Professional Documents

Culture Documents

Apqp Team: Issued Checked Approved

Uploaded by

Phannachet RungsrikeawOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Apqp Team: Issued Checked Approved

Uploaded by

Phannachet RungsrikeawCopyright:

Available Formats

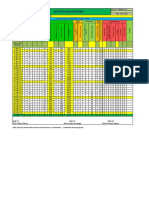

ADVANCED PRODUCT QUALITY PLANNING STATUS REPORT PHASE APPROVED DATE

APQP TEAM APPROVED CHECKED ISSUED

MODEL : 1 PLAN AND DEFINE PROGRAM

PART No : 2 PRODUC DESIGN AND DEVELOPMENT PLAN Rev:

PART NAME : 3 PROCESS DESIGN AND DEVELOPMENT ACTUAL Date:

CUSTOMER : 4 PRODUCT AND PROCESS VALIDATION DELAY Original Date:

MAT'L: 5 FEEDBACK, ASSESSMENT AND CORRECTIVE ACTION FINISH

GYR PROGRAM 2010 2011

CHAMPION

PHASE Item DESCRIPTION STATU NEED JAN FEB MAR APR MAY JUN JUL AUG SEP OCT NOV DEC JAN FEB MAR APR MAY JUN JUL AUG SEP OCT NOV DEC

INITIALS

S DATE 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4

CUSTOMER MASTER SCHEDULE

1 SOURCING DECISION & CUSTOMER INPUT REQUIMENTS G

2 TEAM FEASIBILITY COMMITMENT AND RISK ANALYSYS G

3 DRAWING AND SPECIFICATION AND ENGINEERING CHANGE

# DRAWING PART G

# DRAWING DIE G

# RAW MATERIAL SPEC G

# RAW MATERIAL ORDER G

PHASE 1 & PHASE 2

# ENGINEERING CHANGE REQUEST N/A

4 FACILITIES,TOOLS, DIE AND GAGES

# FACILITIES (NEW LINE /MC /EQUIPMENT) G

# DIES SCHEDULE / ORDER G

# TOOLS SCHEDULE / ORDER N/A

# GAGES SCHEDULE / ORDER G

5 SPECIAL PRODUCT & PROCESS CHARACTERISTICS G

6 GAUGE & TEST EQUIPMENT REQUIREMENT G

7 SUBCONTRACTOR APQP STATUS N/A

7.1 APQP

7.2 PPAP (LEVEL 3)

8 PACKING STANDARD G

9 MANUFACTURING PROCESS FLOW CHART/PLAN LAYOUT G

10 PROCESS FMEA G

11 PRE-LAUNCH CONTROL PLAN / INSPECTION STANDARD G

PHASE 3

12 WORK INSTRUCTION G

13 INSPECTION CHECK SHEET

# PRODUCTION INSPECTION CHECK SHEET G

# QC INSPECTION CHECK SHEET G

14 MEASUREMENT SYSTEMS EVALUATION (MSA) PLAN G

15 PRELIMINARY PROCESS CAPABILITY STUDY(PLAN) G

16 PRODUCTION TRIAL RUN

# TRIAL FORGING G

# TRIAL HEAT TREATMENT N/A

# TRIAL MACHINING G

# INSPECTION

1)INSPECTION LINE CHECK G

2)LAY OUT 100%(1 PC.) G

3)REFER INSPECTION STANDARD(30 PCS.) G

# DELIVERY G

# FUNCTIONAL TEST

1)FIBER FLOW G

2)MICRO STRUCTURE N/A

3)INTERNAL HARDNESS N/A

4)TENSILE TEST N/A

PHASE 4

5)IMPACT TEST N/A

6)STATIC TORSIONAL TEST N/A

7)DYNAMIC TORSIONAL TEST N/A

8)FLANGE BENDINGL TEST N/A

17 MEASUREMENT SYSTEMS EVALUATION (MSA) G

18 PRELIMINARY PROCESS CAPABILITY STUDY G

19 PACKING EVALUATION G

20 MASS PRODUCTION CONTROL PLAN / INSPECTION STD. G

21 PRODUCTION PART APPROVAL (PSW) G

22 QUALITY PLANNING SIGN OFF

23 PERFORMANCE OF PROCESS

23.1 PRODUCTIVITY (PCS/HR) TARGET 180 PCS/HR

23.2 QUALITY(%) TARGET 0.5%

24 FEEDBACK,ASSESSMENT AND CORRECTIVE ACTION

#INITIAL LOT CONTROL G

# REDUCED VARIATION

PHASE 5

# CUSTOMER SATISFACTION

# DELIVERY AND SERVICE

# CONTINUOUS IMPROVEMENT

PLANNING STEP (ITEM)

MONTHLY PROGRESS (ITEM)

TOTAL PLANNING STEP (ITEM) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

TOTAL MONTHLY PROGRESS (ITEM) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

ACHIEVEMEN (%) #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

You might also like

- WSM L3540 4240 5040 5240 5740 enDocument666 pagesWSM L3540 4240 5040 5240 5740 enweldsaidiNo ratings yet

- AIAG-VDA PFMEA Template For Activity - (Delegate)Document38 pagesAIAG-VDA PFMEA Template For Activity - (Delegate)nadia_naaz90No ratings yet

- Ok Part NG: (Vendor Non-Conformance Report)Document2 pagesOk Part NG: (Vendor Non-Conformance Report)BeLlCoNtInEnT MNo ratings yet

- APQP ManualDocument57 pagesAPQP Manual57641No ratings yet

- AIAG & VDA PFMEA FormatDocument1 pageAIAG & VDA PFMEA Formatmahesh KhatalNo ratings yet

- C8 TurtleDiagramCustomerFeedbackProcess顾客反馈过程乌龟图 EnDocument1 pageC8 TurtleDiagramCustomerFeedbackProcess顾客反馈过程乌龟图 EnBAlaNo ratings yet

- 6 PFMEA & Control Plan 1 of 7Document8 pages6 PFMEA & Control Plan 1 of 7P G Suman100% (1)

- Aum Prasad Casting PVT LTD: 1. Types of Audit 2. Objectives Overview 3. Introduction To Clauses. 4. Conducting AuditDocument24 pagesAum Prasad Casting PVT LTD: 1. Types of Audit 2. Objectives Overview 3. Introduction To Clauses. 4. Conducting AuditpraveenNo ratings yet

- APQP Timing Plan SampleDocument3 pagesAPQP Timing Plan SampleDhananjay Patil75% (4)

- Audit Checklist 1Document2 pagesAudit Checklist 1Jagi NikNo ratings yet

- Ppap Worksheet (GM 1411) : S Master Status: Lab StatusDocument6 pagesPpap Worksheet (GM 1411) : S Master Status: Lab Statuscong daNo ratings yet

- Apqp & Ppap PDFDocument52 pagesApqp & Ppap PDFAman Poonia100% (1)

- 1 ApqpDocument30 pages1 ApqpVIPIN YADAVNo ratings yet

- Core ToolsDocument1 pageCore Toolsbil bilNo ratings yet

- PPAP Process Checklist / Sign Off Sheet InstructionsDocument7 pagesPPAP Process Checklist / Sign Off Sheet InstructionsSantosh TiwariNo ratings yet

- Supplier 8D FormDocument3 pagesSupplier 8D FormBen DesireNo ratings yet

- GP-12 Check SheetsDocument2 pagesGP-12 Check SheetsLam Nguyen100% (4)

- Apqp GMDocument73 pagesApqp GMpbvrNo ratings yet

- APQP Chart With Responsibility Matrix: Development Categories Category Details A B C D E F Activity DescriptionDocument6 pagesAPQP Chart With Responsibility Matrix: Development Categories Category Details A B C D E F Activity DescriptionParveen KumarNo ratings yet

- 10 Steps To Conduct A DFMEADocument5 pages10 Steps To Conduct A DFMEAkirthi83No ratings yet

- Apqp Status LogDocument1 pageApqp Status Logsathyabalaraman67% (3)

- Multibagger Stocks For Long Term InvestmentsDocument10 pagesMultibagger Stocks For Long Term InvestmentsSaurav KumarNo ratings yet

- Cqi 122014Document28 pagesCqi 122014Armando Flores Moreno100% (1)

- Iatf TrainingDocument10 pagesIatf TrainingAniket JadhavNo ratings yet

- Apqp 2Document2 pagesApqp 2Isabel SierraNo ratings yet

- Giriraj Precision Screws PVT - Ltd. Quality Manual Procedure APQP (Advanced Product Quality Planning) 1. PurposeDocument9 pagesGiriraj Precision Screws PVT - Ltd. Quality Manual Procedure APQP (Advanced Product Quality Planning) 1. PurposeMohit KaushikNo ratings yet

- List of Documents IATF 16949 Documentation Toolkit EN PDFDocument4 pagesList of Documents IATF 16949 Documentation Toolkit EN PDFRahul SharmaNo ratings yet

- Procedure - Special CharacteristicsDocument13 pagesProcedure - Special Characteristicsalexandru.ghiniaNo ratings yet

- Bolded Text Indicates New To ISO 9001:2015 and IATF 16949:2016Document21 pagesBolded Text Indicates New To ISO 9001:2015 and IATF 16949:2016Ankur Dhir100% (1)

- P!. GM 1927-30 - BIQS Audit v.7.0 2017-04-05Document14 pagesP!. GM 1927-30 - BIQS Audit v.7.0 2017-04-05Duho ConsultoresNo ratings yet

- Required Doc For IATFDocument3 pagesRequired Doc For IATFAbhayNo ratings yet

- Production Part Approval ProcessDocument6 pagesProduction Part Approval ProcessleonardoNo ratings yet

- CPS RFPDocument11 pagesCPS RFPIvan HerreraNo ratings yet

- GstarCAD 2017 USER GUIDE ภาษาไทยDocument269 pagesGstarCAD 2017 USER GUIDE ภาษาไทยPhannachet RungsrikeawNo ratings yet

- Apqp PpapDocument50 pagesApqp PpapMiguel Neto100% (1)

- Guidelines For Making PFMEA - A PDFDocument10 pagesGuidelines For Making PFMEA - A PDFKalimuthu PsNo ratings yet

- MSA WorksheetDocument33 pagesMSA WorksheetSandrawarman BalasundramNo ratings yet

- Sr. No. Requirements: Ppap Check ListDocument3 pagesSr. No. Requirements: Ppap Check Listkamlesh kuchekarNo ratings yet

- Commissioning Guide (V600R001C00 03)Document129 pagesCommissioning Guide (V600R001C00 03)Phannachet RungsrikeawNo ratings yet

- Customer Directory - RRLDocument175 pagesCustomer Directory - RRLganesh kondikireNo ratings yet

- Advanced Product Quality Planning Timing Chart: Plan and Define Programme - PP Trial StageDocument6 pagesAdvanced Product Quality Planning Timing Chart: Plan and Define Programme - PP Trial Stagerajesh sharma100% (2)

- Apqp Product and Process ValidationDocument12 pagesApqp Product and Process Validationrhusseinpos4765No ratings yet

- MFRS 111 Construction ContractsDocument28 pagesMFRS 111 Construction Contractsnatasha thaiNo ratings yet

- HF-0467 - Product Audit Report - C - 2015-08-06Document44 pagesHF-0467 - Product Audit Report - C - 2015-08-06Enis SirbegovicNo ratings yet

- Proforma Invoice No. 85 - 72200183 + 72200408 / 2022: Your Message: Dd. 30 June 2022 Spare Parts For: Boiler SKG 21611Document2 pagesProforma Invoice No. 85 - 72200183 + 72200408 / 2022: Your Message: Dd. 30 June 2022 Spare Parts For: Boiler SKG 21611樊瞳No ratings yet

- Delphi Technologies Customer Specific Requirements: For Use With ISO 9001:2015 and IATF16949:2016Document15 pagesDelphi Technologies Customer Specific Requirements: For Use With ISO 9001:2015 and IATF16949:2016Ram100% (1)

- Wi SPCDocument4 pagesWi SPCSujeet Kumar100% (1)

- Vda 6.1 Parag 06 Product SafetyDocument3 pagesVda 6.1 Parag 06 Product Safetyepimenta_24No ratings yet

- ApqpDocument4 pagesApqpvinayakNo ratings yet

- ASP-NPD-04 (Process of Product Safety)Document5 pagesASP-NPD-04 (Process of Product Safety)akash.vd.1603No ratings yet

- Printout Final IATF 16949 2016 - Key ChangesDocument89 pagesPrintout Final IATF 16949 2016 - Key ChangesSudhagar100% (3)

- Checklist Control PlanDocument1 pageChecklist Control PlanRAJASEKARSUBHUNo ratings yet

- Matrix CSRDocument6 pagesMatrix CSRDiego Jordan Hernández100% (1)

- IATF IA CHecklistDocument2 pagesIATF IA CHecklistDamodaran RajanayagamNo ratings yet

- Apqp Matrix UpdatedDocument2 pagesApqp Matrix Updatedabhishek100% (1)

- Fsqm-080 Ppap ChecklistDocument14 pagesFsqm-080 Ppap ChecklistMohamed Khalifa100% (1)

- CQI-14, How To Perfom The AssesmentDocument4 pagesCQI-14, How To Perfom The AssesmentJose Cepeda50% (2)

- Siegel Robert Automotive Layered Process Audit ChecklistDocument12 pagesSiegel Robert Automotive Layered Process Audit Checklistmahesh KhatalNo ratings yet

- IATF Awareness TrainingDocument81 pagesIATF Awareness TrainingMR KonarengineeringNo ratings yet

- VOLVO APQP-PPAP Deployment Supplier Information 挋嫌挋Document10 pagesVOLVO APQP-PPAP Deployment Supplier Information 挋嫌挋張永松No ratings yet

- API-16AR BOP Remanufaturing API-16AR PSL-2 Rev-0 PDFDocument1 pageAPI-16AR BOP Remanufaturing API-16AR PSL-2 Rev-0 PDFMarouan Nasr100% (1)

- PPAP PriruckaDocument10 pagesPPAP PriruckaKin MattNo ratings yet

- Layout Inspection Report XH5DR June 20 2012Document17 pagesLayout Inspection Report XH5DR June 20 2012nathiven100% (1)

- 8 DsDocument2 pages8 DsAlejandro LunaNo ratings yet

- Register Forum Home Page Post Attachment Files All Help Lost PasswordDocument3 pagesRegister Forum Home Page Post Attachment Files All Help Lost PasswordKirthivasanNo ratings yet

- What Are APQP and PPAPDocument3 pagesWhat Are APQP and PPAPignaunaqNo ratings yet

- QAV-2 Step-3 Audit Check Sheet PDFDocument5 pagesQAV-2 Step-3 Audit Check Sheet PDFRajNo ratings yet

- APQP Format NationalDocument53 pagesAPQP Format NationalqualityNo ratings yet

- Intros WDocument128 pagesIntros WBùi Văn HợpNo ratings yet

- SAP FICO Sample ResumeDocument5 pagesSAP FICO Sample Resumevida adfNo ratings yet

- Amul Ice Cream: Presented byDocument31 pagesAmul Ice Cream: Presented byDhruvil ShahNo ratings yet

- Quotation Sheet DTH Hammer &bit - MiningwellDocument1 pageQuotation Sheet DTH Hammer &bit - MiningwellСергей СоколовNo ratings yet

- Getting - Governance - Right HBook 2016 PDFDocument16 pagesGetting - Governance - Right HBook 2016 PDFRogelio GarcíaNo ratings yet

- 75282bos Transition Scheme NsetDocument54 pages75282bos Transition Scheme NsetPranay JaiswalNo ratings yet

- ACC20020 Management - Accounting Exam - 21-22Document11 pagesACC20020 Management - Accounting Exam - 21-22Anonymous qRU8qVNo ratings yet

- BG CaseDocument23 pagesBG CaseTarun SinghNo ratings yet

- Hidden Costs of Quality: Measurement & Analysis: Sailaja A, P C Basak and K G ViswanadhanDocument13 pagesHidden Costs of Quality: Measurement & Analysis: Sailaja A, P C Basak and K G ViswanadhanAmit PaulNo ratings yet

- Literatura - 1466522385Document20 pagesLiteratura - 1466522385Twings YazaldeNo ratings yet

- Setting Goals and Managing The Sales Force's PerformanceDocument2 pagesSetting Goals and Managing The Sales Force's PerformanceRohanMohapatraNo ratings yet

- 23996678Document12 pages23996678suruth242No ratings yet

- Marble and Onyx Products Manufacturing Unit Rs. 5.98 Million Jun-2019Document28 pagesMarble and Onyx Products Manufacturing Unit Rs. 5.98 Million Jun-2019Muhammad AzeemNo ratings yet

- InvestmentAccounting QuestionClasswork2023 24Document6 pagesInvestmentAccounting QuestionClasswork2023 247013 Arpit DubeyNo ratings yet

- Fikremariam AbebeDocument66 pagesFikremariam Abebejohn accaNo ratings yet

- Report: Material Handling SystemDocument3 pagesReport: Material Handling SystemAmad ShaikhNo ratings yet

- Monthly EHS Progress Report Month of April - 2023Document5 pagesMonthly EHS Progress Report Month of April - 2023PAUL RODRIXNo ratings yet

- Definition of Six SigmaDocument1 pageDefinition of Six SigmahashgtNo ratings yet

- Afm Assignment Financial Ratios Bajaj HavellsDocument5 pagesAfm Assignment Financial Ratios Bajaj HavellsHarsh NangiaNo ratings yet

- FM09-CH 29 PDFDocument2 pagesFM09-CH 29 PDFNaveen RaiNo ratings yet

- FloatDocument8 pagesFloatريم الميسريNo ratings yet

- MBA Employment Report 2023 2024 - 2Document16 pagesMBA Employment Report 2023 2024 - 2Gunjan RajNo ratings yet

- Best HR Practices of General ElectricDocument10 pagesBest HR Practices of General Electricsoumyachoudhary91100% (2)

- Artikel 5Document23 pagesArtikel 5Agus ArwaniNo ratings yet