Professional Documents

Culture Documents

Rockfall protection netting technical data sheet

Uploaded by

sundra0Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rockfall protection netting technical data sheet

Uploaded by

sundra0Copyright:

Available Formats

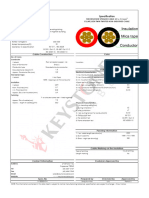

TECHNICAL DATA SHEET

Rev. 19, Date 15.12.2014

ROCKFALL PROTECTION NETTING

ZINC COATED

The mesh consists of double twisted galvanised (Zn) coated

steel woven wire. The mesh is produced in accordance with

standard EN10223-3.The management and production system

is certified in compliance with standards ISO 9001.

Steel woven wire mesh is used as a drapery system to prevent

rocks and debris from falling onto roads and railways.

Dimensions of the Zinc coated net are stated in Table 1.

The nominal tensile strength of the mesh shall be as per Table

2; tests carried out in compliance with EN 10223-3:2013.

The average punching load capacity of the netting is in

compliance with the tests carried out in accordance with UNI

W

11437.

Width

Wire

The steel wire used in the production of the mesh is coated

with Zn class A.

All tests on wire must be performed prior to manufacturing the

mesh. Figure 1

1. Tensile strength: the wire used for the manufacture of

Zinc coated mesh shall have a tensile strength between

350-550 N/mm2 as per EN10223-3:2013. Wire tolerances

(Table 3) are in accordance with EN10218 (Class T1).

2. Elongation: Elongation shall not be less than 8%, as per

EN10223-3:2013.

3. Zinc coating: minimum quantities of Zinc (Table 3) meet the The tolerance on the mesh size

M being the distance between the M

requirements of EN10244-2 (Table 1 - Class A).

axis of two consecutive twists, is

4. Adhesion of Zinc: the adhesion of the Zinc coating to the according to EN 10223-3: 2013

wire must be in accordance with EN 10244.

Figure 2

Example of Rockfall protection netting

Maccaferri reserves the right to amend product specifications without notice and specifiers are requested to

check as to the validity of the specifications they are using.

Table 1 - Sizes for rockfall protection netting 2. Standard mesh - wire combination

L=Length (m) W=Width (m) Nominal Mesh

Wire Average

M Tolerance Tensile

25 2, 3, 4 Type diameter punching

(mm) (mm) Strength

(mm) load kN

50 2, 3, 4 (kN/m)

100 2, 3, 4 6x8 60 -0/+8 2.7 55 82

All sizes and dimensions are nominal.

Tolerances of 0/+1 m of the length, and M of the height shall be 2.7 50 67

8x10 80 -0/+10

permitted 3.0 60 82

3. Standard wire diameter

Lacing Operations

Lacing operations can be made by using the tools shown Mesh wire

Selvedge Lacing

in Fig.5. Zinc coated steel rings having the following wire wire

specification can be used instead of lacing wire (Figs. 3,

4): 2.70 3.40

Internal diameter mm 2.2

3.00 3.90

diameter: 3.00 mm

tensile strength: >1720 MPa Wire tolerance () mm 0.06 0.07 0.06

Pullapart strength > 2.0 kN 245 (2.70) 265 (3.40)

Spacing of the rings must not exceed 200 mm (Fig.3) Min. quantity of coating gr/m2 230

255 (3.00) 275 (3.90)

Quantity Request

When requesting a quote, please specify:

size of rolls (length x height, see Fig.1),

type of mesh,

type of coating

EXAMPLE: No.100 rolls Length=25m, Width=4m - Mesh

type 8x10 - Wire diam. 2.70 mm - Zinc coated

1. Pliers

A 2. Pliers with nipper

3. Nipper

1 2 3

Figure 3: Lacing wire and Rings

B Pneumatic Spenax tool

Open Closed

19 mm

44 mm

Nominal overlap of

25 mm after closure

C Manual tool

Figure 4 Figure 5

MACCAFERRI ASIA

Bureau Veritas Certified Quality System Company with

Unit 3A-11, Block G, Phileo Damansara 1, 9,Jalan 16/11, Off Jalan Damansara, UKAS' s accreditation

46350 Petaling Jaya, Selangor, Malaysia Tel. (+603) 7957 8330 - Fax (+603) 7957 9080

E-mail: regional_hq@maccaferri-asia.com Website: www.maccaferri.com

You might also like

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Polimac Gabion - 0303042018 PDFDocument2 pagesPolimac Gabion - 0303042018 PDFSuntharathevan RamasamyNo ratings yet

- MACCAFERRI TDS-PH-Gabions Zinc 2019-v2Document2 pagesMACCAFERRI TDS-PH-Gabions Zinc 2019-v2Jodel SerranoNo ratings yet

- Rockfall Mesh Technical Data SheetDocument2 pagesRockfall Mesh Technical Data SheetSudipto PaulNo ratings yet

- Tds Gabion GalvanizedDocument2 pagesTds Gabion Galvanizeddinah musyawaroh100% (1)

- Sack Gabions: Technical Data SheetDocument2 pagesSack Gabions: Technical Data SheetSudipto PaulNo ratings yet

- TDS RO GAB GL ENG Rev Jul2014 PDFDocument2 pagesTDS RO GAB GL ENG Rev Jul2014 PDFCatalin GudeiNo ratings yet

- TDS Jumbo Gabion P8+2.2 PVC - PubDocument2 pagesTDS Jumbo Gabion P8+2.2 PVC - PubszemianNo ratings yet

- TDS PH GabionZinc+PVC May2014Document2 pagesTDS PH GabionZinc+PVC May2014SunderNo ratings yet

- 14.Tds-tm-zn+Pvc Ind Eng (10x12)Document2 pages14.Tds-tm-zn+Pvc Ind Eng (10x12)shabenoorNo ratings yet

- Maccaferri - Road Mesh Heavy Duty SpecDocument2 pagesMaccaferri - Road Mesh Heavy Duty SpecNguyen HungNo ratings yet

- TDS Jumbo Gabion P8+2.7 PolimacDocument2 pagesTDS Jumbo Gabion P8+2.7 PolimacszemianNo ratings yet

- Technical Data Sheet for Galvanized GabionsDocument2 pagesTechnical Data Sheet for Galvanized GabionsDharam Singh Jagar SinghNo ratings yet

- Gabiões Zinc CoatedDocument2 pagesGabiões Zinc CoatedAntonio BrasilNo ratings yet

- TS - Helically Formed Fittings For 11 KV and LT LinesDocument17 pagesTS - Helically Formed Fittings For 11 KV and LT LinesAshim BhowmickNo ratings yet

- Data Sheet Gabion GalvDocument2 pagesData Sheet Gabion GalvHafiz MudassirNo ratings yet

- PoliMac Coated Gabion Mattress SpecDocument2 pagesPoliMac Coated Gabion Mattress SpecworkatarNo ratings yet

- TDS - Galmac PVC Coated Gabions June 10Document2 pagesTDS - Galmac PVC Coated Gabions June 10Chana PalominoNo ratings yet

- TS - Double Twist Wire Mesh Mono Oriented CompositeDocument4 pagesTS - Double Twist Wire Mesh Mono Oriented CompositeSOMNATH JANANo ratings yet

- New Steelgrid HR Rockfall NettingDocument2 pagesNew Steelgrid HR Rockfall NettingMario CordovaNo ratings yet

- Reno MattressDocument2 pagesReno MattressnathychidazNo ratings yet

- IS 12779.1989 Steel - Tollerences Hot Rolled Parallel Flange Sections PDFDocument9 pagesIS 12779.1989 Steel - Tollerences Hot Rolled Parallel Flange Sections PDFJostin P JoseNo ratings yet

- Is 12779 1989 PDFDocument9 pagesIs 12779 1989 PDFravi kiranNo ratings yet

- TDS STEELGRID HR SYSTEM - Rev 08 - Jun 2014Document2 pagesTDS STEELGRID HR SYSTEM - Rev 08 - Jun 2014mandeep571No ratings yet

- Steelgrid HR PVC System Datasheet AUDocument2 pagesSteelgrid HR PVC System Datasheet AURodrigo MorgadoNo ratings yet

- Gabion TDSDocument2 pagesGabion TDSPearl ZhaoNo ratings yet

- Earthing Design Procedure & CalculationsDocument35 pagesEarthing Design Procedure & CalculationsAshwin NarayanNo ratings yet

- Tender Specification Gabion MattressesDocument8 pagesTender Specification Gabion Mattressestpushkar9208No ratings yet

- Tools - Earthing Design For LV SystemDocument37 pagesTools - Earthing Design For LV Systemosp005No ratings yet

- Lokfix: Mix and Place Polyester Resin Anchoring GroutsDocument4 pagesLokfix: Mix and Place Polyester Resin Anchoring GroutsMuhamad HisyamNo ratings yet

- TS-Gabion and Geotextile 24082011-R1Document10 pagesTS-Gabion and Geotextile 24082011-R1gopal10120No ratings yet

- Keystone Fire Alarm Cables (Twisted Pair Non Sheathed)Document3 pagesKeystone Fire Alarm Cables (Twisted Pair Non Sheathed)Edwin LoquinaNo ratings yet

- AE Civil Paper IDocument3 pagesAE Civil Paper INaveen KaleraNo ratings yet

- Earthing System Design Tool For Low Voltage InstallationsDocument36 pagesEarthing System Design Tool For Low Voltage InstallationsLim BoraNo ratings yet

- LIMIT STATE DESIGNDocument9 pagesLIMIT STATE DESIGNDiya lizbeth joseNo ratings yet

- CE668 - End Sem Exam-Jul 2021Document3 pagesCE668 - End Sem Exam-Jul 2021santoshNo ratings yet

- Gabion Walls Presentation FijiDocument38 pagesGabion Walls Presentation FijiHuy ChungNo ratings yet

- TDS HEA Panel Galmac C#Document2 pagesTDS HEA Panel Galmac C#szemianNo ratings yet

- CTC Product InformationDocument13 pagesCTC Product InformationPruthvi KrishnaNo ratings yet

- TDS US Gabion Galv May15Document2 pagesTDS US Gabion Galv May15Jhony LucioNo ratings yet

- Hes D3211-99a Mechnical Properties of Steel Bolts and ScreDocument12 pagesHes D3211-99a Mechnical Properties of Steel Bolts and ScrePreetam KumarNo ratings yet

- Uk TDS Steelgrid HR-PVCDocument2 pagesUk TDS Steelgrid HR-PVCKenneth KnoxNo ratings yet

- L01 - TDS - ID - Matren Plus ZN+Polymer - Rev02 - 2021Document2 pagesL01 - TDS - ID - Matren Plus ZN+Polymer - Rev02 - 2021Wika SentiongNo ratings yet

- TDS-US-Gabion, PoliMac-Jan19Document2 pagesTDS-US-Gabion, PoliMac-Jan19johnnee98No ratings yet

- Box GirderDocument8 pagesBox GirderB S Rajput100% (2)

- Rhomboidal Steel Wire Rope Net Panels SpecificationDocument5 pagesRhomboidal Steel Wire Rope Net Panels SpecificationSOMNATH JANANo ratings yet

- Tds Gab Galmac Mce EngDocument2 pagesTds Gab Galmac Mce Enggoe_valceanuNo ratings yet

- TDS SK Green Terramesh Galmac & PVC 8xrev Jul 14Document2 pagesTDS SK Green Terramesh Galmac & PVC 8xrev Jul 14Marjan JerbicNo ratings yet

- Is 278 Draft Galvanized Steel Barbed Wire For Fencing - SpecificationDocument7 pagesIs 278 Draft Galvanized Steel Barbed Wire For Fencing - SpecificationAdonis KumNo ratings yet

- TDS US Gabion Mat, GalMac Jan19Document2 pagesTDS US Gabion Mat, GalMac Jan19johnnee98No ratings yet

- TDS-US-Terramesh GalMac & PVC, July17Document2 pagesTDS-US-Terramesh GalMac & PVC, July17edson_vladimirNo ratings yet

- B 910 - B 910M - 02 Qjkxmc9cotewts1sruqDocument5 pagesB 910 - B 910M - 02 Qjkxmc9cotewts1sruqJuan Sebastián Londoño MartínezNo ratings yet

- Technical Note On Analysis of Support Structure - V2.1Document18 pagesTechnical Note On Analysis of Support Structure - V2.1unnicyriacNo ratings yet

- 1.7 - Is 12779Document6 pages1.7 - Is 12779vrgohilNo ratings yet

- ZTT ACS Strand 7x3.21-1Document4 pagesZTT ACS Strand 7x3.21-1tees220510No ratings yet

- Zinc-Coated Steel Wire Rope and Fittings For Highway GuardrailDocument4 pagesZinc-Coated Steel Wire Rope and Fittings For Highway GuardrailCPA BTKNo ratings yet

- Repot k2Document3 pagesRepot k2Mahendra AdiNo ratings yet

- 1 Scope: 1.1 Normative ReferencesDocument8 pages1 Scope: 1.1 Normative ReferencesYenny300000No ratings yet

- 6.0 Design of Cylindrical ContainerDocument3 pages6.0 Design of Cylindrical ContainerJayNo ratings yet

- TenCate Geolon PE TechnicalData en 502176Document1 pageTenCate Geolon PE TechnicalData en 502176sundra0No ratings yet

- Bi Axial GeogridDocument1 pageBi Axial Geogridsundra0No ratings yet

- Mac DrainDocument24 pagesMac Drainsundra0No ratings yet

- PET Geogrid SeriesDocument1 pagePET Geogrid Seriessundra0No ratings yet

- Macmat: Technical Data SheetDocument2 pagesMacmat: Technical Data Sheetsundra0No ratings yet

- Design of Geocell Reinforced Flexible PavementDocument4 pagesDesign of Geocell Reinforced Flexible Pavementsundra0No ratings yet

- Mactex MXL 35Document1 pageMactex MXL 35sundra0No ratings yet

- Brochure NG Mac Drain NDocument2 pagesBrochure NG Mac Drain Nsundra0No ratings yet

- TN Comparison EngDocument15 pagesTN Comparison Engsundra0100% (1)

- Tds-Mactex N AsiaDocument1 pageTds-Mactex N Asiasundra0100% (1)

- Macgrid Asia BiDocument2 pagesMacgrid Asia Bisundra0No ratings yet

- Airport Runway ExtensionDocument10 pagesAirport Runway ExtensionBalamir YasaNo ratings yet

- Pavement Reinforcement Paper 1Document11 pagesPavement Reinforcement Paper 1sundra0No ratings yet

- River Training Works - WeirsDocument16 pagesRiver Training Works - Weirssundra0No ratings yet

- IG - Eng - MacMat - MacMat R Rev 01 Nov 10Document2 pagesIG - Eng - MacMat - MacMat R Rev 01 Nov 10sundra0No ratings yet

- 2000 07Document15 pages2000 07chithirai10No ratings yet

- ArtigoDocument4 pagesArtigosundra0No ratings yet

- US Marine Raiding ManualDocument170 pagesUS Marine Raiding ManualSOULTAN100% (1)

- AH-64E Apache Attack Helicopter FOT&E Report Assesses Operational EffectivenessDocument44 pagesAH-64E Apache Attack Helicopter FOT&E Report Assesses Operational EffectivenessUser name second nameNo ratings yet

- FAARFIELD Rigid Incl 3D FEMDocument50 pagesFAARFIELD Rigid Incl 3D FEMTim LinNo ratings yet

- IFPSA Master Symbol Chart PDFDocument1 pageIFPSA Master Symbol Chart PDFanush_swaminathanNo ratings yet

- Carrer in MechDocument7 pagesCarrer in MechNithin ChandraNo ratings yet

- Mems 1 16 MarksDocument2 pagesMems 1 16 MarkssubramanikcemechNo ratings yet

- BHT 47G 3B 1 FMDocument82 pagesBHT 47G 3B 1 FMAviacion Jlp100% (3)

- Aerodynamic analysis of curved trailing edge aerofoilsDocument91 pagesAerodynamic analysis of curved trailing edge aerofoilsSheikh Zabed MoyeenNo ratings yet

- SE-622 Issue 14Document21 pagesSE-622 Issue 14Poséidon VahavirakiNo ratings yet

- Follow Health, Safety & Security ProceduresDocument31 pagesFollow Health, Safety & Security ProceduresSash1693No ratings yet

- 3 - 1 Pavement Design - Airfields - UNH - EstimeDocument47 pages3 - 1 Pavement Design - Airfields - UNH - EstimeDavid KisaluNo ratings yet

- ATC Pages IndiaDocument10 pagesATC Pages IndiaRudra GaurNo ratings yet

- Technical Reading 1 Unit IvDocument2 pagesTechnical Reading 1 Unit IvCynthia RodriguezNo ratings yet

- Retwall 1Document7 pagesRetwall 1John SmithNo ratings yet

- 9718.volume 02.amend-1.017Document36 pages9718.volume 02.amend-1.017Basu Dev AryalNo ratings yet

- Senok Aviation Survey 2017Document52 pagesSenok Aviation Survey 2017Dinesh BandaraNo ratings yet

- Siemens UpdatesDocument846 pagesSiemens UpdatescromalestormNo ratings yet

- Kinematics Experiment 102: Velocity and AccelerationDocument1 pageKinematics Experiment 102: Velocity and AccelerationChristopherHiladoNo ratings yet

- WoodDocument24 pagesWoodAhmed LahhamNo ratings yet

- 2017-124 - Aircraft Wheel Assembly - Shipping RequirementsDocument3 pages2017-124 - Aircraft Wheel Assembly - Shipping Requirementsnosh1983No ratings yet

- DFS Aviation Services ATMInsight Flight Procedure Design 1687593951Document9 pagesDFS Aviation Services ATMInsight Flight Procedure Design 1687593951Manuel SchiestlNo ratings yet

- FAA RE&D Committee Vertical Flight SubcommitteeDocument56 pagesFAA RE&D Committee Vertical Flight SubcommitteeMaxwell SmartNo ratings yet

- Short S.20 Mercury SDocument3 pagesShort S.20 Mercury Sseafire47No ratings yet

- 500 MTR Zone Checklist - IsMSBDocument4 pages500 MTR Zone Checklist - IsMSBRamli DisaNo ratings yet

- Cross Reference RolametosDocument3 pagesCross Reference RolametosFABIONo ratings yet

- Vintage Airplane - May 1991Document36 pagesVintage Airplane - May 1991Aviation/Space History Library100% (1)

- Plot No 273 PDFDocument9 pagesPlot No 273 PDFNaresh PrajapatiNo ratings yet

- Approvals and Standardisation Organisation Approvals Docs Part 145 2013 11 25 - Attachment - Documentation IndexDocument3 pagesApprovals and Standardisation Organisation Approvals Docs Part 145 2013 11 25 - Attachment - Documentation Indexdeso tblNo ratings yet

- RvsatDocument14 pagesRvsatAbyan RaidhNo ratings yet

- M14 PropulsionDocument80 pagesM14 PropulsionArslan Shaukat100% (6)