0% found this document useful (0 votes)

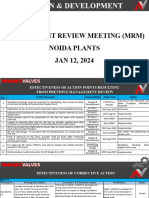

113 views14 pagesDelivery and Quality Issues Overview

1. The document lists issues with the delivery and quality of various products from suppliers. Actions discussed to address issues include searching for new suppliers, developing alternative vendors, providing technical support to existing vendors, and revising specifications and tolerances.

2. Plans are made to trial a new pipe specification, develop moulds, improve concentricity requirements, and automate welding processes to address non-conformances.

3. Responsibilities are assigned for resolving issues such as procuring materials, modifying drawings, checking supplier processes, and finalizing test parameters.

Uploaded by

sanjibkrjanaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

113 views14 pagesDelivery and Quality Issues Overview

1. The document lists issues with the delivery and quality of various products from suppliers. Actions discussed to address issues include searching for new suppliers, developing alternative vendors, providing technical support to existing vendors, and revising specifications and tolerances.

2. Plans are made to trial a new pipe specification, develop moulds, improve concentricity requirements, and automate welding processes to address non-conformances.

3. Responsibilities are assigned for resolving issues such as procuring materials, modifying drawings, checking supplier processes, and finalizing test parameters.

Uploaded by

sanjibkrjanaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd