Professional Documents

Culture Documents

Xfmea Dfmea PDF

Xfmea Dfmea PDF

Uploaded by

veenamkOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Xfmea Dfmea PDF

Xfmea Dfmea PDF

Uploaded by

veenamkCopyright:

Available Formats

REPORT SUMMARY Date: 9/1/2015

Page 1 of 9

In addition to this summary, this report includes the following forms:

Rating Criteria and Classifications

J1739 (2009)

Recommended Actions

Current Controls

Xfmea Report Sample Design FMEA

This report was generated with ReliaSofts Xfmea software in Microsoft Word. Similar reports can also be

generated in Microsoft Excel. You can easily replace the Xfmea logo graphic with your own company

logo. Within Word and Excel, reports can be edited/annotated, if necessary, and generated in PDF

and/or HTML format for easy distribution.

This report includes:

A summary of the rating criteria (Severity Scale, Occurrence Scale, Detection Scale) and

classifications that were used in the analysis.

The Design FMEA (DFMEA) spreadsheet report in the SAE J1739 reporting format.

A summary list of the recommended actions identified during the analysis.

A summary list of the current controls identified during the analysis.

Some graphical charts that were generated in Xfmeas Plot Viewer and copy/pasted into the report

document, along with chart legend information. These include:

o Pareto (bar) chart of the cause RPNs, ranked by initial RPN.

o Pie chart demonstrating the number of causes assigned to each available Occurrence rating.

o Pie chart demonstrating the number of causes assigned to each available Detection rating.

The report is based on the sample analysis provided in the SAE J1739 guidelines, on page 37.

Non-proprietary and non-confidential information.

Date Created: 9/1/2015 Creator ReliaSoft Corporation Generated by ReliaSoft's Xfmea Software http://www.ReliaSoft.com

RATING CRITERIA AND CLASSIFICATIONS Date: 9/1/2015

Page 2 of 9

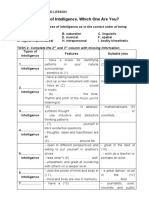

Severity Rating Scale Occurrence Rating Scale

# Description Criteria 1 # Description Criteria

1 No Effect No discernible effect. 1 Very Low Failure is eliminated through preventative control.

Appearance or Audible Noise, vehicle operable, item

No observed failures associated with almost identical

2 Annoyance does not conform. Defect noticed by discriminating 2 Low

design or in design simulation and testing.

customers (< 25%).

Appearance or Audible Noise, vehicle operable, item

Only isolated failures associated with almost identical

3 Annoyance does not conform. Defect noticed by many customers 3 Low

design or in design simulation and testing.

(50%).

Appearance or Audible Noise, vehicle operable, item

Isolated failures associated with similar design or in

4 Annoyance does not conform. Defect noticed by most customers (> 4 Moderate

design simulation and testing.

75%).

Degradation of secondary function (vehicle operable, but

Occasional failures associated with similar designs or in

5 Degradation of Secondary Function comfort / convenience functions at reduced level of 5 Moderate

design simulation and testing.

performance).

Loss of secondary function (vehicle operable, but Frequent failures associated with similar designs or in

6 Loss of Secondary Function 6 Moderate

comfort / convenience functions inoperable). design simulation and testing.

Degradation of primary function (vehicle operable, but at Failure is uncertain with new design, new application, or

7 Degradation of Primary Function 7 High

reduced level of performance). change in duty cycle/operating conditions.

Loss of primary function (vehicle inoperable, does not Failure is likely with new design, new application, or

8 Loss of Primary Function 8 High

affect safe vehicle operation). change in duty cycle/operating conditions.

Potential failure mode affects safe vehicle operation

Failure is inevitable with new design, new application, or

9 Safety and/or Regulatory Compliance and/or involves noncompliance with government 9 High

change in duty cycle/operating conditions.

regulation with warning.

Potential failure mode affects safe vehicle operation

10 Safety and/or Regulatory Compliance and/or involves noncompliance with government 10 Very High New technology/new design with no history.

regulation without warning.

Detection Rating Scale Classification Options

# Description Criteria 1 Abbreviation Description

Failure cause or failure mode cannot occur because it is

Detection Not Applicable - Failure

1 fully prevented through design solutions (e.g. Proven C Critical

Prevention

design standard/best practice or common material, etc.).

Design analysis/detection controls have a strong

detection capability. Virtual Analysis (e.g. CAE, FEA, etc.)

2 Virtual Analysis - Correlated KI Key Intermediate

is highly correlated with actual and/or expected

operating conditions prior to design freeze.

Product validation (reliability testing, development or

3 Prior to Design Freeze validation tests) prior to design freeze using degradation KLd Key Leading

testing (e.g. data trends, before/after values, etc.).

Product validation (reliability testing, development or

4 Prior to Design Freeze validation tests) prior to design freeze using test to KLg Key Lagging

failure (e.g. until leaks, yields, cracks, etc.).

Product validation (reliability testing, development or

validation tests) prior to design freeze using pass/fail

5 Prior to Design Freeze S Significant

testing (e.g. acceptance criteria for performance,

function checks, etc.).

Product verification/validation after design freeze and

6 Post Design Freeze and Prior to Launch prior to launch with degradation testing (Sub-system or KPC Key Product Characteristic

system testing after durability test e.g. Function check).

Non-proprietary and non-confidential information.

Date Created: 9/1/2015 Creator ReliaSoft Corporation Generated by ReliaSoft's Xfmea Software http://www.ReliaSoft.com

RATING CRITERIA AND CLASSIFICATIONS Date: 9/1/2015

Page 3 of 9

Product verification/validation after design freeze and

prior to launch with test to failure testing (Sub-system or

7 Post Design Freeze and Prior to Launch KCC Key Control Characteristic

system testing until failure occurs, testing of system

interactions, etc.).

Product verification/validation after design freeze and

prior to launch with pass/fail testing (Sub-system or

8 Post Design Freeze and Prior to Launch

system testing with acceptance criteria e.g. Ride &

handling, shipping evaluation, etc.).

Design analysis/detection controls have a weak detection

9 Difficult to Detect capability; Virtual Analysis (e.g. CAE, FEA, etc.) is not

correlated to expected actual operating conditions.

No current design control; Cannot detect or is not

10 Absolute Uncertainty

analyzed.

Non-proprietary and non-confidential information.

Date Created: 9/1/2015 Creator ReliaSoft Corporation Generated by ReliaSoft's Xfmea Software http://www.ReliaSoft.com

FAILURE MODE AND EFFECTS ANALYSIS

Front Door L.H

Item 1.1.1 - Front Door L.H DFMEA Number 1234

Model Year/Program(s) 201X/Lion 3dr/Wagon Key Date 7/3/2015

DFMEA Owner (Design Resp.) Body Engineering Prepared By A. Tate - X6412 - Body Engr

T. Fender - Car Product Dev., C. Childers - Manufacturing, J. Ford -

6/29/2015

Core Team / Facilitator Assy Ops (Dalton, Fraser, Henley Assembly Plants) Original Completion Date

Support Team

Action Results

Classification

Potential Potential Current Design Current Design

Potential Failure Recommended Responsibility & Planned

RPNi

OCCi

DETi

SEVi

Name / Function Effect(s) of Cause(s) of Controls Controls Actions Taken &

RPNr

OCCr

DETr

Mode Actions Completion Date

SEVr

Failure Failure (Prevention) (Detection) Actual Completion

Date

Front Door L.H

- Ingress to and Corroded interior Deteriorated life of 7 Upper edge of 6 Vehicle general 7 294 Add laboratory A. Tate Body 6/29/2015 Based on test results 7 2 2 28

egress from low door panels door leading to: protective wax durability test veh. accelerated Engrg (Test No. 1481)

vehicle. - Unsatisfactory application T-118 corrosion testing upper edge spec

- Occupant appearance due to specified for inner T-109 raised 125mm.

protection from rust through paint door panels is too T-301 - 6/29/2015

weather, noise, over time. low.

and side impact. - Impaired function

Insufficient wax 4 Vehicle general 7 196 Add laboratory A. Tate Body 6/30/2015 Test results (Test 2 2 28

- Support of interior door

thickness specified durability testing - accelerated Engrg No. 1481) show

anchorage for door hardware.

as above. corrosion testing. specified thickness is

hardware including

adequate. -

mirror, hinges,

6/29/2015

latch and window

regulator.

- Provide proper Conduct Design of A. Tate Body 7/1/2015 DOE shows 25%

surface for Experiments (DOE) Engrg variation in specified

appearance items - on wax thickness. thickness is

paint and soft trim. acceptable.

- 7/1/2015

Inappropriate wax 2 Physical and Chem 2 28 2 2 28

formulation Lab test - Report

specified. No. 1265.

Entrapped air 5 Design aid 8 280 Add team evaluation Body Engrg & 7/2/2015 Based on test, 1 3 21

prevents wax from investigation with using production Assy Ops additional vent holes

entering nonfunctioning spray equipment will be provided in

corner/edge spray head. and specified wax. affected areas.

access. - 7/2/2015

Wax application 3 Laboratory test 1 21 3 1 21

plugs door drain using "worst case"

holes wax application

and hole size.

Insufficient room 4 Drawing evaluation 4 112 Add team evaluation Body Engrg & 7/2/2015 Evaluation showed 1 1 7

between panels for of spray head using design aid Assy Ops adequate access.

spray head access. access. buck and spray - 7/2/2015

head.

Non-proprietary and non-confidential information.

Date Created: 9/1/2015 Creator ReliaSoft Corporation Generated by ReliaSoft's Xfmea Software http://www.ReliaSoft.com

RECOMMENDED ACTIONS Date: 9/1/2015

Page 5 of 9

# Recommended Action(s) Target Completion Date Responsibility Actions Taken Item Potential Cause(s)/Mechanism(s) of Failure Priority

1 Add laboratory accelerated 6/29/2015 A. Tate Body Engrg Based on test results (Test No. 1481) upper edge spec raised 125mm. Front Door Upper edge of protective wax application specified for Medium

corrosion testing L.H inner door panels is too low.

2 Add laboratory accelerated 6/30/2015 A. Tate Body Engrg Test results (Test No. 1481) show specified thickness is adequate. Front Door Insufficient wax thickness specified Medium

corrosion testing. L.H

3 Conduct Design of Experiments 7/1/2015 A. Tate Body Engrg DOE shows 25% variation in specified thickness is acceptable. Front Door Insufficient wax thickness specified Medium

(DOE) on wax thickness. L.H

4 Add team evaluation using 7/2/2015 Body Engrg & Assy Based on test, additional vent holes will be provided in affected areas. Front Door Entrapped air prevents wax from entering corner/edge Medium

production spray equipment Ops L.H access.

and specified wax.

5 Add team evaluation using 7/2/2015 Body Engrg & Assy Evaluation showed adequate access. Front Door Insufficient room between panels for spray head Medium

design aid buck and spray Ops L.H access.

head.

Non-proprietary and non-confidential information.

Date Created: 9/1/2015 Creator ReliaSoft Corporation Generated by ReliaSoft's Xfmea Software http://www.ReliaSoft.com

CURRENT CONTROLS Date: 9/1/2015

Page 6 of 9

# Current Design Controls Control Type Item Name (Function) Potential Failure Mode Potential Effect(s) of Failure Potential Cause(s)/Mechanism(s) of Failure

1 Vehicle general durability test veh. Detection Front Door - Ingress to and egress Corroded interior low door panels Deteriorated life of door leading to:-- Upper edge of protective wax application specif...

T-118 L.H from vehicle.-- Occupan... Unsatis...

T-109

T-301

2 Vehicle general durability testing - Detection Front Door - Ingress to and egress Corroded interior low door panels Deteriorated life of door leading to:-- Insufficient wax thickness specified

as above. L.H from vehicle.-- Occupan... Unsatis...

3 Physical and Chem Lab test - Detection Front Door - Ingress to and egress Corroded interior low door panels Deteriorated life of door leading to:-- Inappropriate wax formulation specified.

Report No. 1265. L.H from vehicle.-- Occupan... Unsatis...

4 Design aid investigation with Detection Front Door - Ingress to and egress Corroded interior low door panels Deteriorated life of door leading to:-- Entrapped air prevents wax from entering corner...

nonfunctioning spray head. L.H from vehicle.-- Occupan... Unsatis...

5 Laboratory test using "worst case" Detection Front Door - Ingress to and egress Corroded interior low door panels Deteriorated life of door leading to:-- Wax application plugs door drain holes

wax application and hole size. L.H from vehicle.-- Occupan... Unsatis...

6 Drawing evaluation of spray head Detection Front Door - Ingress to and egress Corroded interior low door panels Deteriorated life of door leading to:-- Insufficient room between panels for spray head...

access. L.H from vehicle.-- Occupan... Unsatis...

Non-proprietary and non-confidential information.

Date Created: 9/1/2015 Creator ReliaSoft Corporation Generated by ReliaSoft's Xfmea Software http://www.ReliaSoft.com

CHARTS Date: 9/1/2015

Page 7 of 9

Database: C:\Xfmea Demo.rsr10

Project: Design FMEA

Selected Items:

1.1.1 - Front Door L.H

Causes Ranked by Initial RPN (1 - 6)

1: RPNi = 294, RPNr = 28 - Upper edge of protective wax

application specified for inner door panels is too low. (Item:

1.1.1 - Front Door L.H)

2: RPNi = 280, RPNr = 21 - Entrapped air prevents wax from

entering corner/edge access. (Item: 1.1.1 - Front Door L.H)

3: RPNi = 196, RPNr = 28 - Insufficient wax thickness

specified (Item: 1.1.1 - Front Door L.H)

4: RPNi = 112, RPNr = 7 - Insufficient room between panels

for spray head access. (Item: 1.1.1 - Front Door L.H)

5: RPNi = 28, RPNr = 28 - Inappropriate wax formulation

specified. (Item: 1.1.1 - Front Door L.H)

6: RPNi = 21, RPNr = 21 - Wax application plugs door drain

holes (Item: 1.1.1 - Front Door L.H)

Non-proprietary and non-confidential information.

Date Created: 9/1/2015 Creator ReliaSoft Corporation Generated by ReliaSoft's Xfmea Software http://www.ReliaSoft.com

CHARTS Date: 9/1/2015

Page 8 of 9

Database: C:\Xfmea Demo.rsr10

Project: Design FMEA

Selected Items:

1.1.1 - Front Door L.H

Causes by Initial Occurrence Rating

Not Assigned: Qty 0 (0%)

1 - Very Low: Qty 0 (0%)

2 - Low: Qty 1 (16.67%)

3 - Low: Qty 1 (16.67%)

4 - Moderate: Qty 2 (33.33%)

5 - Moderate: Qty 1 (16.67%)

6 - Moderate: Qty 1 (16.67%)

7 - High: Qty 0 (0%)

8 - High: Qty 0 (0%)

9 - High: Qty 0 (0%)

10 - Very High: Qty 0 (0%)

Non-proprietary and non-confidential information.

Date Created: 9/1/2015 Creator ReliaSoft Corporation Generated by ReliaSoft's Xfmea Software http://www.ReliaSoft.com

CHARTS Date: 9/1/2015

Page 9 of 9

Database: C:\Xfmea Demo.rsr10

Project: Design FMEA

Selected Items:

1.1.1 - Front Door L.H

Causes by Initial Detection Rating

Not Assigned: Qty 0 (0%)

1 - Detection Not Applicable - Failure Prevention: Qty 1

(16.67%)

2 - Virtual Analysis - Correlated: Qty 1 (16.67%)

3 - Prior to Design Freeze: Qty 0 (0%)

4 - Prior to Design Freeze: Qty 1 (16.67%)

5 - Prior to Design Freeze: Qty 0 (0%)

6 - Post Design Freeze and Prior to Launch: Qty 0 (0%)

7 - Post Design Freeze and Prior to Launch: Qty 2 (33.33%)

8 - Post Design Freeze and Prior to Launch: Qty 1 (16.67%)

9 - Difficult to Detect: Qty 0 (0%)

10 - Absolute Uncertainty: Qty 0 (0%)

Non-proprietary and non-confidential information.

Date Created: 9/1/2015 Creator ReliaSoft Corporation Generated by ReliaSoft's Xfmea Software http://www.ReliaSoft.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Banned Mind Control Techniques Unleashed Daniel SmithDocument676 pagesBanned Mind Control Techniques Unleashed Daniel SmithAgus Sanusi0% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Chiller 19xrDocument48 pagesChiller 19xrMarco SosaNo ratings yet

- Innovation Funnel TemplateDocument1 pageInnovation Funnel TemplateIdehen KelvinNo ratings yet

- UBA2014 Evaluation Board: Rev. 01 - 14 October 2009 User ManualDocument24 pagesUBA2014 Evaluation Board: Rev. 01 - 14 October 2009 User ManualIdehen KelvinNo ratings yet

- Me-19F Massuse Relay: FeaturesDocument4 pagesMe-19F Massuse Relay: FeaturesIdehen KelvinNo ratings yet

- Geared DC Instrument Motor 1308 SeriesDocument1 pageGeared DC Instrument Motor 1308 SeriesIdehen KelvinNo ratings yet

- Friction Forces in O-Ring SealingDocument8 pagesFriction Forces in O-Ring SealingIdehen KelvinNo ratings yet

- OringDocument1 pageOringIdehen KelvinNo ratings yet

- Item # Oh, Pneumatic Valve Actuators: Pressures To 150000 Psi (10342 Bar)Document2 pagesItem # Oh, Pneumatic Valve Actuators: Pressures To 150000 Psi (10342 Bar)Idehen KelvinNo ratings yet

- Overview of Materials For Polyimide: To View All Available Suppliers For This MaterialDocument3 pagesOverview of Materials For Polyimide: To View All Available Suppliers For This MaterialIdehen KelvinNo ratings yet

- OringDocument1 pageOringIdehen KelvinNo ratings yet

- In Line High Flow' Insertion Type Regulators For 4" - 8" PipeworkDocument2 pagesIn Line High Flow' Insertion Type Regulators For 4" - 8" PipeworkIdehen KelvinNo ratings yet

- LF310 Datasheet: Low-Flow Pressure RegulatorDocument4 pagesLF310 Datasheet: Low-Flow Pressure RegulatorIdehen KelvinNo ratings yet

- HYD691 Datasheet: Introducing The Hyd691... Standard Materials of ConstructionDocument4 pagesHYD691 Datasheet: Introducing The Hyd691... Standard Materials of ConstructionIdehen KelvinNo ratings yet

- LR-360KAS-BROCHURE-LNG Sampling SystemsDocument4 pagesLR-360KAS-BROCHURE-LNG Sampling SystemsIdehen KelvinNo ratings yet

- Item # Oh, Pneumatic Valve Actuators: Pressures To 150000 Psi (10342 Bar)Document2 pagesItem # Oh, Pneumatic Valve Actuators: Pressures To 150000 Psi (10342 Bar)Idehen KelvinNo ratings yet

- LF311 Datasheet: Low-Flow Pressure RegulatorDocument4 pagesLF311 Datasheet: Low-Flow Pressure RegulatorIdehen KelvinNo ratings yet

- HF250 Datasheet: High-Flow Pressure RegulatorDocument4 pagesHF250 Datasheet: High-Flow Pressure RegulatorIdehen KelvinNo ratings yet

- OH ParkerAutoclaveEngineersFCD 2DSalesDrawing 01 06 2021 PDFDocument1 pageOH ParkerAutoclaveEngineersFCD 2DSalesDrawing 01 06 2021 PDFIdehen KelvinNo ratings yet

- BP-HF301 Datasheet: High-Flow Back Pressure RegulatorDocument4 pagesBP-HF301 Datasheet: High-Flow Back Pressure RegulatorIdehen KelvinNo ratings yet

- HF300 Datasheet: High-Flow Pressure RegulatorDocument4 pagesHF300 Datasheet: High-Flow Pressure RegulatorIdehen KelvinNo ratings yet

- BP-HF251 Datasheet: High-Flow Back Pressure RegulatorDocument4 pagesBP-HF251 Datasheet: High-Flow Back Pressure RegulatorIdehen KelvinNo ratings yet

- 2-Stage Servo Valve Nozzle Flapper, Mechanical Feedback Design and OperationDocument3 pages2-Stage Servo Valve Nozzle Flapper, Mechanical Feedback Design and OperationIdehen KelvinNo ratings yet

- BP301 Datasheet: Back Pressure RegulatorDocument4 pagesBP301 Datasheet: Back Pressure RegulatorIdehen KelvinNo ratings yet

- Installation and Commisioning of Servo & Propotional Control ValvesDocument3 pagesInstallation and Commisioning of Servo & Propotional Control ValvesIdehen KelvinNo ratings yet

- BP010 Datasheet For Pressure RegulatorDocument4 pagesBP010 Datasheet For Pressure RegulatorIdehen KelvinNo ratings yet

- Technology Focus: Three Keys To Specifying Long Life Servo ValvesDocument2 pagesTechnology Focus: Three Keys To Specifying Long Life Servo ValvesIdehen KelvinNo ratings yet

- Material Cascade Pinch AnalysisDocument3 pagesMaterial Cascade Pinch AnalysisLala LuluNo ratings yet

- Aircraft BasicsDocument8 pagesAircraft BasicsSantosh Patil Sunny100% (1)

- Library Management System - RudrahariDocument62 pagesLibrary Management System - RudrahariNitesh Bhura100% (4)

- Magnetic Force Analysis in A Gapped-Core Reactor Model Under Harmonic Magnetizations by Efficient Frequency-Domain DecompositionDocument2 pagesMagnetic Force Analysis in A Gapped-Core Reactor Model Under Harmonic Magnetizations by Efficient Frequency-Domain DecompositionKiran KarthikNo ratings yet

- Powercfg Command-Line OptionsDocument15 pagesPowercfg Command-Line OptionsNiko PaNo ratings yet

- 5 Qualities of A Highly Successful ActorDocument2 pages5 Qualities of A Highly Successful ActorTuan PnNo ratings yet

- MA 103 SlidesDocument11 pagesMA 103 SlidessarisNo ratings yet

- IELTS Listening Part 1Document17 pagesIELTS Listening Part 1GiangNo ratings yet

- Mri and Hearing LossDocument6 pagesMri and Hearing LossadriricaldeNo ratings yet

- Detailed Lesson Plan in Math 5Document6 pagesDetailed Lesson Plan in Math 5Mountain DrewNo ratings yet

- Object Detection in A Cluttered Scene Using Point Feature MatchingDocument2 pagesObject Detection in A Cluttered Scene Using Point Feature MatchingRoopali TharanipathyNo ratings yet

- Deimos-2 - Satellite Missions - EoPortal DirectoryDocument22 pagesDeimos-2 - Satellite Missions - EoPortal Directorynab05No ratings yet

- Killzone Rules v3Document25 pagesKillzone Rules v3dracomaxisNo ratings yet

- TOK Essay - "Context Is All"Document3 pagesTOK Essay - "Context Is All"VivarisNo ratings yet

- Government of India Department of Information Technology, MCIT National Informatics CentreDocument2 pagesGovernment of India Department of Information Technology, MCIT National Informatics CentreDawn RiddleNo ratings yet

- Apple Tree Lesson PlanDocument4 pagesApple Tree Lesson Planapi-372756780No ratings yet

- Is 10719 (Iso 1302) - 14Document1 pageIs 10719 (Iso 1302) - 14Svapnesh ParikhNo ratings yet

- CivilDocument184 pagesCivilPiyush KumarNo ratings yet

- RFIC Inductor ToolkitDocument39 pagesRFIC Inductor ToolkitstepannpNo ratings yet

- Question 13Document4 pagesQuestion 13HotSpireNo ratings yet

- Windows HackingDocument69 pagesWindows HackingLuis Miguel Blad100% (1)

- σcosθ ρgd σ = surface tension in N/m θ = wetting angle, 0 for water d = diameter of tube in m ρ = density of fluidDocument1 pageσcosθ ρgd σ = surface tension in N/m θ = wetting angle, 0 for water d = diameter of tube in m ρ = density of fluidJustine Ejay MoscosaNo ratings yet

- 11 Anh INTENSIVE LISTENING LESSON 01.12Document2 pages11 Anh INTENSIVE LISTENING LESSON 01.12Ha Huy KhanhNo ratings yet

- Latihan NormalisasiDocument3 pagesLatihan NormalisasiFadil0% (1)

- Islamic University: Regular Examination Form (July - 2015)Document2 pagesIslamic University: Regular Examination Form (July - 2015)WaniBazillaNo ratings yet

- Chemistry Project AliDocument21 pagesChemistry Project AliWajahat AliNo ratings yet

- Scientific Explanation of GITADocument29 pagesScientific Explanation of GITARamakrishna ReddyNo ratings yet

- User Guide IRCTCDocument23 pagesUser Guide IRCTCManoj KumarNo ratings yet