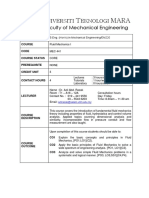

Professional Documents

Culture Documents

SPE-184819-MS Advanced Reservoir Characterization in Antelope Shale Using Chemical Tracer Technology

Uploaded by

SSOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SPE-184819-MS Advanced Reservoir Characterization in Antelope Shale Using Chemical Tracer Technology

Uploaded by

SSCopyright:

Available Formats

SPE-184819-MS

Advanced Reservoir Characterization in Antelope Shale Using Chemical

Tracer Technology

Manish K. Lal and Amit K. Singh, Chevron; Joshua Ezernack and Jon Spencer, Tracerco

Copyright 2017, Society of Petroleum Engineers

This paper was prepared for presentation at the SPE Hydraulic Fracturing Technology Conference and Exhibition held in The Woodlands, Texas, USA, 24-26 January

2017.

This paper was selected for presentation by an SPE program committee following review of information contained in an abstract submitted by the author(s). Contents

of the paper have not been reviewed by the Society of Petroleum Engineers and are subject to correction by the author(s). The material does not necessarily reflect

any position of the Society of Petroleum Engineers, its officers, or members. Electronic reproduction, distribution, or storage of any part of this paper without the written

consent of the Society of Petroleum Engineers is prohibited. Permission to reproduce in print is restricted to an abstract of not more than 300 words; illustrations may

not be copied. The abstract must contain conspicuous acknowledgment of SPE copyright.

Abstract

Understanding zonal contribution is imperative in a well with comingled production from multiple

stimulated zones. This has even more importance in shale plays where a primary appraisal objective is to

identify the prolific zones with a vertical well to decide which layers of the formation will be targeted for

future development. The use of measured inflow over time of each targeted zone provides an excellent

methodology to establish zonal contribution and wellbore evaluation.

The Monterey Formation in the southern San Joaquin valley of California produces from three silica

phases. While the industry has been pretty successful in producing from the shallow Diatomite rock via

cyclic steam operations, the deeper silica-based resources available in the Antelope Shale have yet to be

commercially established. Extracting hydrocarbons locked in these silica phases requires unconventional

technologies to access the high porosity / low permeability network. Unconventional completions require

greater front-end cost and carry an increased risk to return on investment. To minimize the risk, each pay

zone needs to be effectively described using both theoretical and empirical data.

In this paper, we present and discuss a case study where chemical-based tracer technology was used to

develop an accurate identification of the distinct pay zones within the different silica phases of the Antelope

Shale. Unique oil-phase chemical tracers were applied during the permitted hydraulic fracturing on four

vertical wellbores that gave an insight into the zonal production contribution and helped narrow potential

zones for future development. In comparison to tool based zonal contribution measurement methods, which

provide a snapshot in time measurement, the chemical tracers provided the capability to monitor and

measure inflow over a longer period indicating that zonal contribution varied with time. Some formation

layers produced immediately and then declined, while others took longer to cleanup and start contributing

to total production. These results helped narrow the uncertainty around the potential target zones.

Introduction

The Antelope Shale reservoir within the Monterey Formation in San Joaquin valley in California is

of Miocene age (Figure 1) and produces from three silica phases: Opal A (Diatomite), Opal CT, and

Quartz (Figure 2). While the Opal A has heavy oil and has been produced successfully via cyclic steam

operations, the Opal CT and Quartz have relatively light oil and the resources have largely been locked

SPE-184819-MS

since their discovery in the 1960s. With the US shale oil boom in the past decade and advancing stimulation

technologies, there has been a renewed interest in the lower Opal CT and Quartz phases to try to achieve

commercial production.

Figure 1 Monterey Formation Stratigraphy

Figure 2 Silica Phases of Antelope Shale

The Antelope Shale is a silica rich diatom deposition that is naturally fractured, normally pressured,

has migrated oil, decent porosity but low matrix permeability. Numerous pieces of literature have been

published that characterize the Monterey shales and their properties.

In general, unlike most conventional shale plays, the Monterey shales are much thicker (2000 ft. or more),

are not as widespread geographically (less than 2000 sq. miles), are much younger (6-16 million years

old), and have migrated oil. This kind of siliceous shale hydrocarbon reservoir is not very common and

has a complex geology. Drilling is more expensive due to the greater depths which have added to a much

SPE-184819-MS

slower industry adaptation and advancement. A quick overview of the Monterey Formation history (Figure

3) indicates that the recent technological advancements have largely not been implemented in this rock.

Figure 3 Monterey Formation History

Understanding the zonal contribution in a vertical commingled well is a key element for proper wellbore

and reservoir management. This is even more important in thick reservoirs with multiple sub-zones where a

decision on vertical vs. horizontal development needs to be evaluated. Knowing the production contribution

by zone enables engineers to focus on the higher producing zones and assists in picking the target zones

for future development.

Methods to Understand Zonal Contribution

While logging during drilling and post-drilling is used to characterize the wellbore, formation, and in-situ

fluids prior to well completion, there are additional methods available to provide information during most

production operations. The following are the various methods / tools available to the industry that provide

quantitative zonal production measurement and how they can often be used together to provide crucial

information for understanding the reservoir, stimulation effectiveness, and planning future development

strategies:

Fiber Optics

Fiber optics measures and models the Distributed Acoustic Sensing (DAS) / Distributed Temperature

Sensing (DTS) data for allocating production to different zones. There are inherent uncertainties in the

analysis as it requires Water Oil Ratio (WOR) for calculations. This method is relatively expensive with only

qualitative results for a three phase system. Both cost and complexity need to be evaluated when choosing

this method.

Geochemical Analysis

Geochemical analysis for understanding zonal contribution precisely refers to oil fingerprinting wherein

downhole oil samples are collected and analyzed. Oil from each layer / zone has a unique gas

chromatographic (GC) fingerprint. A comparison and correlation of these fingerprints can give an idea of

the relative contribution of a particular interval in a commingled well. A baseline analysis of the in-situ

oil is required, but thereafter all samples analyzed can be compared to the baseline analysis to see if the

flow contribution from any particular zone is changing or is consistent. The information obtained from any

particular analysis is a snapshot in time.

SPE-184819-MS

Sliding Sleeve

A sliding sleeve assembly consists of individual sleeves assembled and run into the wellbore to be placed

across the pay zone. These sleeves can be mechanically operated to open and close an individual zone.

Multiple sleeves can be installed at different depths for selective isolation of different producing zones.

The producing zones are isolated by packers and the sleeves are opened or closed by slick line allowing

flexibility of producing one or multiple zones at a time. The number of isolated zones may be limited due to

physical well constraints (most likely up to 5 sleeves). Wellhead design needs to have penetrations for the

surface control lines to the sleeves. The elastomer seals in the sliding sleeves may deteriorate over time and

special elastomers may be needed for some well fluids. In the case of artificial lift, the pump needs to be

placed above the sleeve. Any time the sleeve is to be operated, the pump needs to be pulled out. The pump

seat nipple should have a large enough Inner Diameter (ID) to allow the shifting tool to pass through.

Intelligent Well Completion (IWC)

An IWC assembly in a well refers to one or more surface controlled sub-surface flow control valves with

sensors that could monitor pressure and temperature and in some cases, flow rates. An IWC assembly

provides the operator with a means to remotely monitor and control downhole production or injection. It

offers real time reservoir surveillance, quick and cheap zonal control or isolation without rig, and prevent

cross-flow in injectors when the well is shut-in. The challenges with IWC are cost, complexity of installation

and operation, and maintenance to reduce the risk of Inflow Control Valve (ICV) failure. ICV failure may

will lead to lost production (despite that ICV are designed to fail in open position).

Produce One Zone at a Time

The method of producing one stage / zone at a time, by far, should be the most effective method for

understanding zonal contribution. It can be achieved by dual completions (for 2 zones) or by producing

one zone at a time (for 2 or more zones). However, this will likely incur more cost with a dual completion

design or lost production due to one zone at a time production, both of which may not be optimal. The dual

completion is a challenge in an unconventional stimulated reservoir. Producing single zone at a time can be

achieved either by selective completion or utilizing sliding sleeve, but it leads to lost production and well

intervention and associated cost in the latter case.

Production Logging Tool (PLT)

A basic production logging incorporating spinner / temperature / fluid density / gamma ray tools is used

in the industry to measure the flow velocity, density and temperature of the fluid in the wellbore. The

flow at each individual perforation cluster can be measured and identified as to fluid type and volume.

The production logging run should be carefully planned with a full wellbore sketch and the tool run under

stable well operations. The well must be under self-flow conditions and the logging results may be impacted

when wellhead flow volumes and pressures vary during the time of the logging operation. The tool may

restrict the flow area and alter the flow regime. PLT runs should be scheduled so as to provide for multiple

runs. Multiple runs at different speeds are essential for the proper in-situ calibration of the spinner and

computation of the absolute flow. Running the tool usually requires rig or coil tubing, all at additional costs

to the operator. Due to the requirement for self-flow, the tool is not usable with rod or sub-surface pumped

wells. The information obtained from any particular tool run is a snapshot in time.

Tracers

Chemical based tracers are available in gas, oil and water phase solutions. The tracers are applied to the

fracture fluid during the hydraulic fracturing of each stage which carries them into the fracture matrix

where they respectively mix with the in-situ production phase. The tracers return with the traced production

phase when the well is put on production. Production samples are collected at surface and analyzed for the

SPE-184819-MS

presence and concentration of each tracer's unique signature. Comparison of the amounts of each tracer

in the sample is the underlying principle of the quantification methodology, as it is a direct indication of

production contribution from each stage in the wellbore. The current numbers of tested and proven unique

chemicals exceeds forty, allowing multiple measurements along the wellbore for detailed definition of stage /

zonal inflow. Using different chemical tracers targeting the oil, water, and gas phases provides information

on the contribution of each phase.

Chemical tracer applications require trained personnel onsite to apply the tracers, at additional cost to the

operator, to ensure correct application and prevent errors. Sample collection can usually be accomplished

by existing flow back personnel as no tracer specific sampling procedures are required. However, care must

be taken to prevent sample contamination that may impact the tracer results.

Each sample provides a "production log" indicating the stage production during the sample time

period, with higher tracer concentration indicative of increased zonal contribution and lower concentration

representing reduced contribution. A comparison of production split per stage for sequential samples

provides a view of changing production over time, and can be used to evaluate the stage / zonal flow

dynamics, stimulation effectiveness (when combined with stimulation data), rock production capability

(when combined with petrophysical data), and assist in decisions on zonal development going forward.

Case Study

Oil-phase chemical tracer technology was utilized during permitted hydraulic fracturing treatments in the

Antelope Shale reservoir in the McKittrick field to understand zonal contribution from the deeper silica

phases: Opal CT, and Quartz.

The chemical tracer technology was preferred over the other methods for primarily 3 reasons:

Provision of zonal contribution information over a significantly longer period of time than wireline

tools.

Full bore flow capability, without tool intrusion.

Relatively low cost.

In Well 1, sliding sleeves and PLT were utilized along with the chemical tracers. A comparison of these

tool's results are presented in this paper.

Application and Design

Four vertical wells in the McKittrick field were drilled into the siliceous shale intersecting similar target

zones within the Quartz and Opal CT phases. These wells were hydraulically fractured with multiple stages:

Well 1 (11 stages), Well 2 (12 stages), Well 3 (7 stages), and Well 4 (7 stages). A unique oil-phase chemical

in an organic solution was added as a distributed emulsion to the fracturing fluid of each stage in each of

the four wells to provide data to differentiate the production characteristics of each zone.

Table 1 identifies and color codes the five unique zones of the formation that were targeted for stimulation

across the Quartz and Opal CT phases, as well as where each intersected in the respective wellbore. Wells 1

& 2 were completed using the coiled tubing Pinpoint Hydrajet Frac system, which allowed fractures to be

isolated to specific sets of perfs, whereas Wells 3 & 4 utilized the Plug-and-Perf completion method which

had a longer interval length per stage that created larger overlap of the individual zones. To compensate

for the variation in stage lengths and overlap of zones, which made it difficult to compare production

contribution from each zone, the perforated footage intersecting each layer was used to establish a (footage)

ratio (per zone) to create a means of normalization (Figure 4a). The established zonal footage ratio was then

allocated proportionally to the measured stage volumes of those stages with overlapping zones under the

assumption that the tracer was evenly distributed across all perfs of the respective stage (Figure 4b).

SPE-184819-MS

Table 1 Targeted Fracture Stages in Antelope Shale

Figure 4aWell and Zonal Perf Lengths (ft)

Figure 4bNormalized Perf Lengths per Zone

SPE-184819-MS

Any possible variance in tracer application between stimulation stages was minimized by using a

controlled process to apply the tracers with tracer injection equipment connected to the suction side of the

high-pressure frac pumps. Tracer application consisted of applying equal volumes of tracer solution during

the same relative time frame of each hydraulic fracturing operation, thereby restricting solution application

variability and ensuring comparative tracer production under the assumption that all stages have the ability

to flowback in the same manner, with the dependent variables being the amount of oil producible from the

stage, stimulation effectiveness (planar or matrix), and rock parameters. The presence and concentration of

the tracers in the samples would then be indicative of actual oil production rates from each hydraulically

fractured matrix.

Sampling and Production

Produced fluid samples are required from the wellbore during initial and subsequent production. The

sampling program is determined by the amount of information desired versus the cost to sample, which

ultimately depends on the operator's objectives. Each tracer sample provides a snap-shot image of

the wellbore's production, detailing each stage's production at the respective sample time. An increased

sampling frequency would provide a greater resolution of each stage's flow response to pressure, fracture

type, and permeability variations in the wellbore. Typically, a greater number of samples are desired when

production is known to be fluctuating amongst individual stages in the wellbore, e.g., during initial flow

back or following any well operations that could affect the flow dynamics.

Sampling of the four wells was performed over a 6-month time period commencing from initial flow

back of each well. The wells had varying uptime during this period. To account for the varying producing

hours of each well, a value was established for equivalent days (Table 2) and used in the production

comparisons. Equivalent days only takes into account the amount of time each well was on production.

It is important to normalize and incorporate the producing time per well as it is assumed that a well that

has been producing for more hours will have increased total production as compared to a well that has not

been producing for as long.

Table 2Equivalent Days

Equivalent Days were calculated for the production comparisons using the equation:

Equivalent Days = (Cumulative Producing Hours) /1440

Tracer Production Methodology

The concentration of each unique tracer in the produced fluid sample was measured in the laboratory. For

comparative results, the quantity of each tracer in the oil sample was measured and correlated to the total

oil volume produced during the sampling interval. This relationship to production flow volume allows the

SPE-184819-MS

tracer responses to be compared on an equalized volumetric basis. In addition to confirmation of oil flow

from the stages, a comparison of the tracer concentration over time provides information on the production

from each stage. The level of tracer concentration in the samples is proportional to the stage oil production,

providing information on the amount of production from the stage.

Stage pressure is also a factor in production, either assisting in producing a large volume from that

stage, or inhibiting production due to a lower pressure factor. Analyzing the tracer response over time was

particularly useful in understanding how each stage produced oil over the sample time frame, i.e. does oil

production begin from one stage sooner or lasts longer than oil production from another stage (Figure 8).

For effective stage comparisons, the total cumulative tracer recovered per stage was determined from

all samples collected and this value was used to establish the total volume of oil produced from each stage

and zone. The cumulative response equation, (Equation 1) provides the cumulative tracer recovered up to

a specific elapsed time interval.

Where [TR] = total tracer produced over time

[Q] = cumulative oil production as a function of time

[C] = tracer measured in the sample

[t] = the elapsed time.

The produced oil flow rate will often be available as a discrete value representing each day. The measured

tracer (sampled) will be available only as an individual measurement established by the sampling program.

Reservoir Characterization and Tracer Results

The tracer results of the zonal contribution from the five targeted zones in each of the four wellbores are

presented in Figures 5a & 5b. Figure 5a shows the normalized cumulative oil production of each zone in

each wellbore. In Figure 5b, the sum value of all oil production from each zone is presented as a single

bar to indicate the comparative production differences between zonal production levels as determined by

the oil produced over time.

Figure 5aZonal Contribution Ratio (Oil) by Wellbore

SPE-184819-MS

Figure 5bZonal Contribution (Oil)

Measured oil volumes normalized to zonal contribution indicate that the Quartz (zone A) was not as

productive as the Opal CT zones. Although the combined zonal contribution bars (Figure 5b) suggest that

zones C & D in Opal CT were the most productive, the individual wellbore bars (Figure 5a) show that zone

C has more production variability across the field as compared to zone D. This could be due to variations

in rock properties in zone C across the field. Zone D may have consistent rock properties across the field

and gives higher confidence to target with horizontal wells.

Tracer vs. Sliding Sleeve Results

A production test of zonal contribution was performed with the sliding sleeves installed in Well 1. Production

was isolated to each zone by mechanically closing all but one sleeve. With the exception of zone A (which

had a bridge plug installed above it during the sleeve operations), each zone's production was monitored

for a 2-week period.

Tracer samples were collected as a method to confirm the sleeve status as open or closed. A positive

tracer presence would indicate an open sleeve, whereas low to no tracer presence would indicate a closed

sleeve. A confirmation of complete isolation is imperative when tools are used downhole to open or squeeze

stages from production, especially when using the data as a metric to understand which zones are to target

for future completions.

A comparison of tracer data with the well's oil production during each open sleeve is shown (Figure 6).

The black bars represent the normalized oil production from each zone when its corresponding sleeve was

in open position. The green bars represent the percentage of the sampled oil that is from the zone targeted

for isolation. Some samples indicated small amounts of leakage past the closed sleeve(s), but it is readily

apparent that the tracer presence or lack thereof, confirms the sliding sleeve operations to be successful.

10

SPE-184819-MS

Figure 6Well 1 Zonal Production: Sliding Sleeve vs. Tracer

A good match was observed between the actual oil production of zones C, D, E (Figure 6) and Well 1's

zonal tracer contribution (Figure 5a). This test proved the usefulness of tracers in the wellbore as a diagnostic

to verify wellbore equipment operations and also gives confidence in the zonal production quantification

using tracers.

Tracer vs. PLT Results

A comparison of the tracer data with the PLT run in Well 1 is shown (Figure 7).

Figure 7Tracer vs. PLT Flow Contribution in Well 1

The PLT and tracer results were in fairly good agreement for zones C, D, and E. However, since the PLT

went only just below the Opal CT and not all the way to the Quartz phase, the production from zone A could

be heavily influenced by that from zone B. As such, the contributions from zones A & B may be difficult

to distinguish. The PLT indicated zero production from zone B after taking a combined reading from the

three stages in zone A. This is an anomaly as compared to the tracer results which showed tracer production

from zone B in all samples collected. In fact, the tracer data recognized zone B as a significant contributor

in each of the four wells, while suggesting zone A to be an uneconomical target. Overall, both technologies

yielded similar zonal contributions based upon a combined flow from zones A and B and individual flows

from zones C, D, and E.

SPE-184819-MS

11

Flow Contribution over Time Using Tracer Data

One of the main advantages of tracer technology is the continuous data monitoring without shutting in the

well and it's relatively low cost. Figure 8 shows the zonal contribution variation of each zone over 150

equivalent days. This type of knowledge helps in understanding the effectiveness of the well stimulation

program and characterizing the true potential of the reservoir. A single snapshot in time will not capture the

true potential of a zone if it is changing.

Figure 8Flow Contribution over Time

Conclusions

Chemical tracer technology gave insight into the zonal production contribution and helped narrow potential

zones for future development. The correlation of high or low producing zones across the 4 wells gave a

spatial understanding of the prolific zones in this area.

The tracer results of zonal contribution were in agreement with zonal contribution results from one

PLT run in Well 1 and from the sliding sleeve manipulations also in Well 1. The results compared well

qualitatively, in the sense that a high producing zone from the tracer analysis was also a high producing zone

from PLT and sliding sleeve methods despite that the exact percentage contribution to flow was slightly

different.

Tracer results clearly indicated that production contribution of individual stage and zones varied over

time. The zonal inflow contribution monitored and measured over a longer period is critical as compared

to a snapshot measurement. These results were then compared to the geological and geophysical data to

develop and advance reservoir characterization of these formations.

Acknowledgement

The authors wish to thank the management of Chevron Corporation and Johnson Matthey Tracerco for

giving permission to publish this paper.

12

SPE-184819-MS

References

Gardien G.J., Pope G.A., and Hill A.D, Hydraulic Fracture Diagnosis Using Chemical Tracers, The University of Texas

at Austin SPE 36675 - 1995

Kaufman R. L., Ahmed, A. S., and Elsinger, R. J., 1990, Gas Chromatography as a development and production tool for

fingerprinting oils from individual reservoirs: applications in the Gulf of Mexico: In: Proceedings of the 9th Annual

Research Conference of the Society of Economic Paleontologists and Mineralogists. (D. Schumaker and B. F. Perkins,

Ed.), New Orleans. 263-282.

Malik, M., Singh, A., & Lal, M. K. (2015, September 28). Stress Profiling with Microfracturing and Sonic Logs in

Antelope Shale. Society of Petroleum Engineers. doi:10.2118/175002-MS

Miller C., Waters G., and Rylander E., Evaluation of Production Log Data From Horizontal Wells Drilled in Organic

Shales. SPE 144326 - 2011

Salman, A., Kurtoglu, B., & Kazemi, H. (2014, September 30). Analysis of Chemical Tracer Flowback in Unconventional

Reservoirs. Society of Petroleum Engineers. doi:10.2118/171656-MS

Spencer J., Bucior D., Catlett R., and Lolon E., Evaluation of Horizontal Wells in the Eagle Ford Using Oil-Bases Chemical

Tracer Technology to Optimize Stimulation Design. SPE 163846 - 2013

Stegent N., Ferguson K., and Spencer J., Comparison of Frac Valves vs Plug and Perf Completion in the Oil Segment of

the Eagle Ford Shale: A Case Study. SPE 148642 - 2011

Stegent N., Wagner A., Stringer C., Tompkins R., and Smith N. Engineering Approach to Optimize Development Strategy

in the Oil Segment of the Eagle Ford Shale: A Case Study. SPE 158846 - 2012

You might also like

- Hydraulic Fracture Design Optimization in Unconventional Reservoirs - A Case History PDFDocument14 pagesHydraulic Fracture Design Optimization in Unconventional Reservoirs - A Case History PDFblackoil1981No ratings yet

- 2-New Completion Technology4Document7 pages2-New Completion Technology4klibiNo ratings yet

- A Partical Numerical Model To Optimize The Productivity Multistage Fracture 146443-msDocument15 pagesA Partical Numerical Model To Optimize The Productivity Multistage Fracture 146443-msAmeer HussainNo ratings yet

- Jurnal 23Document10 pagesJurnal 23TAUFIQ HIDAYATNo ratings yet

- SPE 120271 Predicting Production Outcome From Multi-Stage Horizontal Barnett CompletionsDocument10 pagesSPE 120271 Predicting Production Outcome From Multi-Stage Horizontal Barnett CompletionsJose Gregorio FariñasNo ratings yet

- Spe 21696 MSDocument9 pagesSpe 21696 MSAleks ProañoNo ratings yet

- IPTC 17682 Design, Implementation and Results of An Inter-Well Chemical Water Tracers Pilot Test To Improve Water Flood in Complex ReservoirsDocument9 pagesIPTC 17682 Design, Implementation and Results of An Inter-Well Chemical Water Tracers Pilot Test To Improve Water Flood in Complex ReservoirsHari SudonoNo ratings yet

- SPE-196631-MS Locate The Remaining Oil Ltro and Predictive Analytics Application For Development Decisions On The Z FieldDocument24 pagesSPE-196631-MS Locate The Remaining Oil Ltro and Predictive Analytics Application For Development Decisions On The Z FieldMohamed SlimaniNo ratings yet

- Integrated Sand Management For Effective Hydrocarbon Flow AssuranceFrom EverandIntegrated Sand Management For Effective Hydrocarbon Flow AssuranceNo ratings yet

- MMP 2004Document14 pagesMMP 2004Prasanta Kumar BaskeyNo ratings yet

- SPE 88736 Expandable Tubular Completions For Carbonate ReservoirsDocument5 pagesSPE 88736 Expandable Tubular Completions For Carbonate ReservoirsmsmsoftNo ratings yet

- Spe 103184 MSDocument7 pagesSpe 103184 MSRamanamurthy PalliNo ratings yet

- SPE 170980 - Subsea Well Intervention - Recent Developments and Recommendations To Increase Overall Project ReturnsDocument12 pagesSPE 170980 - Subsea Well Intervention - Recent Developments and Recommendations To Increase Overall Project ReturnsAdri Coca SuaznabarNo ratings yet

- Khedr 2012Document11 pagesKhedr 2012Mahfoud AMMOURNo ratings yet

- Anand 2018Document35 pagesAnand 2018umair qureshiNo ratings yet

- Advanced Deepwater Kick DetectionDocument10 pagesAdvanced Deepwater Kick DetectionRakibul IslamNo ratings yet

- SPE 207069 - Caspian 2021Document10 pagesSPE 207069 - Caspian 2021amithnair078426No ratings yet

- Offshore Drilling Waste Management ReviewDocument289 pagesOffshore Drilling Waste Management ReviewObande OrinyaNo ratings yet

- Core AnalysisDocument46 pagesCore Analysisbrg268100% (3)

- Otc 18950Document13 pagesOtc 18950Nilesh GohelNo ratings yet

- p4 - 13 Project Management Offshore CompletionsDocument10 pagesp4 - 13 Project Management Offshore Completionsintoyou2007No ratings yet

- Otc 24737 MsDocument12 pagesOtc 24737 MsFelipe BañosNo ratings yet

- A Perspective View of Flow Assurance in Deepwater Fields in BrazilDocument8 pagesA Perspective View of Flow Assurance in Deepwater Fields in BrazilmahmoodnazeriNo ratings yet

- OTC 20993 AKPO: The Subsea Production SystemDocument17 pagesOTC 20993 AKPO: The Subsea Production SystemRasheed YusufNo ratings yet

- SPE-187661-MS First Successful Intelligent Tracer ICD Completion - Horizontal Well Inflow Profile PLTDocument11 pagesSPE-187661-MS First Successful Intelligent Tracer ICD Completion - Horizontal Well Inflow Profile PLTMOHD FADLI INDRA PRAJANo ratings yet

- Dokumen - Tips - Spe Spe 172812 Msspe 172812 MsDocument11 pagesDokumen - Tips - Spe Spe 172812 Msspe 172812 MsJes MorNo ratings yet

- Horizontal Wells LoggingDocument18 pagesHorizontal Wells LoggingShubham PrakashNo ratings yet

- Real Time Drilling OptimizationDocument3 pagesReal Time Drilling OptimizationSergio RamirezNo ratings yet

- SPE-97719-MS-P New Developments in Steamflood Modeling PDFDocument11 pagesSPE-97719-MS-P New Developments in Steamflood Modeling PDFSusan Li HBNo ratings yet

- Spe 116537 MS PDocument18 pagesSpe 116537 MS PKunal KhandelwalNo ratings yet

- Integrated Solution For Emulsion Diagnosis in Horizontal Production LogsDocument15 pagesIntegrated Solution For Emulsion Diagnosis in Horizontal Production LogsmbwassefNo ratings yet

- SPE 144112 Application of Silicate/Polymer Water Shut-Off Treatment in Faulted Reservoirs With Extreme High PermeabilityDocument16 pagesSPE 144112 Application of Silicate/Polymer Water Shut-Off Treatment in Faulted Reservoirs With Extreme High PermeabilityQaiser HafeezNo ratings yet

- Horizontal Drilling - M. EconomideDocument36 pagesHorizontal Drilling - M. EconomideRosa K Chang HNo ratings yet

- Ma 2019Document10 pagesMa 2019جمال المغبشيNo ratings yet

- Flotation Equipment Selection - OutotecDocument13 pagesFlotation Equipment Selection - Outoteclouza8No ratings yet

- SPE 122199 Applications of An Advanced Dynamic Underbalance Perforating Eastern VenezuelaDocument8 pagesSPE 122199 Applications of An Advanced Dynamic Underbalance Perforating Eastern VenezuelaEdgar GonzalezNo ratings yet

- A Thixotropic Barrier Fluid Used To Prevent The Commingling of Fluids While Tripping On Managed Pressure Drilling WellsDocument6 pagesA Thixotropic Barrier Fluid Used To Prevent The Commingling of Fluids While Tripping On Managed Pressure Drilling WellsNA NANo ratings yet

- 9 Log InterpretationDocument29 pages9 Log InterpretationSunny BbaNo ratings yet

- Hydraulic Fracturing - Technology FocusDocument15 pagesHydraulic Fracturing - Technology FocusJessica CehNo ratings yet

- SPE 158059 MS Screening SurfDocument11 pagesSPE 158059 MS Screening SurfAnonymous T32l1RNo ratings yet

- Application of Nozzle-Based Inflow Control Devices (ICD) in AL - Khafji Field - IPTC-17171-MSDocument12 pagesApplication of Nozzle-Based Inflow Control Devices (ICD) in AL - Khafji Field - IPTC-17171-MSUser UserNo ratings yet

- SPE 185098 Gas Lift Production Benchmarking Using IPR Risked Inflow Modeling CaseDocument21 pagesSPE 185098 Gas Lift Production Benchmarking Using IPR Risked Inflow Modeling CaseEdgar GonzalezNo ratings yet

- Analysis of Smart Oil Wells-3735 PDFDocument11 pagesAnalysis of Smart Oil Wells-3735 PDFVijaiey AnandNo ratings yet

- Advances in Wireline-Conveyed In-Situ Fluid Analysis: Andhi Marjono, Yoko Morita, Kamal Kader, Younes JalaliDocument5 pagesAdvances in Wireline-Conveyed In-Situ Fluid Analysis: Andhi Marjono, Yoko Morita, Kamal Kader, Younes Jalaliamramazon88No ratings yet

- Surface Inorganic Scale Formation in Oil and Gas IDocument12 pagesSurface Inorganic Scale Formation in Oil and Gas IROZANANo ratings yet

- Spe 120265Document14 pagesSpe 120265Heron Gachuz MuroNo ratings yet

- Basics OF Reservoir Engineering: Oil and Gas Field Development TechniquesDocument20 pagesBasics OF Reservoir Engineering: Oil and Gas Field Development TechniquesMuhammad DaudNo ratings yet

- SPE-185398-MS Radial Jet Drilling in Mature Fields of Oil India Limited-An Experimental ApproachDocument13 pagesSPE-185398-MS Radial Jet Drilling in Mature Fields of Oil India Limited-An Experimental Approachdiego rodriguezNo ratings yet

- Wax DepositionDocument35 pagesWax DepositionArjit KumarNo ratings yet

- Iptc 11171 MS PDocument11 pagesIptc 11171 MS PRalf JonesNo ratings yet

- Pit To Plant - Current TrendsDocument6 pagesPit To Plant - Current Trendsretrospect1000No ratings yet

- Boniface Obah Et AlDocument12 pagesBoniface Obah Et AlIbama MirillaNo ratings yet

- Iptc-19182-Ms An Innovative Reservoir Engineering Method To Identify Bypassed Oil and Derisk The Further Development of A Complex Mature FieldDocument16 pagesIptc-19182-Ms An Innovative Reservoir Engineering Method To Identify Bypassed Oil and Derisk The Further Development of A Complex Mature FieldGilbert OmittaNo ratings yet

- SPE-102200 Waterflooding SurveillanceDocument10 pagesSPE-102200 Waterflooding Surveillancejangolova100% (4)

- Underbalanced Drilling Technology For Unconventional Gas ReservoirsDocument9 pagesUnderbalanced Drilling Technology For Unconventional Gas ReservoirshkaqlqNo ratings yet

- Assignment Oil and GasDocument12 pagesAssignment Oil and GasElla Iloe IggoNo ratings yet

- Spe 120267 PPDocument11 pagesSpe 120267 PPHeron Gachuz MuroNo ratings yet

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- What Is An Incremental Case?: Incremental Cases in PhdwinDocument5 pagesWhat Is An Incremental Case?: Incremental Cases in PhdwinSSNo ratings yet

- Service StandardsDocument107 pagesService StandardsSSNo ratings yet

- Dragon Standard Products Catalog by Size and Pressure 7 11 18Document28 pagesDragon Standard Products Catalog by Size and Pressure 7 11 18SSNo ratings yet

- Continuing Education Program Activity Log Texas Board of Professional EngineersDocument1 pageContinuing Education Program Activity Log Texas Board of Professional EngineersSSNo ratings yet

- SPE-184868-MS A Causation Investigation For Observed Casing Failures Occurring During Fracturing OperationsDocument24 pagesSPE-184868-MS A Causation Investigation For Observed Casing Failures Occurring During Fracturing OperationsSSNo ratings yet

- SPE-184853-MS Smart Proppants With Multiple Down Hole FunctionalitiesDocument11 pagesSPE-184853-MS Smart Proppants With Multiple Down Hole FunctionalitiesSSNo ratings yet

- Spe 175892 PaDocument17 pagesSpe 175892 PaSSNo ratings yet

- Spe 184878 MSDocument8 pagesSpe 184878 MSSSNo ratings yet

- SPE-184868-MS A Causation Investigation For Observed Casing Failures Occurring During Fracturing OperationsDocument24 pagesSPE-184868-MS A Causation Investigation For Observed Casing Failures Occurring During Fracturing OperationsSSNo ratings yet

- Spe 184869 MSDocument16 pagesSpe 184869 MSSS100% (1)

- Spe 184863 MSDocument18 pagesSpe 184863 MSSSNo ratings yet

- Innovative Fermentation Strategies For Proteolytic Enzymes ProductionDocument85 pagesInnovative Fermentation Strategies For Proteolytic Enzymes ProductionDr. Thadikamala SathishNo ratings yet

- Module A Chemistry: Contents: (A) Common Mistakes (B) Commands Task Answering Effectively (C) Sample QuestionsDocument13 pagesModule A Chemistry: Contents: (A) Common Mistakes (B) Commands Task Answering Effectively (C) Sample QuestionsJOANNA MAGDALIN A/P JOSEPH MoeNo ratings yet

- Soaps and DetergentsDocument14 pagesSoaps and DetergentsashNo ratings yet

- Thermal Frequency Response Studies of A Hollow Cylinder Subject To Loads of Different Amplitude and ShapeDocument8 pagesThermal Frequency Response Studies of A Hollow Cylinder Subject To Loads of Different Amplitude and Shape조기현No ratings yet

- Measuring Rates of A Neutralization ReactionDocument8 pagesMeasuring Rates of A Neutralization ReactionElhana DyckNo ratings yet

- 5990 3285en PDFDocument16 pages5990 3285en PDFLutfi CiludNo ratings yet

- A Textbook of Dairy Chemistry PDFDocument208 pagesA Textbook of Dairy Chemistry PDFOner Altınsoy75% (4)

- Errand One A 2009Document9 pagesErrand One A 2009Rebeca CristinaNo ratings yet

- Lab 5 JP Organic ChemistryDocument3 pagesLab 5 JP Organic Chemistryblaze2g1100% (1)

- Project: Slab Number: Engineer: Date:: Design Two-Way Slabs (Method 3 of E.I.T.)Document10 pagesProject: Slab Number: Engineer: Date:: Design Two-Way Slabs (Method 3 of E.I.T.)Mars TinNo ratings yet

- By Himanshu ShekharDocument14 pagesBy Himanshu ShekharrobinkumarNo ratings yet

- Associate Program Material: Cell Energy WorksheetDocument2 pagesAssociate Program Material: Cell Energy Worksheetshaggsdb_650090671No ratings yet

- Thermoplastics and Silicone ResinsDocument30 pagesThermoplastics and Silicone Resins.No ratings yet

- Allowable Ampacities of Insulated Conductors Rated 1Document1 pageAllowable Ampacities of Insulated Conductors Rated 1danwilbur23No ratings yet

- Saponification ProcessDocument4 pagesSaponification ProcessAddison JuttieNo ratings yet

- Stiffness For Structural MomentsDocument27 pagesStiffness For Structural MomentsAbhi EsNo ratings yet

- Presentation On Car Water Kit (HHO) ScamDocument37 pagesPresentation On Car Water Kit (HHO) ScamAsim RiazNo ratings yet

- How Wellbore Dynamic Affect Pressure Transient Analysis PDFDocument10 pagesHow Wellbore Dynamic Affect Pressure Transient Analysis PDFChoiriahAgustinaSaritikaPutrianiNo ratings yet

- Reservoir Organic Geochemistry: Processes and ApplicationsDocument3 pagesReservoir Organic Geochemistry: Processes and ApplicationsMiguel Angel Vidal Arango100% (1)

- HW 1Document1 pageHW 1rahulsaxenaNo ratings yet

- Vizag: M/S KDM Engineers India Pvt. LTDDocument1 pageVizag: M/S KDM Engineers India Pvt. LTDumangNo ratings yet

- Risk Assessment Form - Part A: Hazard ListDocument3 pagesRisk Assessment Form - Part A: Hazard Listapi-308310709No ratings yet

- Electrochem - SimplifiedDocument13 pagesElectrochem - Simplifiedilias1973No ratings yet

- Linings - Nf-E.pdf - Downloadasset Vesuvius PDFDocument8 pagesLinings - Nf-E.pdf - Downloadasset Vesuvius PDFpungkiNo ratings yet

- 04 Column Distillation - Internal BalancesDocument152 pages04 Column Distillation - Internal BalancesAsad Saeed100% (1)

- Api 5LDocument24 pagesApi 5LKaty Flores Orihuela100% (1)

- Course Outline MEC441 - March2015Document4 pagesCourse Outline MEC441 - March2015RusyidiAbdullahNo ratings yet

- States of MatterDocument4 pagesStates of MatterabubakaarbuttNo ratings yet

- 3975 PDFDocument8 pages3975 PDFManas Kumar SethNo ratings yet

- Inconel 82 PDFDocument1 pageInconel 82 PDFMiguel MorenoNo ratings yet