Professional Documents

Culture Documents

Magnetic Particle Inspection - Use and Implementation of ASTM-E-1444

Magnetic Particle Inspection - Use and Implementation of ASTM-E-1444

Uploaded by

kermech21607Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Magnetic Particle Inspection - Use and Implementation of ASTM-E-1444

Magnetic Particle Inspection - Use and Implementation of ASTM-E-1444

Uploaded by

kermech21607Copyright:

Available Formats

DRAFT CAAP 42V-3(0)

Civil Aviation Magnetic Particle Inspection

Advisory Publication

August 2006

- Use and Implementation of

ASTM-E-1444

This publication is advisory

and provides information and The relevant regulations and other references

guidance to the aviation

industry in support of Regulation 2A of the Civil Aviation Regulations (CAR) 1988

particular Civil Aviation Regulation 42V of the Civil Aviation Regulations (CAR) 1988

Regulations 1988 (CAR 1988).

AS 3669-05: Non-destructive testing Qualification and

Always read this advice in registration of personnel - Aerospace

conjunction with the American Society for Testing Materials ASTM-E-1444:

appropriate regulations. Standard Practice for Magnetic Particle Inspection (MPI)

Note: This CAAP should also

American Society for Testing Materials ASTM-E-709: Standard

be read in conjunction with

Guide for Magnetic Particle Examination

ASTM-E-1444 and ASTM-E

Civil Aviation Order (CAO) Part 108.8: Process Control

709.

Magnetic Particle Inspection

Contents

Preamble 3 Who this CAAP applies to

1. Personnel Qualifications

All persons associated with the maintenance of aircraft or aircraft

and Authorisations 3

components.

2. Documentation 4

3. Magnetic Particle Why this CAAP was written

Inspections (MPI) 5

4. MPI Bench Fixed Line This CAAP applies to the actions required for completion of

Facility 8 Magnetic Particle Inspection tasks for:

5. MPI Portable Hand-held Component Maintenance; and

Yokes 9

On Aircraft Maintenance.

6. Quality Control

Equipment Magnetic

Particle 10

Status of this CAAP

7. Use of the Procedures This is the first CAAP written on this subject.

attached to this CAAP 10

Appendix A Procedure for For further information

Magnetic Particle Inspection

Utilising a Fixed Line Bench 12

Telephone the CASA Office closest to you on 131757.

Appendix B Procedure for

Magnetic Particle Inspection

Utilising a Portable Magnetic

Yoke 15

DRAFT August 2006

2 CAAP 42V-3(0): Magnetic Particle Inspection

Abbreviations AC Alternating Current

AS Australian Standard

ASTM American Society for Testing Materials

AVTUR Aviation Turbine Fuel

CAAP Civil Aviation Advisory Publication

CAO Civil Aviation Orders

CAR Civil Aviation Regulations

DC Direct Current

DoD Department of Defence

IAW In Accordance With

LAME Licensed Aircraft Maintenance Engineer

MPI Magnetic Particle Inspection

MPT Magnetic Particle Technician

NANDTB National Aerospace Non-destructive Testing

Board

NDI Non-destructive Inspection

NDT Non-destructive Testing

OEM Original Equipment Manufacturer

RMS Root Mean Square

W Watt

DRAFT August 2006

CAAP 42V-3(0): Magnetic Particle Inspection 3

Preamble

e Standard practice documents produced by the American Society

for Testing Materials (ASTMs) are replacing Military Standards

(Mil-Std). ASTM-E-709 and ASTM-E-1444 have now become the

accepted American Original Equipment Manufacturer (OEM)

published standards for Magnetic Particle Inspections (MPI).

ASTM-E-709 and ASTM-E-1444 standard practice details are the

minimum requirements for conducting Magnetic Particle

Inspections and replace and supersede the use of Australian CAO

108.8.

The ASTM Standards were not specifically drafted for the

aerospace industry. Indeed, the Standard requires clarification

where aspects conflict with current Regulations. This CAAP

documents the requirements for the use of the ASTM-E-709 and

ASTM-E-1444 and where necessary harmonises the Standard with

the CARs and best practices.

1. Personnel 1.1 NON-DESTRUCTIVE TESTING (NDT)

Qualifications and QUALIFICATIONS

Authorisations Personnel carrying out Magnetic Particle Inspections must be

qualified to a minimum of NDT Level 1 in accordance with AS

3669. In addition, personnel must posses a current CASA NDT

Airworthiness Authority for Magnetic Particle Inspection or an

authorisation under CAR 42ZC(6).

Note: Possession of a current CASA Airworthiness Authority in

Magnetic Particle Technician (MPT) and Licensed Aircraft

Mechanical Engineer (LAME) privilege of the licence do not

necessarily assure compliance to AS 3669.

Airworthiness Authorities issued by CASA for MPT do not

reference NDT Technician Levels.

1.2 HARMONISATION OF CASA-ISSUED

AIRWORTHINESS AUTHORITIES WITH AS 3669, NAS 410 &

EN 4179

For the purpose of this CAAP, a person holding a MPT

Airworthiness Authority for more than two years which has "nil

restrictions" annotated against the MPT entry is deemed

equivalent to a Level 2 NDT Technician.

It is a requirement for all CAR 30 organisations employing

personnel responsible for carrying out MPT tasks to ensure a

system of compliance to AS 3669 is in place and operational by

30 September 2007. This system will operate independently of the

Airworthiness Authorities issued by CASA until the

implementation of the CASA regulations.

DRAFT August 2006

4 CAAP 42V-3(0): Magnetic Particle Inspection

1.3 VISUAL ACUITY

The vision examination for all levels shall assure that the

applicants near vision and colour perception meet the

requirements of Table 1. Near vision tests shall be administered

annually and colour perception tests shall be administered prior to

approval or re-approval. These tests shall be administered by

personnel designated by the responsible Level 3, National

Aerospace Non-destructive Testing Board (NANDTB), or the

outside agency utilised for the qualification examination of

personnel. Any limitations in colour perception shall be evaluated

by the responsible Level 3 prior to approval and this shall be

documented.

TABLE 1

VISION REQUIREMENTS

Near Vision Jaeger No 1 or equivalent, at a distance of not

less than 30 cm in at least one eye natural or

corrected or near vision acuity shall permit

reading, a minimum of Times Roman N4.5 or

equivalent letters (Times Roman of 4.5 points

vertical height where 1 point = 1/72" or

0.3528 mm) at not less than 30 cm with one or

both eyes, either corrected or uncorrected.

Colour Personnel shall be capable of adequately

perception distinguishing and differentiating colours

used in the process involved.

Note: It is the responsibility of the employer to ensure currency and

documentation of colour perception and near vision acuity tests.

2. Documentation 2.1 PRECEDENCE OF DOCUMENTATION

The precedence order of data is:

Approved under Regulation 2A of the Civil Aviation

Regulations 1988;

Original Equipment Manufacturer (OEM)

Civil Aviation Advisory Publication (CAAP);

American Society for Testing Materials (ASTM)

2.2 PROCEDURE NOT STATED BY OEM

Where the OEM states "carry out a magnetic particle/magnaflux

liquid inspection" (or something similar) and does not refer to a

written practice or procedure, ASTM-E-1444 must be used as the

default inspection procedure. Where a generic European Standard

or the Department of Defence (DoD) is referred to in the approved

data, ASTM-E-1444 is deemed an equivalent standard and is to be

utilised in conjunction with this CAAP.

DRAFT August 2006

CAAP 42V-3(0): Magnetic Particle Inspection 5

3. Magnetic Particle 3.1 MECHANICAL CLEANING OF COMPONENTS PRIOR

Inspections TO A MAGNETIC PARTICLE INSPECTION (MPI)

Cleaning of components in some circumstances requires the use of

blasting media ranging from glass bead, aluminium oxide or

plastic media. Generally, blasting media that do not cause plastic

deformation (profiling) of the part surface are suitable for pre-

cleaning. Aluminium oxide 120 grit has been found to be suitable.

Ensure hard chromed surfaces are not cleaned utilising abrasive

blasting (plastic media is the exception).

Note: Garnet grit is highly likely to cause plastic deformation of a

part's surface, and therefore, is not suitable for cleaning aircraft

quality steel.

3.2 VAPOUR DEGREASING

Increasingly, the use of the chemicals suitable for use in vapour

degreasers is being phased out for environmental reasons.

Ardrox 6333 is an aqueous-based approved alternate to vapour

degreasing. Generally this chemical is suitable for use in

mechanical washers.

CAUTION: Serviced industrial mechanical cleaners may contain highly

caustic compounds which may be detrimental to aluminium

and magnesium parts.

3.3 SELECTION OF A MAGNETIC PARTICLE

INSPECTION METHOD

When selecting a magnetic particle inspection method, the

following guide should be used:

FIXED MAGNETIC PARTICLE BENCH

Forged, cast or machined magnetic components irregular

or regular in shape with defect orientation unknown and

with a geometry that allows the use of a MPI bench:

o Fluorescent wet continuous method utilizing AC or DC

current, magnetised in two directions circular and

longitudinal.

Magnetic tensile or shear bolts and pins:

o Fluorescent wet continuous method utilising AC or DC

current magnetised with longitudinal magnetism (coil).

Magnetic brake stators and rotors:

o Fluorescent wet continuous method utilising AC or DC

current on a central conductor (in direct contact circular

magnetism) or longitudinal (coil) AC or DC utilising two

shots 90o apart.

DRAFT August 2006

6 CAAP 42V-3(0): Magnetic Particle Inspection

HAND HELD MAGNETIC YOKES

Magnetic tubular structures such as engine, fuselage or

helicopter frames weld or tube inspections either fitted or

removed from the aircraft:

o Fluorescent wet continuous method utilising AC or DC

current with two shots per inspection area 90o apart.

Demagnetisation of aircraft after lightning strike or similar:

o AC current applied at the part surface and withdrawn to a

distance of 900 mm.

Note: Portable magnetising yokes are not designed as an alternative to

a magnetic particle bench. Extreme heat build up can occur in

small parts repeatedly magnetised with a yoke.

3.4 USE OF PRODS ON AIRCRAFT

Prods are not to be used on aircraft or aircraft components due to

the high risk of arcing.

3.5 DRY POWDER MAGNETIC PARTICLES

Dry powder magnetic particles should not be used on aircraft due

to the inability to retrieve the particles from the aircraft.

3.6 PAINTED/PLATED SURFACES

Provided that paint and plating is in good condition, there is no

requirement to remove it prior to an MPI. An exception being: a

part that requires direct contact (circular) magnetisation must

have the paint removed in the contact areas, otherwise arcing will

result.

3.7 NICKEL PLATED COMPONENTS

Although it is not necessary to remove nickel plating from an

inspection surface prior to inspection, operators should be aware

that nickel is magnetic and may present misleading indications.

3.8 BLACK INK MAGNETIC PARTICLES

It is permissible to use black magnetic ink for spot inspections

with a hand held yoke where the background provides adequate

contrast. An example being: defect verification on a steel

undercarriage that is painted white.

DRAFT August 2006

CAAP 42V-3(0): Magnetic Particle Inspection 7

3.9 BLACK LIGHT INTENSITIES AND VERIFICATION

PERIOD

Black lights used for the inspection stage of a MPI are required to

have their black light intensity output checked at no longer than

the maximum intervals as listed below.

The following light intensity verification plan may be used:

Black light intensity @ 15" CAAP Requirement

Above 2,500W/cm2 3 Monthly

2,000 to 2,500W/cm2 Monthly

1,500 to 2,000W/cm2 Weekly

2

1,000 to 1,500W/cm Daily or before use

Note: The justification for the deviation from ASTM-E-1444 is based

upon a conservative approach from black light intensities

recorded over the past ten years from a number of large

organisations.

3.10 BLACK LIGHT AND WHITE LIGHT INTENSITY

METER CALIBRATION

Black light and white light intensity meters should have the

calibration interval of six months. This may be increased to:

As recommended by the meter manufacturer; or

One year, where the meter has a low usage (less than once a

week).

3.11 USE OF THE TOOL STEEL (KETOS) RING FOR

SYSTEM PERFORMANCE TEST

ASTM-E-1444 Appendix XI details the use of the Ketos ring as a

means of a system performance test. Tables X 1.1 and X 1.2 detail

the current types and amperages to be used. The result should be

a number of holes detected according to the tables. Unfortunately,

the standard does not stipulate whether the current measurements

are Peak or RMS values. In Australia there are a large number of

MPI benches, some reading RMS value and others peak value. It is

common for MPI benches not to perform as per the requirements

of ASTM-E-1444 Appendix XI.

A suitable use for the Ketos ring would be to determine the

amperages required for a hole or holes to become visible on a

particular MPI bench and use this information as a trend

monitoring tool.

It is noted in the ASTM-E-1444 that the use of the tool steel (Ketos)

rings is not mandatory.

DRAFT August 2006

8 CAAP 42V-3(0): Magnetic Particle Inspection

3.12 USE OF FLEXIBLE LAMINATED STRIPS (CASTROL

TYPE II OR EQUIVALENT)

For the purpose of this CAAP, the Castrol Type 2 Strips (or

equivalent) should be used to determine field direction and

strength for all inspections. The formulas for determining the

current required as stated in ASTM-E-709 should only be used as a

guide to obtain a ballpark amperage prior to using the laminated

strips.

3.13 CURRENT TYPE

This CAAP applies to aircraft and aircraft components that have

been released by the manufacturer. The majority of defects

encountered in-service initiate at the parts surface. Given this,

Technicians should consider that the AC wet continuous method

is most suited for locating small surface defects.

4. Magnetic Particle 4.1 PRE CLEANING

Inspection (MPI) Vapour degreasing is the preferred method; however,

Bench Fixed Line environmental factors are rapidly causing the demise of the

Facility Facility

chemicals used in this type of equipment. An environmentally

friendlier option is a water-based cleaner such as Ardrox 6333

(approved as an alternate to vapour degreasing for MPI) or the

approved solvent cleaner for the penetrant system (usually

dispensed via an aerosol can) should be used.

4.2 MAGNETIC PARTICLE BENCH

A MPI bench is generally a self-contained unit capable of

magnetising ferrous components. The bench can be divided into

the following components:

Heads: The heads provide a means of circularly magnetising a

component via copper contact pads located on each head. The left

hand head is usually fixed which contains an air ram (or similar)

used to clamp the part between the heads. The right hand head is

usually moveable to accommodate various lengths of the test

parts. This head slides on a bed and can be locked into position. It

is important that the condition of the contact pads is monitored

regularly (usually daily or before use). If they become frayed the

risk of arcing to the test part increases.

Note: Ensure the part is firmly clamped between the heads prior to

engaging the current.

Central Conductors: Central conductors (also known as threader

bars) are used between the heads. They provide an indirect means

of producing circular magnetism. The central conductors should

be covered with electrical heat shrink to reduce the likelihood of

arcing. The heat shrink should be terminated approximately 5 mm

from each end of the central conductor.

DRAFT August 2006

CAAP 42V-3(0): Magnetic Particle Inspection 9

Coil: The coil provides a means of longitudinally magnetising a

component. The coil is generally a four or five turn coil. Some new

generation coils contain numerous turns of smaller diameter lower

current carrying coils and are rated as an effective four or five turn

coil.

Control Panel: The control panel generally contains:

An ammeter for displaying the applied magnetising

current.

Current selector for dialling the required amperage

AC/DC selector switch (optional)

Head/coil selector switch

Demagnetisation button (optional)

Magnetisation button

Sump: The sump contains the magnetic particle fluid. Sumps will

vary in size from 20 litres (newer generation) to 200 litres for the

older style of benches. The sump contains a pump and applicator

nozzle.

Note: The use of AVTUR as a magnetic particle carrier fluid is not

permitted due to the high risk of fire.

Black light: The black light is usually mounted on the bench via

an arm to allow hands-free operation of the bench.

Note: Black light should not be operated with cracked, chipped or

missing filters. Failure to comply may result in injury.

4.3 POST CLEANING

Usually a solvent bath is provided near the MPI bench for rinsing

of the part to remove residual magnetic particles. After the rinse,

the parts are cleaned and inhibited (if required) in a similar

manner to the pre-cleaning process.

5. Magnetic Particle 5.1 EQUIPMENT REQUIREMENTS

Inspection (MPI) To carry out MPI on an aircraft in-situ, the following equipment is

Portable Hand-held required:

Yokes

Black light (capable of 1000W/cm2 @ 15 inches);

Light protective cloak approx 1 metre square;

Approved marking media, mirror and rule;

Lint free cloth and cleaning solvent;

Hand held AC/DC magnetic yoke;

Castrol Type II strips (or equivalent);

Ardrox 8561 MPI fluid in aerosol can (or equivalent); and

Field indicator or gauss meter.

DRAFT August 2006

10 CAAP 42V-3(0): Magnetic Particle Inspection

6. Quality Control 6.1 THE FOLLOWING IS A LIST OF EQUIPMENT

Equipment REQUIRED:

Magnetic Particle

Black and white light meter;

100 ml pear-shaped centrifuge;

Tool steel ring (Ketos ring) is optional

Flexible laminated strips (Castrol strips);

Field indicator;

Shunt meter for bench verification;

Dead weight 4.5 kg for permanent and AC yokes; and

Dead weight 13.5 kg for DC yokes.

7. Use of the 7.1 APPROVED DATA

Procedures

attached to this Attached as Appendixes to this CAAP are two Magnetic Particle

CAAP Procedures. These procedures have CAR 2A (4) approval and

should be used in the absence of approved OEM data or where

approved data refers an inspection to be carried out in accordance

with ASTM-E-1444 (or a European equivalent).

7.2 QUALIFICATIONS

A Level 2 MPI Technician should select the most suitable MPI

Method Procedure based on the information contained at

paragraph 3.3 of this CAAP. If a Level 1 MPI Technician is to

perform the inspection, a person qualified to Level 2 or 3 MPI is to

nominate which procedure is appropriate.

DRAFT August 2006

CAAP 42V-3(0): Magnetic Particle Inspection 11

APPENDIX A TO CAAP 42V-3(0)

CASA/MPI/1 ISSUE 1

PROCEDURE FOR MAGNETIC PARTICLE INSPECTION UTILISING

A FIXED LINE BENCH

INTRODUCTION

1 ASTM-E-1444 establishes a requirement to use a dedicated procedure for the inspection of

parts. In the absence of an approved procedure, this procedure has CAR 2A (4) approval and is an

acceptable means of compliance for the completion of Magnetic Particle Inspections utilising a fixed

line magnetic particle bench as detailed in CAAP 42V-3.

Note: This procedure does not supersede or replace procedures supplied by an Original

Equipment Manufacturer (OEM).

PROCEDURE NOMINATION

2 This procedure must be accepted by a Level 2 or 3 MPI Technician prior to use on a particular

component.

OPERATOR LEVEL

3 Personnel carrying out this procedure must posses a current CASA NDT Airworthiness

Authority or an authorisation under CAR 42ZC (6). In addition, personnel must be qualified to a

minimum of AS 3669 NDT Level 1.

Note: When approved data (usually the OEM) requires a Technician to be qualified to Level 2

MPI to carry out an inspection in accordance with ASTM-E-1444, this takes precedence

over the Operator Level stated in this procedure.

APPLICABILITY

4 This procedure must be used in conjunction with CAAP 42V-3 and is applicable to all

component types as listed at Selection of a Magnetic Particle Inspection Method in

CAAP 42V-3(0).

LIMITATIONS

5 This procedure should detect surface breaking defects of 2 mm (0.080") in length or greater

and may detect some near surface defects (less than 3 mm into the parent material) of 5 mm in

length. This procedure may detect smaller defects than stated and technicians should not ignore

these indications if located.

PRE-INSPECTION REQUIREMENTS

6 Ensure the parts are removed from the aircraft, disassembled and cleaned utilising an

appropriate cleaning method or methods.

Note: Paint in good condition does not have to be removed unless the risk of arcing exists.

DRAFT August 2006

12 CAAP 42V-3(0): Magnetic Particle Inspection

EQUIPMENT REQUIREMENTS

7 The equipment applicable to this procedure is:

a Fixed wet Magnetic Particle Inspection Bench;

WARNING: DO NOT USE BLACK LIGHTS WITH CRACKED OR MISSING FILTERS.

HARMFUL ULTRA VIOLET RADIATION EMITTED CAN DAMAGE EYES.

b Black light with a minimum intensity of 1,000W/cm2 @ 40 cm (15");

c Castrol flux indicator strips (or equivalent);

d Permanent marking pen and field indicator;

e Lint free cloth and approved cleaning solvent.

INSPECTION PROCEDURE

8 After a minimum of one minute dark adaptation, carry out the inspection as follows:

Circular Magnetism (when required)

a Place the part between the heads, preferably on a central conductor (geometry

permitting) to reduce the risk of arcing.

b Utilising a Type II Castrol Strip (or equivalent) in accordance with the manufacturers

instructions, magnetise the part utilising 800-1,000 amps per 25 mm of cross-section utilising

AC or DC wet continuous method. Ensure correct flux density is evident on the Castrol

strip. Adjust the magnetising current if necessary. Three distinct lines should be evident on

the flux indicator strip.

Note: Calculate and obtain the correct current requirements for the thinner sections first,

working to the larger diameters (higher amperages) as the inspection progresses,

utilising the Castrol strips each time there is a significant change in part geometry.

c Once adequate flux density has been obtained, carry out the wet continuous method

utilising AC or DC. Inspect the part for defect indications. Defect indications will appear as

sharp, well-defined lines. Conversely, non-relevant indications will generally appear broad

and fuzzy and generally follow part geometry.

d Mark any suspect defect indications for further visual/optical evaluation.

Longitudinal Magnetism

e Place the part in the coil. Effective magnetising length is approximately 150 mm either

side of the coil, hence several shots may be required on longer parts such as crankshafts, etc.

f Establish the approximate current requirement utilising the following formula:

I = K (constant 45,000)

L x N

D

Where: L is the length-to-diameter ratio

D

and N refers to the number of effective number of turns in the coil.

Note: The formula stated provides a guide and is based on the part cross-section being less

than 10% of the coil opening and having a length to diameter ratio of less than 15.

DRAFT August 2006

CAAP 42V-3(0): Magnetic Particle Inspection 13

g Utilising a Type II Castrol Strip (or equivalent) in accordance with the manufacturer's

instructions, magnetise the part utilising the resultant amperage derived from sub-

paragraph f. utilising AC or DC wet continuous method. Ensure correct flux density is

evident on the Castrol strip. Adjust magnetising current if necessary. Three distinct lines

should be evident on the flux indicator strip.

h Once adequate flux density has been established, carry out the wet continuous method

utilising AC or DC. For the required number of shots, inspect the part for defect indications

between each shot. Defect indications will appear as sharp, well-defined lines. Conversely,

non-relevant indications will generally appear broad and fuzzy and generally follow part

geometry.

i Mark any suspect defect indications for further visual/optical evaluation.

j Demagnetise the part to where the residual magnetism shown on a field indicator does

not exceed three divisions either side of zero.

ACCEPTANCE/REJECTION CRITERIA

9 Any confirmed defect indication is cause for part rejection.

BACKUP PROCEDURE

10 Perform a visual inspection utilising a binocular microscope or other suitable magnifying

device.

POST-INSPECTION REQUIREMENTS

11 Ensure the parts are cleaned with a suitable cleaning method to remove all traces of MPI

particles.

RECORDING PROCEDURE

12 Procedure compliance is to be recorded in the relevant worksheet, NDI Report or aircraft

maintenance log.

13 An example of a typical worksheet entry for a Sensitivity Level 3 Inspection is:

"MPI carried out IAW CASA/MPT/1 Method A, Sensitivity Level 3, in conjunction with ASTM-E-1444.

Nil cracking evident."

"Mr B.A.Bethany A522148 15 May 06"

DRAFT August 2006

14 CAAP 42V-3(0): Magnetic Particle Inspection

INTENTIONALLY LEFT BLANK

DRAFT August 2006

CAAP 42V-3(0): Magnetic Particle Inspection 15

APPENDIX B TO CAAP 42V-3(0)

CASA/MPI/2 ISSUE 1

PROCEDURE FOR MAGNETIC PARTICLE INSPECTION UTILISING A

PORTABLE MAGNETIC YOKE

INTRODUCTION

1 ASTM-E-1444 establishes a requirement to use a dedicated procedure for the inspection of

parts. In the absence of an approved procedure, this procedure has CAR 2A (4) approval and is an

acceptable means of compliance for the completion of Magnetic Particle Inspections utilising a

portable magnetic yoke as detailed in CAAP 42V-3.

Note: This procedure does not supersede or replace procedures supplied by an OEM.

PROCEDURE NOMINATION

2 This procedure must be accepted by a Level 2 or 3 MPI Technician prior to use on a particular

component.

OPERATOR LEVEL

3 Personnel carrying out this procedure must posses a current CASA NDT Airworthiness

Authority or an authorisation under CAR 42ZC (6). In addition, personnel must be qualified to a

minimum of AS 3669 NDT Level I.

Note: When approved data (usually the OEM) requires a Technician to be qualified to Level 2 MPT to

carry out an inspection in accordance with ASTM-E-1444, this takes precedence over the

Operator Level stated in this procedure.

APPLICABILITY

4 This procedure must be used in conjunction with CAAP 42V-3 and is applicable to all

component types as listed at Selection of a Magnetic Particle Inspection Method in CAAP 42V-3.

LIMITATIONS

5 This procedure should detect surface breaking defects of 2 mm (0.080") in length or greater and

may detect some near surface defects (less than 3 mm into the parent material) of 5 mm in length.

This procedure may detect smaller defects than stated and technicians should not ignore these

indications if located.

PRE-INSPECTION REQUIREMENTS

6 Ensure the parts to be inspected are clean and free from loose or flaking paint.

Note: Paint in good condition does not have to be removed unless required by the relevant

maintenance data.

DRAFT August 2006

16 CAAP 42V-3(0): Magnetic Particle Inspection

EQUIPMENT REQUIREMENTS

7 The equipment applicable to this procedure is:

a Portable magnetic yoke which complies to the requirements of ASTM-E-1444;

b Light exclusion hood/sheet;

WARNING: DO NOT USE BLACK LIGHTS WITH CRACKED OR MISSING FILTERS.

HARMFUL ULTRAVOILET RADIATION EMITED CAN DAMAGE EYES

c Black light with a minimum intensity of 1,000W/cm2 @ 40cm (15");

d Ardrox 8561 Fluorescent MPI fluid in a spray can (or equivalent);

e Castrol flux indicator strips (or equivalent);

f Permanent marking pen and field indicator;

g Lint free cloth and approved cleaning solvent.

INSPECTION PROCEDURE

8 After a minimum of one minute dark adaptation; carry out the inspection as follows:

a Place the yoke legs on the inspection area with the yoke legs spaced approximately

100 mm apart.

b Test the inspection area for adequate flux density utilising a Type II Castrol Strip (or

equivalent) in accordance with the manufacturer's instructions. It is important that the

magnetising current is applied whilst simultaneously spraying the MPI fluid onto the flux

indicator strip. A minimum of three second magnetising is recommended. Three distinct

lines should be evident on the flux indicator strip.

Note: If difficulty is experienced in gaining an adequate flux density, reduce the yoke leg

spacing and maximize the yoke contact area to the test part. In extreme cases, pole

pieces contoured to the part surface may be required.

c Once adequate flux density has been obtained carry out the wet continuous method

utilising the yoke with either AC or DC current. Inspect the part for defect indications.

Defect indications will appear as sharp, well-defined lines. Conversely, non-relevant

indications will generally appear broad and fuzzy and generally follow part geometry.

d Mark any suspect defect indications for further visual/optical evaluation.

e Where defect orientation is unknown, rotate the yoke through 90o and repeat sub-

paragraph c and d.

Note: In-service bolts and shear pins only require magnetising through the longitudinal axis

of the bolt. Do not repeatedly magnetise a bolt or similar item in rapid succession as

the part may become excessively heated.

f When the inspection is complete, ensure the residual magnetism in the part does not

exceed three divisions either side of zero on a field indicator.

DRAFT August 2006

CAAP 42V-3(0): Magnetic Particle Inspection 17

ACCEPTANCE/REJECTION CRITERIA

9 Any confirmed defect indication is cause for part rejection.

BACKUP PROCEDURE

10 Perform a visual inspection utilising a binocular microscope or other suitable magnifying

device.

POST-INSPECTION REQUIREMENTS

11 Ensure the parts are cleaned with a suitable cleaning method to remove all traces of MPI

particles.

RECORDING PROCEDURE

12 Procedure compliance is to be recorded in the relevant worksheet, NDI Report or aircraft

maintenance log.

13 An example of a typical worksheet entry for a Sensitivity Level 3 Inspection is:

"MPI carried out IAW CASA/MPT/1 Method A, Sensitivity Level 3, in conjunction with ASTM-E-1444.

Nil cracking evident."

"Mr B.A.Bethany A522148 15 May 06"

DRAFT August 2006

You might also like

- Klein Gordon and Dirac in Curved SpacetimeDocument104 pagesKlein Gordon and Dirac in Curved Spacetimezcapg17No ratings yet

- Thickness GaugingDocument3 pagesThickness GaugingAmit HasanNo ratings yet

- 4-5-6. Non Destructive TestingDocument59 pages4-5-6. Non Destructive TestingTEZ ANALYSIS AND STORIES100% (1)

- Procedure of UT-TestDocument2 pagesProcedure of UT-TestJohn ShermanNo ratings yet

- Senior High School Lesson Plan g11 g12Document3 pagesSenior High School Lesson Plan g11 g12heidi belle caleja100% (2)

- Acceptance Standards UtDocument3 pagesAcceptance Standards UtAhmed GomaaNo ratings yet

- Brinell Hardness of Metallic Materials: Standard Test Method ForDocument32 pagesBrinell Hardness of Metallic Materials: Standard Test Method ForJeffersonCruzNo ratings yet

- Asme Questions and Answers Part IIIDocument6 pagesAsme Questions and Answers Part IIIYan FerizalNo ratings yet

- Midwifery Terminology: Mrs.V.Elizebeth Rani ReaderDocument14 pagesMidwifery Terminology: Mrs.V.Elizebeth Rani ReaderSamira MohamudNo ratings yet

- HCL Domino Volt StepByStep TutorialDocument28 pagesHCL Domino Volt StepByStep TutorialPIngNo ratings yet

- Procedure For Magnetic Particle Testing: Ramachal NDT ServicesDocument3 pagesProcedure For Magnetic Particle Testing: Ramachal NDT ServicesAman SarfarazNo ratings yet

- Barcol ProcedureDocument1 pageBarcol ProcedureseetharamannNo ratings yet

- Wall Thickness - ReportDocument1 pageWall Thickness - ReportPetro100% (1)

- Asme Viii - Div.1 (2019) Appendix 4 RTDocument1 pageAsme Viii - Div.1 (2019) Appendix 4 RTionexchangeqcNo ratings yet

- Jha-195 To Carry Out Mpi, PT TestDocument12 pagesJha-195 To Carry Out Mpi, PT Testhammadgull100% (1)

- B. The Demagnetisation Curve and Its ParametersDocument4 pagesB. The Demagnetisation Curve and Its ParametersLalit MisraNo ratings yet

- Vlosi Holiday Test Report No-16Document1 pageVlosi Holiday Test Report No-16Anonymous uJzSZ5100% (1)

- Radiation Safety Program 2Document16 pagesRadiation Safety Program 2Ahmed shabanNo ratings yet

- PT ProcedureDocument12 pagesPT ProcedureLuong Ho VuNo ratings yet

- Lrut Special AplicationDocument20 pagesLrut Special AplicationAbdur Rahim100% (1)

- ARE144 Core ReviewDocument50 pagesARE144 Core Reviewshanmuga8950% (2)

- Diaphragm Walls and Stractures 60Document1 pageDiaphragm Walls and Stractures 60jaga67No ratings yet

- Radiography Testing - NDT Inspection - TWIDocument5 pagesRadiography Testing - NDT Inspection - TWIKolusu SivakumarNo ratings yet

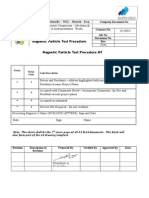

- Magnetic Particle Test Procedure Magnetic Particle Test Procedure MTDocument14 pagesMagnetic Particle Test Procedure Magnetic Particle Test Procedure MTsamer8saif100% (3)

- The Extec C-12: Features and Benefits BookDocument21 pagesThe Extec C-12: Features and Benefits BookReyna CoaquiraNo ratings yet

- NDT 2019Document32 pagesNDT 2019Muhammad OsamaNo ratings yet

- Comparison ASTM A 3388 & ISO 11496Document1 pageComparison ASTM A 3388 & ISO 11496Rahul MoottolikandyNo ratings yet

- NDT Certification Systems:: Written PracticeDocument3 pagesNDT Certification Systems:: Written PracticeKhaled MeraashliNo ratings yet

- Insulation Inspection ReportDocument1 pageInsulation Inspection ReportKarthikNo ratings yet

- GE Mentor EM Weld BrochureDocument6 pagesGE Mentor EM Weld BrochuredimachampionNo ratings yet

- Achieving Zero Force Outages by Auto Rigorousinspection by Ivan PistsovDocument26 pagesAchieving Zero Force Outages by Auto Rigorousinspection by Ivan PistsovLeon Valentino PanjaitanNo ratings yet

- Sample of Corrosion Mapping Using Thickness Gauge Grid FileDocument3 pagesSample of Corrosion Mapping Using Thickness Gauge Grid FileBagus HadiwibowoNo ratings yet

- Distructive & Non-Destructive Testing of MaterialDocument16 pagesDistructive & Non-Destructive Testing of MaterialEngr.Hamid Ismail CheemaNo ratings yet

- Se 797Document7 pagesSe 797donaldoguerreroNo ratings yet

- Asme Sec V A-15-2006Document4 pagesAsme Sec V A-15-2006Muhammed Abo-FandoodNo ratings yet

- Eddy Current Testing PDFDocument1 pageEddy Current Testing PDFMai Sỹ HảiNo ratings yet

- NDTSNTDocument20 pagesNDTSNTEugenia Le FosseNo ratings yet

- CV Hotrungtinh QC-NDT PDFDocument6 pagesCV Hotrungtinh QC-NDT PDFTrung Tinh HoNo ratings yet

- Ultrasonic Inspection Report: Item Specification Inspection SubjectDocument6 pagesUltrasonic Inspection Report: Item Specification Inspection Subjectehsan.mNo ratings yet

- Agpl QP RFT 03 PDFDocument8 pagesAgpl QP RFT 03 PDFMaged Ali RaghebNo ratings yet

- LS - prt.TUB.073 Residual Magnetic Inspection MethodDocument6 pagesLS - prt.TUB.073 Residual Magnetic Inspection MethodAlphonse YACKAMAMBO DIBACKANo ratings yet

- NDT Training Syllabus PDFDocument8 pagesNDT Training Syllabus PDFNkwor AndersonNo ratings yet

- Vacuum Box Test Procedure: PurposeDocument4 pagesVacuum Box Test Procedure: Purposesaravan1891No ratings yet

- Penguard ZP AO - English (Uk) - Issued.06.12.2007Document3 pagesPenguard ZP AO - English (Uk) - Issued.06.12.2007Mohamed FaragNo ratings yet

- 1.4 Rope Access Job Method StatementDocument6 pages1.4 Rope Access Job Method StatementMohammad YusoffNo ratings yet

- Procedure For UtDocument12 pagesProcedure For UtMohammad SyeduzzamanNo ratings yet

- PDS Na GTS65 PDFDocument2 pagesPDS Na GTS65 PDFMoaatazz NouisriNo ratings yet

- Ultrasonic Testing of Tube To Tube SheetDocument6 pagesUltrasonic Testing of Tube To Tube SheetDARSHIL RAJPURANo ratings yet

- GPS Survey AGM Placement Specifications ProcedureDocument6 pagesGPS Survey AGM Placement Specifications ProcedureAfif Nugroho100% (1)

- Is 9902 2004Document11 pagesIs 9902 2004cbbasakNo ratings yet

- Operating Manual CrxvisionDocument45 pagesOperating Manual CrxvisionChandrashekhar ThiramdasuNo ratings yet

- Introduction To NDT BasicDocument27 pagesIntroduction To NDT BasicAngela WalkerNo ratings yet

- Temperature Controllers: Installation and MaintenanceDocument5 pagesTemperature Controllers: Installation and MaintenanceJose Uriel Ortega LeonNo ratings yet

- Ultrasonics Blank ReportDocument3 pagesUltrasonics Blank ReportSteven GoughNo ratings yet

- NDTDocument23 pagesNDTRaj KumarNo ratings yet

- Chapter 1 NDTDocument56 pagesChapter 1 NDTJohn Edward Quilang ObienaNo ratings yet

- Luxaprime1400 Alkyd Zinc Phosphate PrimerDocument2 pagesLuxaprime1400 Alkyd Zinc Phosphate PrimerGurdeep Sungh AroraNo ratings yet

- Article 1 Article 1 Mandatory Appendix I I-121.3Document6 pagesArticle 1 Article 1 Mandatory Appendix I I-121.3SandraNo ratings yet

- Duplex IQI To en 462Document1 pageDuplex IQI To en 462Jhordy Moises Pinedo CàrdenasNo ratings yet

- 2018 Sea Cswip Course Exam FeeDocument4 pages2018 Sea Cswip Course Exam FeeAmar MohammedNo ratings yet

- Penetrants TESTINGDocument86 pagesPenetrants TESTINGsankaran_muthukumarNo ratings yet

- Ometry of Bolted Connections:: Hole Spacing and Code FormulaDocument17 pagesOmetry of Bolted Connections:: Hole Spacing and Code FormulaSimi NagyNo ratings yet

- Saferad ProcedureDocument19 pagesSaferad ProcedureExsan OthmanNo ratings yet

- Recommended Practice No SNT TC 1A 2020 ADocument59 pagesRecommended Practice No SNT TC 1A 2020 Arabia akramNo ratings yet

- Magnetic Particle InspectionDocument11 pagesMagnetic Particle InspectionLuis Guevara0% (1)

- Diaphragm Walls and Stractures 56Document1 pageDiaphragm Walls and Stractures 56jaga67No ratings yet

- Diaphragm Walls and Stractures 49Document1 pageDiaphragm Walls and Stractures 49jaga67No ratings yet

- Diaphragm Walls and Stractures 46Document1 pageDiaphragm Walls and Stractures 46jaga67No ratings yet

- Diaphragm Walls and Stractures 42Document1 pageDiaphragm Walls and Stractures 42jaga67No ratings yet

- Diaphragm Walls and Stractures 55Document1 pageDiaphragm Walls and Stractures 55jaga67No ratings yet

- Diaphragm Walls and Stractures 41Document1 pageDiaphragm Walls and Stractures 41jaga67No ratings yet

- Construction of Concrete1Document1 pageConstruction of Concrete1jaga67No ratings yet

- Diaphragm Walls and Stractures 40Document1 pageDiaphragm Walls and Stractures 40jaga67No ratings yet

- Math Test One PDFDocument20 pagesMath Test One PDFjaga67No ratings yet

- Diaphragm Walls and Stractures 37Document1 pageDiaphragm Walls and Stractures 37jaga67No ratings yet

- Diaphragm Walls and Stractures 28Document1 pageDiaphragm Walls and Stractures 28jaga67No ratings yet

- Diaphragm Walls and Stractures 27Document1 pageDiaphragm Walls and Stractures 27jaga67No ratings yet

- Diaphragm Walls and Stractures 24Document1 pageDiaphragm Walls and Stractures 24jaga67No ratings yet

- SYNC 3 USB MAPS-Update-GuideDocument8 pagesSYNC 3 USB MAPS-Update-Guidetatamata2539No ratings yet

- Audiolab 8000S Service Manual PDFDocument36 pagesAudiolab 8000S Service Manual PDFMarcelo IpolitoNo ratings yet

- Fast Ethernet Switch at-FS705L (Data Sheet) - EngDocument2 pagesFast Ethernet Switch at-FS705L (Data Sheet) - EngBaroszNo ratings yet

- ReadmeDocument3 pagesReadmeArslan AjmalNo ratings yet

- The House On Mango Street Literary GuideDocument26 pagesThe House On Mango Street Literary GuidePeter PasqNo ratings yet

- Resume Training 1Document2 pagesResume Training 1api-231079644No ratings yet

- Lesson Plan 1Document8 pagesLesson Plan 1api-711747954No ratings yet

- 518 IFE Level 4 Certificate in Fire InvestigationDocument15 pages518 IFE Level 4 Certificate in Fire Investigationajit kumbharNo ratings yet

- Plant Protection and QuarantineDocument79 pagesPlant Protection and QuarantineDr. Rama krishna PullaNo ratings yet

- Nonogram Assignment Instructions 2022Document14 pagesNonogram Assignment Instructions 2022PrestigiousNo ratings yet

- Scada Pro - 7 - Example - Masonry - Ec8 - EN PDFDocument47 pagesScada Pro - 7 - Example - Masonry - Ec8 - EN PDFrelu59No ratings yet

- Application To Resume Australian Citizenship: Step 1 - EligibilityDocument15 pagesApplication To Resume Australian Citizenship: Step 1 - Eligibilityulysses.carvalhoNo ratings yet

- Lecture9A - CpE 690 Introduction To VLSI DesignDocument20 pagesLecture9A - CpE 690 Introduction To VLSI DesignjvandomeNo ratings yet

- Job EnrichmentDocument44 pagesJob EnrichmentSeema RahulNo ratings yet

- Master Direction Draft On Information Technology Governance Risk ControlsDocument15 pagesMaster Direction Draft On Information Technology Governance Risk Controlsabee narayanNo ratings yet

- SPE 136967 Evaluation of Compressibility Factor Correlations For Niger Delta Gas ReservoirsDocument9 pagesSPE 136967 Evaluation of Compressibility Factor Correlations For Niger Delta Gas ReservoirsekeneNo ratings yet

- Improving And: Service Quality ProductivityDocument42 pagesImproving And: Service Quality ProductivityThuTrangNo ratings yet

- A Field Guide To Assessing Creative Thinking in Schools - March2022Document88 pagesA Field Guide To Assessing Creative Thinking in Schools - March2022sagheer ahmadNo ratings yet

- ELD1-GW Sem2 Grammar WorkbookDocument42 pagesELD1-GW Sem2 Grammar WorkbookhuongquynhNo ratings yet

- BO Interview Questions & Answers& Servers Details PDFDocument120 pagesBO Interview Questions & Answers& Servers Details PDFamanblr12No ratings yet

- Irc ListDocument16 pagesIrc ListMegha PatidarNo ratings yet

- MaldivasDocument13 pagesMaldivasNaym ElizabethNo ratings yet

- OmniGear Tech Info BinderDocument86 pagesOmniGear Tech Info BinderMiguel Matias ReineroNo ratings yet

- Material Safety Data Sheet: Carbon Dioxide (Fire Extinguishing Agent and Expellant)Document6 pagesMaterial Safety Data Sheet: Carbon Dioxide (Fire Extinguishing Agent and Expellant)RobertoNo ratings yet