Professional Documents

Culture Documents

Counterbored Holes: 1.8.20 Screw Threads

Uploaded by

HOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Counterbored Holes: 1.8.20 Screw Threads

Uploaded by

HCopyright:

Available Formats

1.8.

20 Screw Threads

Methods of specifying and dimensioning screw

threads are covered in ASME Y14.6.

2.5 SINGLE LIMITS

MIN or MAX is placed after a dimension where other

elements of the design definitely determine the other

unspecified limit. Features, such as depths of holes,

lengths of threads, corner radii, chamfers, etc., may be

limited in this way. Single limits are used where the

intent will be clear, and the unspecified limit can be zero

or approach infinity and will not result in a condition

detrimental to the design.

2.9 SCREW THREADS

Each tolerance of orientation or position and datum

reference specified for a screw thread applies to the axis

of the thread derived from the pitch cylinder. Where an

exception to this practice is necessary, the specific feature

of the screw thread (such as MAJOR DIA or MINOR

DIA) shall be stated beneath the feature control frame,

or beneath or adjacent to the datum feature symbol, as

applicable. See Fig. 7-35.

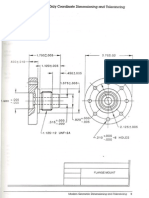

Counterbored Holes

7.4.2 Counterbored Holes

Where positional tolerances are used to locate coaxial

features, such as counterbored holes, the following practices

apply:

(a) Where the same positional tolerance is used to

locate both holes and counterbores, a single feature control

frame is placed under the notes specifying hole and

counterbore requirements. See Fig. 7-24. Identical diameter

tolerance zones for hole and counterbore are coaxially

located (constrained in translation and rotation) at

true position relative to the specified datums.

(b) Where different positional tolerances are used

to locate holes and counterbores (relative to common

datum features), two feature control frames are used.

One feature control frame is placed under the note

specifying hole requirements and the other under the

note specifying counterbore requirements. See Fig. 7-25.

Different diameter tolerance zones for hole and counterbore

are coaxially located at true position relative to the

specified datums.

(c) Where positional tolerances are used to locate

holes and to control individual counterbore-to-hole

relationships (relative to different datum features),

two feature control frames are used as in subpara.

(b) above. In addition, a note is placed under the datum

feature symbol for the hole and under the feature

control frame for the counterbore, indicating the

number of places each applies on an individual basis.

See Fig. 7-26.

You might also like

- Drill ModelingDocument13 pagesDrill Modelingantonio87No ratings yet

- Manual of Engineering Drawing: British and International StandardsFrom EverandManual of Engineering Drawing: British and International StandardsRating: 3.5 out of 5 stars3.5/5 (4)

- EC3 Design (Staad Manual)Document29 pagesEC3 Design (Staad Manual)chidsalazarNo ratings yet

- CH 7 Simple Beam End Connections-9-13Document60 pagesCH 7 Simple Beam End Connections-9-13JakesNo ratings yet

- Geometric Dimensioning and TolerancingDocument6 pagesGeometric Dimensioning and TolerancingPedro LeosNo ratings yet

- GD T ExamplesDocument10 pagesGD T ExamplesJuan Posada GNo ratings yet

- EPM212 - Chapter 9 Slides GD T HandoutDocument15 pagesEPM212 - Chapter 9 Slides GD T HandoutJosephRomeraloNo ratings yet

- GD&T PDFDocument49 pagesGD&T PDFnupurvinodNo ratings yet

- CNH Spec DWGA150 - Casting & Forging DrawingsDocument8 pagesCNH Spec DWGA150 - Casting & Forging DrawingsJoe ScopeliteNo ratings yet

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsFrom EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsRating: 4 out of 5 stars4/5 (1)

- Drawing PracticesDocument60 pagesDrawing Practicespverma02No ratings yet

- Datum ShiftDocument11 pagesDatum ShiftHarshottam DhakadNo ratings yet

- GD&T StandardDocument100 pagesGD&T StandardsudhirNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- GD&T QuestionsDocument12 pagesGD&T Questionsநளின் கான்100% (1)

- GD&T Day 1 Part 1Document22 pagesGD&T Day 1 Part 1harshkallani100% (2)

- Multi-Spring Representation of Fasteners For Msc/nastran ModelingDocument13 pagesMulti-Spring Representation of Fasteners For Msc/nastran ModelingSteve MahoneyNo ratings yet

- Flow Measurement: By Square-Edged Orifice Plate Using Corner TappingsFrom EverandFlow Measurement: By Square-Edged Orifice Plate Using Corner TappingsRating: 5 out of 5 stars5/5 (1)

- Design of Welded Connections PDFDocument37 pagesDesign of Welded Connections PDFMarat Khodzhaiev100% (1)

- Materials Science and Technology of Optical FabricationFrom EverandMaterials Science and Technology of Optical FabricationNo ratings yet

- Dimensioning and Tolerancing: (C) Where Positional Tolerances Are Used To Locate Holes andDocument56 pagesDimensioning and Tolerancing: (C) Where Positional Tolerances Are Used To Locate Holes andavr8784100% (1)

- (B) (C) (D) (E) in A General Tolerance Block Referring To All Dimensions OnDocument17 pages(B) (C) (D) (E) in A General Tolerance Block Referring To All Dimensions Onavr8784No ratings yet

- AWC DA6 BeamFormulas 0710Document9 pagesAWC DA6 BeamFormulas 0710Shivaranjan HJNo ratings yet

- Anchor Bolt Specification Conflicts December 2006Document7 pagesAnchor Bolt Specification Conflicts December 2006Bruce SuprenantNo ratings yet

- Wylie Manual PDFDocument20 pagesWylie Manual PDFNaingminn HtoonNo ratings yet

- A Strategy For Tolerancing Parts: P1: Pbu MHBD031-14 MHBD031-Cogorno-v6.cls April 11, 2006 21:50Document22 pagesA Strategy For Tolerancing Parts: P1: Pbu MHBD031-14 MHBD031-Cogorno-v6.cls April 11, 2006 21:50harsharg6_8No ratings yet

- Functional Inspection TechniquesDocument31 pagesFunctional Inspection TechniquesSenthil KumarNo ratings yet

- Bs Punching Shear PDFDocument6 pagesBs Punching Shear PDFMrStructuralNo ratings yet

- Bond or LinkDocument3 pagesBond or Linkshams sultaniNo ratings yet

- Geometric TolerancesDocument113 pagesGeometric TolerancesVinod SaleNo ratings yet

- Volvo Geometric TolerancesDocument113 pagesVolvo Geometric Tolerancestleomilshaw0% (1)

- CourseMTM QE-Chap1Document8 pagesCourseMTM QE-Chap1Iheb MarsaouiNo ratings yet

- Pinned Base Plates 40Document1 pagePinned Base Plates 40pawkomNo ratings yet

- CRSI Manual To Design RC Diaphragms - Part16Document4 pagesCRSI Manual To Design RC Diaphragms - Part16Adam Michael GreenNo ratings yet

- Steel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Document2 pagesSteel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Andres CasadoNo ratings yet

- WI-007 Machining Standard Practices ManualDocument10 pagesWI-007 Machining Standard Practices ManualmanimeczNo ratings yet

- ANSYS Customization For Bridges and Prestressed Concrete Structures Analysis and DesignDocument11 pagesANSYS Customization For Bridges and Prestressed Concrete Structures Analysis and DesignrramadanNo ratings yet

- Chapter 20-ExcerptDocument6 pagesChapter 20-ExcerptMaciej SergielNo ratings yet

- Ma App 24Document7 pagesMa App 24ahmedNo ratings yet

- Reinforced Concrete Structures 2nd Edition Fanella 2015 - 16Document1 pageReinforced Concrete Structures 2nd Edition Fanella 2015 - 16SardarNo ratings yet

- Steel Girder Bridge - ChecklistDocument2 pagesSteel Girder Bridge - ChecklistMahmud ShalehudinNo ratings yet

- Full-Paper 164Document8 pagesFull-Paper 164liamNo ratings yet

- Steel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Document2 pagesSteel Interchange: Modern Steel's Monthly Steel Interchange Is For You!hector diazNo ratings yet

- Structural Steel Load and Resistance Factor Design Short VersionDocument8 pagesStructural Steel Load and Resistance Factor Design Short Versionjack.simpson.changNo ratings yet

- Release Notes Csi Bridge V 2100Document10 pagesRelease Notes Csi Bridge V 2100thekrauser96No ratings yet

- App E - Dim RulesDocument4 pagesApp E - Dim RulesIbadurrahman KahfiNo ratings yet

- 1.0 General: Drafting ManualDocument8 pages1.0 General: Drafting ManualMubashar Khalil Hashmi100% (1)

- Stress Relieving As Per IS 2825Document4 pagesStress Relieving As Per IS 2825Sudhir DwivediNo ratings yet

- Figure 1 Example of D-Regions in A Common Building StructureDocument13 pagesFigure 1 Example of D-Regions in A Common Building StructureCristobal Jimenez MuchoNo ratings yet

- Datum SystemsDocument16 pagesDatum Systemstemp83a69% (13)

- C StructuralDesign MorganDocument5 pagesC StructuralDesign MorganALINo ratings yet

- Sp208-04ex 6Document22 pagesSp208-04ex 6Žarko LazićNo ratings yet

- Dfma PDFDocument385 pagesDfma PDFA.Rishi sivaNo ratings yet

- Design of Anchor Bolts Embedded in Concrete MasonryDocument9 pagesDesign of Anchor Bolts Embedded in Concrete MasonryYoesuf DecipherNo ratings yet