Professional Documents

Culture Documents

Coatings Manual PDF

Coatings Manual PDF

Uploaded by

Chozha RajanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Coatings Manual PDF

Coatings Manual PDF

Uploaded by

Chozha RajanCopyright:

Available Formats

COATINGS MANUAL

CHEVRON RESEARCH AND TECHNOLOGY COMPANY

RICHMOND, CA

December 1998

Manual sponsor: For information or help regarding this manual,

contact R.A. (Rich) Doyle, (510) 242-3247

Printing History

Coatings Manual

First Edition October 1988

First Revision December 1990

Second Revision February 1992

Third Revision August 1992

Fourth Revision January 1995

Second Edition September 1996

First Revision December 1998

Restricted Material

Technical Memorandum

This material is transmitted subject to the Export Control Laws of the

United States Department of Commerce for technical data. Furthermore,

you hereby assure us that the material transmitted herewith shall not be

exported or re-exported by you in violation of these export controls.

The information in this Manual has been jointly developed by Chevron Corporation and its Operating

Companies. The Manual has been written to assist Chevron personnel in their work; as such, it may be

interpreted and used as seen fit by operating management.

Copyright 1988, 1990, 1992, 1995, 1996, 1998 CHEVRON CORPORATION. All rights reserved. This

document contains proprietary information for use by Chevron Corporation, its subsidiaries, and affili-

ates. All other uses require written permission.

December 1998 Chevron Corporation

List of Current Pages

Coatings Manual

The following list shows publication or revision dates for the contents of this manual. To verify that your

manual contains current material, check the sections in question with the list below. If your copy is not

current, contact the Technical Standards Team, Chevron Research and Technology Company, Richmond,

CA (510) 242-7241.

Section Date

50 September 1996

100 November 1998

200 September 1996

300 September 1996

400 September 1996

500 September 1996

600 September 1996

700 September 1996

800 September 1996

900 September 1996

Quick Reference November 1998

Appendix A None Given

Appendix B January 1995

Index September 1996

2000 September 1996

COM-MS-4042 January 1996

COM-MS-4732 January 1996

COM-MS-4738 January 1996

COM-MS-4739 January 1996

COM-MS-4743 January 1996

COM-MS-4771 January 1996

COM-MS-5005 January 1996

COM-MS-5006 January 1996

List of Drawings See the list in the Standard Drawings and

Forms section of this manual. Current revi-

sion dates are shown for Forms. Current

revision numbers are shown for Standard

Drawings.

Chevron Corporation December 1998

(This page reserved for future use.)

December 1998 Chevron Corporation

Maintaining This Manual

Coatings Manual

If you have moved or you want to change the distribution of this manual, use the form below. Once you

have completed the information, fold, staple, and send by company mail. You can also FAX your change

to (510) 242-2157.

Change addressee as shown below.

Replace manual owner with name below.

Remove the name shown below.

Previous

Owner: Title:

Last First M.I.

Current

Owner: Title:

Last First M.I.

Company: Dept/Div:

Street: P.O. Box:

City: State: Zip:

Requesting Signature Date

Send this completed form to: Document Control, Room 50-4328

Chevron Research and Technology Company

100 Chevron Way (P.O. Box 1627)

Richmond, CA 94802

CRTC Consultants Card

The Chevron Research and Technology Company (CRTC) is a full-service, in-house engineering organi-

zation.

CRTC periodically publishes a Consultants Card listing primary contacts in the CRTC specialty divi-

sions. To order a Consultants Card, contact Ken Wasilchin of the CRTC Technical Standards Team at

(510) 242-7241, or email him at KWAS.

Chevron Corporation December 1998

(This page reserved for future use.)

December 1998 Chevron Corporation

Reader Response Form

Coatings Manual

We are very interested in comments and suggestions for improving this manual and keeping it up to date.

Please use this form to suggest changes; notify us of errors or inaccuracies; provide information that

reflects changing technology; or submit material (drawings, specifications, procedures, etc.) that should

be considered for inclusion.

Feel free to include photocopies of page(s) you have comments about. All suggestions will be reviewed as

part of the update cycle for the next revision of this manual.

Send your comments to: Document Control, Room 50-4328

Chevron Research and Technology Company

100 Chevron Way (P.O.Box 1627)

Richmond, CA 94802

Page or Section Number Comments

Name

Address

Phone

Chevron Corporation December 1998

(This page reserved for future use.)

December 1998 Chevron Corporation

Coatings

Manual Sponsor: R.A. (Rich) Doyle / Phone: (510) 242-3247 / E-mail: rdoy@chevron.com

This document contains extensive hyperlinks to figures and cross-referenced sections.

The pointer will change to a pointing finger when positioned over text which contains a link.

List of Current Pages

50 Using this Manual 50-1

100 General Information 100-1

200 Environment, Health & Safety 200-1

300 Coatings Selection 300-1

400 Surface Preparation 400-1

500 Application 500-1

600 Coating Concrete 600-1

700 Downhole Tubular Coatings & Linings 700-1

800 Offshore Coatings 800-1

900 Pipeline Coatings 900-1

Quick Reference Guide QR-1

Appendices

Appendix A Conversion Charts

Appendix B Color Chips

Chevron Corporation December 1998

50 Using this Manual

Abstract

In this manual, you will find procedures for coating steel and other metal

substrates. Additionally, there are individual sections for those surfaces and logis-

tics requiring special consideration: concrete, downhole tubulars, offshore, and pipe-

line coatings.

This section offers broad, general information: the reasons for coatings, the compo-

nents of a coating and coatings systems, a successful coatings program, and the

structure of this manual.

Contents Page

51 Scope and Application

52 Organization

60 Reasons for Coating 50-3

61 External Coatings

62 Under Thermal Insulation and Fireproofing

63 Internal Coatings

70 Components of Coatings and Coating Systems 50-5

71 Components of Coatings

72 Coating Systems

80 The Successful Coating Program 50-7

90 References 50-7

Chevron Corporation 50-1 September 1996

50 Using this Manual Coatings Manual

51 Scope and Application

The Coatings Manual is intended:

For Company personnel who are responsible for selecting, applying, or

inspecting coatings

For both entry-level personnel and non-specialists regardless of experience

As a source of practical, useful information based on the Company's

experiences

Your input and experience are important for improving subsequent revisions and

keeping this manual up-to-date; therefore, we have included a form in the front of

the manual to facilitate your suggesting changes.

Note Do not use this manual as a substitute for sound engineering judgment.

52 Organization

The colored tabs in the manual will help you find information quickly. In summary:

White tabs are for table of contents, introduction, appendices, index, and general

purpose topics.

Blue tabs denote Engineering Guidelines.

Gray tabs are used for Specifications and related forms.

Red tab marks a place for you to keep coatings documents that are developed at

your facility.

Engineering Guidelines

The Engineering Guidelines cover:

An overview of coatings

General information about selecting coatings; preparing surfaces; and

applying, inspecting, and maintaining coatings

Specific information about surfaces and logistics that require special

considerationconcrete, downhole tubulars, offshore, and pipelines

Specifications

The specifications include:

A Quick Reference Guide (for selecting coating systems; coatings system data

sheets; list of acceptable brands; and Coating Compatibility Chart)

The Company's specifications in commented form

Standard Forms

September 1996 50-2 Chevron Corporation

Coatings Manual 50 Using this Manual

Other Company Manuals

Within this manual, there are references to documents in other Company manuals

(example: COM-MS-4738 in this manual). These documents carry the prefix of the

particular manual.

These prefixes are as follows:

Prefixes Company Manuals

CIV Civil and Structural

CMP Compressor

COM Coatings

CPM Corrosion Prevention

DRI Driver

ELC Electrical

EXH Heat Exchanger and Cooling Tower

FFM Fluid Flow

FPM Fire Protection

HTR Fired Heater and Waste Heat Recovery

ICM Instrumentation and Control

IRM Insulation and Refractory

MAC Machinery Support Systems

NCM Noise Control

PIM Piping

PMP Pump

PPL Pipeline

PVM Pressure Vessel

TAM Tank

UTL Utilities

WEM Welding

60 Reasons for Coating

The Company coats structures and equipment for several reasons. Many of these

reasons are discussed below.

61 External Coatings

External coatings are generally for aesthetics, corrosion prevention, evaporation

reduction, and safety.

Chevron Corporation 50-3 September 1996

50 Using this Manual Coatings Manual

Aesthetics

Coatings improve the appearance of objects, which contributes to good employee

morale, advertising, neighborhood relations, and civic pride.

Corrosion Protection

Atmospheric corrosion is a significant problem in humid, warm, coastal locations;

in chemical and fertilizer plants; and on offshore structures.

Regardless of the geographical location, coating is essential for protection against

corrosion in most plant areas.

Evaporation Reduction

Painted in light colors, the roofs of storage tanks reflect rather than absorb the sun's

energy thus reducing evaporative loss of the stored material.

Safety

Special coatings mark fire equipment, traffic lanes, and piping that carries

hazardous materials.

62 Under Thermal Insulation and Fireproofing

A properly designed coating system, applied to the substrate under thermal insula-

tion and fireproofing systems, gives the best long-term protection against chloride

stress-corrosion cracking (CSCC) of stainless steel and reduces corrosion of carbon

steel.

CSCC and increased corrosion occur:

When moisture permeates the insulation or fireproofing system and condenses

against the substrate, creating a condition similar to immersion service

Because steel operating temperatures affect the corrosivity of water

As long as the temperature of the water remains below its boiling point: the

hotter the steel, the hotter the water, the higher the rate of corrosivity

When moisture leaches soluble salts that contain chloride or sulfide ions

Again, the hotter the solution, the greater the effect.

Because they develop under insulation and fireproofing, these conditions are very

hard to detect. Maintenance and inspection are very difficult and usually require

removing the insulation or fireproofing. Often the first indication of a problem is an

equipment failure.

For guidance on choosing coatings, refer to Coatings Under Insulation and Fire-

proofing in the System Number Selection Guide (part of the Quick Reference

Guide).

September 1996 50-4 Chevron Corporation

Coatings Manual 50 Using this Manual

63 Internal Coatings

Internal coatings can maintain product purity, reduce stockside and underside corro-

sion, and affect potable water.

Product Purity

Even at low corrosion rates, some corrosion occurs. An internal coating may be

necessary to prevent the products of corrosionsuch as iron oxide (rust) or scales

from contaminating the stock and causing problems.

Stockside Corrosion

Internal coatings extend the life of the tank or vessel and reduce the chance of

leaks, especially in storage tank bottoms. The water layer which settles out in the

bottom of the tank causes most of the tank bottom internal corrosion.[1]

Underside Corrosion

For tanks, the corrosion rate of the underside depends mainly on soil composition

and moisture content. Based on experience, you can predict when underside corro-

sion may be a problem.[1]

Potable Water

The U.S. Food and Drug Administration regulates coatings for lining potable water

tanks.

70 Components of Coatings and Coating Systems

71 Components of Coatings

A coating consists of a pigment, a vehicle (binder plus solvent), and additives.

Pigments give color and protective properties to the paint.

The vehicle provides curing to form a continuous film and adhesion to the

substrate. The vehicle is made of the binder (which forms the film) and the solvent

(which dissolves the binder and adjusts viscosity to improve application). The

solvent also partly controls drying rate.

Additives are drying and wetting agents, ultraviolet screening agents, etc.

Methods of Film Formation

Understanding how binders work is critical when choosing a coating system. For

most coatings, film forms in one of several ways.

Thermoplastic. The solid resin, melted for application, resolidifies when it cools.

Example: Tar in roof coatings.

Chevron Corporation 50-5 September 1996

50 Using this Manual Coatings Manual

Solvent Evaporation. The coating dries as the solvent evaporates (or dries at lower

temperatures than those which involve a chemical reaction). If re-exposed to the

same solvent, the coating can redissolve.

Example: Vinyls, chlorinated rubbers and lacquers.

Oxidation. Coatings composed of drying oils cure by reacting with air. Oxygen

cross links the resin molecules into a solid gel.

Example: Alkyds.

Cross Link. Dual-component products cross link at room temperature, either with

or without a catalyst.

Example: Epoxies (two polymers react, no catalyst), polyesters (catalyzed) and

urethanes (catalyzed).

Heat Cure. Heat causes direct cross-linking between filmformer molecules, or acti-

vates a catalyst to cause cross-linking. Normally, these coatings are shop-applied

only, because of the special heating requirements.

Example: Baked phenolic linings.

Emulsion. When the water evaporates from an emulsion of resin particles and

water, the resin particles coalesce to form a film.

Example: Latex acrylics.

72 Coating Systems

A coating system refers to the layers that make a complete coating: primer, tiecoat

or intermediate coat, and topcoat.

Primer Coats

Primer coats adhere well to the substrate and inhibit corrosion and undercutting at

defects, such as pin holes or holidays (breaks) in the film.

Note that holidays are pinholes or thin spots which either develop during applica-

tion or nicks and scrapes which occur later. Corrosion will start at these spots.

Primer coats also bond well to the intercoat, tolerate variations in application condi-

tions and handling, and resist weathering (helpful because delays may occur

between priming and topcoating).

Tiecoats

Tiecoats (or intermediate coats) build film thickness, bond the primer to the topcoat,

and protect substrate and primer from aggressive chemicals in the environment.

Topcoats

Topcoats protect the substrate and undercoats from the environment, provide chem-

ical resistance, enhance the surface appearance, and provide non-skid and other

properties.

September 1996 50-6 Chevron Corporation

Coatings Manual 50 Using this Manual

Some coatings are incompatible. Before choosing coatings to apply over previously

coated surfaces, see the Coating Compatibility Chart in the Quick Reference Guide.

80 The Successful Coating Program

The successful coating program has four elements:

Selection

Surface preparation

Application

Quality control (inspection and on-going maintenance)

Each of these elements is described in more detail in this manual.

90 References

1. Chevron Corporation. Corrosion Prevention Manual, Corrosion of Storage

Tank Bottoms, Chevron Research and Technology Company. Richmond, CA:

January, 1994.

Chevron Corporation 50-7 September 1996

100 General Information

Abstract

Among the general information in this section is a description of the coatings and

coating systems, which includes the advantages, disadvantages, and uses. Coatings

are also described in the individual sections for special surfaces such as: concrete,

downhole tubulars, and pipelines.

Note This manual does not contain information about coatings for architectural

surfaces.

Quality control is essential for any project. Among the key elements of quality

control for coatings are inspections, monitoring progress, and protecting the

Companys equipment. For assistance with specific questions about coatings, see the

listing of the Companys specialists and coating manufacturers in the Quick Refer-

ence Guide.

Contents Page

110 Coating Descriptions (A-E) 100-3

111 Acrylics

112 Alkyds

113 Epoxies

114 Elastomers

120 Coatings Descriptions (PZ) 100-13

121 Phenolics

122 Polyesters

123 Polyurethanes

124 Silicones

125 Vinyls

126 Zinc-rich Coatings

130 Petroleum-based Tapes 100-21

140 Water-based Coatings 100-21

150 Coating Systems for Immersion Service 100-22

Chevron Corporation 100-1 November 1998

100 General Information Coatings Manual

151 Non-reinforced Thin-film Coatings

152 Glass-flake-reinforced Coatings

153 Laminate-reinforced Coatings

160 Quality Control 100-27

161 General Information

162 Inspection Programs

163 Inspectors

164 Monitoring Progress

165 General Inspection Procedures

166 Specific Inspection Procedures

167 Instruments, Tools, and Equipment

168 Protecting the Companys Equipment

170 References 100-46

November 1998 100-2 Chevron Corporation

Coatings Manual 100 General Information

110 Coating Descriptions (A-E)

The following coatings are described in this section:

Acrylics

Alkyds

Epoxies

Elastomers

For details about each type of coating, read the following descriptions. See also

Figure 100-1, Summary of Properties in Coatings.

111 Acrylics

Acrylic ester resins are polymers and co-polymers of the esters of acrylic and meth-

acrylic acids. As thermoplastics, they soften at high temperatures.

Advantages:

Good moisture and mild chemical resistance

Either fast-drying solvent evaporation or coalescence

Disadvantages:

Poor resistance to aromatic solvents

Uses:

Solvent acrylic: truck and machinery finishes

Latex emulsions: stucco, wood, and masonry

By Company: as architectural coatings

112 Alkyds

Alkyd resins are basically modified polyesters. An alkyd is the reaction product of a

polyhydric alcohol and a polybasic acid. A common alkyd resin uses glycerol as the

alcohol and phthalic acid as the polybasic acid.

Oxidation in the air cures alkyd coating resins. Adding drying oils to pure alkyd

modifies the alkyd into alkyd coating resins.

These resins are classified by oil length (long, medium, and short). The alkyd resin

without oil modification is hard and brittle. As the oil length increases (more oil

added), the film becomes softer and more flexible.

Advantages:

Perform well in moderate environments

Easy-to-handle, single-component coatings

Inexpensive

Fair-to-good performance in most of the Company's environments

Chevron Corporation 100-3 November 1998

100 General Information Coatings Manual

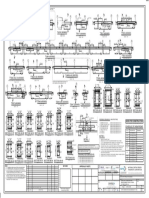

Fig. 100-1 Summary of Properties in Coatings (1 of 2)

1. Atmosphere

Wet

2. Splash/Spillage

Effect of Atmo-

Coatings Type of Cure Sunlight sphere Acid Alkali Oxidizing Solvent

Acrylic Solvent Chalk Good 1. Good 1. Good 1. Good 1. Fair

Evaporation Resistant 2. Poor- Fair 2. Poor-Fair 2. Poor-Fair 2. N/R

Alkyd Oxidation Slow Poor-Good 1. Fair- Poor 1. Poor 1. Fair 1. Fair

Chalk Yellows 2. N/R 2. N/R 2. N/R 2. N/R

Amine-cured & Cross Linked Chalks Excellent 1. Good 1. Excellent 1. Limited 1. Excellent

Amine Adduct Yellow 2. Fair 2. Excellent 2. N/R 2. Excellent

Epoxy

Polyamide Cross Linked Chalks Excellent 1. N/R 1. N/R 1. N/R 1. N/R

Epoxy Yellow 2. Poor-Fair 2. Excellent 2. N/R 2. Very Good

Coal-tar Epoxy Cross Linked Chalks, N/R 1. Excellent 1. Excellent 1. Excellent 1. Poor

Polyamide Cracks 2. Good 2. Good 2. N/R 2. N/R

Chlorinated Solvent Evap. Slow Excellent 1. N/R 1. N/R 1. N/R 1. N/R

Rubber Chalk 2. Very Good 2. Very Good 2. Good 2. N/R

Epoxy Phenolic Cross Linked N/R N/R 1. N/R(1) 1. N/R(1) 1. N/R(1) 1. N/R(1)

(1) (1) (1)

2. Good 2. Very Good 2. N/R 2. Very Good(1)

Baked Phenolic Heat Cured N/R N/R 1. Good(1) 1. Good(1) N/R(1) 1. Poor(1)

(1)

2. Lid 2. N/R 2. Out-

Mineral standing(1)

Acids(1)

Moisture-cured Cross Linked Aromatic Very Good 1. Good 1. Good 1. Poor 1. Excellent

Urethane (II) Yellows; 2. Fair 2. Fair 2. N/R 2. Good

Aliphatic

Excellent

Silicone Heat Cured Excellent Very Good 1. Good 1. Good 1. Very 1. Fair

Cross Linked 2. Poor 2. Poor Good 2. Fair

2. Poor

Silicone Alkyd Oxidation Excellent Very Good 1. Good 1. Good 1. Good 1. Good

2. Poor 2. Fair 2. Poor 2. Good-Poor

Vinyl Solvent Evap. Slow Excellent 1. Excellent 1. Excellent 1. Excellent 1. Poor

Chalk 2. Very Good 2. Good 2. Good 2. N/R

Organic Cross Linked Chalk Excellent(2) 1. Topcoat 1. Topcoat 1. Topcoat 1. Excellent

Zinc-rich 2. N/R 2. N/R 2. N/R 2. Very Good

(2)

Post-cured Cross Linked None Excellent 1. Topcoat 1. Topcoat 1. Topcoat 1. Excellent

Inorganic Zinc 2. N/R 2. N/R 2. N/R 2. Excellent

(2)

Solvent-based Cross Linked None Excellent 1. Topcoat 1. Topcoat 1. Topcoat 1. Excellent

Self-cured 2. N/R 2. N/R 2. N/R 2. Excellent

Inorganic Zinc

November 1998 100-4 Chevron Corporation

Coatings Manual 100 General Information

Fig. 100-1 Summary of Properties in Coatings (2 of 2)

Physical Properties

Tank

Coatings Immersion Linings Abrasion Heat Hardness Gloss Range of Color

Acrylic N/R N/R Good Limited Good High to Semi Full

Alkyd N/R N/R Fair Fair Fair Chalks to Flat Full

Amine-cured & Very Good N/R Good Good Very hard Chalks to Flat Full

Amine Adduct

Epoxy

Polyamide Very Good Solvents Good Good Hard Chalks to Flat Full

Epoxy Water

Coal-tar Epoxy Excellent Water Limited Excellent Very Hard Flat Black, Red

Polyamide

Chlorinated Very Good Water Fair-Poor Poor Good Semi to Flat Wide

Rubber

Epoxy Phenolic Very Good Wide- Good Outstanding Very Hard High Dark

range

Solvent

Baked Phenolic 1. Excellent(1) Wide Good Excellent Excellent Excellent Clear Dark

2. Very Good Resis-

tance

Moisture-cured N/R N/R Excellent Good Excellent High Full

Urethane (II)

Silicone N/R N/R Good Excellent Good High Full

Silicone Alkyd N/R N/R Good Very Good Good High Full

Vinyl Very good Water Fair-Poor Poor Good Semi to Flat Wide

Organic Good(3) N/R Good Good Very Good Semi to Flat Some

Zinc-rich

Post-cured Good(3) Fuels Excellent Excellent Excellent Flat Earth Tones

Inorganic Zinc Solvent

Solvent-based Good(3) Fuels Excellent Excellent Very Good Flat Earth Tones

Self-cured Solvent

Inorganic Zinc

(1) As tank lining

(2) When top-coated

(3) With epoxy topcoat

Good service on large, flat surfaces

Example: Good service is exemplified by this coatings almost 20 years on

Hawaiian refinery tanks.

Disadvantages:

Long drying time

Not chemically resistant; unsuitable for highly corrosive areas such as chem-

ical and fertilizer plants or offshore structures

Unsatisfactory for water immersion

Chevron Corporation 100-5 November 1998

100 General Information Coatings Manual

Not suited to highly alkaline surfaces such as fresh concrete, galvanized steel,

and inorganic zinc

Chalk in sunlight

Usually fail within a few years on piping and structural components

Not VOC-compliant

Uses:

In external primers and finish coatings

Long-oil Alkyds (60 to 70 Percent Oil)

Advantages:

Good flexibility and wetting properties

Disadvantages:

Very slow drying

Uses:

Over poorly prepared steel where the oil penetrates rust and develops adhesion

Medium-oil Alkyds (45 to 60 percent oil)

Advantages:

Hard, tough films

Dry faster, generally, than long-oil alkyds

Uses:

Finish coats

Note The Companys most popular choice of alkyd

Short-oil Alkyds (35 to 45 percent oil)

Uses:

Fast air drying and baking enamels for hardness and mar resistance

Note The Company uses very little of these.

113 Epoxies

The most common epoxy resins are formed by the reaction of epichlorhydrin and

bisphenol-A. This reaction can be controlled to produce resins ranging from liquids

of low-molecular weight to solids of high-molecular weight.

November 1998 100-6 Chevron Corporation

Coatings Manual 100 General Information

Complete curing gives epoxies their chemical and water resistance. Curing time

increases at temperatures below about 70F, essentially stopping below about 50F

unless it is a specially formulated low-temperature epoxy.

Epoxies have very good resistance to bases and many solvents. Epoxies have poor

acid resistance unless modified with a phenolic.

Advantages:

Resist water and chemicals, especially caustics, superbly

Resist weather well

Adhere well, particularly to concrete

Apply easily

Disadvantages:

Do not retain color and gloss as well as alkyds

Tend to chalk rapidly

Do not have good acid resistance

Need surfaces between layers of epoxy roughened by solvent or blasting when

applying multiple coats as many epoxies cure with a hard, slick surface

Need successive coats of epoxy applied as soon as possible to obtain satisfac-

tory adhesion between coats. Manufacturers normally recommend a maximum

time between coats.

Need long cure time. For epoxy linings at 70F, curing may take one week. In

the field, coatings applicators often accelerate the curing of an internal coating

with a low-temperature bake (100 to 150F).

Caution Do not put internal coatings into service until they are fully cured.

Uses:

Epoxy resins are the most popular resin for thin-film coatings on concrete.

There are six groups of epoxy coatings in this section: amine cured, amine adduct,

polyamide, coal tar, epoxy mastics, and epoxy novolac.

Amine-cured Epoxies

These coatings are epoxy resins cross-linked with one of several amine compounds.

Caution Because the amines can present a health hazard, apply them according to

manufacturers safety recommendations.

Amine Adduct Epoxies

Amine adducts are stable intermediate products resulting from the reaction of a

portion of the epoxy resin with an amine curing agent. The amine adduct, instead of

the amine, is added to the epoxy coating to cure it.

Chevron Corporation 100-7 November 1998

100 General Information Coatings Manual

Advantages:

Same properties as liquid amines, but much less hazardous

Very good resistance to oils, solvents, and chemicals

Disadvantages:

Ultraviolet degradation causes rapid chalking

Uses:

Lining gasoline storage tanks, chemical tanks

Corrosion-resistant primer under polyurethane foam insulation

Polyamide Epoxies

Polyamide resins are produced from polyamines and fatty acids. Epoxy coatings for

atmospheric exposures are usually polyamides. Mastic coatings which adhere to wet

surfaces and which will cure under water are formulated with polyamide epoxies.

Advantages:

Good surface-wetting properties

Longer pot life, more flexibility and better water resistance than amine or

amine-adduct cured epoxies

Good resistance to alkalies, petroleum products, and salt water

Disadvantages:

Not quite as chemically resistant as amine adduct epoxies.

Uses:

Topcoats and tiecoats in severe exposures

Coal-tar Epoxies

As the name suggests these coatings are blends of epoxy resins and coal tar.

Note Coal tar is a suspected carcinogen but is tied up sufficiently in the polymer

so that manufacturers consider the cured film safe.

Coal-tar epoxies can be either polyamide- or amine-adduct cured. Usually applied in

two heavy coats of eight mils each, these coatings are normally self-priming.

Advantages:

Outstanding for water-immersion service

Disadvantages:

Chalk rapidly and fail in (ultraviolet) sunlight

November 1998 100-8 Chevron Corporation

Coatings Manual 100 General Information

Uses:

Underwater, in water tank linings (except potable water tanks), and on buried

structural steel

Note Although coatings manufacturers continue to use them for municipal water-

tank linings, the Company prefers FDA-approved polyamide or amine-adduct

epoxies for potable-water tank linings.

Epoxy Mastics

Advantages:

Perform better than alkyds

Adhere to a variety of surface preparations, including tightly adhered rust

Adhere to any old coating firmly attached to the substrate

VOC compliant

Disadvantages:

More expensive than alkyds

Uses:

For less-than-perfectly prepared surfaces

Epoxy Novolac

Epoxy novolac resins are second-generation epoxies with greater cross-linking

density.

Advantages:

Greater resistance to chemical attack and high temperatures than standard

epoxies

Disadvantages:

More expensive and less flexible than standard epoxies

Uses:

Common coating for concrete

114 Elastomers

An elastomer is a polymeric substance with more than 100 percent elongation in a

tensile test. Included in this category are natural- and synthetic-rubber products

(which also have the physical characteristics of natural rubber). The chemical, oil,

and water resistance of elastomers vary widely.

Coatings applicators can apply modified elastomers as coatings. The Company uses

many elastomeric coatings, such as chlorinated rubber and hypalon, alone over steel

and other surfaces or, as required, with special primers such as inorganic zinc.

Chevron Corporation 100-9 November 1998

100 General Information Coatings Manual

There are two classes of elastomers: cross-linking and air-drying.

Catalyzed Cross-linking Elastomers

Neoprene, butyl, thiokol, silicone, and hypalon are the most common, catalytic-

setting, elastomer coatings.

Neoprene. A synthetic rubber, produced by polymerizing chloroprene, neoprene is

either pigmented or clear and is manufactured as thin flexible films or mastics.

Advantages:

Good heat and flame resistance

Good acid, alkali, and water resistance

Disadvantages:

Softened by aromatic solvents

Uses:

Block insulation coatings

Butyl. A copolymer of isobutylene and isoprene, butyl is polymerized with an

aluminum chloride catalyst.

Advantages:

Exceptionally low water permeability

Better sunlight and weather resistance than most rubbers

Disadvantages:

Unknown

Uses:

Coating urethane foam and block insulation

Piping tape wrap primers and tape mastics

Thiokol. Thiokol is a polysulfide rubber.

Advantages:

Excellent gasoline and water resistance

Disadvantages:

Unknown

Uses:

Caulking compounds

Flexible seal over leaking rivet seams in oil tanks

Pond and tank linings (in sheet form)

November 1998 100-10 Chevron Corporation

Coatings Manual 100 General Information

Silicone Rubber. Silicone rubber is a room-temperature vulcanizing (RTV) sili-

cone.

Advantages:

Good for hot service

Disadvantages:

Poor solvent resistance

Uses:

Gaskets in hot services

Caulking

Potting materials

Hypalon. Hypalon is a chlorinated polyethylene resin.

Advantages:

Excellent sunlight resistance

Good chemical resistance

Disadvantages:

Unknown

Uses:

Flexible coating vehicles or mastics and sheet lining

Mild acid spill protection for concrete (the Company's most popular use)

Topcoat over polyurethane foam or block insulation

Pond and tank linings

Air-drying Elastomers

Chlorinated rubber, an air-dried formulation of hypalon, and butadiene-styrene are

the most popular elastomers for air-drying coatings.

Chlorinated Rubber. Chlorine and natural rubber latex produce chlorinated rubber

resins. When suitably plasticized and pigmented, these resins exhibit outstanding

resistance to a broad range of corrosive chemicals and environments.

Advantages:

Shows outstanding resistance to severe chemical environments such as acids,

alkalies, salt fog, water, oxidizing agents, bleaches, and cleaning compounds

Dries rapidly, allowing application of several coats in one day

Produces excellent bond between old and new coats as the solvents in the new

coat penetrate the old coat

Disadvantages:

Chevron Corporation 100-11 November 1998

100 General Information Coatings Manual

Does not resist sunlight damage as well as alkyds and acrylics

Causes alkyd or oil coatings to blister if applied over them

Dissolves in oils and solvents

Caution Oil spills could potentially soften these coatings.

Uses:

Offshore platforms

Humid coastal refineries

Hypalon. The air-drying hypalon is a chlorosulfonated polyethelene.

Advantages:

Good weatherability

Disadvantages:

Unknown

Uses:

Topcoat elastomers to improve weather resistance

Butadiene-Styrene. The most widely used type of synthetic rubber, butadiene-

styrene is a copolymer of three parts butadiene and one part styrene.

Advantages:

Good resistance to alkali, water, and mild acids

Excellent external durability if pigmented properly

Disadvantages:

Embrittles with age if formulated improperly

Uses:

Vehicles in coatings and mastics for stucco and masonry

Polyurethane Elastomers. Polyurethane elastomers are thermal plastic polymers.

Advantages:

AliphaticExcellent color and gloss retention

Disadvantages:

AromaticYellows badly in sunlight

Uses:

Vehicles for thin or semi-mastic coatings for sealing polyurethane foam

insulation

Deck and floor coatings

November 1998 100-12 Chevron Corporation

Coatings Manual 100 General Information

120 Coatings Descriptions (PZ)

The following coatings are described in this section:

Phenolics

Polyesters

Polyurethanes

Silicones

Vinyl

Zinc rich

121 Phenolics

Phenolic resins, formed by the reaction of phenol with formaldehyde, produce a

range of coatings from hard plastics (Bakelite) to oil-soluble resins and from heat-

reactive varnishes to air drying oils. The Company uses two phenolic resins in coat-

ings: a baked pure phenolic and an air-drying epoxy phenolic.

Baked Phenolics

Baked phenolics are almost exclusively shop-applied due to a complicated baking

procedure. They contain resins which are polymerized by being heated above 300F.

The reaction time and temperature depend on the modifying oils and resins.

Note The Company uses baked phenolics only in the most severe immersion

services where no other material will work, such as container inner-coatings and

tank car linings.

Advantages:

Excellent chemical and water resistance

Withstand immersion in almost all petroleum products

Good abrasion resistance

Disadvantages:

Poor wetability (the ability of a coating to flow over a surface)

Require maximum surface preparation

Poor adhesion

Embrittles

Note To overcome poor adhesion and brittleness, some formulas are modified with

epoxy resins, giving them better caustic resistance than pure phenolics but not equal

resistance to strong solvents.

Epoxy Phenolics

Catalytic setting (non-baking) phenolics are usually composed of phenolic resins

and epoxies.

Chevron Corporation 100-13 November 1998

100 General Information Coatings Manual

Advantages:

Better chemical and solvent resistance than pure epoxies

Disadvantages:

Lower resistance to chemicals and solvents than pure baked phenolics

Uses:

Lining tanks, vessels, containers, etc.

122 Polyesters

While there are two major classes of polyester resins, the Company uses only isophthalic.

Isophthalic polyesters, the resin preferred for corrosion protection, is also the main

resin in laminate-reinforced systems.

While the chemical and temperature resistance of polyester is usually poorer than

any of the other resins, they are also the least expensive.

123 Polyurethanes

Polyurethane resins are formed by the reaction of isocyanates with polyols and are

used for a variety of purposes from foam insulation to air-drying coatings and

varnishes. The isocyanate may be either aromatic or aliphatic.

There are literally thousands of polyurethane formulationsfrom hard roller skate

wheels to elastomeric materials that stretch like rubber bandswhich have many

different properties. Some of these properties are:

Abrasion resistance

Chemical resistance

Elasticity

Impact resistance

Tensile strength

Caution Remember that increases in one property result in decreases in another.

Because of this, many elastomeric polyurethanes are not as chemically resistant as

the more rigid polyurethanes.

The most common polyols are acrylics and polyesters, although there are epoxies,

vinyls, and alkyds.

Advantages:

Highly resistant to abrasion and impact

Catalyzed urethanes are highly chemical resistant

Better performance than alkyds

AliphaticFor atmospheric coatings, usually as easy to overcoat as epoxies

AromaticMore chemically resistant than aliphatic urethanes

November 1998 100-14 Chevron Corporation

Coatings Manual 100 General Information

Disadvantages:

More expensive than alkyds

AromaticNot designed for external exposure as they chalk and yellow; diffi-

cult to overcoat because adhesion is poor

Uses:

AliphaticNon-fading, non-chalking external finishes

AromaticTank linings, chemically resistant coatings, flexible elastomeric

coatings for polyurethane foam insulation coverings

Classifications. Urethane coatings cure by a variety of mechanisms as classified by

ASTM D16-75 types. Types II, IV, and V are considered high performance and are

described below. Most of the Company's experience has been with Type V, the two-

package polyol-cured urethane.

Type II, One-package Moisture-cured. The Company has limited experience with

these urethanes which cure by reacting with moisture in the air. The moisture reacts

with a prepolymer containing isocyanate so that the isocyanate is released for cross-

linking. The reaction also releases CO2 which must migrate to the surface before the

film sets up.

Caution In high humidity areas, such as offshore, the reaction can occur so

rapidly that the CO2 cannot escape; and the film is filled with gas bubbles and

pinholes.

Type IV, Two-package Catalyzed. These urethanes cure by reacting with a low-

molecular-weight-reactive catalyst. They cure in a similar way not only to moisture-

cure (although the catalyst is in a separate package), but also to epoxy coatings.

Type V, Two-package Polyol-cured. These urethanes are the Company's most

common choice for high-performance coating systems such as for offshore plat-

forms and chemical plants. To cure, polyol-cured coatings react with pre-reacted

(adduct) hydroxyl-bearing polyols. They require no additional curing agent;

however, coatings applicators may add an agent to promote low-temperature curing.

124 Silicones

Silicones are a group of various organo-silicon-oxide polymers available as fluids,

elastomers, and resins. Because of their chemical composition, silicones have excel-

lent resistance to heat, weathering, and moisture.

Note Repairing silicone coatings is very difficult because almost nothing will

adhere to them. For small repairs, sand the failure and apply fresh silicone coating

with a brush. For large repairs, remove the coating by abrasive blasting and recoat.

The Company uses both classes of silicone coating resins: heat-reactive and modified.

Chevron Corporation 100-15 November 1998

100 General Information Coatings Manual

Heat-reactive

Silicone resins are cross-linked polymers which require a high-temperature cure to

produce heat-stable films. Catalyzed formulations which cure at room temperature

are now available. Non-catalyzed formulations remain tacky until heated above

about 300 to 400F. For this reason, most field applications use the catalyzed, room-

temperature cure.

The film thickness of baked silicone coatings is low compared to that of other coat-

ings. A self-primed two-coat application usually produces only 1 to 2 mils dry

film thickness (DFT).

Advantages:

Excellent sunlight resistance

Good durability at high temperatures

Disadvantages:

Apply only on abrasion-blasted surfaces

Uses:

Furnaces and stacks up to 600F (up to 750F for aluminum and black colors)

Note The color and gloss retention of baked silicones depends on the pigments.

Modified or Air-drying

Modified or air-drying silicones are produced by reaction with organic resins such

as alkyds or acrylics.

Advantages:

Excellent gloss and color retention

Good weather and sunlight resistance

Many resist temperatures up to 300F

Disadvantages:

Tend to cure quite slowly even at ambient temperature, taking weeks to harden

and resist damage in cool weather.

Note Topcoat inorganic zinc with an epoxy or silicone acrylic.

125 Vinyls

Vinyl resins are formed from the reaction of acetylene with acetic or hydrochloric

acids. Varying this process produces resins consisting of 100 percent vinyl chloride, or

100 percent vinyl acetate. The resins in protective coatings are usually co-polymers

containing 80 to 90 percent vinyl chloride and 5 to 15 percent vinyl acetate.

November 1998 100-16 Chevron Corporation

Coatings Manual 100 General Information

Vinyl resins are hard and brittle and must be combined with plasticizers and

dissolved in solvents to form vehicles for coatings. Vinyl solutions contain only

15 to 40 percent solids depending on the co-polymers.

The various vinyl-resin solutions are compatible and may be blended to emphasize

desired properties. Some blends adhere very well to concrete and metal and are used

in formulating primers. Other blends are pigmented and plasticized to produce high-

build films. Used for finish coats, some blends have low solids and adhere poorly to

steel but have very good chemical and weather resistance.

The Company uses vinyls for many services, often where water exposure is

expected such as on floating tank roofs, docks, and on offshore platforms near the

water.

Advantages:

Excellent chemical, water, and aliphatic oil resistance

Excellent shelf life

Ready bond to weathered vinyl films

Removable with a solvent wash when desired

Easy to patch old coatings without blistering or wrinkling

Easy to apply by spray

Disadvantages:

May lose their plasticizer over time and embrittle, a problem with vinyl as a

weathercoat over polyurethane-foam insulation

Do not have good gloss retention or stain resistance

Dissolved by ketones, esters, chlorinated solvents, and some aromatics

Need good ventilation to avoid prolonged (solvent evaporation) drying

Tend to lift and blister because of the strong solvents

Difficult to brush or roll because of their rapid drying

Tend to bubble and pinhole when applied over porous inorganic zinc

Uses:

With alkyds or epoxy esters to improve film build, gloss, and adhesion which

are excellent as vehicles:

In rust-inhibiting primers for ferrous metals

In seal or tiecoats over inorganic zinc primers to improve adhesion of

vinyl, alkyd, chlorinated rubber

In epoxy ester topcoats

In formulae ranging from thin-bodied, air-drying coatings to semi-mastic

putties and air-drying, baking plastisols

Chevron Corporation 100-17 November 1998

100 General Information Coatings Manual

To formulate a wide variety of latex materials in glues, paper sizes, and emul-

sion coatings

In vinyl-emulsion-latex coatings for both internal and external services. The

retention of deep colors by vinyl latexes is superior to that of most other coatings.

Vinyl Ester

Vinyl ester resin is a reaction product between polyesters and epoxies and shares

many of the attributes of polyesters.

Advantages:

Resistance to acid, solvent attack, and high temperatures

Disadvantages:

More expensive than an isophthalic polyester or normal epoxy

Uses:

Coating concrete

126 Zinc-rich Coatings

Zinc-rich coatings, which have zinc dust as the pigment and inorganic or organic

vehicles, are divided into two classes: inorganic and organic zinc.

Zinc-rich coatings offer good corrosion resistance for steel due to the sacrificial

nature of the zinc pigment. The zinc acts as an anode to protect the steel galvani-

cally and prevent corrosion. This coating is applied alone or as a primer under a

variety of topcoats. Under suitable topcoats, all of these primers greatly enhance the

life of the coating system in many exposures, especially in marine services.

When testing to determine the benefit of zinc in a coating, the Company found the

quality of performance to be rated (best to worst) as follows:

1. Inorganic zincs

2. Zinc-rich organic coatings

3. Organic coatings

Inorganic-zinc Coatings

Inorganic-zinc coatings consist of two components:

A pigment composed solely or principally of zinc powder

Any of a variety of patented and proprietary inorganic or semi-inorganic vehi-

cles to form the matrix of the coating

Post-cured inorganic zincs have a third component: a curing agent such as phos-

phoric acid.

Among the vehicles are ethyl and sodium silicate, phosphates, and other complexes.

November 1998 100-18 Chevron Corporation

Coatings Manual 100 General Information

When properly mixed, applied to blasted steel surfaces, and allowed to cure, the

resultant coatings have outstanding resistance to weathering, humidity, elevated

temperatures, organic solvents, animal and vegetable oils, both fresh and salt water,

and most petroleum products. In addition, these coatings (especially post-cured) have

excellent abrasion resistance. The corrosion resistance of the cured film is similar to

that of galvanized iron; the weather resistance is superior to galvanized iron.

Two types of inorganic zinc coatings are self-cured and post-cured.

Self-Cured Inorganic Zinc Coatings

Self-cured inorganic zinc coatings are either solvent- or water-based vehicles. While

both produce an inorganic film, their methods differ. Current technology is almost

all solvent-alkyl-silicate-resin based.

Solvent-based Coatings. The Company uses self-cured, solvent-based, inorganic

zincs in many places such as piping, tanks, and offshore. Although manufacturers

have used several inorganic silicate vehicles such as ethyl silicate and bi-metallic

alkoxide complexes to make these coatings, almost all self-cured inorganic zincs are

now alkyl silicates such as ethyl silicate.

Ethyl-silicate-based coatings convert to an inorganic, insoluble state in reaction to

moisture. Some formulae require long periods (three to four weeks) of high

humidity to reach ultimate hardness. Many manufacturers now claim their ethyl sili-

cates can be topcoated almost immediately since enough moisture permeates

through the topcoats to cure the primer.

Solvent-based coatings are popular because their vehicles show superior wetting

ability, they dry fast and resist water immediately, and their film thickness is less

critical than for post-cured inorganic zinc coatings.

Some self-cured inorganic zincs are modified to include some organic resin for

more rapid film formation and increased flexibility. Properly formulated, they can

perform as well as normal alkyl silicates.

Caution The Company does not recommend single-component inorganic zincs.

Laboratory tests and experience show that these zincs do not perform as well as the

two-component zincs. One reason is that the zinc settles in the can and is not easily

put back in suspension. The applied coating is, therefore, deficient in zinc.

Coatings applicators mix the multi-component zincs at the time of application and

agitate them continuously to avoid the settling problem.

Water-based Coatings. Tests show that, for weather resistance, water-based coat-

ings are inferior to solvent-based and post-cured inorganic zincs.

Note Future changes to clean air regulations may force us to use water-based or

new, presently untested, formulations of inorganic zincs.

Composed of zinc dust pigment and vehicles containing sodium silicate, or phos-

phates, the vehicles are water solutions similar to those of the post-cured coatings.

After application, the film is water sensitive for some time, the length of which

depends on the formula. The vehicles reaction with moisture in the air converts the

Chevron Corporation 100-19 November 1998

100 General Information Coatings Manual

water-soluble film to an insoluble film. Conversion time depends on the vehicle and

the relative humidity and temperature.

Some of these coatings undergo a color change as they cure, indicating when they

are completely cured.

Caution Do not topcoat or place these coatings in water-immersion service until

they are thoroughly cured.

Post-Cured Inorganic Zinc Coatings

Post-cured inorganic-zinc coatings are composed principally of zinc powder and

sodium silicate. When mixed, the zinc-dust pigment and sodium silicate produce a

water-soluble coating. coatings applicators must keep the applied film dry until it

has cured by a chemical curing agent, such as phosphoric acid, which converts the

film to a water insoluble coating.

Advantages:

Long life under extreme service conditions such as exposure to marine

environments

Disadvantages:

Sensitivity to moisture until cured

White-metal surface preparation

Necessity of removing the powder-like post-cure reaction chemicals (by

washing very thoroughly) before topcoats will adhere

Uses:

Extreme conditions such as offshore structures in marine environments.

Note While post-cured inorganic zinc coatings have a long, successful field

history, the Company limits post-cured zincs to extreme services where their long

life is needed such as near the water on offshore platforms. Today, however, because

self-cured inorganic zincs can last almost as long and are much easier to apply

properly, you may choose them instead.

Zinc-rich Organic Coatings

Epoxies, urethanes, chlorinated rubbers, phenolics, styrenes, silicones, and vinyls

are vehicles for zinc-rich organic coatings. Epoxies are most common. The zinc

content of these coatings should generally be about 80 percent by weight of total

solids.

The mechanism for curing zinc-rich organic coatings depends on the binder. (See

Section 70 of this manual for methods of film formation.) The coatings can be either

single- or multi-component. Performance tends to be a function of the durability of

the binder, and epoxies are generally considered superior.

November 1998 100-20 Chevron Corporation

Coatings Manual 100 General Information

Advantages:

Excellent water and weather resistance

Better wetting ability, because of their organic vehicles, than inorganic zinc

Usable over a broader range of surface preparation conditions than inorganic zinc

Disadvantages:

Not as oil resistant as the inorganic coatings

Uses:

Touch up for inorganic-zinc-primed systems

Subsea equipment primers

As primers under other coatings

Note Often one coat of IOZ alone gives excellent performance. For higher perfor-

mance or aesthetics, topcoat with epoxy or epoxy plus urethane.

Example: One coat of IOZ has lasted 15 plus years on a Richmond Long Wharf line.

Pascagoula successfully used a two-coat system of Carboline Coating Companys

IOZ with Carboline high-build urethane.

130 Petroleum-based Tapes

Petroleum-based tapes, such as denso, work well in severe service as a wrapping for

pipe and structural components.

Advantages:

Adheres to moist surfaces with minimum surface preparation

Adheres to irregular shapes, valves, and pipe fittings

Disadvantages:

Could shield cathodic protection if tape fails

Uses:

Reinforce heavily corroded lines

140 Water-based Coatings

Chevron Corporation OpCos are required to use coating systems that meet both

federal and local regulations controlling the emissions of VOCs. Because

water-based coatings use water instead of solvents as the pigment carrier, they typi-

cally do not contain any Volatile Organic Compounds (VOC) that could be

released into the air. Many OpCos may, in the future, be required to use water-based

coating systems in order to meet these regulations.

After 6 months of testing the major manufacturers water-based coatings, Chevron

has concluded that several are acceptable for inclusion in the Coatings Manual.

However, since these coatings do not perform as well as solvent based coatings, we

Chevron Corporation 100-21 November 1998

100 General Information Coatings Manual

cannot recommend them for severe exposure environments (ie: offshore or indus-

trial environments). Refer to the System Number Selection Guide in the Coat-

ings Manual Quick Reference Guide for a listing of the acceptable brands of

water-based coatings for both new construction and maintenance systems.

150 Coating Systems for Immersion Service

Coating systems usually include a first coat (primer), second coat (tiecoat), and a

final coat (topcoat).

There are three types of coating systems for immersion service and each is described

below along with its advantages, disadvantages, and cost. The coatings described are:

Non-reinforced, thin-film coatings

Glass-flake-reinforced coatings

Laminate-reinforced coatings

151 Non-reinforced Thin-film Coatings

Typically only 10 to 20 mils thick (thin films), these non-reinforced coatings:

Contain no glass flakes or fibers or laminates for reinforcement

Usually have inert fillers such as silica or carbon to reduce shrinkage during

cure and to improve abrasion resistance

Resemble some of the high-build layers of external coating systems

Usually are spray applied in two or more coats: a primer/sealer and one or two

high-build topcoats

Have recommended dry film thickness (DFT) of 15 to 20 milsthicker systems

for more severe services

Most thin-film coatings for tanks are based on epoxy resins, although vinyls, inor-

ganic zinc, and other types of coatings have been used.

Advantages:

Low cost

Use least amount of material

Require no expensive hand work

Easiest to apply

Product purity

Disadvantages:

Lack of thickness leads to no resistance to abrasion, severe chemical attack,

physical abuse

Absence of reinforcement means inability to bridge existing cracks

November 1998 100-22 Chevron Corporation

Coatings Manual 100 General Information

Always have some damaged areas, called holidays

Uses:

Temporary service

Protection from mild corrosion, splash, or spillage environments

Note Apply and inspect this coating system properly to ensure that there are rela-

tively few holidays. The small amount of corrosion which occurs will not be a

problem in mild-corrosion environments if the product is pure.

If the corrosion environment is severe, however, the holidays will initiate pits that

quickly become unacceptable leaks. For severe corrosion service, pre-coated tanks

may have similar problems if they are scratched or damaged while being erected.

For severe corrosion applications, select a thin film coating if the tanks interior is

also cathodically protected to prevent corrosion at damaged areas of the coating. [1]

Life Expectancy

The expected life of a thin-film internal coating is approximately ten years. After

ten years, the coating commonly blisters, and corrosion at holidays is usually occur-

ring over enough of the surface that blasting and replacing the entire coating are

required.

Note Early failure due to blistering often indicates either a problem with the

surface preparation or an incorrect coating selection.

Periodic inspection and repair (touch-up) of the internal coating may extend its life.

As the Company inspects tanks on a ten-year cycle, periodic inspection and touch-

up is usually not possible.

Limitations and Cost

Because they can be sprayed, thin-film coating systems are generally the easiest and

fastest to apply, and also the least expensive.

Example: For a tank over 50,000 bbls, it might take a total of four weeks at a

minimum to carry out the entire project:

Approximately two weeks to clean, blast, and prime

Approximately one week to apply the coating

An additional week for final curing

Ease of application and cost also vary among different categories of thin film coat-

ings. Factors which make a coating easier or more difficult to apply include:

Its ability to flow smoothly and form an even film

How well it hangs on vertical surfaces without running or sagging

Its tendency to form pinholes

Its tolerance to inadequate surface preparation

The amount of drying time required between coats

Chevron Corporation 100-23 November 1998

100 General Information Coatings Manual

These factors also vary from product to product within a category, so it is difficult to

make general statements. Coal-tar epoxies are, however, usually very easy to apply

and relatively inexpensive, but the black color makes them difficult to inspect.

Straight epoxies (polyamides or amine adduct) are also fairly easy to apply and only

slightly more expensive than the coal tars. Epoxy-phenolics are often significantly

more expensive and more difficult to apply.

152 Glass-flake-reinforced Coatings

Glass flakes in coatings, available in spray and trowel formulae:

Make the coating less permeable and more abrasion resistant

Reinforce the resin, allowing thicker film buildup

Note Epoxy and polyester resins are used for glass-flake-reinforced coatings.

The main difference between these two formulae is that the trowel coatings have

larger reinforcing glass flakes than the spray. The layers are therefore as follows:

Trowel: Two 20 to 40 mil (DFT) coats for a total of 60 to 80 mils (DFT)

Spray: Two 15 to 20 mil (DFT) coats for a total of 30 to 40 mils (DFT)

Coatings applicators must roll each layer of both spray and trowel formulae to orient

the glass flakes parallel to the surface. Rolling reduces the permeability of the coat-

ings.

Cathodic protection should not be required with glass-flake-reinforced coatings

(especially trowel-applied types) because they are so thick and are not easily

damaged.

Advantages:

Both (trowel and spray) are more protective than thin-film coatings because

they are thicker and have fewer holidays.

Both are highly advantageous in services where erosion or abrasion would

damage thin-film coatings.

Spray can be applied at twice the thickness of thin-film systems, and over more

uneven surfacesbecause of the coating's thicknessthan thin film.

Trowel is more resistant to chemical attack, abrasion, and physical abuse than

either spray formula or thin-film coatings.

Disadvantages:

Spray is marginally more expensive than thin-film coatings and rolling is

required to improve resistance to chemical attack.

Trowel is much more expensive than thin-film coatings; it is considerably more

difficult and time-consuming to apply than either the spray formula or thin

films, and hand smoothing and rolling is required.

November 1998 100-24 Chevron Corporation

Coatings Manual 100 General Information

Note The cost of glass-flake-reinforced coating may be justified if corrosion rates

are expected to be relatively high but not severe, or permeation through the coating

is a potential problem.

Uses:

Recommended for both mild and severe corrosion applications. Generally, select:

Spray for mild corrosion and for uneven surfaces

Trowel for severe corrosion (as an alternative to a thin-film coating with

cathodic protection)

Note This coating system is the most widely used one for concrete because of its

excellent properties for most environments and lower cost than laminate systems.

Life Expectancy

Expect glass-flake-reinforced coatings to last at least ten years before inspection.

Depending on the condition of the coating and the service, making necessary repairs

may allow the coating to last another ten years. Frequently, however, it will be

necessary to replace the coating after only ten years, especially for sprays. Trowel

applications have a better chance of lasting through a second decade.

Limitations and Cost

The spray-applied glass-flake-reinforced coatings are usually only slightly more

difficult to apply than non-reinforced coatings. Rolling the glass flake properly

takes additional time during application. Spray-applied glass-flake coatings are

more costly than non-reinforced coatings.

Trowel-applied glass-flake coatings are considerably more difficult and time

consuming to apply than sprays. The coating is hand smoothed and rolled to orient

the glass flakes. Coating application may take two to three weeks for an average

size tank (increasing the total time to five to six weeks), and the total installed cost

will be higher than sprayed glass-flake coatings.

Epoxy-glass-flake coatings are generally easier to apply than polyesters or vinyl

esters, both of which require a final wax coat to obtain full surface curing. If the

coating is premixed with wax, common for sprays, the coatings applicator must

apply the second coat within the manufacturer-specified time (known as the

maximum allowable time) because the second coat will not adhere well if the wax

layer has fully cured the first coat.

153 Laminate-reinforced Coatings

The coatings applicator applies laminate reinforced coatings by hand, alternating

layers of resin and fiberglass mat to a total thickness of typically 80 to 125 mils.

Generally, they apply three layers of resin and two layers of mat.

For some services, specifications call for an additional layer of a special surfacing

veil of chemical grade glass or polyester and another coat of resin.

Chevron Corporation 100-25 November 1998

100 General Information Coatings Manual

Note The veil prevents any glass fibers from protruding through the resin surface,

which could allow wicking or chemical attack of the glass itself.

After the completed laminate is inspected, the coatings applicator applies a final

coat of resin. For epoxy resins, this gel coat simply provides additional protection

from chemical attack.

For polyester resins, the coatings applicator adds a wax to the final resin coat to

obtain full curing. Without the wax coat the surface of a polyester coating always

remains slightly tacky and lacks its optimum chemical resistance, and the body of

the laminate cures very slowly.

Advantages:

A laminate-reinforced coating provides the best protection against severe corrosion.

Laminates should not require cathodic protection as they should not contain any

holidays.

A laminate is the only type of internal coating which has significant structural

strength by itself.

Because it does not need to be as thick, epoxy-resin laminates are less expen-

sive than polyester or vinyl ester laminates.

Disadvantages:

Compared to thin-film and glass-flake-reinforced coatings, laminates are the

most expensive coating.

Laminate-reinforced coatings are the most difficult and time consuming to

apply.

Uses:

Laminates are generally used for stockside corrosion only when there is severe

corrosion or when underside corrosion is expected or has occurred.

Life Expectancy

Laminate reinforced coatings will last for 20 years, but inspect and repair them after

10 years. Eventually, the laminate will start to crack and lose its adhesion to the

steel, especially if the tank bottom flexes or settles significantly.

If underside corrosion occurs, remove the coupons to check the condition of the

steel bottom. Replace the laminate and the bottom if the bottom is essentially

corroded through.

Caution Never apply a second laminate over a failed laminate.

Limitation and Cost

Laminate-reinforced coatings are the most difficult and time consuming to apply.

The hand layering of fiberglass mat is a slow process, normally requiring at least

three weeks for an average-size tank, increasing the total time to a minimum of six

November 1998 100-26 Chevron Corporation

Coatings Manual 100 General Information

weeks. Laminates are also expensive. The total cost per square foot is equal to or

higher than that of trowel-applied glass-flake coatings.

Because it does not need to be as thick, epoxy-resin laminates are less expensive

than polyester or vinyl ester laminates. Polyesters and vinyl esters require a final

wax coat to obtain full surface curing; however, as they remain fluid longer before

starting to cure, they are easier to use.

Note The time between mixing and cure is called the gel time.

The coatings applicator can adjust the gel time by mixing different amounts of cata-

lyst and promoter into the resin. After the resin sets, it will reach 90 percent of full

cure in a short time. As epoxy resins do not have a gel time, they cure at a relatively

constant rate, starting immediately after mixing, and therefore do not remain as fluid

for as long as laminates.

160 Quality Control

161 General Information

Do the job right the first time.

Essentially a system of checks and balances, quality control helps ensure that a

projects participants fulfill the specifications requirements. For coatings projects,

the process should yield a high-quality result that:

Contributes to the maximum service life of the structure and equipment

Reduces future expenditures for field maintenance

Offshore

Achieving high-quality coatings is more difficult offshore than onshore due to some

of the following conditions:

Adverse weather

Simultaneous operations with other platform activities

Congested platform areas

Limited availability of transportation

Existing substrate surfaces that can be deeply pitted and contaminated with

soluble surface salts

Inaccessible items

Careful design and planning help to minimize the effects of these conditions.

A major component of quality for offshore coatings includes cure and recoat times

before returning a facility to service. Critical areas are the +/- 10-foot splash zone,

work decks and helidecks, and sweating equipment and piping. See detailed infor-

mation about quality control for offshore coatings in Section 800 of this manual.

Chevron Corporation 100-27 November 1998

100 General Information Coatings Manual

Keys to Successful Projects

Comprehensive quality control activities are, however, key to any successful

project.

The quality control for a specific project depends not only on type of project but

also on available resources: financial and personnel. Most projects have the best

financial result over the structures life by involving qualified individuals in the

project at the most appropriate time for as long as necessary to ensure that the speci-

fications are prepared properly and met.

Regardless of the size, among the keys to success of any coating project are the

specifications, specialists and inspectors, and the Companys Project Development

and Execution Process (CPDEP).

Specifications

Caution Avoid the pitfall of writing specifications so vague and general that they

confuse everyone and allow the contractor to provide substandard work.

A well-written specification includes:

Requirements for the pre-job conference

Coating schedule for all items

Work schedule

Materials, including coatings and abrasive

Minimum standards for equipment

Example: Equipment such as moisture traps on coating and blast pots, coating gun

types and hose sizes, and quality of compressed air.

Coating Specialists and Inspectors

Industrial coating applications are highly specialized work processes that require

support from individuals with particular knowledge and experience: the coating

specialist and inspector.

Coating Specialist. A coating specialist provides the project's engineering team with:

Advice about selecting, inspecting, and applying coatings

Information about premature failures

Technical and tactical recommendations for day-to-day activities and interac-

tion with the contractor

Coating Inspector. The goal of the project's coating inspector, usually a contractor,

parallels the program's objectives to ensure that all surfaces are prepared and all

coatings applied within specification. The inspector:

Enforces the specification during each phase of the work activities

Maintains detailed records of the coating activities

November 1998 100-28 Chevron Corporation

Coatings Manual 100 General Information

Note These records are extremely important in case of litigation and provide the

engineering team with daily work updates and recommendations.

See also the sections below on Inspections and Inspectors.

Companys Project Development & Execution Process (CPDEP)

By taking the Front End Loading (FEL) approach of CPDEP (adding coating

experts to the team during the design-and-fabrication phases), the projects team

eliminates the problem of materials leaving the fabrication yard with an aestheti-

cally acceptable, yet otherwise short-term and non-corrosion-resistant coating.

Example: During the 1980s, one of the Companys profit centers spent over $15MM

to repair fabrication work that had failed prematurely (needing major re-work in

four years or less). Costly replacement of corroded equipment/structures and repair

of premature coating failures are often attributable to the work in fabrication yards.

162 Inspection Programs

An inspection adage states: People do not as you expect. People do as you inspect.

Inspecting a coating ensures that it meets specifications for the particular project

and provides maximum protection over the coatings expected life.

In the Company, there are three inspection programs: one complete and two levels

of partial inspections (Figures 100-2, 100-3, 100-4). The three inspection programs

require inspectors of varying levels of qualification.

The level of inspection chosen for a coating project is primarily a function of the

acceptable risk involved if a coating fails prematurely.

Corrosion and aesthetics are the two main reasons for applying an external coating.

The engineer must choose the best inspection program to meet the needs of the

particular project cost effectively.

For external coating projects where corrosion is a concern, the Company

recommends a complete inspection program, the most conservative, reliable,

and costly method of inspection.

If aesthetics are the only concern, then either of the two partial inspection

programs may be adequate; but some of these projects may require complete

inspection.

The Company's representative and the inspector (if different) should agree on a

method of reporting the test results and observations of the inspection. A copy of the

Company's recommended form, COM-EF-844, is available in this manual.

The inspector files a copy of reports with the Company's representative.

Chevron Corporation 100-29 November 1998

100 General Information Coatings Manual

Complete Inspections

A complete inspection requires a full-time, qualified inspector. The most conserva-

tive and costly of the three programs, a complete inspection is recommended when a

coatings reliability is critical.

The complete inspection checklist (Figure 100-2) is a compilation of items the

inspector should examine to ensure that the work satisfies all requirements of the

specification. While all items are important, they are ranked in terms of relative

importance: ccritical, nnecessary, and aapplies. Missing an a item has

lower potential effect on the life of the coating than missing the others.

Fig. 100-2 Inspection ChecklistComplete Inspection (1 of 2)

A qualified coatings inspector ensures the lining work meets the Chevron Specification. The inspector keeps

records (using the Company's Standard Form COM-EF-844 or another form agreed upon by the Chevron represen-

tative and the inspector) and files a copy of the report with the Chevron OPCO.

Each inspection item below has a code letter that indicates its relative importance. Items marked with a (c) are

critical, those with an (n) are necessary, and those with an (a) apply. All items are important; but, if an (a) item is

missed, the potential impact on the coating life would not be as great as missing a (c) or an (n) item.

I. Pre-Job Check Out

A. (c) Review Chevron OPCO Specifications.

B. (c) Check tank for inaccessible areas, laps, patches, rough welds, weld spatter, etc.

C. (c) Check surface for grease, oil, moisture, etc.

D. (c) Check abrasive for cleanliness, dryness, etc.

E. (a) Check abrasive for type and size.

F. (c) Check compressed air for oil and moisture.

G. (a) Check nozzle air pressure.

H. (n) Check that proper coatings and thinners are present.