Professional Documents

Culture Documents

11 18 Evaporator Treatment PDF

11 18 Evaporator Treatment PDF

Uploaded by

gkmkgmOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

11 18 Evaporator Treatment PDF

11 18 Evaporator Treatment PDF

Uploaded by

gkmkgmCopyright:

Available Formats

WATER TREATMENT EVAPORATOR TREATMENT

EVAPORATOR TREAT

The production of pure fresh water for engine department and domestic use is one of the most vital requirements

aboard ship.

EVAPORATOR TREAT is a new and patented polymer evaporator treatment that has been developed to alter the

normal crystal habits of scale forming minerals. These minerals normally form a hard scale incrustation; however,

with the use of EVAPORATOR TREAT, the scale formation is eliminated, while the minerals are held in a soft, easily

removed suspension. EVAPORATOR TREAT incorporates special anti-foam agents that are stable and will perform

even under the high temperatures.

ADVANTAGES OF EVAPORATOR TREAT

- Greater distilled water production due to the ability to use higher steam inlet temperatures.

- Greater production because of less scale build-up and better heat transfer.

- Greater production due to special anti-foam agents allowing higher water levels.

- No need to employ shocking which may be damaging to the evaporators.

- Reduces need for acid cleaning.

- Easily mixed with water.

- Effective in reducing water scale formation in heat transfer equipment other than evaporators.

INSTRUCTIONS

Dosing Equipment:

Treatment mixing tank plus flowmeter control valve where vacuum drag is possible; or tank with proportioning

pump where pressures require their use.

Dosages:

Are based on rated evaporator capacity or actual water production, whichever is higher. The rate is Half Lt. (500 ml)

for 20 tons of water produced with sea water evaporators; 3/4 Lt. (750 ml) for fresh water evaporators. Evaporators

designed to maintain a higher brine density, such as vapor compression types, should be dosed at the rate of 1 lt.

(1000 ml) per 20 tons of distillate. Mix the required amount of EVAPORATOR TREAT with fresh water in a mixing tank

and feed continuously and uniformly during evaporator operation.

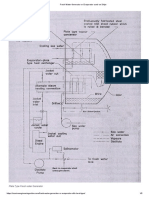

A - GRAVITY SYSTEM WITH FLOWMETER

B - DOSING SYSTEM WITH DOSING PUMP TYPE CP 7905

Vecom Marine is a joint venture of Vecom Group & Unimarine Group - Version 3.1 - Chapter 11 - Page 50

You might also like

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- Aquafresh Watermakers Manual PDFDocument35 pagesAquafresh Watermakers Manual PDFTzvi BloomNo ratings yet

- B1 Freshwater GeneratorDocument32 pagesB1 Freshwater GeneratorAhmad Aslam MohamadNo ratings yet

- How Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisFrom EverandHow Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisRating: 5 out of 5 stars5/5 (1)

- FWGDocument30 pagesFWGNor AshimyNo ratings yet

- Fresh Water Production Plants 1 DMOE2002Document16 pagesFresh Water Production Plants 1 DMOE2002Yohannes DennisNo ratings yet

- Alpacon ALTREAT 400Document2 pagesAlpacon ALTREAT 400ECO Green and BlueNo ratings yet

- Fresh Water Generator On ShipsDocument19 pagesFresh Water Generator On ShipsSheshraj VernekarNo ratings yet

- Automatic Softening Plants Series Stfa: A Group of Co-Operating European Water Treatment SpecialistsDocument4 pagesAutomatic Softening Plants Series Stfa: A Group of Co-Operating European Water Treatment Specialistsitsirc67No ratings yet

- Aqua Blue Freshwater Generator Mdd00056enDocument4 pagesAqua Blue Freshwater Generator Mdd00056enMuhd Khir RazaniNo ratings yet

- Vignesh. S Aravindhkumar. K Saravanan. K Guided by Mr.S. Thangakasi Rajan M.E (PH.DDocument33 pagesVignesh. S Aravindhkumar. K Saravanan. K Guided by Mr.S. Thangakasi Rajan M.E (PH.Dvelmurugan100% (1)

- Lecture 1 Boiler Feed Water PDFDocument12 pagesLecture 1 Boiler Feed Water PDFJAIRAH SONNo ratings yet

- H2O On The Go BrochureDocument4 pagesH2O On The Go BrochureJoanne DavisNo ratings yet

- Why Purchase From American Aquarium Products: View CartDocument8 pagesWhy Purchase From American Aquarium Products: View Cartزهرة النرجسNo ratings yet

- This Doc. Is in Used Base On Simulator Class TutorialsDocument9 pagesThis Doc. Is in Used Base On Simulator Class TutorialsFatih KayalarNo ratings yet

- Ceasa Softening 2008Document24 pagesCeasa Softening 2008Sasa JadrovskiNo ratings yet

- Water Maze Delta-3000a 1Document2 pagesWater Maze Delta-3000a 1Marcelita AraujoNo ratings yet

- Vapor-Flo Humidity Generator Operation and Maintenance: Thermal Product SolutionsDocument14 pagesVapor-Flo Humidity Generator Operation and Maintenance: Thermal Product SolutionsVirginia MartelliNo ratings yet

- Fresh Water GenDocument2 pagesFresh Water GenTharindu GunawardaneNo ratings yet

- Ecocool - Matl - ECO FRESHDocument28 pagesEcocool - Matl - ECO FRESHMurugavel VenkatNo ratings yet

- Demineralization PlantsDocument7 pagesDemineralization PlantsPraveen KhatriNo ratings yet

- HG Raindance Showersystems Planning InstallationDocument56 pagesHG Raindance Showersystems Planning InstallationMoizuddin KhajaNo ratings yet

- Our Latest Technology: Flash Water Heat Recovery SystemDocument5 pagesOur Latest Technology: Flash Water Heat Recovery SystemLintang KinanthiNo ratings yet

- Distilling Plant - Week 8Document35 pagesDistilling Plant - Week 8இராம் பாபுNo ratings yet

- Fresh Water Generator or Evaporator Used On Ships BRAVO 2Document5 pagesFresh Water Generator or Evaporator Used On Ships BRAVO 2Dan EzraNo ratings yet

- Matachana - AP4 - Water Treatment System For Steriliser - User ManualDocument8 pagesMatachana - AP4 - Water Treatment System For Steriliser - User ManualWahidi AzaniNo ratings yet

- Wärtsilä MSF Marine LowResDocument7 pagesWärtsilä MSF Marine LowResBarbara VasconcelosNo ratings yet

- Al Khaleej Water Efficient Refinery 2000Document12 pagesAl Khaleej Water Efficient Refinery 2000roy@daesNo ratings yet

- AC-TEC Mini PDFDocument11 pagesAC-TEC Mini PDFClever ArisacaNo ratings yet

- SP PH II DTS 11.2.8 Dist & FWG Teaching Material & Handouts-1Document12 pagesSP PH II DTS 11.2.8 Dist & FWG Teaching Material & Handouts-1singhsamarjeet275No ratings yet

- Evaporation TechnologyDocument24 pagesEvaporation TechnologymetashriNo ratings yet

- Exp 3Document15 pagesExp 3mjunaidNo ratings yet

- Asws Reverse Osmosis PlantDocument7 pagesAsws Reverse Osmosis PlantEngenharia MecânicaNo ratings yet

- Seawater Membrane Filtration Used To Control Scale in Syd Arne ReservoirDocument2 pagesSeawater Membrane Filtration Used To Control Scale in Syd Arne ReservoirBinu KaaniNo ratings yet

- Evaporators SugarDocument28 pagesEvaporators SugarAnkur KoulNo ratings yet

- Schenkerbrochure2020 ENDocument29 pagesSchenkerbrochure2020 ENbob wongNo ratings yet

- Fresh Water GeneratorDocument26 pagesFresh Water GeneratorNILANJAN JANANo ratings yet

- Waterpurifier: Mobile Drinking Water Treatment SystemDocument4 pagesWaterpurifier: Mobile Drinking Water Treatment SystemSteveAbonyiNo ratings yet

- Water SoftenersDocument3 pagesWater SoftenersyashjbtechNo ratings yet

- Vitra Faucets and AccessoriesDocument272 pagesVitra Faucets and AccessoriescothacoNo ratings yet

- Reverse OsmosisDocument14 pagesReverse OsmosisAlo Lorin RengmaNo ratings yet

- Waterland Water Treatment Environmental TechnologiesDocument36 pagesWaterland Water Treatment Environmental TechnologiesSiraj AL sharifNo ratings yet

- Step 1:: Amazing Efficiency!Document4 pagesStep 1:: Amazing Efficiency!Aziz RahmatullahNo ratings yet

- Etp Process - RefineryDocument3 pagesEtp Process - Refinerysumit gulatiNo ratings yet

- WM-S - FWGDocument50 pagesWM-S - FWGwww.kiva123No ratings yet

- EVAPCO Fill Offerings 1Document4 pagesEVAPCO Fill Offerings 1Walter J Naspirán CastañedaNo ratings yet

- Pci Africa - WatefDocument4 pagesPci Africa - WatefEmelia JugdavNo ratings yet

- Sander Protein SkimmersDocument18 pagesSander Protein Skimmerslleimicojon100% (1)

- Water Treatment SystemDocument12 pagesWater Treatment SystemArunNo ratings yet

- Hardness and Water SofteningDocument5 pagesHardness and Water SofteningKarl TimtimNo ratings yet

- 7807 Rev - (Village Marine Product Brochure)Document32 pages7807 Rev - (Village Marine Product Brochure)Jonathan Marcelo Lara CraveroNo ratings yet

- DOLPHIN Series: Freshwater Generators For The Oil and Gas IndustryDocument2 pagesDOLPHIN Series: Freshwater Generators For The Oil and Gas IndustryProf. Flávio - Physics and MathNo ratings yet

- Corrosion ControllerDocument1 pageCorrosion ControllerFernando HerreraNo ratings yet

- (Culligan) Mark89and812softenerownersguideDocument20 pages(Culligan) Mark89and812softenerownersguideGreg ReynekeNo ratings yet

- Assignment: NAME: Sultan Shahab Class: MLT ROLL NO:041 Subject:Clinical Lab Subbmitted To: Mam SabaDocument8 pagesAssignment: NAME: Sultan Shahab Class: MLT ROLL NO:041 Subject:Clinical Lab Subbmitted To: Mam SabaSultan ShahabNo ratings yet

- How Reverse Osmosis Works: A Look at Industrial ROFrom EverandHow Reverse Osmosis Works: A Look at Industrial RORating: 2.5 out of 5 stars2.5/5 (2)

- Aquaponics System, Plants. Volume 2: Sistemas de acuaponíaFrom EverandAquaponics System, Plants. Volume 2: Sistemas de acuaponíaNo ratings yet

- Aquarium Supply Buyers Guide: Best Practices for Keeping Fish RevealedFrom EverandAquarium Supply Buyers Guide: Best Practices for Keeping Fish RevealedRating: 3 out of 5 stars3/5 (1)