Professional Documents

Culture Documents

Overview of Materials For Polyimide: To View All Available Suppliers For This Material

Uploaded by

Idehen KelvinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Overview of Materials For Polyimide: To View All Available Suppliers For This Material

Uploaded by

Idehen KelvinCopyright:

Available Formats

Overview of materials for Polyimide

Categories: Polymer; Thermoplastic; Polyimide, Thermoplastic

Material This property data is a summary of similar materials in the MatWeb database for the category "Polyimide". Each property range of values reported is minimum

Notes: and maximum values of appropriate MatWeb entries. The comments report the average value, and number of data points used to calculate the average. The

values are not necessarily typical of any specific grade, especially less common values and those that can be most affected by additives or processing

methods.

Vendors: Click here to view all available suppliers for this material.

Please click here if you are a supplier and would like information on how to add your listing to this material.

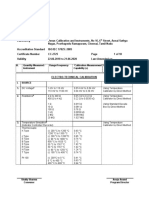

Physical Properties Metric English Comments

Density 0.00545 - 1.88 g/cc 0.000197 - 0.0679 lb/in³ Average value: 1.34 g/cc Grade Count:157

Filler Content 0.000 - 40.0 % 0.000 - 40.0 % Average value: 22.9 % Grade Count:33

Water Absorption 0.0400 - 1.86 % 0.0400 - 1.86 % Average value: 0.481 % Grade Count:73

0.260 - 3.15 % 0.260 - 3.15 % Average value: 1.73 % Grade Count:17

@Temperature 50.0 - 80.0 °C @Temperature 122 - 176 °F

0.900 - 3.29 % 0.900 - 3.29 % Average value: 1.73 % Grade Count:11

@Temperature 50.0 - 80.0 °C @Temperature 122 - 176 °F

0.900 - 3.29 % 0.900 - 3.29 % Average value: 1.73 % Grade Count:11

@Time 86400 - 173000 sec @Time 24.0 - 48.0 hour

Moisture Absorption at Equilibrium 0.0700 - 3.90 % 0.0700 - 3.90 % Average value: 0.661 % Grade Count:39

Water Absorption at Saturation 0.420 - 3.80 % 0.420 - 3.80 % Average value: 1.78 % Grade Count:21

2.30 - 4.17 % 2.30 - 4.17 % Average value: 3.20 % Grade Count:3

@Temperature 80.0 - 80.0 °C @Temperature 176 - 176 °F

Loss On Ignition 45.0 % 45.0 % Average value: 45.0 % Grade Count:12

Thickness 5.00 - 127 microns 0.197 - 5.00 mil Average value: 72.2 microns Grade Count:3

Linear Mold Shrinkage 0.000100 - 0.0140 cm/cm 0.000100 - 0.0140 in/in Average value: 0.00626 cm/cm Grade Count:44

Linear Mold Shrinkage, Transverse 0.00500 - 0.0140 cm/cm 0.00500 - 0.0140 in/in Average value: 0.00671 cm/cm Grade Count:14

Melt Flow 2.00 - 37.0 g/10 min 2.00 - 37.0 g/10 min Average value: 12.9 g/10 min Grade Count:19

Mechanical Properties Metric English Comments

Hardness, Rockwell E 20.0 - 91.0 20.0 - 91.0 Average value: 55.6 Grade Count:11

Hardness, Rockwell M 95.0 - 125 95.0 - 125 Average value: 111 Grade Count:11

Hardness, Rockwell R 123 - 129 123 - 129 Average value: 126 Grade Count:9

Hardness, Shore D 65.0 - 92.0 65.0 - 92.0 Average value: 85.6 Grade Count:34

Ball Indentation Hardness 138 - 140 MPa 20000 - 20300 psi Average value: 140 MPa Grade Count:12

Tensile Strength, Ultimate 0.0480 - 345 MPa 6.96 - 50000 psi Average value: 95.4 MPa Grade Count:120

23.0 - 324.054 MPa 3340 - 47000.1 psi Average value: 83.9 MPa Grade Count:31

@Temperature 150 - 260 °C @Temperature 302 - 500 °F

Tensile Strength, Yield 15.0 - 230 MPa 2180 - 33300 psi Average value: 103 MPa Grade Count:41

27.579 - 141.343 MPa 4000.0 - 20500.0 psi Average value: 88.8 MPa Grade Count:6

@Temperature 149 - 260 °C @Temperature 300 - 500 °F

Elongation at Break 0.350 - 200 % 0.350 - 200 % Average value: 15.6 % Grade Count:132

1.70 - 90.0 % 1.70 - 90.0 % Average value: 10.8 % Grade Count:28

@Temperature 150 - 260 °C @Temperature 302 - 500 °F

Elongation at Yield 2.00 - 90.0 % 2.00 - 90.0 % Average value: 8.99 % Grade Count:20

4.00 - 90.0 % 4.00 - 90.0 % Average value: 25.5 % Grade Count:4

@Temperature 149 - 149 °C @Temperature 300 - 300 °F

Modulus of Elasticity 0.107 - 46.9 GPa 15.5 - 6800 ksi Average value: 6.36 GPa Grade Count:93

1.03421 - 3.71627 GPa 150.002 - 539.008 ksi Average value: 2.29 GPa Grade Count:7

@Temperature 260 - 260 °C @Temperature 500 - 500 °F

Flexural Yield Strength 24.8 - 490 MPa 3600 - 71000 psi Average value: 155 MPa Grade Count:122

20.6843 - 314 MPa 3000.01 - 45500 psi Average value: 125 MPa Grade Count:28

@Temperature 149 - 260 °C @Temperature 300 - 500 °F

Flexural Modulus 1.38 - 37.9 GPa 200 - 5500 ksi Average value: 6.63 GPa Grade Count:117

0.0102 - 19.8 GPa 1.48 - 2870 ksi Average value: 7.27 GPa Grade Count:27

@Temperature 149 - 300 °C @Temperature 300 - 572 °F

Flexural Strain at Yield 1.40 - 7.90 % 1.40 - 7.90 % Average value: 4.08 % Grade Count:27

Compressive Strain at Break 21.0 - 31.0 % 21.0 - 31.0 % Average value: 26.3 % Grade Count:2

@Temperature 260 - 260 °C @Temperature 500 - 500 °F

Compressive Yield Strength 0.00217 - 570 MPa 0.315 - 82700 psi Average value: 166 MPa Grade Count:69

71.0 - 414 MPa 10300 - 60000 psi Average value: 131 MPa Grade Count:11

@Temperature 149 - 260 °C @Temperature 300 - 500 °F

96.0 - 172 MPa 13900 - 24900 psi Average value: 131 MPa Grade Count:2

@Temperature 260 - 260 °C @Temperature 500 - 500 °F

96.0 - 172 MPa 13900 - 24900 psi Average value: 131 MPa Grade Count:2

@Strain 10.0 - 10.0 % @Strain 10.0 - 10.0 %

MatWeb, Your Source for Materials Information - WWW.MATWEB.COM / Page 1 / 3

Compressive Modulus 0.00164 - 4.00 GPa 0.238 - 580 ksi Average value: 2.08 GPa Grade Count:40

1.663 - 2.997 GPa 241.2 - 434.7 ksi Average value: 2.17 GPa Grade Count:3

@Temperature 260 - 260 °C @Temperature 500 - 500 °F

Poissons Ratio 0.250 - 0.410 0.250 - 0.410 Average value: 0.370 Grade Count:4

0.320 - 0.320 0.320 - 0.320 Average value: 0.320 Grade Count:1

@Temperature 190 - 190 °C @Temperature 374 - 374 °F

Fatigue Strength 16.5474 - 26.2001 MPa 2400.00 - 3800.01 psi Average value: 21.4 MPa Grade Count:1

@# of Cycles 1000 - 1.00e+7 @# of Cycles 1000 - 1.00e+7

16.5474 - 26.2001 MPa 2400.00 - 3800.01 psi Average value: 21.4 MPa Grade Count:1

@Temperature 260 - 260 °C @Temperature 500 - 500 °F

Shear Strength 81.4 - 110 MPa 11800 - 16000 psi Average value: 90.5 MPa Grade Count:7

60.8 - 78.5 MPa 8820 - 11400 psi Average value: 71.9 MPa Grade Count:3

@Temperature 150 - 150 °C @Temperature 302 - 302 °F

Izod Impact, Notched 0.0700 - 6.94 J/cm 0.131 - 13.0 ft-lb/in Average value: 0.811 J/cm Grade Count:78

0.740 - 0.740 J/cm 1.39 - 1.39 ft-lb/in Average value: 0.740 J/cm Grade Count:12

@Temperature -30.0 - -30.0 °C @Temperature -22.0 - -22.0 °F

Izod Impact, Unnotched 1.12 - 5340 J/cm 2.10 - 10000 ft-lb/in Average value: 6.81 J/cm Grade Count:37

Izod Impact, Notched (ISO) 0.0430 - 27.0 kJ/m² 0.0205 - 12.8 ft-lb/in² Average value: 6.11 kJ/m² Grade Count:19

5.00 - 5.00 kJ/m² 2.38 - 2.38 ft-lb/in² Average value: 5.00 kJ/m² Grade Count:12

@Temperature -30.0 - -30.0 °C @Temperature -22.0 - -22.0 °F

Izod Impact, Unnotched (ISO) 0.320 kJ/m² - NB 0.152 ft-lb/in² - NB Average value: 118 kJ/m² Grade Count:14

147 kJ/m² - NB 69.9 ft-lb/in² - NB Average value: 147 kJ/m² Grade Count:12

@Temperature -30.0 - -30.0 °C @Temperature -22.0 - -22.0 °F

Charpy Impact Unnotched 0.780 - 1000 J/cm² 3.71 - 4760 ft-lb/in² Average value: 3.41 J/cm² Grade Count:36

999.9 - 999.9 J/cm² 4759 - 4759 ft-lb/in² Grade Count:12

@Temperature -30.0 - -30.0 °C @Temperature -22.0 - -22.0 °F

Charpy Impact, Notched 0.160 - 0.930 J/cm² 0.761 - 4.43 ft-lb/in² Average value: 0.416 J/cm² Grade Count:20

Instrumented Impact Total Energy 33.0 J 24.3 ft-lb Average value: 33.0 J Grade Count:12

Coefficient of Friction 0.0600 - 0.350 0.0600 - 0.350 Average value: 0.223 Grade Count:16

Coefficient of Friction, Static 0.200 - 0.350 0.200 - 0.350 Average value: 0.294 Grade Count:5

K Factor (Wear Factor) 0.400 - 13.1 0.400 - 13.1 Average value: 5.48 Grade Count:3

K (wear) Factor 20.1 - 568 x 10-8 mm³/N-M 10.0 - 282 x 10-10 in³-min/ft-lb-hr Average value: 260 x 10-8 mm³/N-M Grade Count:3

Limiting Pressure Velocity 0.525 - 12.0 MPa-m/sec 15000 - 343000 psi-ft/min Average value: 6.48 MPa-m/sec Grade Count:4

Compression Set 12.5 - 98.0 % 12.5 - 98.0 % Average value: 45.1 % Grade Count:27

Electrical Properties Metric English Comments

Electrical Resistivity 0.100 - 4.00e+19 ohm-cm 0.100 - 4.00e+19 ohm-cm Average value: 1.29e+18 ohm-cm Grade Count:36

Surface Resistance 0.100 - 1.00e+18 ohm 0.100 - 1.00e+18 ohm Average value: 3.38e+16 ohm Grade Count:37

Dielectric Constant 1.11 - 62.0 1.11 - 62.0 Average value: 5.79 Grade Count:52

Dielectric Strength 3.00 - 248 kV/mm 76.2 - 6290 kV/in Average value: 27.8 kV/mm Grade Count:40

Dissipation Factor 0.000900 - 0.310 0.000900 - 0.310 Average value: 0.0133 Grade Count:37

Dielectric Loss Index 0.00180 - 0.0106 0.00180 - 0.0106 Average value: 0.00490 Grade Count:5

Comparative Tracking Index 125 - 399 V 125 - 399 V Average value: 200 V Grade Count:19

Hot Wire Ignition, HWI 30.0 - 120 sec 30.0 - 120 sec Average value: 67.5 sec Grade Count:6

High Amp Arc Ignition, HAI 0.000 - 15.0 arcs 0.000 - 15.0 arcs Average value: 7.50 arcs Grade Count:6

Thermal Properties Metric English Comments

CTE, linear 5.40 - 504 µm/m-°C 3.00 - 280 µin/in-°F Average value: 52.9 µm/m-°C Grade Count:61

0.234 - 144 µm/m-°C 0.130 - 80.0 µin/in-°F Average value: 45.6 µm/m-°C Grade Count:38

@Temperature 15.6 - 316 °C @Temperature 60.0 - 600 °F

CTE, linear, Transverse to Flow 6.00 - 55.0 µm/m-°C 3.33 - 30.6 µin/in-°F Average value: 47.9 µm/m-°C Grade Count:30

36.0 - 70.0 µm/m-°C 20.0 - 38.9 µin/in-°F Average value: 51.9 µm/m-°C Grade Count:10

@Temperature 50.0 - 300 °C @Temperature 122 - 572 °F

Specific Heat Capacity 0.920 - 1.13 J/g-°C 0.220 - 0.270 BTU/lb-°F Average value: 1.02 J/g-°C Grade Count:15

0.895376 - 1.42256 J/g-°C 0.214000 - 0.340000 BTU/lb-°F Average value: 1.14 J/g-°C Grade Count:7

@Temperature 60.0 - 300 °C @Temperature 140 - 572 °F

Thermal Conductivity 0.0330 - 1.73 W/m-K 0.229 - 12.0 BTU-in/hr-ft²-°F Average value: 0.316 W/m-K Grade Count:49

0.220 - 2.05 W/m-K 1.53 - 14.2 BTU-in/hr-ft²-°F Average value: 0.607 W/m-K Grade Count:11

@Temperature 40.0 - 300 °C @Temperature 104 - 572 °F

Melting Point 247 - 388 °C 477 - 730 °F Average value: 373 °C Grade Count:20

Maximum Service Temperature, Air 200 - 395 °C 392 - 743 °F Average value: 287 °C Grade Count:52

Hot Ball Pressure Test 125 °C 257 °F Average value: 125 °C Grade Count:12

Deflection Temperature at 0.46 MPa (66 psi) 237 - 377 °C 459 - 711 °F Average value: 266 °C Grade Count:28

Deflection Temperature at 1.8 MPa (264 psi) 217 - 417 °C 423 - 783 °F Average value: 271 °C Grade Count:68

Vicat Softening Point 238 - 260 °C 460 - 500 °F Average value: 243 °C Grade Count:15

Glass Transition Temp, Tg -20.0 - 385 °C -4.00 - 725 °F Average value: 313 °C Grade Count:52

UL RTI, Electrical 50.0 - 160 °C 122 - 320 °F Average value: 123 °C Grade Count:11

UL RTI, Mechanical with Impact 50.0 - 130 °C 122 - 266 °F Average value: 110 °C Grade Count:11

UL RTI, Mechanical without Impact 50.0 - 160 °C 122 - 320 °F Average value: 123 °C Grade Count:11

MatWeb, Your Source for Materials Information - WWW.MATWEB.COM / Page 2 / 3

Flammability, UL94 V -0 - 5VA V -0 - 5VA Grade Count:60

Flame Spread Index 0.000 - 5.00 0.000 - 5.00 Average value: 1.67 Grade Count:4

Oxygen Index 30.0 - 53.0 % 30.0 - 53.0 % Average value: 43.0 % Grade Count:15

Glow Wire Test 850 - 960 °C 1560 - 1760 °F Average value: 905 °C Grade Count:12

Optical Properties Metric English Comments

Haze 0.100 - 2.00 % 0.100 - 2.00 % Average value: 1.69 % Grade Count:11

Transmission, Visible 58.0 - 91.6 % 58.0 - 91.6 % Average value: 61.6 % Grade Count:11

Processing Properties Metric English Comments

Processing Temperature 70.0 - 420 °C 158 - 788 °F Average value: 314 °C Grade Count:22

Nozzle Temperature 375 - 405 °C 707 - 761 °F Average value: 388 °C Grade Count:15

Melt Temperature 360 - 416 °C 680 - 780 °F Average value: 388 °C Grade Count:26

Mold Temperature 135 - 232 °C 275 - 450 °F Average value: 183 °C Grade Count:32

Drying Temperature 150 - 204 °C 302 - 400 °F Average value: 176 °C Grade Count:26

Moisture Content 0.0100 - 0.0200 % 0.0100 - 0.0200 % Average value: 0.0158 % Grade Count:26

Dew Point -40.0 °C -40.0 °F Average value: -40.0 °C Grade Count:11

Injection Pressure 138 - 193 MPa 20000 - 28000 psi Average value: 165 MPa Grade Count:17

Vent Depth 0.00250 - 0.00760 cm 0.000984 - 0.00299 in Average value: 0.00505 cm Grade Count:15

Some of the values displayed above may have been converted from their original units and/or rounded in order to display the information in a consistent format. Users requiring more precise data for scientific or

engineering calculations can click on the property value to see the original value as well as raw conversions to equivalent units. We advise that you only use the original value or one of its raw conversions in your

calculations to minimize rounding error. We also ask that you refer to MatWeb's terms of use regarding this information. Click here to view all the property values for this datasheet as they were originally entered into

MatWeb.

MatWeb, Your Source for Materials Information - WWW.MATWEB.COM / Page 3 / 3

You might also like

- MaterialData - 77933-Glass Fiber FilledDocument2 pagesMaterialData - 77933-Glass Fiber FilledSANKHGOND BASAVRAJ ISHWARNo ratings yet

- (POM + 30 FG) Acetal Copolymer, 30% Glass Fiber ReinforcedDocument2 pages(POM + 30 FG) Acetal Copolymer, 30% Glass Fiber ReinforcedDario de SantiagoNo ratings yet

- Overview of Materials For Polypropylene With 20% Glass Fiber FillerDocument4 pagesOverview of Materials For Polypropylene With 20% Glass Fiber FillerbiroutiNo ratings yet

- Overview of Materials For Polyethylene Terephthalate (PET), UnreinforcedDocument3 pagesOverview of Materials For Polyethylene Terephthalate (PET), UnreinforcedFernando FuentesNo ratings yet

- Overview of Materials For Acrylonitrile Butadiene Styrene (ABS), MoldedDocument3 pagesOverview of Materials For Acrylonitrile Butadiene Styrene (ABS), MoldedarmandoNo ratings yet

- PP - Polypropylene Overview of Materials For, MoldedDocument5 pagesPP - Polypropylene Overview of Materials For, MoldedRajendra Kumar SharmaNo ratings yet

- Overview of Materials For Thermoset Polyurethane Foam, UnreinforcedDocument4 pagesOverview of Materials For Thermoset Polyurethane Foam, Unreinforcedvaratharajan g rNo ratings yet

- Silicone RubberDocument2 pagesSilicone RubberJhon GuerreroNo ratings yet

- Overview of Materials For Nylon 66/6, 40% Glass Fiber ReinforcedDocument2 pagesOverview of Materials For Nylon 66/6, 40% Glass Fiber ReinforcedPrabhat SharmaNo ratings yet

- MaterialData - 77935 - PTFE FilledDocument2 pagesMaterialData - 77935 - PTFE FilledSANKHGOND BASAVRAJ ISHWARNo ratings yet

- Overview of Materials For Thermoset Polyurethane, Elastomer, UnreinforcedDocument2 pagesOverview of Materials For Thermoset Polyurethane, Elastomer, UnreinforcedMironNo ratings yet

- Overview of Materials For Epoxy/Carbon Fiber CompositeDocument2 pagesOverview of Materials For Epoxy/Carbon Fiber CompositeDavid Alfonso Mantilla MejiaNo ratings yet

- Nylon 66/6 Reinforced GuideDocument4 pagesNylon 66/6 Reinforced GuideBenNo ratings yet

- Acrylic Material Data (From PARSGLASS)Document2 pagesAcrylic Material Data (From PARSGLASS)Amir100% (3)

- Overview of Materials For Acrylic, Cast 6mmDocument3 pagesOverview of Materials For Acrylic, Cast 6mmoportunidade.engenharia.slzNo ratings yet

- Overview of Materials For Magnesium AlloyDocument3 pagesOverview of Materials For Magnesium AlloyNishant SinghNo ratings yet

- Overview of materials for LDPE, MoldedDocument4 pagesOverview of materials for LDPE, MoldedRajendra Kumar SharmaNo ratings yet

- Overview of Materials For Polyester FilmDocument4 pagesOverview of Materials For Polyester FilmMaterial Science DivisionNo ratings yet

- Overview of materials for PVC, High ImpactDocument1 pageOverview of materials for PVC, High Impactvongoctu2016No ratings yet

- Mechanical Properties of High Carbon SteelDocument3 pagesMechanical Properties of High Carbon SteelSabirul SkNo ratings yet

- Thermal Properties of Aluminium AlloysDocument4 pagesThermal Properties of Aluminium Alloysgopinadh57No ratings yet

- Overview of Materials For PVC, Extruded: To View All Available Suppliers For This MaterialDocument2 pagesOverview of Materials For PVC, Extruded: To View All Available Suppliers For This Materialvongoctu2016No ratings yet

- MaterialData 81691Document2 pagesMaterialData 81691Carlos LorenzanaNo ratings yet

- Matweb Carbon SteelDocument1 pageMatweb Carbon SteelSuzy ChenNo ratings yet

- Overview of Polypropylene, Extrusion Grade Properties and Processing DataDocument2 pagesOverview of Polypropylene, Extrusion Grade Properties and Processing Datavongoctu2016No ratings yet

- HDPE Blow Molding Properties OverviewDocument2 pagesHDPE Blow Molding Properties Overviewtayyabmubarik2417No ratings yet

- English: DatasheetDocument5 pagesEnglish: DatasheetAdrianNo ratings yet

- 34CrNiMo6-1 6582Document1 page34CrNiMo6-1 6582Ardiansyah Oktavianus WahyudiNo ratings yet

- 5080A Multi Product Calibrator MegOhm Meter Calibration Option Extended Specifications 49776 KBDocument4 pages5080A Multi Product Calibrator MegOhm Meter Calibration Option Extended Specifications 49776 KBAna Safranec VasicNo ratings yet

- Pendapatan, Harga dan Statistik Lain Tahu dan Rumah TanggaDocument17 pagesPendapatan, Harga dan Statistik Lain Tahu dan Rumah TanggaDzik KovvNo ratings yet

- ASTM A213 T11 Alloy Steel, Chromium Molybdenum, F11-1: Metal Ferrous Metal Tool Steel Cold Work SteelDocument1 pageASTM A213 T11 Alloy Steel, Chromium Molybdenum, F11-1: Metal Ferrous Metal Tool Steel Cold Work SteelsemetayNo ratings yet

- Gauge Calibration Certificate DetailsDocument2 pagesGauge Calibration Certificate DetailsProyectos Ashes Fire ColombiaNo ratings yet

- Master Bond EP17HT LODocument3 pagesMaster Bond EP17HT LORusty AllenNo ratings yet

- Deutsche Akkreditierungsstelle GMBH: Gigahertz Optik GMBH An Der Kälberweide 12, 82299 TürkenfeldDocument5 pagesDeutsche Akkreditierungsstelle GMBH: Gigahertz Optik GMBH An Der Kälberweide 12, 82299 TürkenfeldMauroNo ratings yet

- Resistencia de PrecisiónDocument4 pagesResistencia de PrecisiónLuis MartinNo ratings yet

- Laboratory Calibration Instruments ChennaiDocument10 pagesLaboratory Calibration Instruments ChennaiRavichandran DNo ratings yet

- Lecture 2 - Introductory StatisticsDocument55 pagesLecture 2 - Introductory Statisticscheta21No ratings yet

- Laboratory Calibration Centre ISO Accreditation CertificateDocument25 pagesLaboratory Calibration Centre ISO Accreditation CertificateVAIBHAV INSTRUMENTATIONNo ratings yet

- Measure pH, Conductivity & More with Portable CDS107 MeterDocument1 pageMeasure pH, Conductivity & More with Portable CDS107 Metergeraldyne janetNo ratings yet

- Senso Direct Manual PDFDocument28 pagesSenso Direct Manual PDFSandra Milena Sanchez RamirezNo ratings yet

- Aluminum 3004-O: Metal Nonferrous Metal Aluminum Alloy 3000 Series Aluminum AlloyDocument3 pagesAluminum 3004-O: Metal Nonferrous Metal Aluminum Alloy 3000 Series Aluminum AlloyLuis BadoffNo ratings yet

- DHG SeriesDocument13 pagesDHG SeriesPrasadi AttanayakeNo ratings yet

- Anexo A - Magnesium Elektron Elektron® ZRE1 Magnesium Alloy, UNS M12330 - DatasheetDocument3 pagesAnexo A - Magnesium Elektron Elektron® ZRE1 Magnesium Alloy, UNS M12330 - DatasheetAmilton CardosoNo ratings yet

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocument25 pagesSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksVAIBHAV INSTRUMENTATIONNo ratings yet

- Lab Calibration CertificationDocument24 pagesLab Calibration CertificationVAIBHAV INSTRUMENTATIONNo ratings yet

- Calibrador de Procesos HT824Document4 pagesCalibrador de Procesos HT824Edylai Luque CondoriNo ratings yet

- Katalog Baume MeterDocument6 pagesKatalog Baume MeterZacky NeutronNo ratings yet

- Polikim EFALON® T-100 Virgin PTFEDocument2 pagesPolikim EFALON® T-100 Virgin PTFEPriyadarshini KrishnaswamyNo ratings yet

- Universal Temperature Calibrator Simulates Thermocouples & RTDsDocument4 pagesUniversal Temperature Calibrator Simulates Thermocouples & RTDsP M Shashank RaoNo ratings yet

- FTang Probes-Boards Transmitters 2013 21-11-17Document8 pagesFTang Probes-Boards Transmitters 2013 21-11-17dftghsNo ratings yet

- WTW Multi 350i 3500i PDFDocument5 pagesWTW Multi 350i 3500i PDFMichel Brus Quispe LinoNo ratings yet

- Special Metals INCONEL® Alloy 625: Categories: Material NotesDocument6 pagesSpecial Metals INCONEL® Alloy 625: Categories: Material Notesdheeraj616No ratings yet

- Icet MinilectureDocument94 pagesIcet Minilectureapi-3845041No ratings yet

- Thermocouple Tolerance PDFDocument1 pageThermocouple Tolerance PDFValeria Sanchez VillarroelNo ratings yet

- AI-5600 Handheld Thermometer SpecsDocument31 pagesAI-5600 Handheld Thermometer SpecsKiranNo ratings yet

- 1823-01 - A2la - Iso 17025 - Schope - Cert - 2020-2022 - Rlws - Concord-Ca - RevisedDocument22 pages1823-01 - A2la - Iso 17025 - Schope - Cert - 2020-2022 - Rlws - Concord-Ca - RevisedLeandroNo ratings yet

- Range 1St Best Ecio Histogram Range 1St Best RSCP HistogramDocument14 pagesRange 1St Best Ecio Histogram Range 1St Best RSCP Histogramdavis tukwaNo ratings yet

- Presented By: Nitin Raghav Prashant ChauhanDocument33 pagesPresented By: Nitin Raghav Prashant ChauhanPrashant ChauhanNo ratings yet

- Specification HI 9829-02042,03042,12042,13042 PDFDocument3 pagesSpecification HI 9829-02042,03042,12042,13042 PDFAnonymous ULGKO76alNo ratings yet

- Innovation Funnel TemplateDocument1 pageInnovation Funnel TemplateIdehen KelvinNo ratings yet

- Geared DC Instrument Motor 1308 SeriesDocument1 pageGeared DC Instrument Motor 1308 SeriesIdehen KelvinNo ratings yet

- OringDocument1 pageOringIdehen KelvinNo ratings yet

- UBA2014 Evaluation Board: Rev. 01 - 14 October 2009 User ManualDocument24 pagesUBA2014 Evaluation Board: Rev. 01 - 14 October 2009 User ManualIdehen KelvinNo ratings yet

- Me-19F Massuse Relay: FeaturesDocument4 pagesMe-19F Massuse Relay: FeaturesIdehen KelvinNo ratings yet

- Friction Forces in O-Ring SealingDocument8 pagesFriction Forces in O-Ring SealingIdehen KelvinNo ratings yet

- OringDocument1 pageOringIdehen KelvinNo ratings yet

- OringDocument1 pageOringIdehen KelvinNo ratings yet

- Hardware Configuration:: International: MMDocument1 pageHardware Configuration:: International: MMIdehen KelvinNo ratings yet

- Hardware Configuration:: International: MMDocument1 pageHardware Configuration:: International: MMIdehen KelvinNo ratings yet

- OringDocument1 pageOringIdehen KelvinNo ratings yet

- Hardware Configuration:: International: MMDocument1 pageHardware Configuration:: International: MMIdehen KelvinNo ratings yet

- Copper and Copper Alloys: CW721R High Tensile Brass Manganese BronzeDocument2 pagesCopper and Copper Alloys: CW721R High Tensile Brass Manganese BronzeIdehen KelvinNo ratings yet

- OringDocument1 pageOringIdehen KelvinNo ratings yet

- Hardware Configuration:: International: MMDocument1 pageHardware Configuration:: International: MMIdehen KelvinNo ratings yet

- OringDocument1 pageOringIdehen KelvinNo ratings yet

- OringDocument1 pageOringIdehen KelvinNo ratings yet

- OringDocument1 pageOringIdehen KelvinNo ratings yet

- Astra SealingDocument3 pagesAstra SealingIdehen KelvinNo ratings yet

- OringDocument1 pageOringIdehen KelvinNo ratings yet

- OringDocument1 pageOringIdehen KelvinNo ratings yet

- Pneumatic Valve Actuators for Autoclave EngineersDocument1 pagePneumatic Valve Actuators for Autoclave EngineersIdehen KelvinNo ratings yet

- Item # Oh, Pneumatic Valve Actuators: Pressures To 150000 Psi (10342 Bar)Document2 pagesItem # Oh, Pneumatic Valve Actuators: Pressures To 150000 Psi (10342 Bar)Idehen KelvinNo ratings yet

- LF310 Datasheet: Low-Flow Pressure RegulatorDocument4 pagesLF310 Datasheet: Low-Flow Pressure RegulatorIdehen KelvinNo ratings yet

- Item # Oh, Pneumatic Valve Actuators: Pressures To 150000 Psi (10342 Bar)Document2 pagesItem # Oh, Pneumatic Valve Actuators: Pressures To 150000 Psi (10342 Bar)Idehen KelvinNo ratings yet

- In Line High Flow' Insertion Type Regulators For 4" - 8" PipeworkDocument2 pagesIn Line High Flow' Insertion Type Regulators For 4" - 8" PipeworkIdehen KelvinNo ratings yet

- LR-360KAS-BROCHURE-LNG Sampling SystemsDocument4 pagesLR-360KAS-BROCHURE-LNG Sampling SystemsIdehen KelvinNo ratings yet

- LF240 Datasheet: Low-Flow Pressure RegulatorDocument4 pagesLF240 Datasheet: Low-Flow Pressure RegulatorIdehen KelvinNo ratings yet

- LF311 Datasheet: Low-Flow Pressure RegulatorDocument4 pagesLF311 Datasheet: Low-Flow Pressure RegulatorIdehen KelvinNo ratings yet

- Heat and Mass TransferDocument20 pagesHeat and Mass TransferHamid AlkaseriNo ratings yet

- Shear Stress in Rectangular & Circular SectionDocument16 pagesShear Stress in Rectangular & Circular SectionBaldev MakwanaNo ratings yet

- Me6301 Engineering Thermodynamics Nov Dec 2007Document3 pagesMe6301 Engineering Thermodynamics Nov Dec 2007BIBIN CHIDAMBARANATHANNo ratings yet

- 1 s2.0 S0038080621001037 MainDocument17 pages1 s2.0 S0038080621001037 MainFred AgliamNo ratings yet

- Engineering Calculation Sheet Consulting EngineersDocument11 pagesEngineering Calculation Sheet Consulting EngineersJONAS NGNo ratings yet

- Vertical anchor design methodsDocument29 pagesVertical anchor design methodsLesego MatojaneNo ratings yet

- P-7302 - CCR 25-160 PDFDocument1 pageP-7302 - CCR 25-160 PDFArjun KrishnakumarNo ratings yet

- Govt - Polytechnic, Beed. 2021-22: CertificateDocument9 pagesGovt - Polytechnic, Beed. 2021-22: CertificateUttareshwarNo ratings yet

- Design of Cold-Formed Steel Built-Up Post Members - TSNDocument12 pagesDesign of Cold-Formed Steel Built-Up Post Members - TSNNuno PedrinhoNo ratings yet

- Cooling and Dehumidifying Heat Load Estimate FormDocument4 pagesCooling and Dehumidifying Heat Load Estimate FormKaushikNo ratings yet

- Sepermarket TrendDocument17 pagesSepermarket TrendOnofreNo ratings yet

- Chapter 4 TorsionDocument20 pagesChapter 4 Torsionشكار حسينNo ratings yet

- AISC Seismic Design-Module2-Moment Resisting Frames Vol 1Document76 pagesAISC Seismic Design-Module2-Moment Resisting Frames Vol 1Percy Romero MurilloNo ratings yet

- Considerations in Designing Multiphase Flow LinesDocument7 pagesConsiderations in Designing Multiphase Flow Linespmr80_2004No ratings yet

- AISC DG02 Example 003 PDFDocument7 pagesAISC DG02 Example 003 PDFMohamed Abo-ZaidNo ratings yet

- Candace MaharajDocument11 pagesCandace MaharajCharlotte BNo ratings yet

- AerospaceDocument8 pagesAerospaceGrace KamauNo ratings yet

- STEAMDocument15 pagesSTEAMLohith Narasimha swamyNo ratings yet

- Question Bank Mass Transfer IDocument12 pagesQuestion Bank Mass Transfer IpandianvijaybharathiNo ratings yet

- UTT General Exam #2Document8 pagesUTT General Exam #2nathaniel ekaiko100% (2)

- Heat Exchangers IndexDocument3 pagesHeat Exchangers IndexVuong BuiNo ratings yet

- Roark's Formula 7Document1 pageRoark's Formula 7Jay CeeNo ratings yet

- Basel Heave Goh2017Document5 pagesBasel Heave Goh2017Ahmed Arafa100% (1)

- Exam Set 09Document1 pageExam Set 09allovidNo ratings yet

- Experiment 6 DrillingDocument17 pagesExperiment 6 DrillingAnusha Anu100% (1)

- Astm C177Document23 pagesAstm C177Angel Egoavil Rosas100% (3)

- Assignment 2 - Hydrostatic Pressure and Pascal - S LawDocument8 pagesAssignment 2 - Hydrostatic Pressure and Pascal - S LawluluNo ratings yet

- AM-17 Air Receiver VesselDocument72 pagesAM-17 Air Receiver VesselAfaqNo ratings yet

- Hooke's Law experimentDocument15 pagesHooke's Law experimentHaneen MoosaNo ratings yet