Professional Documents

Culture Documents

Neptune Orthopaedics Standard Operating Procedure-Production

Neptune Orthopaedics Standard Operating Procedure-Production

Uploaded by

dhir.ankurOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Neptune Orthopaedics Standard Operating Procedure-Production

Neptune Orthopaedics Standard Operating Procedure-Production

Uploaded by

dhir.ankurCopyright:

Available Formats

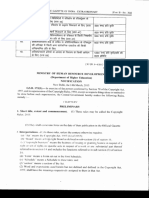

NEPTUNE ORTHOPAEDICS DOC NO: NO/SOP-P/7.

0

QUALITY

MANAGEMENT STANDARD OPERATING PROCEDURE- ISSUE NO: 01

SYSTEM

PRODUCTION ISSUE DATE:-15/07/10

Combine Dressing PAGE 1 OF 2

1.0 PURPOSE:

The purpose of this procedure is to define and control critical activities in production as per the

requirement of ISO 13485: 2003.

2.0 SCOPE:

This procedure covers standard operating procedure of the concerned area in production.

3.0 RESPONSIBILITY:

Refer Responsibility & authority chart NO/QSM/AX04.

4.0 APPROVAL:

This procedure is approved by CEO and can be amended only by him.

5.0 DEFINITIONS: Nil

6.0 PROCEDURE:

Mount the non-woven rolls of 25cm width on the roller of equipment no.

Place at the centre of non-woven the cotton roll of 10cm width & GSM (NLT 200)

Mount the Blue thread at the back of equipment roll it & pass it through the Adhesive Box.

Adjust the folding assembly in such a way that the overlapping is 2.5 cm + 0.5 cm & Blue

thread is placed between the overlap.

Start the machine and let the pad pas through the roller.

The width of the pad should be 10.5 + 0.6 cm

Pass the strip of pad through cutting machine equipment no. Set the Cutting length for 10cm

10.5cm + 0.6 cm for 20cm 20.5cm + 0.6 cm. Check the sealing of overlap.

GSM of the pad should not be less than 370.

PREPARED APPROVED ISSUED

REVISION HISTORY

BY BY BY

REV.NO

ISO 13485:2003

DATE

PM CEO MR

NEPTUNE ORTHOPAEDICS DOC NO: NO/SOP-P/7.0

QUALITY

MANAGEMENT STANDARD OPERATING PROCEDURE- ISSUE NO: 01

SYSTEM

PRODUCTION ISSUE DATE:-15/07/10

Combine Dressing PAGE 2 OF 2

PREPARED APPROVED ISSUED

REVISION HISTORY

BY BY BY

REV.NO

ISO 13485:2003

DATE

PM CEO MR

You might also like

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- Production: Eco Beauty Wholesale & LabsDocument12 pagesProduction: Eco Beauty Wholesale & LabsMj AndresNo ratings yet

- Guidance On INTERNAL AUDITSDocument7 pagesGuidance On INTERNAL AUDITSdhir.ankurNo ratings yet

- 5-Operation & Cleaning of Ropp Sealing MachineDocument3 pages5-Operation & Cleaning of Ropp Sealing MachineananthNo ratings yet

- QSP 01 - Document Control ProcedureDocument7 pagesQSP 01 - Document Control ProcedureVivek VNo ratings yet

- Holiday Detector ProcedureDocument2 pagesHoliday Detector ProcedurenathgsurendraNo ratings yet

- Piping Fabrication ProcedureDocument11 pagesPiping Fabrication ProcedureMohammed Elsaid Yousef Harhera100% (2)

- SOP PRODUCTION of Cosmetics According ToDocument12 pagesSOP PRODUCTION of Cosmetics According Tosudar147750% (2)

- Asq Presentation Iso 13485Document48 pagesAsq Presentation Iso 13485dhir.ankur100% (1)

- Img 0004Document3 pagesImg 0004Shruti BhatiaNo ratings yet

- Bsi MD Risk Management For Medical Devices QaDocument10 pagesBsi MD Risk Management For Medical Devices Qadhir.ankurNo ratings yet

- Sop OPOP Eng 007 - Operating Diesel Bowsers and TanksDocument8 pagesSop OPOP Eng 007 - Operating Diesel Bowsers and Tankscontrax8100% (3)

- QSP Format Product SafetyDocument4 pagesQSP Format Product Safetydhir.ankurNo ratings yet

- Checklist MDRDocument162 pagesChecklist MDRdhir.ankurNo ratings yet

- Method Statement For Ceramic Tiles-Wall & Floor) (K)Document11 pagesMethod Statement For Ceramic Tiles-Wall & Floor) (K)Akash YadavNo ratings yet

- Holiday Detector ProcedureDocument2 pagesHoliday Detector Procedurenathgsurendra100% (1)

- TOTL-SP02 Factilities and Environmental Conditions ProcedureDocument9 pagesTOTL-SP02 Factilities and Environmental Conditions ProcedureahmedNo ratings yet

- 1.2 Patent Rules 1970 - 11 March 2015Document95 pages1.2 Patent Rules 1970 - 11 March 2015dhir.ankurNo ratings yet

- Secure & Simple – A Small-Business Guide to Implementing ISO 27001 On Your Own: The Plain English, Step-by-Step Handbook for Information Security PractitionersFrom EverandSecure & Simple – A Small-Business Guide to Implementing ISO 27001 On Your Own: The Plain English, Step-by-Step Handbook for Information Security PractitionersNo ratings yet

- C 106 Components Handbook LowDocument48 pagesC 106 Components Handbook LowMauricio Mpinto100% (1)

- Flat Panel Display ManufacturingFrom EverandFlat Panel Display ManufacturingJun SoukNo ratings yet

- MDR Classification DocumentDocument17 pagesMDR Classification Documentdhir.ankurNo ratings yet

- QSP 02 - Record Control ProcedureDocument5 pagesQSP 02 - Record Control ProcedureVivek V100% (1)

- SOP5Document7 pagesSOP5ASHOK KUMAR LENKANo ratings yet

- MS (TP-50002)Document13 pagesMS (TP-50002)Benasher IbrahimNo ratings yet

- Document Transmittal: SAW-CWCO-TR149 15 January 2013Document8 pagesDocument Transmittal: SAW-CWCO-TR149 15 January 2013Budi IndraNo ratings yet

- SOP - FRP Pipe Jointing Procedure.Document10 pagesSOP - FRP Pipe Jointing Procedure.Ali Mari BalochNo ratings yet

- Core Tools Alphabet SoupDocument72 pagesCore Tools Alphabet Soupdhir.ankurNo ratings yet

- Exercise For IMS INTERNAL AUDITINGDocument12 pagesExercise For IMS INTERNAL AUDITINGdhir.ankur100% (2)

- 010-Method Statement of Coal Mill InstattalationDocument26 pages010-Method Statement of Coal Mill InstattalationHandri PuriNo ratings yet

- IEEE STD 404-2012 RedlineDocument89 pagesIEEE STD 404-2012 Redlineanonimoefra100% (1)

- SOP (Standard Operating Procedure) "WELDING PROCESS": Shoes Hand Glows GogglesDocument3 pagesSOP (Standard Operating Procedure) "WELDING PROCESS": Shoes Hand Glows GogglesMagesh Waran100% (1)

- Fabrication of Pneumatic Belt Conveyor PDFDocument2 pagesFabrication of Pneumatic Belt Conveyor PDFBikerbob0% (1)

- Clear Desk and Clear Screen PolicyDocument4 pagesClear Desk and Clear Screen Policydhir.ankurNo ratings yet

- Neptune Orthopaedics Standard Operating Procedure-ProductionDocument2 pagesNeptune Orthopaedics Standard Operating Procedure-Productiondhir.ankurNo ratings yet

- Neptune Orthopaedics Standard Operating Procedure-ProductionDocument1 pageNeptune Orthopaedics Standard Operating Procedure-Productiondhir.ankurNo ratings yet

- Neptune Orthopaedics Standard Operating Procedure-ProductionDocument2 pagesNeptune Orthopaedics Standard Operating Procedure-Productiondhir.ankurNo ratings yet

- Neptune Orthopaedics Standard Operating Procedure-ProductionDocument2 pagesNeptune Orthopaedics Standard Operating Procedure-Productiondhir.ankurNo ratings yet

- Neptune Orthopaedics Standard Operating Procedure-ProductionDocument2 pagesNeptune Orthopaedics Standard Operating Procedure-Productiondhir.ankurNo ratings yet

- Neptune Orthopaedics Standard Operating Procedure-ProductionDocument4 pagesNeptune Orthopaedics Standard Operating Procedure-Productiondhir.ankurNo ratings yet

- Neptune Orthopaedics Standard Operating Procedure-ProductionDocument2 pagesNeptune Orthopaedics Standard Operating Procedure-Productiondhir.ankurNo ratings yet

- Neptune Orthopaedics Standard Operating Procedure-ProductionDocument4 pagesNeptune Orthopaedics Standard Operating Procedure-Productiondhir.ankurNo ratings yet

- Neptune Orthopaedics Standard Operating Procedure-ProductionDocument3 pagesNeptune Orthopaedics Standard Operating Procedure-Productiondhir.ankurNo ratings yet

- Neptune Orthopaedics Standard Operating Procedure-ProductionDocument4 pagesNeptune Orthopaedics Standard Operating Procedure-Productiondhir.ankurNo ratings yet

- Neptune Orthopaedics Standard Operating Procedure-ProductionDocument3 pagesNeptune Orthopaedics Standard Operating Procedure-Productiondhir.ankurNo ratings yet

- Neptune Orthopaedics Standard Operating Procedure-ProductionDocument4 pagesNeptune Orthopaedics Standard Operating Procedure-Productiondhir.ankurNo ratings yet

- Neptune Orthopaedics Standard Operating Procedure-ProductionDocument3 pagesNeptune Orthopaedics Standard Operating Procedure-Productiondhir.ankurNo ratings yet

- EDO-PRO-HSE-COR-INT-XXX-017-777-1068-Rev-A-SEA ANODE INSTALLATION PROCEDUREDocument5 pagesEDO-PRO-HSE-COR-INT-XXX-017-777-1068-Rev-A-SEA ANODE INSTALLATION PROCEDUREErol DAĞNo ratings yet

- 12.0 PSV Calibration ProcedureDocument9 pages12.0 PSV Calibration ProcedureISAACNo ratings yet

- RT ProcedureDocument51 pagesRT ProcedureAwale UdinNo ratings yet

- Hydro TEST PROCEDURE FOR BELLOWDocument4 pagesHydro TEST PROCEDURE FOR BELLOWselvakumarNo ratings yet

- Radiographic Examination Procedure: Document No. KIE - TP - R297 Revision No. 0Document35 pagesRadiographic Examination Procedure: Document No. KIE - TP - R297 Revision No. 0EdAlmNo ratings yet

- QO-F-7.1-9 Ver. 1.0 Quality Audit Report ADocument27 pagesQO-F-7.1-9 Ver. 1.0 Quality Audit Report Apuri16No ratings yet

- Procedure PMT 100 BarDocument9 pagesProcedure PMT 100 BarShankar NarayananNo ratings yet

- Img 0005Document6 pagesImg 0005Shruti BhatiaNo ratings yet

- Oel Protocol Flexible Capsule Filling Machine IsolatorDocument19 pagesOel Protocol Flexible Capsule Filling Machine Isolatormohd naveeduddin musaNo ratings yet

- Material Submittal No. 0003 r.01 For Mdpe Pipes & Fittings, Sdr-11 (Naffco Flow Control, U.a.e.)Document136 pagesMaterial Submittal No. 0003 r.01 For Mdpe Pipes & Fittings, Sdr-11 (Naffco Flow Control, U.a.e.)rheynavarro24No ratings yet

- ISO 248 - Rubber, Raw - Determination of Volatile Matter Content (6-15-2005)Document14 pagesISO 248 - Rubber, Raw - Determination of Volatile Matter Content (6-15-2005)axeldanyNo ratings yet

- APEX - Manual - Revised As Per PAS99.2012-R1Document95 pagesAPEX - Manual - Revised As Per PAS99.2012-R1alrances01No ratings yet

- Method Statement For AFS.15.04.19 R0 PDFDocument12 pagesMethod Statement For AFS.15.04.19 R0 PDFkrishna100% (1)

- 34 Phosphating Process ProcedureDocument7 pages34 Phosphating Process ProcedureuraliNo ratings yet

- Certificado 5x20 BBDocument1 pageCertificado 5x20 BBFernando CercalNo ratings yet

- SOP ON of Cosmetics According ToDocument11 pagesSOP ON of Cosmetics According Tokishan chiraniaNo ratings yet

- SNO-P-ES-009 Specification For Precomm Cleaning of Piping System Rev - 0Document11 pagesSNO-P-ES-009 Specification For Precomm Cleaning of Piping System Rev - 0Langit GanjarNo ratings yet

- Instruction Manual ED 50-100ADocument25 pagesInstruction Manual ED 50-100AcrafzaclubNo ratings yet

- Iso TS 11135 2 2008Document14 pagesIso TS 11135 2 2008Candice TangNo ratings yet

- SopDocument7 pagesSopSrinivasNo ratings yet

- 06 Maintenanace ProcedureDocument2 pages06 Maintenanace ProcedureZarai MaherNo ratings yet

- TMT 035 Nde 04Document14 pagesTMT 035 Nde 04rameshqcNo ratings yet

- PurposeDocument4 pagesPurposeopd pharmacyNo ratings yet

- Indra::::: 0-7382-2-P-:::: Ge - Te.Co - Valves S.R.LDocument6 pagesIndra::::: 0-7382-2-P-:::: Ge - Te.Co - Valves S.R.LSkan DerNo ratings yet

- Ses-Pgb-Co-Itp-0058 Itp For HRSG SystemDocument4 pagesSes-Pgb-Co-Itp-0058 Itp For HRSG SystemzhangNo ratings yet

- PTE - OI - 06 - Input AccetanceDocument1 pagePTE - OI - 06 - Input AccetanceAbhinav SinghNo ratings yet

- Hepco Motion - Clean RoomDocument2 pagesHepco Motion - Clean RoomjoechengshNo ratings yet

- 4.3 Design (Amendment) Rules, 2008Document26 pages4.3 Design (Amendment) Rules, 2008dhir.ankurNo ratings yet

- 3.3 Copyright Rules, 2013Document41 pages3.3 Copyright Rules, 2013dhir.ankurNo ratings yet

- DNV Brochure FOOD Tcm163-344274Document12 pagesDNV Brochure FOOD Tcm163-344274dhir.ankurNo ratings yet

- Establishing An Integrated Management SyDocument65 pagesEstablishing An Integrated Management Sydhir.ankurNo ratings yet

- Pharma News 27 June 2022 PDF-1Document13 pagesPharma News 27 June 2022 PDF-1dhir.ankurNo ratings yet

- Halalindia EcodesDocument5 pagesHalalindia Ecodesdhir.ankurNo ratings yet

- Mandatory Documents For IatfDocument6 pagesMandatory Documents For Iatfdhir.ankurNo ratings yet

- MDD Classification Document: Mapping of RequirementsDocument12 pagesMDD Classification Document: Mapping of Requirementsdhir.ankurNo ratings yet

- Environmental Management System 8.1.9 Waste Management Operational ProcedureDocument15 pagesEnvironmental Management System 8.1.9 Waste Management Operational Proceduredhir.ankurNo ratings yet

- FundamentalsDocument880 pagesFundamentalsshaileshbhanushali5488No ratings yet

- Service Letter: Pilatus Aircraft Ltd. Ch-6371 Stans, SwitzerlandDocument54 pagesService Letter: Pilatus Aircraft Ltd. Ch-6371 Stans, SwitzerlandDiego CabreraNo ratings yet

- 8th India Rubber Expo & Tyre ShowDocument76 pages8th India Rubber Expo & Tyre ShowAshish Angelz ExhibitionsNo ratings yet

- SRF Corporate Brochure PDFDocument25 pagesSRF Corporate Brochure PDFAmritesh MishraNo ratings yet

- Iso Certificate of ApprovalDocument4 pagesIso Certificate of ApprovalLisel SalibioNo ratings yet

- JSA - ELLECTRICAL AINDAR LAYING TERMINATION - CompressedDocument8 pagesJSA - ELLECTRICAL AINDAR LAYING TERMINATION - Compressedmalikshoaib8528No ratings yet

- Adhesives For Film Laminating: Flextra SBA9000 / SBA9750Document3 pagesAdhesives For Film Laminating: Flextra SBA9000 / SBA9750anitaNo ratings yet

- 8703802Document13 pages8703802Quantudogon DangNo ratings yet

- Project Repport: Myk Laticrete India PVT - Ltd. KolkataDocument76 pagesProject Repport: Myk Laticrete India PVT - Ltd. KolkatamonishaNo ratings yet

- Miscellaneous StorageDocument1 pageMiscellaneous StorageSamson ArayanNo ratings yet

- 14-Wing - Tube Care and RepairDocument3 pages14-Wing - Tube Care and Repaircarlos morales100% (1)

- BHEL - Safety Shoes - All-Specifications-1409915671 PDFDocument14 pagesBHEL - Safety Shoes - All-Specifications-1409915671 PDFsajithv78No ratings yet

- Lean Practices and Supply Chain Trends in Indian Auto IndustryDocument15 pagesLean Practices and Supply Chain Trends in Indian Auto IndustryVarunSinghNo ratings yet

- Goodyear Tire & Rubber Co. of The Phils., Ltd. vs. Reyes, Sr. 123 SCRA 273, July 02, 1983Document6 pagesGoodyear Tire & Rubber Co. of The Phils., Ltd. vs. Reyes, Sr. 123 SCRA 273, July 02, 1983mary elenor adagioNo ratings yet

- Vishy-Strain Gauge AccessoriesDocument107 pagesVishy-Strain Gauge AccessoriesSafwat El RoubyNo ratings yet

- PidiliteDocument16 pagesPidiliteAnisha NagavekarNo ratings yet

- Alternate Coverage ofDocument70 pagesAlternate Coverage ofnist_nitesh100% (1)

- CEAT Material DetailsDocument6 pagesCEAT Material DetailsAmazon Special offerNo ratings yet

- Trevor Pope. Stator Rubber Innovation Vs ApplicationDocument11 pagesTrevor Pope. Stator Rubber Innovation Vs ApplicationAkash YadavNo ratings yet

- History of TupperwareDocument3 pagesHistory of TupperwareKimbre BellhouseNo ratings yet

- Bridgestone - 2005 - InfoTechDocument39 pagesBridgestone - 2005 - InfoTechEdgard Marroquin ColqueNo ratings yet

- Toilet Paper Making Machine: Zhengzhou Ean Machinery Co.,LtdDocument3 pagesToilet Paper Making Machine: Zhengzhou Ean Machinery Co.,LtdDennis NwanevuNo ratings yet

- Apollo Tyres PPT FinalDocument17 pagesApollo Tyres PPT FinalGeena Mary GeorgeNo ratings yet

- Protect Rubber Goods To Prevent Failure: Tears ProtuberanceDocument2 pagesProtect Rubber Goods To Prevent Failure: Tears ProtuberancePedro SarmientoNo ratings yet

- Memm 1013 - Emerging Technologies and ManagementDocument10 pagesMemm 1013 - Emerging Technologies and ManagementfarhanNo ratings yet

- ATEC Catalogue Issue 6Document84 pagesATEC Catalogue Issue 6tvasinNo ratings yet