocument4 pagesBeer Recovery ArticleAndor MolitoriszNo ratings yet

- PROIECTDocument39 pagesPROIECTAndor MolitoriszNo ratings yet

- Brushless Ac Servo MotorsDocument7 pagesBrushless Ac Servo MotorsAndor MolitoriszNo ratings yet

- Angrenaje.1.2 Engl RomDocument34 pagesAngrenaje.1.2 Engl RomAndor MolitoriszNo ratings yet

- HHS En02 Windows and LinuxDocument15 pagesHHS En02 Windows and LinuxnipunaNo ratings yet

- RPP 6Document47 pagesRPP 6Andor MolitoriszNo ratings yet

- Getting Started With LabVIEWDocument94 pagesGetting Started With LabVIEWsudiceNo ratings yet

- Salem RPGDocument16 pagesSalem RPGabstockingNo ratings yet

- Manual 35S EnglishDocument41 pagesManual 35S EnglishgugiNo ratings yet

- Motor CAT C13 AcertDocument3 pagesMotor CAT C13 AcertJosé Gonzalez100% (4)

- Opex and CapexDocument5 pagesOpex and CapexATM Shafiq Ul AlamNo ratings yet

- Procter and Gamble-1Document5 pagesProcter and Gamble-1Abegiel MendozaNo ratings yet

- Full Download Short Term Financial Management 3rd Edition Maness Test BankDocument35 pagesFull Download Short Term Financial Management 3rd Edition Maness Test Bankcimanfavoriw100% (31)

- Army Aviation Digest - Nov 1978Document52 pagesArmy Aviation Digest - Nov 1978Aviation/Space History Library100% (1)

- The Dry Bulk Management StandardDocument18 pagesThe Dry Bulk Management Standardamu_more44100% (1)

- Assignment 4 SolutionsDocument9 pagesAssignment 4 SolutionsNengke Lin100% (2)

- John Sisler CISSP Study GuideDocument126 pagesJohn Sisler CISSP Study GuideAnthonyNo ratings yet

- Top Coat-200 - Data PDFDocument4 pagesTop Coat-200 - Data PDFLiliana GeorgianaNo ratings yet

- The Ieee Test System Methods: Reliability ofDocument11 pagesThe Ieee Test System Methods: Reliability ofFsdaSdsNo ratings yet

- Understanding Bernoulli's Principle Through Simulations PDFDocument4 pagesUnderstanding Bernoulli's Principle Through Simulations PDFIoannis GaroufalidisNo ratings yet

- Me8072 Renewable Sources of EnergyDocument13 pagesMe8072 Renewable Sources of EnergyNallappan Rajj ANo ratings yet

- Microbiology Part 3Document74 pagesMicrobiology Part 3Authentic IdiotNo ratings yet

- Prawn ProcessingDocument21 pagesPrawn ProcessingKrishnaNo ratings yet

- Pineapple in JohorDocument6 pagesPineapple in JohorHaiqal AzizNo ratings yet

- Zest O CorporationDocument21 pagesZest O CorporationJhamane Chan53% (15)

- Orofacial Complex: Form and FunctionDocument34 pagesOrofacial Complex: Form and FunctionAyushi Goel100% (1)

- Abnormalities of Placenta, Amniotic Fluid and Cord: Prepared By, B. Ezhilarasi, Nursing TutorDocument21 pagesAbnormalities of Placenta, Amniotic Fluid and Cord: Prepared By, B. Ezhilarasi, Nursing TutorGopala KrishnanNo ratings yet

- Report - IvatanDocument28 pagesReport - IvatanJohara Winel PerezNo ratings yet

- Earth Sciences Notes Csir-Ugc Net JRFDocument57 pagesEarth Sciences Notes Csir-Ugc Net JRFmanas773No ratings yet

- 2 Contoh Narative TextDocument9 pages2 Contoh Narative TextRini RienzNo ratings yet

- Mini Project 1 - 1Document9 pagesMini Project 1 - 1Sameer BaraNo ratings yet

- American University of BeirutDocument21 pagesAmerican University of BeirutWomens Program AssosciationNo ratings yet

- Complete Processing Lines For Extruded Pet FoodDocument13 pagesComplete Processing Lines For Extruded Pet FoodденисNo ratings yet

- YogaDocument116 pagesYogawefWE100% (2)

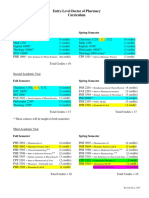

- Pharmd CurriculumDocument18 pagesPharmd Curriculum5377773No ratings yet

- Donna Hay Magazine 2014-10-11 PDFDocument172 pagesDonna Hay Magazine 2014-10-11 PDFlekovic_tanjaNo ratings yet

- QuantAssay Software Manual 11-Mar-2019Document51 pagesQuantAssay Software Manual 11-Mar-2019LykasNo ratings yet