0% found this document useful (0 votes)

1K views22 pagesAdvanced Product Quality Planning (APQP)

The document provides an overview of Advanced Product Quality Planning (APQP), which is a structured process used to ensure customer satisfaction for new products and processes. It involves planning across marketing, design, manufacturing, and other functions from the beginning of a project. The document discusses what APQP is, why it's important, when to use it, and how it works in five phases from planning to feedback and improvement. It aims to identify risks early and prevent defects by integrating quality into design and development.

Uploaded by

mjapmgCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

1K views22 pagesAdvanced Product Quality Planning (APQP)

The document provides an overview of Advanced Product Quality Planning (APQP), which is a structured process used to ensure customer satisfaction for new products and processes. It involves planning across marketing, design, manufacturing, and other functions from the beginning of a project. The document discusses what APQP is, why it's important, when to use it, and how it works in five phases from planning to feedback and improvement. It aims to identify risks early and prevent defects by integrating quality into design and development.

Uploaded by

mjapmgCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- Introduction to APQP: Provides an introduction to Advanced Product Quality Planning and its importance in product development processes.

- Why Apply APQP: Discusses the benefits and necessity of applying APQP in organizational and manufacturing processes.

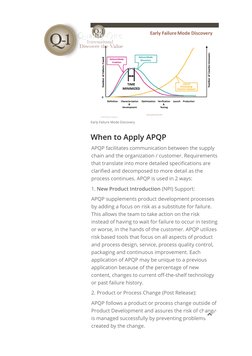

- When to Apply APQP: Examines appropriate scenarios and timelines for applying APQP during different stages of product development.

- How to Apply APQP: Outlines the stages and methodologies involved in properly implementing APQP in projects.

- How to Develop a Product Quality Plan (PQP): Explains the steps to creating a tailored Product Quality Plan as part of the APQP framework.

- The APQP Cross Functional Team (CFT): Describes the role and composition of cross-functional teams in the execution of APQP processes.

- Example of APQP, NPI and DFSS Relationship: Provides examples showing the interaction and relationship between APQP, New Product Introduction (NPI), and Design for Six Sigma (DFSS).

- Example of a Product Quality Plan: Illustrates a sample Product Quality Plan using qualitative and quantitative analysis.

- Product Quality Plan Flow Chart: Presents a visual flow chart outlining the steps involved in the Product Quality Planning process.

- Learn More About APQP: Encourages further exploration and learning opportunities in APQP, offering consulting and training services.