Professional Documents

Culture Documents

Ar Condicionado

Uploaded by

2008profCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ar Condicionado

Uploaded by

2008profCopyright:

Available Formats

2.

6 Air Conditioning (A/C) (Tempmatic) Contents

2.6 Model 163

Diagnosis Page

Function Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11/1

Reading Actual Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12/1

Version Coding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14/1

Diagnostic Trouble Code (DTC) Memory . . . . . . . . . . . . . . . . 15/1

Electrical Test Program

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21/1

Preparation for Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22/1

Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23/1

b Diagnostic Manual Climate Control 12/98 2.6 A/C C/1

2.6 Air Conditioning (A/C) (Tempmatic) Model 163

Diagnosis Function Test

Preparation for Test

Note: Applies for vehicles up to 12/99 production only.

For vehicles as of 12/99 production see 11/2

1. Check condition of fuses: F 16, F 41, F 43, F 44

2. Check in car temperature sensor suction venturi jet

(B10/4) by placing a small piece of paper (approx.

sq.) over suction venturi jet vent grille (arrow) with

ignition ON . If there is sufficient ventilation the paper

will remain on the vent grille.

3. Run engine at idle (approx. 80C coolant temperature)

when performing the entire test procedure.

4. Outside air temperature > 15 C (58 F).

5. Manually open center and side air outlets.

6. Ensure that the 2 button is not depressed.

P83.30-0785-11

7. Set blower fan to stage 4.

b Diagnostic Manual Climate Control 12/99 2.6 A/C 11/1

2.6 Air Conditioning (A/C) (Tempmatic) Model 163

Diagnosis Function Test

Preparation for Test

Note: Applies for vehicles as of 12/99 production only

1. Check condition of fuses: F 16, F 41, F 43, F 44

2. Check in car temperature sensor aspirator blower

(B10/4) by placing a small piece of paper (approx.

sq.) over aspirator blower vent grille (arrow) with ignition

ON . If there is sufficient ventilation the paper will

remain on the vent grille.

3. Run engine at idle (approx. 80C coolant temperature)

when performing the entire test procedure.

4. Outside air temperature > 15 C (58 F).

5. Manually open center and side air outlets.

6. Ensure that the 2 button is not depressed.

7. Set blower fan to stage 1.

P83.30-0785-11

i

Beware of after-run timespan.

b Diagnostic Manual Climate Control 12/99 2.6 A/C 11/2

2.6 Air Conditioning (A/C) (Tempmatic) Model 163

Diagnosis Function Test

Review 11, 12, 15, 21, 22

Review ETM document: PE83.00-P-1100E

Test step/Test sequence Test condition Nominal value Possible cause/Remedy 1)

O 1.0 Defrost Temperature selector wheel in "white Air venting from center vents. 23 O 1.0 9.0

range". Air venting from defroster outlets.

x button indicator lamp is illuminated. A/C compressor engaged.

Air distribution dial set at 12 o'clock

position (vertical).

O 2.0 Normal ventilation in Temperature selector wheel in "white Air venting from lower and upper 23 O 8.0 9.0

regulating mode range". outlets.

x button indicator lamp is illuminated. A/C compressor engaged.

Tempered air from center air outlet.

Air distribution dial set at 4 o'clock

Coolant circulation pump runs at the

position.

same time.

O 3.0 Economy setting not in Temperature selector wheel in "blue Air venting from center air outlets 23 O 8.0

heating mode range". (ambient temperature).

A/C compressor not engaged.

x button indicator lamp is not

illuminated.

Air distribution dial set at 9 o'clock

position.

b Diagnostic Manual Climate Control 12/99 2.6 A/C 11/3

2.6 Air Conditioning (A/C) (Tempmatic) Model 163

Diagnosis Function Test

Test step/Test sequence Test condition Nominal value Possible cause/Remedy 1)

O 4.0 Economy setting in Temperature selector wheel in "red Heated air venting from lower, upper 23 O 8.0

heating mode range". and center air outlets.

A/C compressor not engaged.

x button indicator lamp is not

illuminated.

Air distribution dial set at 4 o'clock

position.

O 5.0 Recirculation mode 2 button is illuminated. Blower fan noise increases noticeablly. Wiring,

Set blower fan to stage 4. Recirculation switch,

Recirculation/fresh air flap actuator

motor (M39).

b Diagnostic Manual Climate Control 12/99 2.6 A/C 11/4

2.6 Air Conditioning (A/C) (Tempmatic) Model 163

Diagnosis Reading Actual Values via Hand-Held tester (HHT)

1. Review 11, 14, 15, 21, 22

2. Connect HHT, see section 0

Test step/Test sequence Test condition Nominal value Possible cause/Remedy 1)

A

0I II - I4 V Wiring,

Circuit 30 Battery.

02 Ignition: ON Operating temperature approx. 80 C Wiring,

Engine temperature Start engine and bring to operating ECT sensor (B11/4),

temperature. All Activity Module (AAM) (N10).

03 Ignition: ON Based on yearly season, Wiring,

Outside air temperature approx. 20 C Outside temperature indicator

temperature sensor (B14),

All Activity Module (AAM) (N10).

04 Ignition: ON ON Wiring,

Blower relay (F1k21) Blower set to stage 4 F1k21,

Voltage supply OFF Blower motor (M2),

All Activity Module (AAM) (N10).

05 Ignition: ON ON Wiring,

Engine cooling fan stage 1 F1k26,

relay (F1k26) OFF Auxiliary fan (M4),

All Activity Module (AAM) (N10).

b Diagnostic Manual Climate Control 12/99 2.6 A/C 12/1

2.6 Air Conditioning (A/C) (Tempmatic) Model 163

Diagnosis Reading Actual Values via Hand-Held tester (HHT)

Test step/Test sequence Test condition Nominal value Possible cause/Remedy 1)

A

08 Ignition: ON ON Wiring,

Circulation pump relay (F1k19) F1k19,

OFF Coolant circulation pump (M13),

All Activity Module (AAM) (N10).

09 Start engine. I2 bar 23 O 9.0

Refrigerant pressure x button is illuminated.

Blower motor set to stage 4

I0 Start engine. ON 23 O 8.0,

A/C compressor (A9) x button is illuminated. All Activity Module (AAM) (N10),

OFF A9

Blower motor set to stage 4

II Ignition: ON YES Wiring,

Activate A/C system A/C pushbutton control module (N19),

NO All Activity Module (AAM) (N10)

b Diagnostic Manual Climate Control 12/99 2.6 A/C 12/2

2.6 Air Conditioning (A/C) (Tempmatic) Model 163

Version Coding

Version coding is performed via the HHT and is menu-driven. In order to readout the version coding of the A/C system, the position 2

Communication is possible as soon as the ignition key is inserted into the must be selected.

ignition switch (the ignition switch position is of no importance). Listed within the above selection, the position 7 is used for version coding

The version coding menu (position 1) is attained via the main menu and of the A/C system.

control module adaption (position 5). The selection of

Within the version coding two possibilities are available: 1. A/C system installed

2. A/C system is not installed

1. Readout of version code and transfer same to new control module. can be used.

2. Readout of version code/alter same.

Version Coding Selection

A/C system Installed/Not installed

b Diagnostic Manual Climate Control 12/99 2.6 A/C 14/1

2.6 Air Conditioning (A/C) (Tempmatic) Model 163

Diagnosis Diagnostic Trouble Code (DTC) Memory

Notes regarding Diagnostic trouble Code Memory Prerequisite for reading out DTC Memory

To each fault (short circuit, open circuit etc) a certain numerical code Electrical wiring diagrams:

has been assigned, i.e. Diagnostic Trouble Code (DTC). Electrical Troubleshooting Manual, Model 163, Group 83

Additionally, current and intermittently appearing DTC's are (available on the Workshop Information System [WIS] only).

differentiated from each other.

When retrieving DTC's from the A/C pushbutton control module, short

circuits and open circuits can not be differentiated from each other in

every case.

When reading out the DTC memory from any control module, all

stored DTC's are shown, which means that some DTCs will be shown

which do not apply to the current system being checked.

Special Tools

965 589 00 01 00 965 589 00 40 00

Hand-Held-Tester Test cable

b Diagnostic Manual Climate Control 12/99 2.6 A/C 15/1

2.6 Air Conditioning (A/C) (Tempmatic) Model 163

Diagnosis Diagnostic Trouble Code (DTC) Memory

Prior to Test:

1. Review 11, 14, 15, 21, 22

2. Connect HHT, see section 0, and read out DTC fault codes.

3. When reading out the DTCs, be aware that same DTCs belong to other control modules, this means that DTCs will appear that do not apply to the

system being checked.

DTC Possible cause Hint Remedy

A

No communication using the HHT is Diagnostic line 23

possible.

No DTC stored No DTC recognized. Complaint valid and present:

See A/C Electrical Test Program - Test 23

BI232 Refrigerant pressure sensor (B12) 23O 9.0

BI4I9 Electromagnetic clutch (A9k1) Wiring,

A9k1

b Diagnostic Manual Climate Control 12/99 2.6 A/C 15/2

2.6 Air Conditioning (A/C) (Tempmatic) Model 163

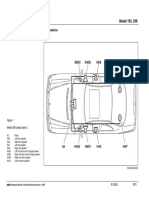

Electrical Test Program Component Locations

Components Location in

Passenger Compartment

P83.30-0806-09

Figure 1 1 Temperature selector wheel R14 Blower motor preresistor group

B10/4 In-car temperature sensor R35 Icing protection temperature sensor

M16/8 Blend air flap actuator motor S98 Heater/AC switch

M39 Recirculation air flap element

b Diagnostic Manual Climate Control 12/99 2.6 A/C 21/1

2.6 Air Conditioning (A/C) (Tempmatic) Model 163

Electrical Test Program Component Locations

Components Location in Passenger

Compartment

As of 12/99

Figure 2

M9 In-car temperature sensor aspirator blower

B10/5 Outside temperature sensor

B10/5x1 Outside temperature sensor connector

P83.30-3353-06

b Diagnostic Manual Climate Control 12/99 2.6 A/C 21/2

2.6 Air Conditioning (A/C) (Tempmatic) Model 163

Electrical Test Program Component Locations

Components Location in Passenger

Compartment

Figure 3

1 Heater/AC switch

2 Cover plate

3 A/C housing

4 Screw

5 Connector

N19 A/C pushbutton control module

P83.30-0752-12

b Diagnostic Manual Climate Control 12/99 2.6 A/C 21/3

2.6 Air Conditioning (A/C) (Tempmatic) Model 163

Electrical Test Program Component Locations

Components Location in Engine Compartment

Figure 4

M4 Auxiliary Fan

M4x1 Auxiliary Fan connector

M13 Coolant circulation pump

N10 All Activity Module (AAM)

P83.30-0803-06

b Diagnostic Manual Climate Control 12/99 2.6 A/C 21/4

2.6 Air Conditioning (A/C) (Tempmatic) Model 163

Electrical Test Program Component Locations

Component Locations of the A/C System

Up to 11/99

1 Expansion valve

2 Evaporator

3 Suction line

4 High pressure line to evaporator

5 High pressure line to receiver/drier

6 Receiver/drier

7 Condenser

8 High pressure line to condensor

A Low pressure connection

B High pressure connection

A9 A/C compressor

B12 Refrigerant pressure sensor

Figure 5

P83.30-0784-06

b Diagnostic Manual Climate Control 12/99 2.6 A/C 21/5

2.6 Air Conditioning (A/C) (Tempmatic) Model 163

Electrical Test Program Component Locations

Component Locations of the A/C System

As of 12/99

1 Expansion valve

2 Evaporator

3 Suction line

4 High pressure line to evaporator

5 High pressure line to condensor

6 Receiver/drier

7 Condenser

8 High pressure line to condensor

A Low pressure connection

B High pressure connection

A9 A/C compressor

B12 Refrigerant pressure sensor

M4/7 Engine/climate control electric cooling fan with

integrated control

N76 Engine/climate control electric cooling fan control

module (shown as insert)

P83.30-3356-06

b Diagnostic Manual Climate Control 12/99 2.6 A/C 21/6

2.6 Air Conditioning (A/C) (Tempmatic) Model 163

Electrical Test Program Preparation for Test

Electrical wiring diagrams:

1. Review 11, 14, 15, 21, 22 Electrical Troubleshooting Manual, Model 163, Group 83.

2. Review electrical diagram: PE83.00-P-1100E (available on the Workshop Information System [WIS] only).

3. Connect HHT, after completion of all test erase DTC memory in N19

4. Review 12

i

Testing of the Recirculated air flap element (M39) is performed in 11

Special Tools

124 589 00 21 00 124 589 37 63 00 163 589 01 63 00

35-pin socket box Fused cable Test cable 14-pin

Test equipment; See MBUSA Standard Service Equipment Program

Description Brand, model, etc.

Digital multimeter Fluke models 23, 77 III, 83, 85, 87

b Diagnostic Manual Climate Control 12/99 2.6 A/C 22/1

2.6 Air Conditioning (A/C) (Tempmatic) Model 163

Electrical Test Program - Preparation for Test

Connection Diagram - Socket box

Figure 1

1 k Multimeter

2 l Socket Box

3 l Test cable

N19 A/C pushbutton control module

P83.30-0790-12

b Diagnostic Manual Climate Control 12/99 2.6 A/C 22/2

2.6 Air Conditioning (A/C) (Tempmatic) Model 163

Electrical Test Program Test

O A Test scope Test connection Test condition Nominal value Possible cause/Remedy

1.0 Voltage supply N19 Ignition: ON 11-14 V Wiring.

Circuit 15 k

9w c L7

2.0 Ground circuit 31 N19 Ignition: OFF 0] Wiring.

Resistance k Disconnect N19 from k.

ow b L9

3.0 In-car temperature N19 Ignition: ON C V Wiring,

sensor (B10/4) k Temperature selector: 20 1.9 B10/4

Voltage 9w c L 12 Red range detent

3.1 In-car temperature N19 Ignition: OFF C k] Wiring,

sensor (B10/4) k Disconnect N19 from k. 20 2.1 B10/4

Resistance 12 w b L2 25 1.7

40 0.9

4.0 Icing protection N19 Ignition: ON C V Wiring,

temperature sensor (R35) k 0 2.0 2.4 R35

Voltage 9w c L 11 15 1.4 1.8

b Diagnostic Manual Climate Control 12/99 2.6 A/C 23/1

2.6 Air Conditioning (A/C) (Tempmatic) Model 163

Electrical Test Program Test

O A Test scope Test connection Test condition Nominal value Possible cause/Remedy

4.1 Icing protection N19 Ignition: OFF C k] Wiring,

temperature sensor (R35) k Disconnect N19 from k. 6 3.6 R35

Resistance 11 w b L3 15 2.3

22 1.7

25 1.5

5.0 Activation voltage N19 Ignition: ON Wiring,

Temperature reduction k Temperature selector: S98s2

Voltage 9w c L 2 From blue range detent >2 V

turn temperature selector

to red detent stop >3 V

5.1 Activation voltage N19 Ignition: ON Wiring,

Temperature increase k Temperature selector: S98s2

Voltage 9w c L 5 From blue range detent >3 V

turn temperature selector

to red detent stop >4 V

6.0 Actuator motor N19 Ignition: ON Wiring,

Blend air flap actuator k Temperature selector: M16/8

motor (M16/8) 9w c L 1 From blue range detent <1V

Voltage

turn temperature selector

to red detent stop 11-14 V

b Diagnostic Manual Climate Control 12/99 2.6 A/C 23/2

2.6 Air Conditioning (A/C) (Tempmatic) Model 163

Electrical Test Program Test

O A Test scope Test connection Test condition Nominal value Possible cause/Remedy

6.1 Actuator motor N19 Ignition: OFF 0.12 k] Wiring,

Blend air flap actuator k Disconnect N19 from k. M16/8

motor (M16/8) 8w b L1

Resistance

7.0 Actuator motor N19 Ignition: ON Wiring,

Blend air flap actuator k Temperature selector: M16/8

motor (M16/8) 9w c L 8 From Red range detent

stop <1 V

turn temperature selector

to blue detent 11-14 V

8.0 Activation of: N19 Ignition: ON Wiring,

A/C switch (S98s3) to A/C k x button is illuminated. S98s3

pushbutton control 9w c L 10

Blower stage 4 <1 V

module (N19)

Voltage

x button is not

illuminated, OR

Blower stage= 0 11 14 V

b Diagnostic Manual Climate Control 12/99 2.6 A/C 23/3

2.6 Air Conditioning (A/C) (Tempmatic) Model 163

Electrical Test Program Test

O A Test scope Test connection Test condition Nominal value Possible cause/Remedy

8.1 Activation of: N19 Ignition: ON Wiring,

A/C pushbutton control k x button is illuminated. N19

module (N19) to All Activity 9w c L4

Blower stage 4 >3 V

Module (N10)

Voltage 11 w u L 4 Insert bridge: <1 V

124 589 37 63 00

9.0 Refrigerant pressure B12 Disconnect refrigerant 4.75-5.25 V Wiring,

sensor (B12) Aw c L B pressure sensor connector B12,

Ignition: ON N10

10.0 Outside temperature N19 Ignition: OFF C k] Wiring,

sensor k Disconnect N19 from 20 2.1 B10/5

(B10/5) 3w b L 12 k 25 1.7

Resistance 40 0.9

(as of 12/99) 50 0.6

b Diagnostic Manual Climate Control 12/99 2.6 A/C 23/4

You might also like

- Dados Tecnicos Mercedes 201Document5 pagesDados Tecnicos Mercedes 2012008profNo ratings yet

- 10002Document9 pages10002ricbxavierNo ratings yet

- CabosDocument14 pagesCabos2008profNo ratings yet

- Service Manual Chassis and Body Series 201Document5 pagesService Manual Chassis and Body Series 201Greg Hanna100% (1)

- Diagrama Control Pressure CableDocument1 pageDiagrama Control Pressure Cable2008profNo ratings yet

- Service Manual Chassis and Body Series 201Document5 pagesService Manual Chassis and Body Series 201Greg Hanna100% (1)

- Manual Problemas Eletricos 190EDocument12 pagesManual Problemas Eletricos 190E2008profNo ratings yet

- Acoustic Warnings2 - FunctionDocument1 pageAcoustic Warnings2 - Function2008profNo ratings yet

- Freio Content PDFDocument16 pagesFreio Content PDF2008profNo ratings yet

- Som p21 PDFDocument3 pagesSom p21 PDF2008profNo ratings yet

- Center Console - (Up To 31.08.01) - Rear Center Section of ConsoleDocument1 pageCenter Console - (Up To 31.08.01) - Rear Center Section of Console2008profNo ratings yet

- A Covers C Screws B Nuts: Remove/installDocument2 pagesA Covers C Screws B Nuts: Remove/install2008profNo ratings yet

- Abrir Garagem p23 PDFDocument3 pagesAbrir Garagem p23 PDF2008profNo ratings yet

- Roland Resource Book PDFDocument201 pagesRoland Resource Book PDF2008prof100% (1)

- 22.1 Garage Door Opener (GDO) Model 129, 163, 170, 202, 208, 210, 215, 220Document2 pages22.1 Garage Door Opener (GDO) Model 129, 163, 170, 202, 208, 210, 215, 2202008profNo ratings yet

- Airbag SaftyDocument1 pageAirbag Safty2008profNo ratings yet

- Esquema Fusiveis ml320Document5 pagesEsquema Fusiveis ml3202008profNo ratings yet

- 5.12 Loudspeaker System (LS) Model 163, 208: Electrical Test Program - Component LocationsDocument3 pages5.12 Loudspeaker System (LS) Model 163, 208: Electrical Test Program - Component Locations2008profNo ratings yet

- XP-80 System UpdateDocument1 pageXP-80 System Update2008profNo ratings yet

- Abrir Garagem p23Document3 pagesAbrir Garagem p232008profNo ratings yet

- Freio ContentDocument16 pagesFreio Content2008profNo ratings yet

- AR68.10-P-1520GH Remove/install Cover Below Instrument Panel (Right) 4.2.97Document1 pageAR68.10-P-1520GH Remove/install Cover Below Instrument Panel (Right) 4.2.972008profNo ratings yet

- Midi Guide Manual RolandDocument27 pagesMidi Guide Manual RolandJoeriDD100% (1)

- Accelerator Control 30014Document1 pageAccelerator Control 300142008profNo ratings yet

- Accelerator Control 30014 PDFDocument14 pagesAccelerator Control 30014 PDF2008profNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Toshiba AC RAS 16 Service ManualDocument108 pagesToshiba AC RAS 16 Service ManualCiortan TiberiuNo ratings yet

- Sea Water Air Conditioning - Makai Ocean Engineering PDFDocument7 pagesSea Water Air Conditioning - Makai Ocean Engineering PDFRishabh Melwanki100% (1)

- Ventilation Checklist: Instructions 1. Outdoor Air IntakesDocument6 pagesVentilation Checklist: Instructions 1. Outdoor Air IntakesUntung SuropatNo ratings yet

- Service Bulletin: Heater/Air Conditioner Cab Control Board Fuse - CX, CV, CH and CL Models With Bergstrom Hvac UnitDocument3 pagesService Bulletin: Heater/Air Conditioner Cab Control Board Fuse - CX, CV, CH and CL Models With Bergstrom Hvac UnitPhil B.No ratings yet

- As-T-T022 S11 Body Electric SystemDocument91 pagesAs-T-T022 S11 Body Electric SystemJunior Edder Aguilar Apolaya100% (1)

- XPower Safirus Brochure Bifold v11Document2 pagesXPower Safirus Brochure Bifold v11Eduardo GarcíaNo ratings yet

- ATZ Worldwide EMagazine Volume 115 Issue 11 2013 (Doi 10.1007/s38311-013-0128-1) Dr.-Ing. Manuel Wehowski, Dr.-Ing. Jürgen Grünwald - Thermoelectric Heat Pump For Lithium-Ion BatteriesDocument6 pagesATZ Worldwide EMagazine Volume 115 Issue 11 2013 (Doi 10.1007/s38311-013-0128-1) Dr.-Ing. Manuel Wehowski, Dr.-Ing. Jürgen Grünwald - Thermoelectric Heat Pump For Lithium-Ion BatteriesEliasA.TiongkiaoNo ratings yet

- Manual AerDocument8 pagesManual AergigelNo ratings yet

- ACC WE GCL0001 Legionnella DirectiveDocument15 pagesACC WE GCL0001 Legionnella DirectivetienlamNo ratings yet

- Air Conditioning SystemsDocument3 pagesAir Conditioning SystemsArman Ul NasarNo ratings yet

- NMS Complete English TOC 1-11-18Document33 pagesNMS Complete English TOC 1-11-18Anonymous BAzcBzWuNo ratings yet

- Mining SoftwareDocument12 pagesMining SoftwaresunilsinghmNo ratings yet

- A New Synthetic Hybrid Refrigeration Oil For R410A and R407CDocument7 pagesA New Synthetic Hybrid Refrigeration Oil For R410A and R407CoioizoiiNo ratings yet

- Ar CarrosDocument82 pagesAr Carroskeila_aline_2No ratings yet

- JPT Davao - Akri QuizDocument311 pagesJPT Davao - Akri QuizDaniell Ives Casicas100% (1)

- 2021-Sakhri-New Passive Thermal Comfort System Using Three Renewable - Wind Tower-SC and GAHEDocument18 pages2021-Sakhri-New Passive Thermal Comfort System Using Three Renewable - Wind Tower-SC and GAHEraviNo ratings yet

- AHRICertificate (18) MOVB - 36CDN1 - M18MDocument1 pageAHRICertificate (18) MOVB - 36CDN1 - M18Mfrio industrialNo ratings yet

- Roof Top - R407C YorkDocument64 pagesRoof Top - R407C YorkAmro Metwally El HendawyNo ratings yet

- 2018 MHG-R410a SpecDocument2 pages2018 MHG-R410a SpecEmilio MatarNo ratings yet

- 50zpb-05pd Carrier 024 Btu PDFDocument18 pages50zpb-05pd Carrier 024 Btu PDFmicerinosNo ratings yet

- Ize04001a HKGSG v1 02manualDocument46 pagesIze04001a HKGSG v1 02manualfebime100% (1)

- DesignBuilder 2.1 Users-Manual LTRDocument642 pagesDesignBuilder 2.1 Users-Manual LTREsteban Omar Bugueño Lara100% (1)

- Rasb 10 GkvpeDocument134 pagesRasb 10 GkvpeAR&MENDES ENGENHARIANo ratings yet

- (Carrier) HVAC Handbook - New Edition - Part.7 - Refrigeration EquipmentDocument71 pages(Carrier) HVAC Handbook - New Edition - Part.7 - Refrigeration Equipmentlyly20983% (6)

- Hybrid MemranDocument35 pagesHybrid MemranDianita Citra DewiNo ratings yet

- Split-Type Air Conditioners: Indoor UnitDocument24 pagesSplit-Type Air Conditioners: Indoor UnitRichard RoperNo ratings yet

- Catalogo HFCADocument14 pagesCatalogo HFCALê TrungNo ratings yet

- 301.hydraulic Separator Calculating Its Heating PowerDocument3 pages301.hydraulic Separator Calculating Its Heating PoweramandaNo ratings yet

- Multi V Catalog - Europe (50Hz, R410A)Document46 pagesMulti V Catalog - Europe (50Hz, R410A)Maxmore KarumamupiyoNo ratings yet

- Earth Air Heat Exchanger PerformanceDocument4 pagesEarth Air Heat Exchanger Performanceviraj shettyNo ratings yet