Professional Documents

Culture Documents

Vizag: M/S KDM Engineers India Pvt. LTD

Uploaded by

umangOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vizag: M/S KDM Engineers India Pvt. LTD

Uploaded by

umangCopyright:

Available Formats

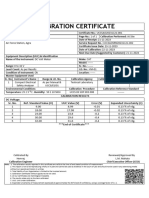

Issued For : M/S KDM ENGINEERS INDIA PVT. LTD. ULR No.

: CC319321000000513F

VIZAG

Cal. Certificate No. : DRS/08/21/513

SRF No. & Date : DRS/SRF/21/318

Date of Calibration : 05.08.2021

Calibration Due on : 04.08.2022

Details of Unit Under Calibration Issue Date of Certificate : 06.08.2021

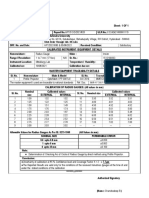

Type : PROVING RING

Make : - Date of Reciept : 02.08.2021

Mode of Calibration : Compression Customer Ref. No. & Date : : BY COURIER

Serial Number : PR.10KN.377 Condition on receipt : OK

ID Number : -

Capacity : 10 KN

Cable Length : N/A Environmental Condition

Details of Dial gauge Room Temperature : 24±1°C

Indicator Type : Dial Gauge Humidity

: 43.1% RH

Make : MERCER

Correction of Temperature Variation:-

Model : -

Serial Number : - Apply ±0.027% Correction to each Reading for each

Resolution : 0.1 Div. (1 Div. = 0.002mm) degree celcius rise or fall of temperature.

Accessories : Self-aligning Compression Pads.

Standard used : 10 kN DEAD Weight Force Calibration Machine (DRS/DWFCM-02)

Associated Uncertainty : 0.041% at (k=2)

Traceability : FRI/09/20/DWCM/021 Dated 03/09/2020 Valid upto 03/09/2022.

Principle/Methodology of Calibration and Calibration Procedure:

1. Work Instruction Number: DRS/SOP/01F Based on IS 4169-2014 & ISO 376 : 2011

2. Preloading : Before the application of the calibration forces, the instrument was preloaded thrice to its maximum capacity and kept at

full load for about 90 seconds.

3. Calibration : The sequence of applied calibration force in Compression is given below:

At 0° : Two series of calibration forces in increasing values. At 120° and 240° positions: One series of calibration forces each increasing

values. Creep test is performed by calculating the difference in output i30 obtained at 30s and i300 obtained at 300s after the removal of

the maximum calibration force and express this difference as percentage of the maximum deflection. The calibration was made by using

self aligning Compression Pads provided along with the instrument to ensure axial application of the force. Between each series, the

instrument was rotated along its axis so as to occupy during calibration three positions (0°,120°,240°) and the instrument was subjected to

the full load once for about 90 seconds each time before starting in a new position. Between the loadings, readings corresponding to no

load after waiting at least 30 seconds for the return to zero were noted.

Calibrated by Approved by

Gurdeep Singh Kaushal Kishore

(Technical Manager)

FORMAT NO. : DRS/CF/18.01 Page 1 of 2

You might also like

- Vizag: M/S KDM Engineers India Pvt. LTDDocument1 pageVizag: M/S KDM Engineers India Pvt. LTDumangNo ratings yet

- KapDocument29 pagesKapRajesh KumarNo ratings yet

- TESTO 104 Digital Thermometer OKDocument3 pagesTESTO 104 Digital Thermometer OKAaron Matthew BasteNo ratings yet

- 020-600kN-UTM-CELL COM TELESERVICES PVT. LTD. - 11.03.2023Document1 page020-600kN-UTM-CELL COM TELESERVICES PVT. LTD. - 11.03.2023SwaleheenNo ratings yet

- Water Flow Meter OkDocument3 pagesWater Flow Meter OkAaron Matthew BasteNo ratings yet

- CFC2023 2398 ML 1Document2 pagesCFC2023 2398 ML 1chandra332No ratings yet

- Draft AOCDocument5 pagesDraft AOCuniquecalibrationservicesNo ratings yet

- Electro Meter Corporation P-5, C.I.T Road KOLKATA - 700014Document2 pagesElectro Meter Corporation P-5, C.I.T Road KOLKATA - 700014Saptarshi DasNo ratings yet

- U 5753 Centrifuge 17300Document1 pageU 5753 Centrifuge 17300NENO BHUBANESWAR100% (1)

- U 929 RPM MeterDocument7 pagesU 929 RPM MeterAmit KumarNo ratings yet

- Certificate of Calibration: 08-Oc31356 - Revno:0Document1 pageCertificate of Calibration: 08-Oc31356 - Revno:0Eby JoyNo ratings yet

- RDS - TTR 1887Document1 pageRDS - TTR 1887emc roorkee59No ratings yet

- AccreditationDocument40 pagesAccreditationWalid BdeirNo ratings yet

- 0547-22.05 Grinding MachineDocument1 page0547-22.05 Grinding MachineAlvin RejisNo ratings yet

- 0547-22.04 Grinding MachineDocument1 page0547-22.04 Grinding MachineAlvin RejisNo ratings yet

- Hydrostatico D2321186Document1 pageHydrostatico D2321186Iandeyara CarvalhoNo ratings yet

- 1 NablDocument11 pages1 NablNeha SharmaNo ratings yet

- 0547-22.03 Grinding MachineDocument1 page0547-22.03 Grinding MachineAlvin RejisNo ratings yet

- 0547-22.01 Grinding MachineDocument1 page0547-22.01 Grinding MachineAlvin RejisNo ratings yet

- Electro Meter Corporation P-5, C.I.T ROAD, KOLKATA - 700014Document2 pagesElectro Meter Corporation P-5, C.I.T ROAD, KOLKATA - 700014Saptarshi DasNo ratings yet

- St. Joseph Hospital: Nehruji Nagar, Dindigul, Tamil Nadu 624001Document19 pagesSt. Joseph Hospital: Nehruji Nagar, Dindigul, Tamil Nadu 624001ARAVIND V RNo ratings yet

- RUNOUTDocument1 pageRUNOUTvishal.bdyNo ratings yet

- FF - 01 - Vernier CaliperDocument2 pagesFF - 01 - Vernier CaliperMechtek LabNo ratings yet

- Calibration Certificate - Cum-Report: FORM-04.TSD, Version 1.0Document1 pageCalibration Certificate - Cum-Report: FORM-04.TSD, Version 1.0Ashutosh NarayanNo ratings yet

- Water Flow MeterDocument3 pagesWater Flow Meterajay singhNo ratings yet

- Calibration Certificate: 140.2223.1019 - 01 Ambre Resort & SpaDocument2 pagesCalibration Certificate: 140.2223.1019 - 01 Ambre Resort & SpaAkash PraveshNo ratings yet

- 1.0 Customer's Details: Calibration Certificate NDocument2 pages1.0 Customer's Details: Calibration Certificate NCyriaque KagororaNo ratings yet

- Electro Meter Corporation P-5, C.I.T ROAD, KOLKATA - 700014Document2 pagesElectro Meter Corporation P-5, C.I.T ROAD, KOLKATA - 700014Saptarshi DasNo ratings yet

- Vernier CaliperDocument2 pagesVernier CaliperMechtek LabNo ratings yet

- Adobe Scan 02-Jul-2022Document5 pagesAdobe Scan 02-Jul-2022Shamsher SinghNo ratings yet

- QC 64256-1 Ring Spacer Inspection ReportDocument1 pageQC 64256-1 Ring Spacer Inspection ReportSenthil KumarNo ratings yet

- QC 64247-1 Contact Plate Inspection ReportDocument2 pagesQC 64247-1 Contact Plate Inspection ReportSenthil KumarNo ratings yet

- LA Ravi Sir NC 7Document6 pagesLA Ravi Sir NC 7mangalamtestingbureaNo ratings yet

- 01.RPM Meter 4to20Document1 page01.RPM Meter 4to20Sathish KarunNo ratings yet

- 1114-1182 Vij Engineers & Consultants PVT LTD UTE - 40-1156Document1 page1114-1182 Vij Engineers & Consultants PVT LTD UTE - 40-1156VikasNo ratings yet

- RR3-3269 Eo1352Document2 pagesRR3-3269 Eo1352Deepak HoleNo ratings yet

- Heat Treatment CertificateDocument1 pageHeat Treatment CertificateSuresh KrishnanNo ratings yet

- Thermography Report 125Document3 pagesThermography Report 125madhavanNo ratings yet

- U 5754 Micro Pipette 100-1000Document1 pageU 5754 Micro Pipette 100-1000NENO BHUBANESWARNo ratings yet

- UntitledDocument2 pagesUntitledMohitrajranikashyapNo ratings yet

- SARENS HEAVY CalibarationDocument2 pagesSARENS HEAVY CalibarationSusil Kumar SahooNo ratings yet

- Castor: Calibration CertificateDocument1 pageCastor: Calibration Certificatevijay narayanNo ratings yet

- Certificación Gammadensimetro. Oct. 2021Document3 pagesCertificación Gammadensimetro. Oct. 2021Vladimir DovalNo ratings yet

- Certificate of Calibration: CustomerDocument1 pageCertificate of Calibration: Customergaconvt92No ratings yet

- Gpti Qicl J931 Mut 041Document3 pagesGpti Qicl J931 Mut 041uselessinstaid52No ratings yet

- NGR 3000 DNV 10 27Document2 pagesNGR 3000 DNV 10 27Oleg GerasimovNo ratings yet

- Thermography Report 134Document3 pagesThermography Report 134madhavanNo ratings yet

- Ground Bound Tester. Phoenix Calibration.Document3 pagesGround Bound Tester. Phoenix Calibration.Vladimir DovalNo ratings yet

- Doosan Power Systems Indai PVT Limited: System CalibrationDocument3 pagesDoosan Power Systems Indai PVT Limited: System CalibrationBalkishan DyavanapellyNo ratings yet

- RTD CertificateDocument2 pagesRTD CertificateraghuNo ratings yet

- Calibration Certificate: Calibrated By: Nithin Approved By: AjeeshDocument6 pagesCalibration Certificate: Calibrated By: Nithin Approved By: AjeeshSpectex dubaiNo ratings yet

- Failure Analysis Report AFA 1Document5 pagesFailure Analysis Report AFA 1bartanto59No ratings yet

- Certificate of Calibration: A. ArámburoDocument2 pagesCertificate of Calibration: A. ArámburoEmily Hernandez CincoNo ratings yet

- NMS FT 78 Calibration Certificate Format SoundDocument1 pageNMS FT 78 Calibration Certificate Format SoundYeswe calNo ratings yet

- UV Light Meter-23 To 24Document2 pagesUV Light Meter-23 To 24monwar hosenNo ratings yet

- Testi: OrationDocument1 pageTesti: OrationSusil Kumar SahooNo ratings yet

- Certificate of Calibration: CustomerDocument1 pageCertificate of Calibration: Customergaconvt92No ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Panel Mount Load Cell Indicator: Operating Manual - English 2.00Document53 pagesPanel Mount Load Cell Indicator: Operating Manual - English 2.00umangNo ratings yet

- 1-3kva HP300 SeriesDocument2 pages1-3kva HP300 SeriesumangNo ratings yet

- Calibration Certificate: Cert. No.: S22060701 - 04 ULR No.:CC338822000000004FDocument2 pagesCalibration Certificate: Cert. No.: S22060701 - 04 ULR No.:CC338822000000004FumangNo ratings yet

- 20 Deep FreezerDocument1 page20 Deep FreezerumangNo ratings yet

- Result: Compression Mode: The Calibration Data Is Only For Following Dial Gauge SettingDocument1 pageResult: Compression Mode: The Calibration Data Is Only For Following Dial Gauge SettingumangNo ratings yet

- MET. Microscope 249FDocument1 pageMET. Microscope 249Fumang100% (1)

- Scope Location 1 CC-2460Document75 pagesScope Location 1 CC-2460umangNo ratings yet

- APT - cc.D.2021.820 (5 Files Merged)Document5 pagesAPT - cc.D.2021.820 (5 Files Merged)umangNo ratings yet

- Friction WeldingDocument8 pagesFriction WeldingGopi KrishnaNo ratings yet

- Nuclear Heat TransferDocument14 pagesNuclear Heat TransferDilip YadavNo ratings yet

- Determining Wicking of Fibrous Glass Fiber Blanket Insulation (Aircraft Type)Document3 pagesDetermining Wicking of Fibrous Glass Fiber Blanket Insulation (Aircraft Type)Ahmed AlzubaidiNo ratings yet

- Introduction To Materials: Prof. H. K. KhairaDocument75 pagesIntroduction To Materials: Prof. H. K. KhairaDhanush NairNo ratings yet

- Grade 7 Science Chapter 8 NotesDocument80 pagesGrade 7 Science Chapter 8 Notesapi-23858960280% (5)

- Physical Science Summative Exam. First QuarterDocument5 pagesPhysical Science Summative Exam. First QuarterIsagani WagisNo ratings yet

- Degassed Acid Conductivity (DAC) : - The Fast Way To The TurbineDocument12 pagesDegassed Acid Conductivity (DAC) : - The Fast Way To The TurbinesivamNo ratings yet

- CSIR NET June 2021 Organic ChemistryDocument99 pagesCSIR NET June 2021 Organic ChemistrySankar AdhikariNo ratings yet

- Maruti Suzuki Placement Papers-1Document3 pagesMaruti Suzuki Placement Papers-1Rabindra2416No ratings yet

- Proposal: Analysis of A Double Wishbone Suspension SystemDocument11 pagesProposal: Analysis of A Double Wishbone Suspension SystemSebastianTamayoNo ratings yet

- Irregularities in Building ConfigurationDocument15 pagesIrregularities in Building ConfigurationHannah MrudulynNo ratings yet

- Sieving Methods of Sieve AnalysisDocument6 pagesSieving Methods of Sieve AnalysisAlyssa Joy Santos PaguioNo ratings yet

- As Competition Paper 2007 Solutions: Section A: Multiple ChoiceDocument8 pagesAs Competition Paper 2007 Solutions: Section A: Multiple ChoiceAhmad HaikalNo ratings yet

- Presentation NanofluidDocument23 pagesPresentation NanofluidnitaicheNo ratings yet

- Cutting Tool Materials and Cutting FluidsDocument21 pagesCutting Tool Materials and Cutting FluidsRam27092003 GermanNo ratings yet

- ALLEN - NCERT Based Objective - Physics - Question BankDocument144 pagesALLEN - NCERT Based Objective - Physics - Question Banksamsuzzaman sahin100% (1)

- What Is Tribology - Bearing Design, Lubrication & Friction by GGB PDFDocument8 pagesWhat Is Tribology - Bearing Design, Lubrication & Friction by GGB PDFMohan AyyappanNo ratings yet

- Speed and Velocity: Circular and Satellite Motion NameDocument1 pageSpeed and Velocity: Circular and Satellite Motion NameAnthony QuanNo ratings yet

- Product Overview - PROCESS OVERVIEWDocument8 pagesProduct Overview - PROCESS OVERVIEWxuyen tranNo ratings yet

- Theodolite HandbookDocument37 pagesTheodolite HandbooksuhasNo ratings yet

- Mechanical Vibration WorksheetDocument6 pagesMechanical Vibration Worksheetduraiprakash83No ratings yet

- Calculating Aeration Flow and Pressure RequirementsDocument34 pagesCalculating Aeration Flow and Pressure RequirementsFelipe BrainNo ratings yet

- Lecture 4 - Forced Vibration of SDOF SystemsDocument70 pagesLecture 4 - Forced Vibration of SDOF SystemsĐạt Tạ ThànhNo ratings yet

- AssignmentDocument2 pagesAssignmentVageesha Shantha Veerabhadra Swamy100% (2)

- Chemical Plant Interview Book by Industrial GuideDocument14 pagesChemical Plant Interview Book by Industrial GuideTom Jose KooduthottiyilNo ratings yet

- Graphene Based TextileDocument10 pagesGraphene Based TextileTaofiqur Rahman ShochchoNo ratings yet

- Matching: Match Each Item With The Correct Statement BelowDocument16 pagesMatching: Match Each Item With The Correct Statement BelowwallaNo ratings yet

- Experiment #3: Sublimation and Melting Point DeterminationDocument3 pagesExperiment #3: Sublimation and Melting Point DeterminationMarthy DayagNo ratings yet

- A Study of Preparation of Light Colored Photosensitive Lquid NRDocument225 pagesA Study of Preparation of Light Colored Photosensitive Lquid NRThai KhangNo ratings yet

- 4PH0 2PR Que 20170616Document20 pages4PH0 2PR Que 20170616aya abdulfattahNo ratings yet