Professional Documents

Culture Documents

Polipropileno Homopolimero2306N

Uploaded by

DieguitoOmarMoralesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Polipropileno Homopolimero2306N

Uploaded by

DieguitoOmarMoralesCopyright:

Available Formats

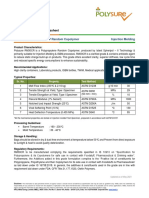

Formolene 2306N

Impact Copolymer for Compression and Injection Molded Caps and Closures

Formolene 2306N is a polypropylene copolymer formulated for compression and injection molded cap

applications. It was created specifically to meet the demands of beverage closures including those containing

carbonation. 2306N offers advantages in both processing and physical properties over traditional

polypropylene grades. Of interest is good resistance to blushing caused typically through secondary process

operations or supply chain handling.

Formolene 2306N meets all requirements of the U. S. Food and Drug Administration as specified in 21

CFR 177.1520, covering safe use of polyolefin articles and components of articles intended for direct food

contact.

Typical Properties of this Commercial Grade

Melt Flow Rate, I2 @ 230C, g/10 min ASTM D1238 6.0

3

Density, g/cm ASTM D1505 0.9

Tensile Strength at Yield (50 mm/min), psi ASTM D638 4,350

Elongation at Yield (50 mm/min), % ASTM D638 9

Flexural Modulus (1.3 mm/min), 1% Secant, psi ASTM D790 200,000

Rockwell Hardness, R Scale ASTM D785 110

Notched Izod Impact Strength @ 73F, ft-lb/in ASTM D256 5.0

Notched Izod Impact Strength @ 0C, ft-lb/in ASTM D256 1.6

o

Heat Deflection Temperature @ 66psi, C ASTM D648 115

Note: Specimens were injection molded according to the conditions specified in ASTM D4101.

Published 1/01, Revised 08/10

4/10

You might also like

- Corrosion: Corrosion ControlFrom EverandCorrosion: Corrosion ControlL L ShreirRating: 5 out of 5 stars5/5 (1)

- 1203K PDFDocument1 page1203K PDFarslanNo ratings yet

- Formolene 2610A: Impact Copolymer For Compounding and Injection Molded ApplicationsDocument1 pageFormolene 2610A: Impact Copolymer For Compounding and Injection Molded ApplicationsMiguel Angel Perez EsparzaNo ratings yet

- Hopelen PP Homopolymer General Information: DescriptionDocument2 pagesHopelen PP Homopolymer General Information: DescriptionKormanyos JoppeNo ratings yet

- Topilene J640Document1 pageTopilene J640EmmylouCasanovaNo ratings yet

- P O L Y P R O P Y L E N E: Reliance Industries LimitedDocument1 pageP O L Y P R O P Y L E N E: Reliance Industries LimitedSiddheshNo ratings yet

- Polysure PP RB02CRDocument1 pagePolysure PP RB02CRPiyush A JoshiNo ratings yet

- Polysure PP RM30CRDocument1 pagePolysure PP RM30CRyansyafNo ratings yet

- Sabic Hdpe B5429: High Density PolyethyleneDocument2 pagesSabic Hdpe B5429: High Density Polyethylenegetasew altasebNo ratings yet

- HJ541CP: Polypropylene Block CopolymerDocument1 pageHJ541CP: Polypropylene Block CopolymerEmmylouCasanovaNo ratings yet

- Topilene J800Document1 pageTopilene J800KevinGarciaNo ratings yet

- TDS B0155DDocument1 pageTDS B0155DtechnopackishvarlalNo ratings yet

- POLYMER C150Y - Jan15 - New - Rev1Document2 pagesPOLYMER C150Y - Jan15 - New - Rev1W I Prayogo100% (1)

- FT200WVDocument1 pageFT200WVdata1plasticirNo ratings yet

- Topilene HJ541CPDocument1 pageTopilene HJ541CPEmmylouCasanovaNo ratings yet

- DMDH6400Document2 pagesDMDH6400JUAN SEBASTIAN BUSTOS GARNICANo ratings yet

- 3 - 2 - 4 - Hdpe Film 2-7000F PTT - TDSDocument2 pages3 - 2 - 4 - Hdpe Film 2-7000F PTT - TDSPhuoc TranNo ratings yet

- Upp Tds Ep548s EnglishDocument1 pageUpp Tds Ep548s EnglishRula SiuNo ratings yet

- 202-Rohm Cyrolite GS-90 Technical Data SheetDocument2 pages202-Rohm Cyrolite GS-90 Technical Data Sheetismail hakkıNo ratings yet

- Ficha Tecnica Polipropileno Moplen Ep300l (J440)Document1 pageFicha Tecnica Polipropileno Moplen Ep300l (J440)Carlos SiuNo ratings yet

- UPP TDS EP241N+ (Trial) EnglishDocument1 pageUPP TDS EP241N+ (Trial) EnglishRula SiuNo ratings yet

- TDS HP740T DaelimDocument1 pageTDS HP740T Daelimbrandon abella gutierrezNo ratings yet

- Impact Copolymer: For Injection Moulded ProductsDocument1 pageImpact Copolymer: For Injection Moulded ProductsarthymanicNo ratings yet

- TDS Hpr1018ha AstmDocument2 pagesTDS Hpr1018ha AstmOsamah JoubsenNo ratings yet

- Haldia Petrochemicals PP Packing CoverDocument1 pageHaldia Petrochemicals PP Packing CoverAnand Kumar MunirajuNo ratings yet

- 3 Property H7900 EngDocument1 page3 Property H7900 EngMohit MohataNo ratings yet

- Polypropylene Homo Polymer Injection Molding: Provisional Technical DatasheetDocument2 pagesPolypropylene Homo Polymer Injection Molding: Provisional Technical DatasheetMohit MohataNo ratings yet

- y 130영문 (Astm)Document1 pagey 130영문 (Astm)qshakimNo ratings yet

- Re H200MKDocument1 pageRe H200MKnisargpatel766No ratings yet

- Glass Fiber Reinforced PBT Material Injection Molding Grade Pellets / GranulesDocument2 pagesGlass Fiber Reinforced PBT Material Injection Molding Grade Pellets / GranulesmuthuNo ratings yet

- Hyosung Topilene HJ541CPDocument1 pageHyosung Topilene HJ541CPJ C DNo ratings yet

- Total PPR 7238 Polypropylene Random Copolymer Blow MoldingDocument1 pageTotal PPR 7238 Polypropylene Random Copolymer Blow Moldingquanghoang10986No ratings yet

- Globalene 7011: Polypropylene Impact copolymer 聚丙烯耐衝擊共聚合物Document1 pageGlobalene 7011: Polypropylene Impact copolymer 聚丙烯耐衝擊共聚合物medo.k016No ratings yet

- Sabic® Ldpe Hp0322Nn: Low Density PolyethyleneDocument2 pagesSabic® Ldpe Hp0322Nn: Low Density PolyethyleneGabriela Lopez MunozNo ratings yet

- Tds DGDX 6097 Astm ButeneDocument2 pagesTds DGDX 6097 Astm ButeneLakshay UniplarNo ratings yet

- HB5502BDocument1 pageHB5502BDe SaripudinNo ratings yet

- Description: High Density Polyethylene General InformationDocument2 pagesDescription: High Density Polyethylene General InformationLuca GuadagnoNo ratings yet

- Petrothene: Technical Data SheetDocument3 pagesPetrothene: Technical Data SheetEli DelgadoNo ratings yet

- SABIC® HDPE - M200056 - Global - Technical - Data - SheetDocument2 pagesSABIC® HDPE - M200056 - Global - Technical - Data - SheetAhmed Elgazar100% (1)

- PP FPT300F BraskemDocument1 pagePP FPT300F BraskemJulio GarcíaNo ratings yet

- Polypropylene Impact Co Polymer Injection Molding: Provisional Technical DatasheetDocument2 pagesPolypropylene Impact Co Polymer Injection Molding: Provisional Technical DatasheetMohit MohataNo ratings yet

- Aegis5-14 Film Validation Guide: Five-Layer, 14 Mil Cast Fi LMDocument15 pagesAegis5-14 Film Validation Guide: Five-Layer, 14 Mil Cast Fi LMCampaign MediaNo ratings yet

- Hopelen PP Homopolymer General Information: DescriptionDocument1 pageHopelen PP Homopolymer General Information: DescriptionBrijesh PatelNo ratings yet

- Tds Hp450j EnglishDocument1 pageTds Hp450j EnglishMd Abdul SalamNo ratings yet

- TDS - TR144 - Astm (Eng)Document2 pagesTDS - TR144 - Astm (Eng)Darwin Lenin Iza PradoNo ratings yet

- TDS DGDZ 6097 ASTM HexeneDocument2 pagesTDS DGDZ 6097 ASTM HexenegauravmishraanalystNo ratings yet

- Polypropylene Homo Polymer BOPP Films: Provisional Technical DatasheetDocument2 pagesPolypropylene Homo Polymer BOPP Films: Provisional Technical DatasheetMohit MohataNo ratings yet

- SABIC® FORTIFY™ - C3080 - Global - Technical - Data - Sheet PDFDocument2 pagesSABIC® FORTIFY™ - C3080 - Global - Technical - Data - Sheet PDFvishal mehtaNo ratings yet

- 150601 J-560M 물성 (영문 ASTM 단위통합)Document2 pages150601 J-560M 물성 (영문 ASTM 단위통합)Vu Thanh ThuongNo ratings yet

- PP Trilene Hi10hoDocument2 pagesPP Trilene Hi10hoLaili AzkiyahNo ratings yet

- HD5403AA - New - Revision September 2020Document2 pagesHD5403AA - New - Revision September 2020AthonioMourinhoNo ratings yet

- Product Description: Properties Value Unit Test MethodDocument1 pageProduct Description: Properties Value Unit Test MethodRPM28XINo ratings yet

- Im B120MADocument1 pageIm B120MAPrashant MalikNo ratings yet

- Opal - Hdpe - 4Document2 pagesOpal - Hdpe - 4Piyush A JoshiNo ratings yet

- SABIC® PP COPO - 412MK49 (MFR 45 DG - Min 2.16 KG)Document2 pagesSABIC® PP COPO - 412MK49 (MFR 45 DG - Min 2.16 KG)yang chinaNo ratings yet

- Topilene J700N ENDocument1 pageTopilene J700N ENJoni Sie MssNo ratings yet

- Gas Sweetening and Processing Field ManualFrom EverandGas Sweetening and Processing Field ManualRating: 4 out of 5 stars4/5 (7)

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Corrosion and Materials Selection: A Guide for the Chemical and Petroleum IndustriesFrom EverandCorrosion and Materials Selection: A Guide for the Chemical and Petroleum IndustriesNo ratings yet

- Fluorocarbon Elastomers EnciclopediaDocument14 pagesFluorocarbon Elastomers EnciclopediaDieguitoOmarMoralesNo ratings yet

- Cyclohexanedimethanol Polyesters EnciclopediaDocument8 pagesCyclohexanedimethanol Polyesters EnciclopediaDieguitoOmarMoralesNo ratings yet

- Chromatography, Affinity PDFDocument19 pagesChromatography, Affinity PDFDieguitoOmarMoralesNo ratings yet

- Critical Phase Polymerizations EnciclopediaDocument16 pagesCritical Phase Polymerizations EnciclopediaDieguitoOmarMoralesNo ratings yet

- Hyperbranched Polymers EnciclopediaDocument22 pagesHyperbranched Polymers EnciclopediaDieguitoOmarMoralesNo ratings yet

- Dental ApplicationsDocument33 pagesDental ApplicationsgumymotyNo ratings yet

- Light Emitting Diodes EnciclopediaDocument14 pagesLight Emitting Diodes EnciclopediaDieguitoOmarMoralesNo ratings yet

- Enzymatic Polymerization EnciclopediaDocument37 pagesEnzymatic Polymerization EnciclopediaDieguitoOmarMoralesNo ratings yet

- Color Ants EnciclopediaDocument23 pagesColor Ants EnciclopediaDieguitoOmarMoralesNo ratings yet

- Six Introduction A03Document26 pagesSix Introduction A03DieguitoOmarMorales0% (1)

- Thermal Analysis of PolymersDocument86 pagesThermal Analysis of PolymersMarister OliveiraNo ratings yet

- Asme Sec Viii d2 Art D-6Document8 pagesAsme Sec Viii d2 Art D-6DieguitoOmarMoralesNo ratings yet

- Acetylenic Polymers, SubstitutedDocument41 pagesAcetylenic Polymers, SubstitutedhanicNo ratings yet

- Ionic Liquids Polymerizationin PDFDocument15 pagesIonic Liquids Polymerizationin PDFAndres FacuNo ratings yet

- Asme Sec Viii D2 Art D-3 PDFDocument12 pagesAsme Sec Viii D2 Art D-3 PDFDieguitoOmarMoralesNo ratings yet

- Asme Sec Viii d2 Art R-5Document5 pagesAsme Sec Viii d2 Art R-5DieguitoOmarMoralesNo ratings yet

- Asme Sec Viii d2 Art R-5Document5 pagesAsme Sec Viii d2 Art R-5DieguitoOmarMoralesNo ratings yet

- Asme Sec Viii D2 Art D-2 PDFDocument10 pagesAsme Sec Viii D2 Art D-2 PDFDieguitoOmarMoralesNo ratings yet

- 100-XXX-1 - 1-2side - DWG 100 XXX 1 - 1-2 SideDocument1 page100-XXX-1 - 1-2side - DWG 100 XXX 1 - 1-2 SideMohamedNo ratings yet

- Asme Sec Viii d2 Art R-1Document8 pagesAsme Sec Viii d2 Art R-1DieguitoOmarMoralesNo ratings yet

- Asme Sec Viii d2 Art R-4Document2 pagesAsme Sec Viii d2 Art R-4DieguitoOmarMoralesNo ratings yet

- Asme Sec Viii d2 Ma App 10Document4 pagesAsme Sec Viii d2 Ma App 10DieguitoOmarMoralesNo ratings yet

- Asme Sec Viii d2 Art G-1Document10 pagesAsme Sec Viii d2 Art G-1DieguitoOmarMoralesNo ratings yet

- Cement PDFDocument26 pagesCement PDFDieguitoOmarMoralesNo ratings yet

- Flange DDocument16 pagesFlange DDieguitoOmarMoralesNo ratings yet

- DoubleDocument14 pagesDoubleDieguitoOmarMoralesNo ratings yet

- Double PDFDocument1 pageDouble PDFDieguitoOmarMoralesNo ratings yet

- Asme Sec Viii d2 Art D-1Document17 pagesAsme Sec Viii d2 Art D-1DieguitoOmarMoralesNo ratings yet

- ThreadedDocument7 pagesThreadedDieguitoOmarMoralesNo ratings yet

- Flang CemDocument3 pagesFlang CemDieguitoOmarMoralesNo ratings yet