Professional Documents

Culture Documents

For Solved Answers Please: Click Here

Uploaded by

Arun SOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

For Solved Answers Please: Click Here

Uploaded by

Arun SCopyright:

Available Formats

WWW.DIESELSHIP.

COM 1

MARINE ENGINEERING KNOWLEDGE (GENERAL)

Instructions:

1. Answer SIX questions

2. All Questions carry equal marks

3. Neatness in handwriting and clarity in expression carries weightage

4. Illustration of an Answer with clear sketches /diagram carries weightage

5. All unused pages of the answer script must be cancelled out by two lines (X) across the page

SEPTEMBER 2016

Q1. During routine soundings it is found that leakage into a cofferdam is occurring from an adjacent deep cargo oil tank. As Second Engineer state

the procedure for directing safe entry by the engine room staff to ascertain the cause of the leakage.

If the leakage persists discuss EACH of the following options as a possible remedy: 1. Leave the cofferdam to flood with oil (ii) Flood the cofferdam

with sea water (iii) Seal the Cofferdam and pressurize with air (iv) Pump the leakage to bunker tanks.

Q2. A.(i) Sketch a combustion gas system, suitable for inerting the cargo spaces of a vessel. (ii)Describe the operation of this system.

B. State the percentage analysis by volume of the inert gas generated by the system in (A).

Q3. Sketch a section through a keyless sleeved propeller.

B. What are the advantages of using a keyless sleeved propeller

C. Which metal sleeve should be made for contact with the forged mild steel tail shaft? Give reasons

D. State the material; used to bond the sleeve to the propeller and the general thickness of the bonding material.

Q4. Sketch suitable welded joints indicating the approximate plate thickness and dimensions of preparation for the following purposes A. End

plate connection to the shell of an unfired pressure vessel; B. Longitudinal seam of an unfired pressure vessel; C. Prefabricated combustion

chamber for an auxiliary boiler

Q5. With respect to main boiler super heater arrangements:

A. Compare the advantages and disadvantages of contra flow with parallel flow design.

B. Describe how the element tube banks are supported yet allow for expansion.

C. Describe how boiler carryover affects super heater effectiveness and condition. ALREADY DONE 2016/SR09

Q6. A. Explain how and why the performance of reciprocating air compressor tends to fall off in service. B. State how fall off is indicated and to

what extent permissible before correction; C. Describe how optimum performance is restored; D. What is the significance of clearance volume: for

reciprocating air compressors

Q7. With reference to the carriage and pumping of liquefied gas cargo: A. Sketch a suitable pumping system labeling the component parts; State;

B. Why submerged hydraulically driven pumps are not used; C. How overheating of pump drive shaft bearings is avoided; D. How tank is rendered

safe both in loaded & unloaded condition. E Why at the end of discharge about 2% of liquid cargo is left in the tank. F. State, how the risk of fire

and explosion in cargo tanks is obviated both in the loaded and discharged condition.

Q8. With reference to electro-hydraulic steering gears: A. Explain in terms of control parlance, the function of the Hunting gear; B. Explain the

consequences if the standby pumping unit is motored; C. State TWO methods employed to prevent the standby hydraulic pump being motored by

the operating unit

Q9. A. the UMS monitoring and control system of your ship has recently started to give false alarms and incorrect data printouts. State, with

reasons, possible causes if the false alarms and reading are:

I. Localized to a particular area of engine operation; ii. General to the engine room

B. State, with reasons, the action you, as Second Engineer, would take to ensure continued safe operation of the vessel if the defects were general

to the engine room.

C. Explain the procedure you, as Second Engineer, would adopt in order to locate and rectify a general fault in the UMS system.

FOR SOLVED ANSWERS PLEASE CLICK HERE WWW.DIESELSHIP.COM

You might also like

- Visco ThermDocument4 pagesVisco ThermArun SNo ratings yet

- Marine Engineering Oral1Document27 pagesMarine Engineering Oral1toe tetNo ratings yet

- TaxonomyDocument56 pagesTaxonomyKrezia Mae SolomonNo ratings yet

- Members Section Timing Chains Tensioning A Timing ChainDocument1 pageMembers Section Timing Chains Tensioning A Timing ChainArun SNo ratings yet

- April 2000: Function: Marine Engineering at Operational LevelDocument31 pagesApril 2000: Function: Marine Engineering at Operational LevelAnshu BhushanNo ratings yet

- Ship Construction Theory Section I & II LAST UPDATED IN DEC 2023Document7 pagesShip Construction Theory Section I & II LAST UPDATED IN DEC 2023Ganesh MohiteNo ratings yet

- Operational Theory Force On Crosshead GuidesDocument2 pagesOperational Theory Force On Crosshead GuidesArun SNo ratings yet

- Boost productivity and networking with a co-working café in Iligan CityDocument4 pagesBoost productivity and networking with a co-working café in Iligan CityJewel Cabigon0% (1)

- Tensioning Chain PDFDocument1 pageTensioning Chain PDFArun SNo ratings yet

- Shipboard High VoltageDocument62 pagesShipboard High VoltageArun SNo ratings yet

- Administration and Supervisory Uses of Test and Measurement - Coronado, Juliet N.Document23 pagesAdministration and Supervisory Uses of Test and Measurement - Coronado, Juliet N.Juliet N. Coronado89% (9)

- Members Section Turbocharging Turbocharger SurgingDocument3 pagesMembers Section Turbocharging Turbocharger SurgingArun SNo ratings yet

- MAN B&W MC Engine VIT Fuel Pump OperationDocument6 pagesMAN B&W MC Engine VIT Fuel Pump OperationArun S100% (1)

- Small Unmanned Fixed-wing Aircraft Design: A Practical ApproachFrom EverandSmall Unmanned Fixed-wing Aircraft Design: A Practical ApproachNo ratings yet

- Marine and Offshore Pumping and Piping SystemsFrom EverandMarine and Offshore Pumping and Piping SystemsRating: 4.5 out of 5 stars4.5/5 (2)

- 2-Trim Stability Booklet PDFDocument16 pages2-Trim Stability Booklet PDFsanthiniNo ratings yet

- TURNOMATDocument2 pagesTURNOMATArun SNo ratings yet

- Members Section Fuel Oil Fuel Oil TestingDocument3 pagesMembers Section Fuel Oil Fuel Oil TestingArun SNo ratings yet

- Members Section Fuel Oil Fuel Oil TestingDocument3 pagesMembers Section Fuel Oil Fuel Oil TestingArun SNo ratings yet

- EKM Question Bank (COC Written) - 1Document15 pagesEKM Question Bank (COC Written) - 1Tarek AzizNo ratings yet

- Marpol Generic Discharge CriteriaDocument14 pagesMarpol Generic Discharge CriteriaArun SNo ratings yet

- Treatment and Maint of LO PDFDocument8 pagesTreatment and Maint of LO PDFArun SNo ratings yet

- IAMI Revision Questions Electrical & Ship ConstructionDocument4 pagesIAMI Revision Questions Electrical & Ship ConstructionStewart Long100% (1)

- General Engineering Knowledge SurveyDocument169 pagesGeneral Engineering Knowledge SurveyRahul KolazhiNo ratings yet

- X Head LubricationDocument3 pagesX Head LubricationArun SNo ratings yet

- Camless Two Stroke Main Propulsion engine-B&W ME - CDocument21 pagesCamless Two Stroke Main Propulsion engine-B&W ME - CNarayana Prakash96% (52)

- Treatment and Maint of LODocument8 pagesTreatment and Maint of LOArun SNo ratings yet

- TC BRGDocument6 pagesTC BRGArun SNo ratings yet

- JSMSC - TDv3 6 20Document251 pagesJSMSC - TDv3 6 20Jason20170% (1)

- Ekg 8Document2 pagesEkg 8Arun SNo ratings yet

- Ekg 8Document2 pagesEkg 8Arun SNo ratings yet

- Trouble Shooting GuideDocument26 pagesTrouble Shooting GuideArun S100% (1)

- Class 1 UK PDFDocument7 pagesClass 1 UK PDFArun SNo ratings yet

- General Engineering Knowledge Past Questions 2001-2005Document20 pagesGeneral Engineering Knowledge Past Questions 2001-2005Hemachandren SubramaniNo ratings yet

- TC BRG and LubDocument3 pagesTC BRG and LubArun SNo ratings yet

- Tail-shaft survey guidelines for Indian cargo shipsDocument6 pagesTail-shaft survey guidelines for Indian cargo shipsArun S100% (1)

- Class IV-Model Question paper-MEK (General)Document2 pagesClass IV-Model Question paper-MEK (General)ritheshNo ratings yet

- Science, Technology, Engineering and Mathematics (Stem) Grade 11 Grade 12 First Semester Second Semester First Semester Second SemesterDocument1 pageScience, Technology, Engineering and Mathematics (Stem) Grade 11 Grade 12 First Semester Second Semester First Semester Second SemesterJhondriel Lim71% (7)

- ALFA LAVAL Manual P605 High Speed SeparatorDocument181 pagesALFA LAVAL Manual P605 High Speed SeparatorMery A. Dominguez88% (8)

- Marine engine knowledge questionsDocument1 pageMarine engine knowledge questionsArun SNo ratings yet

- Ekg March 2016Document74 pagesEkg March 2016Thomas JoseNo ratings yet

- 95MEP-4 Exam of Marine Engineer Officer Maintenance & RepairDocument2 pages95MEP-4 Exam of Marine Engineer Officer Maintenance & RepairBhupender RamchandaniNo ratings yet

- Ekm QB Jan 2010 Apr 2016Document34 pagesEkm QB Jan 2010 Apr 2016Amit Kumar NarayanNo ratings yet

- Class IV-Model Question paper-MEK (General)Document3 pagesClass IV-Model Question paper-MEK (General)ritheshNo ratings yet

- For Solved Answers Please: Click HereDocument1 pageFor Solved Answers Please: Click HereArun SNo ratings yet

- Ekm Feb 2017Document1 pageEkm Feb 2017Arun SNo ratings yet

- Qbmepmarch2016 PDFDocument95 pagesQbmepmarch2016 PDFRizu90No ratings yet

- Q&A GeneralDocument8 pagesQ&A GeneralRaunaq AroraNo ratings yet

- MEO CL2 - Gen WrittenDocument12 pagesMEO CL2 - Gen WrittenAnkit KumaarNo ratings yet

- meoekmII 2001decDocument2 pagesmeoekmII 2001decAmit Kumar GuptaNo ratings yet

- Function: Marine Engineering at Operational LevelDocument3 pagesFunction: Marine Engineering at Operational LevelBhupender RamchandaniNo ratings yet

- EKG ClII PDFDocument7 pagesEKG ClII PDFvivekNo ratings yet

- Qbs Sep March 2016Document104 pagesQbs Sep March 2016S SanchitNo ratings yet

- Ekg - March - 2023Document3 pagesEkg - March - 2023only indianNo ratings yet

- 95MEKM-4 Marine Engineer Officer Exam QuestionsDocument3 pages95MEKM-4 Marine Engineer Officer Exam QuestionsBhupender RamchandaniNo ratings yet

- Mep - December - 2023Document2 pagesMep - December - 2023Apoorv SinghNo ratings yet

- Ekg Class2Document46 pagesEkg Class2Anonymous 4ylE57C6No ratings yet

- MEK Motor Solved Till March 2023Document147 pagesMEK Motor Solved Till March 2023Prince Kumar GuptaNo ratings yet

- meomepII 7004Document2 pagesmeomepII 7004Deepak PandeyNo ratings yet

- Function: Marine Engineering at Operational LevelDocument2 pagesFunction: Marine Engineering at Operational LevelBhupender RamchandaniNo ratings yet

- H.S.N.A. LUCKNOW MEO CLASS II Marine Engineering Practice Final ExamDocument2 pagesH.S.N.A. LUCKNOW MEO CLASS II Marine Engineering Practice Final ExamsuveshNo ratings yet

- Function: Marine Engineering at Operational LevelDocument3 pagesFunction: Marine Engineering at Operational LevelJomon JohnyNo ratings yet

- Function: Marine Engineering at Management LevelDocument3 pagesFunction: Marine Engineering at Management LevelkhalidhunerkarNo ratings yet

- Advanced Marine Technologies: Safety Devices and SystemsDocument14 pagesAdvanced Marine Technologies: Safety Devices and SystemsNitin ChaurasiaNo ratings yet

- meossepIV 3003Document2 pagesmeossepIV 3003545G Parmeshwar UpadhyayNo ratings yet

- Mek 2000 March 95 SR - No.2Document2 pagesMek 2000 March 95 SR - No.2Bhupender RamchandaniNo ratings yet

- Certificates of Competency in The Merchant Navy - Marine Engineer OfficerDocument4 pagesCertificates of Competency in The Merchant Navy - Marine Engineer OfficersumitNo ratings yet

- 95 MEKM4 SR No4Document3 pages95 MEKM4 SR No4Bhupender RamchandaniNo ratings yet

- EKG Questions Bank (COC Written)Document24 pagesEKG Questions Bank (COC Written)shamratNo ratings yet

- Marine Engineer Exam QuestionsDocument4 pagesMarine Engineer Exam QuestionsBhupender RamchandaniNo ratings yet

- Candidate's Motor Engineering ExamDocument11 pagesCandidate's Motor Engineering ExamMobin GhariNo ratings yet

- 78EKG-1 Sr. No. 9 Examination of Marine Engineer Officer Engineering KnowledgeDocument2 pages78EKG-1 Sr. No. 9 Examination of Marine Engineer Officer Engineering KnowledgeThiet PhamNo ratings yet

- Paper 6 Safety, Environment Protection and Personal CareDocument2 pagesPaper 6 Safety, Environment Protection and Personal CaresuveshNo ratings yet

- Ilovepdf MergedDocument16 pagesIlovepdf MergedDeb Sankar MukhopadhyayNo ratings yet

- Ilovepdf MergedDocument107 pagesIlovepdf MergedDeb Sankar MukhopadhyayNo ratings yet

- October 2016: 2010/SR10 2010/SR11 2011/SR3 2011/SR10 2012/SR6 2013/SR1 2013/SR7 2016/SR02 2016/SR04 2016/SR10Document2 pagesOctober 2016: 2010/SR10 2010/SR11 2011/SR3 2011/SR10 2012/SR6 2013/SR1 2013/SR7 2016/SR02 2016/SR04 2016/SR10Arun SNo ratings yet

- Marine Diesel Engine Parameters and Fault DiagnosisDocument32 pagesMarine Diesel Engine Parameters and Fault DiagnosisAnshu BhushanNo ratings yet

- Sample c2 EgDocument6 pagesSample c2 EgJack TouNo ratings yet

- Mep - Oct - 2022Document2 pagesMep - Oct - 2022shaan51019888No ratings yet

- Ship safety, environmental and personnel questionsDocument1 pageShip safety, environmental and personnel questionsArun SNo ratings yet

- Ship Safety & Environment ProtectionDocument2 pagesShip Safety & Environment ProtectionSuresh JagadeesanNo ratings yet

- Marine engineering exam questionsDocument3 pagesMarine engineering exam questionsBhupender RamchandaniNo ratings yet

- Marine Engine Exam QuestionsDocument2 pagesMarine Engine Exam QuestionsSHUSHEELNo ratings yet

- Ekm - January - 2023Document2 pagesEkm - January - 2023Shivashish SharmaNo ratings yet

- Ship Construction 2nd Eng - Question 2020Document6 pagesShip Construction 2nd Eng - Question 2020thaher zaidNo ratings yet

- Ship Construction Ch. Mate. Question 2020Document6 pagesShip Construction Ch. Mate. Question 2020مرتضى جبار السودانيNo ratings yet

- Marine engineering exam questions and answersDocument2 pagesMarine engineering exam questions and answersDeepak PandeyNo ratings yet

- Paper 1 Engineering Knowledge GeneralDocument2 pagesPaper 1 Engineering Knowledge GeneralsuveshNo ratings yet

- EKG Class4 Questions OnlyDocument6 pagesEKG Class4 Questions OnlyVyas SrinivasanNo ratings yet

- Crew Change Protocol ChecklistDocument2 pagesCrew Change Protocol ChecklistArun SNo ratings yet

- Pump Room Ventilation RequirementsDocument1 pagePump Room Ventilation RequirementsNUm SaiChon RT100% (1)

- Prediction and Measurement of Propeller Singing: C e C Ec e EeDocument1 pagePrediction and Measurement of Propeller Singing: C e C Ec e EeArun SNo ratings yet

- Safety Surveyor Wise QuestionsDocument16 pagesSafety Surveyor Wise QuestionsArun SNo ratings yet

- DG Circular 13 Oct 2017 PDFDocument6 pagesDG Circular 13 Oct 2017 PDFA RNo ratings yet

- Tensioning Chain PDFDocument1 pageTensioning Chain PDFArun SNo ratings yet

- Water Booster Pump Calculations - Plumbing Engineering - Eng-TipsDocument3 pagesWater Booster Pump Calculations - Plumbing Engineering - Eng-TipsNeal JohnsonNo ratings yet

- CFPA E Guideline No 2 2013 FDocument39 pagesCFPA E Guideline No 2 2013 Fmexo62No ratings yet

- Engine Rear Oil Seal PDFDocument3 pagesEngine Rear Oil Seal PDFDIEGONo ratings yet

- Decision Flow Chart: For Suspicious PackagesDocument2 pagesDecision Flow Chart: For Suspicious PackagesHervian LanangNo ratings yet

- MBA Regular Part-I (Sem I)Document17 pagesMBA Regular Part-I (Sem I)Jasdeep SinghNo ratings yet

- Drainage Manual: State of Florida Department of TransportationDocument78 pagesDrainage Manual: State of Florida Department of TransportationghoyarbideNo ratings yet

- Telegram Log File Details Launch Settings Fonts OpenGLDocument5 pagesTelegram Log File Details Launch Settings Fonts OpenGLThe nofrizalNo ratings yet

- LQRDocument34 pagesLQRkemoNo ratings yet

- The History of Coins and Banknotes in Mexico: September 2012Document35 pagesThe History of Coins and Banknotes in Mexico: September 2012Mladen VidovicNo ratings yet

- Cambridge English Business Vantage Sample Paper 1 Listening v2Document5 pagesCambridge English Business Vantage Sample Paper 1 Listening v2salma23478No ratings yet

- TN Govt RecruitmentDocument12 pagesTN Govt RecruitmentPriyanka ShankarNo ratings yet

- Asian Paint FMVRDocument20 pagesAsian Paint FMVRdeepaksg787No ratings yet

- Handwashing and Infection ControlDocument23 pagesHandwashing and Infection ControlLiane BartolomeNo ratings yet

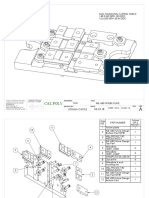

- Fixture Design ProjectDocument4 pagesFixture Design ProjectJosh CastleNo ratings yet

- Art PDFDocument10 pagesArt PDFbobNo ratings yet

- CopyofCopyofMaldeepSingh Jawanda ResumeDocument2 pagesCopyofCopyofMaldeepSingh Jawanda Resumebob nioNo ratings yet

- LV 2000L AD2000 11B 16B Metric Dimension Drawing en 9820 9200 06 Ed00Document1 pageLV 2000L AD2000 11B 16B Metric Dimension Drawing en 9820 9200 06 Ed00FloydMG TecnominNo ratings yet

- SDRRM Earthquake Drill TemplateDocument3 pagesSDRRM Earthquake Drill TemplateChristian Bonne MarimlaNo ratings yet

- Confidentiality Agreement With Undertaking and WaiverDocument1 pageConfidentiality Agreement With Undertaking and WaiverreddNo ratings yet

- Performance Evaluation of Root Crop HarvestersDocument15 pagesPerformance Evaluation of Root Crop HarvestersIJERDNo ratings yet

- Wave Optics - I: Created by C. Mani, Principal, K V No.1, AFS, Jalahalli West, BangaloreDocument16 pagesWave Optics - I: Created by C. Mani, Principal, K V No.1, AFS, Jalahalli West, BangaloreNitesh Gupta100% (1)

- MDF 504 Investment Analysis and Portfolio Management 61017926Document3 pagesMDF 504 Investment Analysis and Portfolio Management 61017926komalkataria2003No ratings yet

- Fraud Ebook Latest - Databricks PDFDocument14 pagesFraud Ebook Latest - Databricks PDFmohitbguptaNo ratings yet

- Parison of Dia para FerroDocument4 pagesParison of Dia para FerroMUNAZIRR FATHIMA F100% (1)

- Few Words About Digital Protection RelayDocument5 pagesFew Words About Digital Protection RelayVasudev AgrawalNo ratings yet